Maintenance Management in Odoo 18

The Maintenance module in Odoo is like a digital tool that helps companies take care of machines, equipment and tools in a systematic way. Instead of waiting for something to break down, Odoo allows you to plan regular check-ups and services so that assets run smoothly. If any problem happens suddenly, the system helps raise a maintenance request and track its progress until it is fixed.

It connects well with Manufacturing, Inventory and Asset modules, so maintenance activities can be directly linked to machines, work centers or even products. This avoids confusion, reduces downtime and ensures that production does not stop unnecessarily.

With proper scheduling, reminders and tracking of requests, Odoo helps companies save cost, extend the life of their equipment and keep operations running without unexpected breakdowns

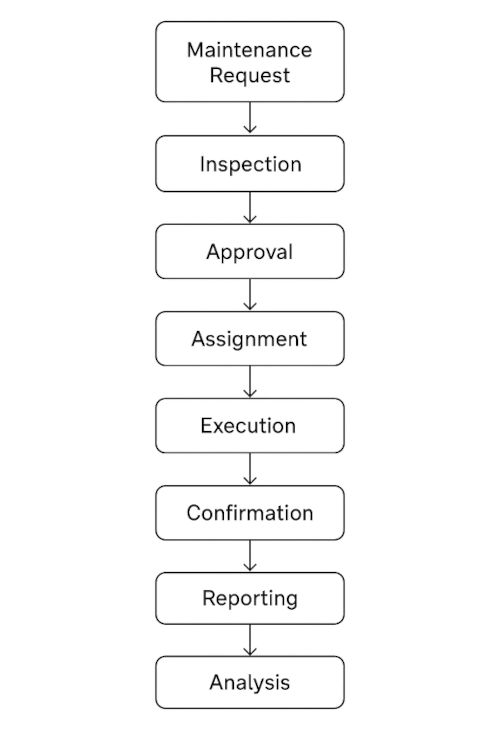

Work Flow

Business Rules / Key Features

- Keep track of all machines, tools and equipment in one place

- Organize equipment by location, category or responsible person

- Store complete details like specifications, warranty and purchase history

- Set up preventive maintenance schedules based on time or usage triggers

- Automate maintenance tasks to reduce sudden breakdowns and downtime

- Get detailed reports on maintenance activities, costs and equipment performance

- Analyze downtime and identify recurring issues

- Monitor downtime and easily spot repeated issues

- Create maintenance requests quickly whenever a problem is found

- Assign requests to technicians or teams

- Set priority and schedule tasks based on urgency

- Improve maintenance strategy using real data and insights

Maintenance Master Management

- Maintenance Teams

- Equipment Categories

- Maintanance Stages

- Worksheet Templates

- Activity Type

- Work Centers

Maintenance Process Management

- Maintenance Requests

- Maintenance Calender

- Mechines & Tools

Maintenance Report Management

- Maintenance Requests

Maintenance Master Management

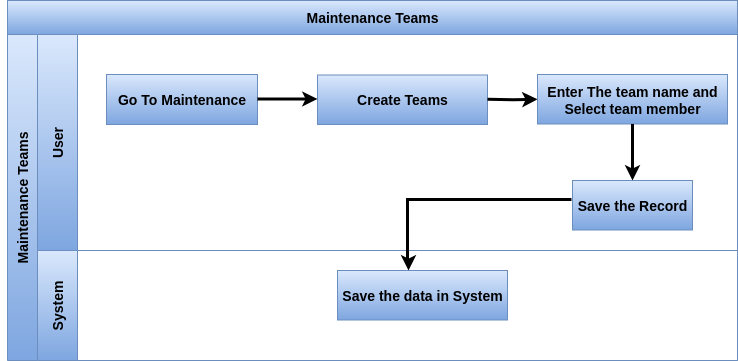

Maintenance Teams

Overview

In Odoo’s Maintenance module, Maintenance Teams represent the groups responsible for handling equipment repairs, preventive checks and overall upkeep of company assets. These teams can be structured based on departments (like Production, IT or Facilities), locations (factory, warehouse, office), or specific types of machinery. Defining teams ensures that all maintenance requests are properly routed, monitored and completed by the right people

Process Flow

Business Rules / Key Features

- Create and manage multiple maintenance teams for different departments or sites

