Rice Mill ERP Inventory Management

MR Inventory Management helps you to manage the process of ordering, storing, consuming and selling of Company’s Inventories such as Raw Materials, Spares, and finished products. It also helps you to manage maximum/minimum inventory levels, facilitating maximum orders and initiating timely deliveries.

MR Rice Mill ERP Inventory process involves the following features

- It manages multiple warehouses and locations.

- It helps to manage products and their variants segregated by different product categories. It efficiently manages the inventory by maintaining maximum and minimum levels, which eliminates the possibilities of overstock of the products.

- It seamlessly keeps track of the incoming and outgoing inventory.

- It organizes data by fetching the necessary details from various resources.

- It controls the processing time by automating the inventory transactions, improving transparency.

- Manage the overall warehouse within the same system.

- Manage the multiple warehouse locations, packing, efficient scrap management, stock transfer option, etc.

- Unload incoming material and transfer to outbound gates with no storage in between.

- Maintain purchase order propositions based on supplier leads and other inventory forecasts.

- Tracking Lot/Serial numbers on products.

- It helps to move stock from one warehouse location to another.

- Manage Physical Inventory Adjustments based on physical stock availability.

- Helps to set up perpetual (real-time, automated) or periodic inventory valuation mode by product.

- It helps to integrate with Third-Party Shippers.

- Helps to calculate Landed Cost.

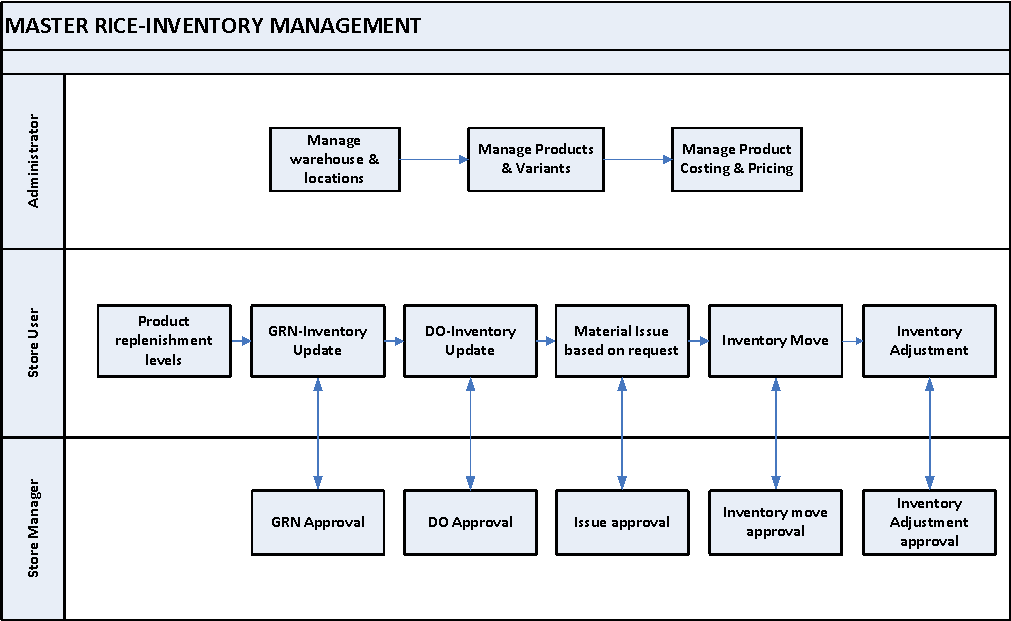

Master Rice Inventory Process Flow

Rice Mill ERP Inventory Module Dependencies

The other modules to which the inventory module depends on are,

- Purchase

- Sales

- Manufacturing

- Accounting

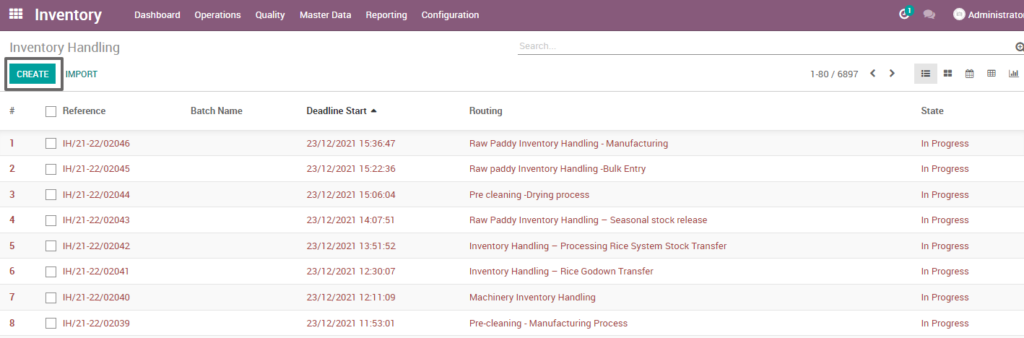

Inventory handling

Inventory handling is the process of managing and tracking stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Go to inventory → Click on Operations menu → Select Inventory handling