- Assign equipment and maintenance requests to a specific team for better ownership

- Define a team lead or responsible person for accountability

- Track workload and request status by team

- Streamline preventive and corrective maintenance activities by team

- Use smart filters to view requests per team, equipment type or priority

- Collaborate with other departments through internal notes and messaging within the request

- Link teams with equipment categories for automatic request assignment

- Get real-time dashboards and reporting on team efficiency and resource utilization

Screenshot

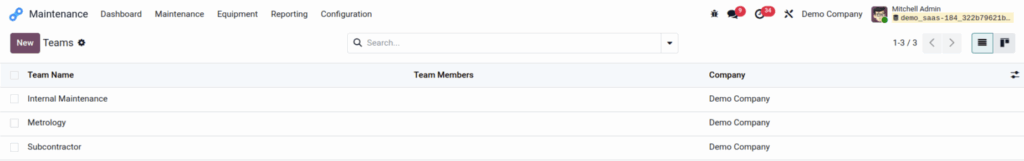

Maintenance Teams

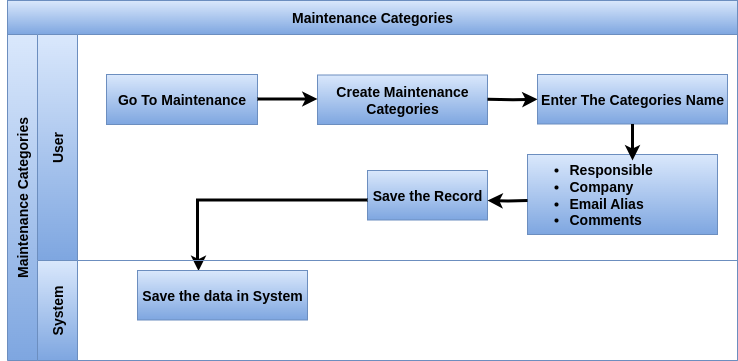

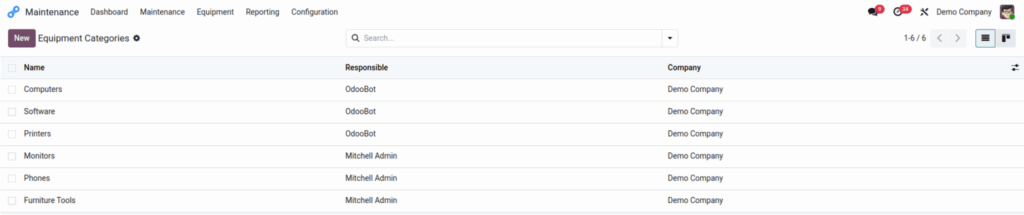

Equipment Categories

Overview

In Odoo Maintenance, Equipment Categories are used to group and classify all company equipment into logical sets. Categories help organize assets based on their type, usage or location (Ex: Production Machines, IT Equipment, Office Assets, Vehicles). This makes it easier to manage preventive maintenance, assign responsibilities and track costs per category

Process Flow

Business Rule

- Create and manage different equipment categories (Ex, Computers, Machines, Tools,..etc)

- Assign equipment to a specific category for better organization

- Define a responsible team or technician for each category

- Link maintenance requests automatically to the relevant team via category assignment

- Maintain category-level details like usage type, department or location

- Support preventive maintenance schedules based on the equipment category

- Allow filtering of equipment lists and requests by category for quick tracking

- Facilitate structured management when handling large numbers of assets

- Ensure accountability by linking categories with specific teams or persons

- Provides an Email Alias option, allowing incoming emails to auto-create maintenance requests to the respective categories

Screenshot

Equipment Categories

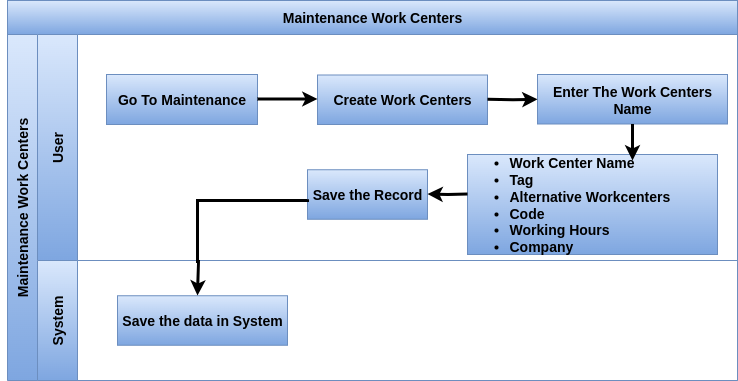

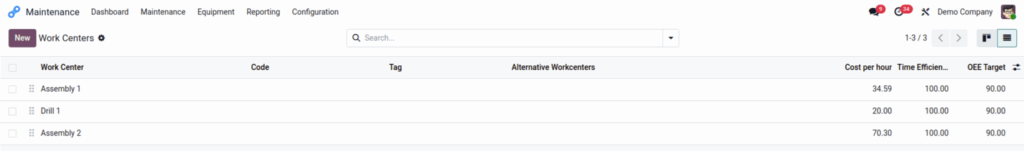

Work Centers

Overview

In Odoo, a Work Center represents a physical or logical location where specific operations are carried out, such as a machine, workstation or production.

When linked with the Maintenance Module, Work Centers help monitor equipment performance, plan preventive maintenance and reduce downtime directly in production environments.

Process Flow

Business Rule

- Each Work Center can be associated with one or more pieces of equipment, making it easy to track machine health

- Allows scheduling preventive maintenance activities to avoid unexpected breakdowns during production

- Supports automatic creation of maintenance requests when equipment linked to the Work Center shows issues

- Provides visibility into downtime analysis, helping understand how equipment stoppages affect production efficiency

- Integrates with Manufacturing (MRP) so that maintenance activities are considered while planning production orders

- Tracks performance metrics like OEE (Overall Equipment Effectiveness), downtime and load in relation to maintenance

- Allows assigning a responsible maintenance team per Work Center for quicker request handling

- Enables prioritization of repairs based on production criticality of the Work Center

- Supports multi-company and multi-location setup for enterprises managing distributed operations

- Acts as a bridge between production planning and maintenance, ensuring smooth workflows

- Analytical account linking helps track maintenance and operational costs per work center for detailed cost allocation and reporting

Screenshot

Work Centers

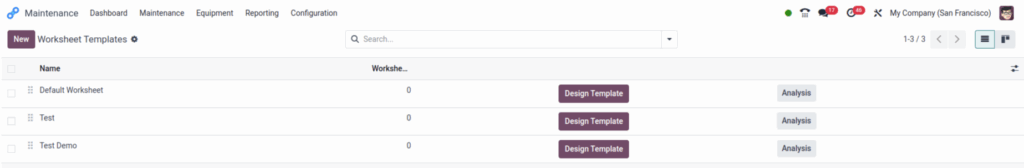

Worksheet Templates

Overview

In Odoo Maintenance, Worksheet Templates are customizable forms used by technicians or maintenance teams while performing maintenance tasks.They standardize the process by defining what information should be captured during preventive or corrective maintenance.This ensures consistency, compliance and accurate reporting across all equipment and work centers.

Business Rule

- Allow creation of structured forms for maintenance tasks

- Support adding custom fields such as checklists, text, numeric inputs or selection fields

- Can be linked to specific equipment categories, work centers or types of maintenance

- Ensure technicians follow step-by-step procedures while carrying out maintenance activities

- Capture critical data like readings, condition status, replacement parts used and technician notes.

- Templates can be reused across multiple maintenance requests, saving setup time

- Help enforce standard operating procedures (SOPs) for compliance and audits

- Improve traceability by keeping maintenance history tied with the completed worksheets

- Integrated with reporting so managers can analyze trends and recurring issues from collected data

- Easy to update and modify when maintenance processes evolve

Screenshot

Worksheet Templates

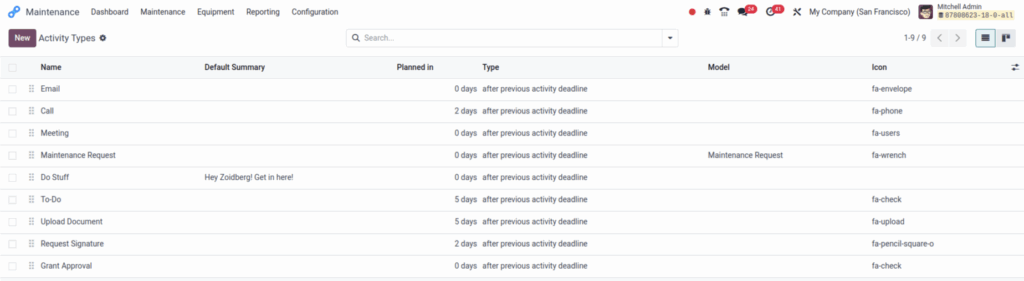

Activity Types

Overview

Activity Types in Odoo Maintenance are used to define and standardize the kinds of tasks or actions that need to be carried out during maintenance operations. They help teams follow a clear process by setting rules for inspections, repairs, preventive tasks or follow-ups. With activity types, organizations can ensure consistency, timely execution and proper tracking of all maintenance-related activities

Process Flow

Business Rule

- Define different categories of activities like inspection, corrective repair, preventive service or follow-up

- Allow setting default deadlines, responsible roles and recurrence rules for each activity type

- Activities can be scheduled directly from a maintenance request or equipment record

- Support linking to calendar and reminders, ensuring technicians do not miss deadlines

- Provide notes or instructions inside the activity type to standardize procedures

- Integrated with chatter/log notes so activities are tracked for history and audits

- Enable reporting on pending, overdue and completed activities to monitor team efficiency

- Support color-coding and categorization for easier identification of activity types

Screenshot

Activity Types

Maintenance Stages

Overview

Maintenance Stages in Odoo define the different steps that a maintenance request goes through, from creation to completion. They allow teams to organize, track, and monitor the progress of each request in a structured way. By customizing stages, businesses can adapt the workflow to their own processes and ensure that no maintenance task is overlooked

Process Flow

Business Rule

- Define different stages such as New, In Progress, Waiting for Parts, Completed, Cancelled

- Configure stage names and order to match the company’s workflow

- Assign stage-specific settings like “folded in kanban view” for better visibility

- Add notes, instructions or policies to each stage for clarity

- Track maintenance requests visually through Kanban boards

- Allow quick drag-and-drop of requests between stages

- Customize stages separately for preventive and corrective maintenance

- Provide a structured and transparent process for all maintenance operations

Screenshot

Maintenance Stages

Maintenance Process Management

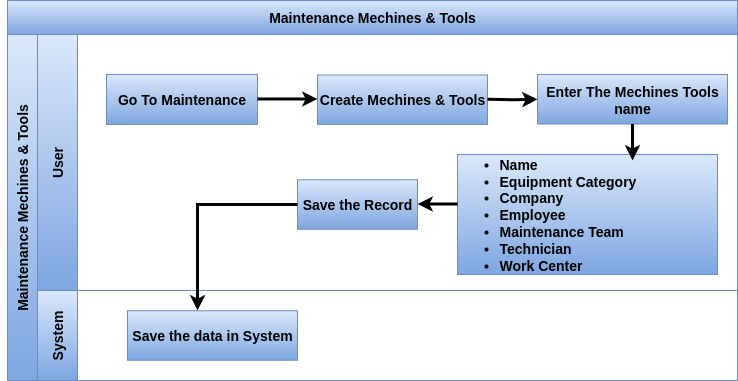

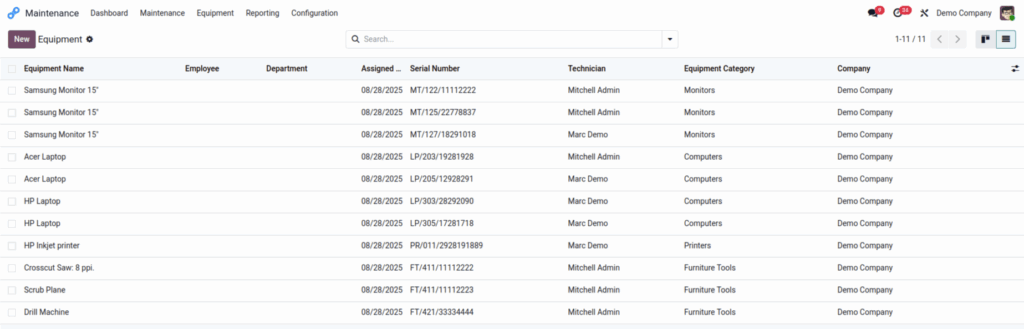

Mechines & Tools

Overview

In Odoo within the Maintenance application, the machines & tools feature under the Equipment menu lets you register, manage, and track various items—like machinery, devices, tools, or even office equipment—that require maintenance over time.

Process Flow

Business Rule

- You must enter a name when creating a machine or tool; otherwise, the record cannot be saved.

- You can assign categories, maintenance teams, work centers, and employees to link related records.

- The Company field is automatically filled based on the company of the user who is currently logged in.

- The Vendor field, write the name of the vendor where you bought the equipment.

- The Vendor Reference field, write the product number from the vendor, if you have one.

- The Model field, write the model name or number of the equipment, if you know it.

- The equipment has a serial number, write it in the Serial Number field.

- The Effective Date field, click the box to open a calendar, then choose the date when you started using the equipment.

- This date shows when the equipment was first used and helps calculate how long it works before breaking.

- The Cost field, write how much the equipment cost, if you know.

- The equipment has a warranty, pick the Warranty Expiration Date using the calendar.

Screenshot

Mechines & Tools

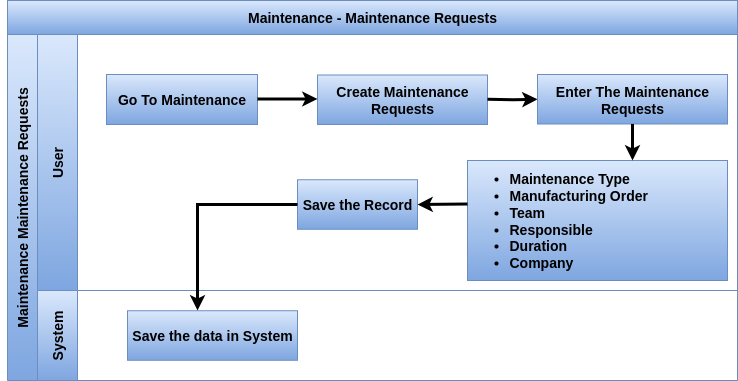

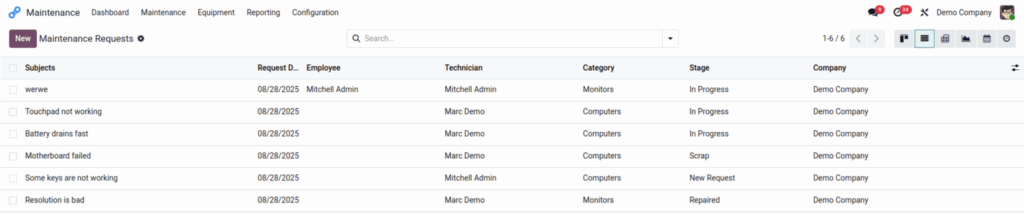

Maintenance Requests

Overview

A Maintenance Request in Odoo is used to report, track, and manage any issue, repair or preventive maintenance task related to equipment, machines, or work centers. It ensures that all maintenance needs are properly logged, assigned and followed up until completion. Requests can be created manually by employees, generated automatically from preventive schedules or even submitted via email alias. This provides transparency, reduces downtime and helps in better planning of maintenance activities

Process Flow

Business Rule

- You must enter a request and equipment when creating a machine or tool; otherwise, the record cannot be saved.

- The next field is called Request Date. It shows the date when the maintenance request was created. You cannot change this date.

- In the Maintenance Type field, choose Corrective if the request is to fix a problem. Choose Preventive if the request is to stop problems from happening.

- If the request is for a problem that happened during a specific Manufacturing Order, select that MO in the Manufacturing Order field.

- If you selected an MO, a Work Order field will appear below. If the problem happened during a specific work order, choose it here.

- In the Team field, choose the maintenance team that will handle this request. If one person is responsible, pick them in the Responsible field.

- The Scheduled Date field is for when the maintenance should happen and the time it should start. Click the field to open a calendar, pick a day, then enter the hour and minute in the boxes below. Click Apply to save.

- The Duration field is for how long the maintenance will take. Write the time in this format: 00:00.

- If you picked Work Center in the For field, a checkbox called Block Workcenter will appear below the Duration. Check this box to stop other work or maintenance from being scheduled in that work center while this request is active.

- The Priority field shows how important the request is. You can choose from 0 to 3 stars by clicking the stars. Requests with more stars show up first on the Kanban board.

- At the bottom of the form, in the Notes tab, write any important details about the maintenance (like why it happened or when).

- In the Instructions tab, add how the maintenance should be done. Choose one of these three options and add instructions:

- PDF: Click Upload your file to open your device’s files, then pick a file to upload.

- Google Slide: Paste a Google Slide link in the box that appears.

- Text: Write the instructions in the box that appears.

Screenshot

Maintenance Requests

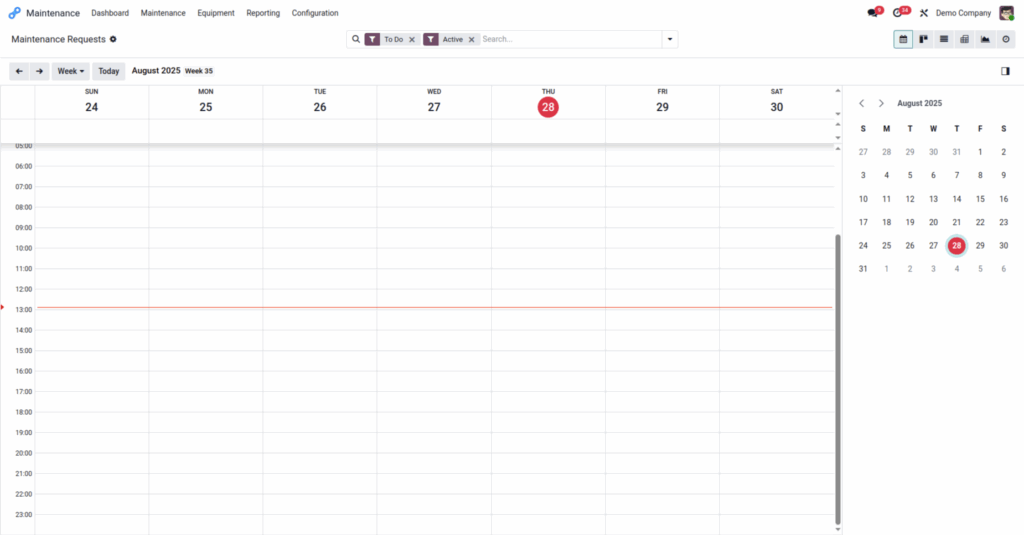

Maintenance Calender

Overview

To prevent equipment from breaking down and to avoid delays in warehouse work centers, it’s important to regularly maintain all machines and tools. When equipment breaks unexpectedly, it should be repaired quickly. Regular checks and servicing help avoid such problems before they happen. This keeps warehouse operations running smoothly.

In Odoo Maintenance, users can use the maintenance calendar to create, schedule, and update both corrective and preventive maintenance tasks. This helps them manage equipment and work centers effectively.

Business Rule

- To make a new request, click anywhere on the calendar. This will open a New Event window.In the Name field, type a title for the new request.

- Click Create to save the request with no extra details. If you want to stop creating the request, click Cancel.

- To add more details and choose a date and time, click Edit.

- Clicking Edit opens a blank form where you can fill in information about the request.

Screenshot

Maintenance Calender

Maintenance Report Management

Maintenance Requests

The number and duration of maintenance requests can be used as measurement tools. The Odoo Maintenance module helps improve your business operations and workflow efficiently, without wasting time or employee effort.

Business Rule

- View detailed reports on all maintenance requests, including the number of requests, their status and types.

- Analyze data on machines and tools, such as how often they break down, average repair time, and mean time between failures. This helps identify problematic equipment.

- Track maintenance activities and performance by work center, helping you monitor workload and efficiency in different areas of your operation.

- Reports show how many maintenance tasks each technician has completed, their average repair time, and workload balance.

- A visual calendar report helps you plan and track upcoming maintenance tasks, both preventive and corrective.

- Use Odoo’s reporting dashboards to combine different maintenance and visualize trends with charts and graphs.

Screenshot

Maintenance Requests