Field Description

- Create – Click create button to create new inventory handling

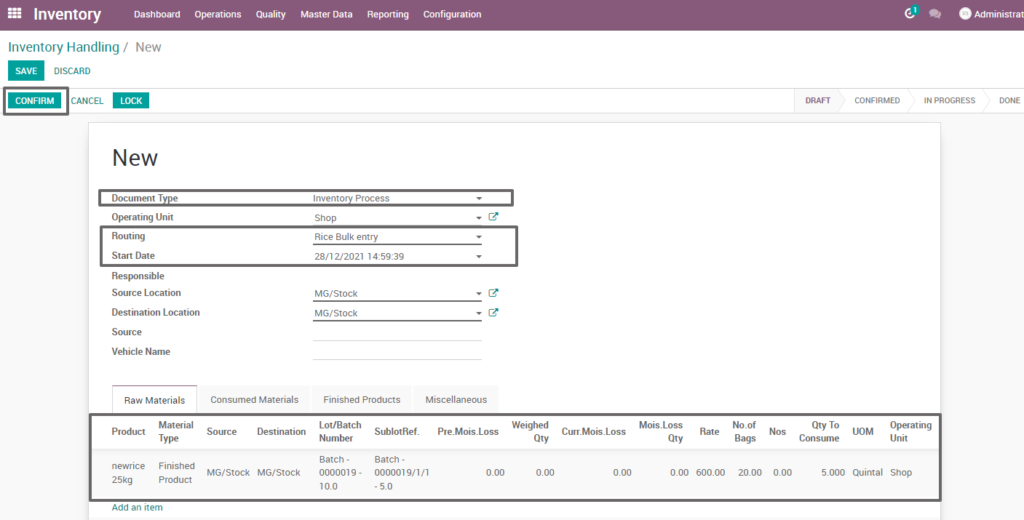

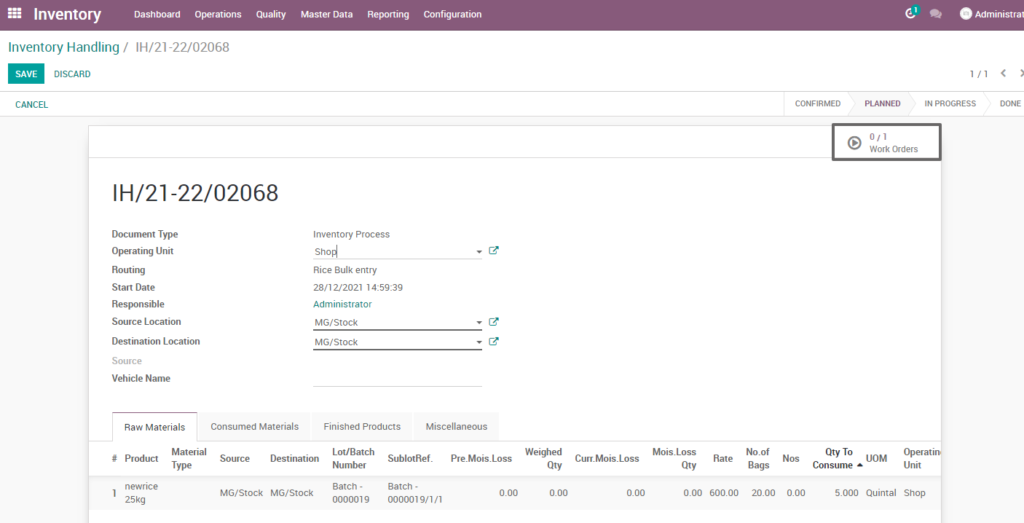

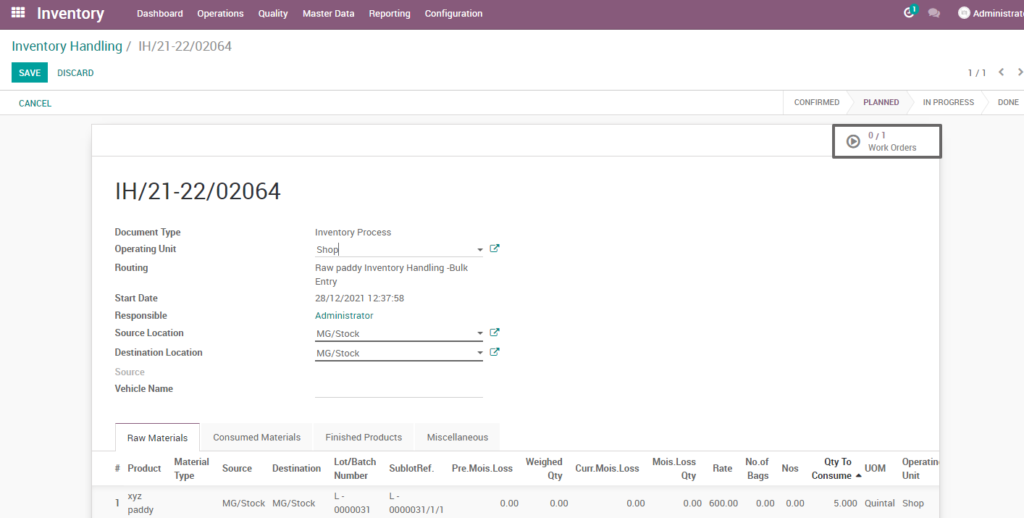

1. User scenario – Rice bulk entry

It is a process of combining many minimal quantities of rice products from different lots and brands into one large quantity of rice product as per business requirement.

Field Description

- Document type – Select the document type (i.e. Inventory process, production process, move request, etc.,) (mandatory)

- Routing – Select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – Choose the data for input location

- Destination location – Choose the data for output location

- Product – Add one or more products for processing

- Lot/batch number – Select lot no for chosen product

- Sub lot – Select sub lot no for chosen lot no

- No. Of bags – Choose no of bags to process quantity

- Quantity – Enter the required product quantity

- Confirm- Click on confirm button to create work order

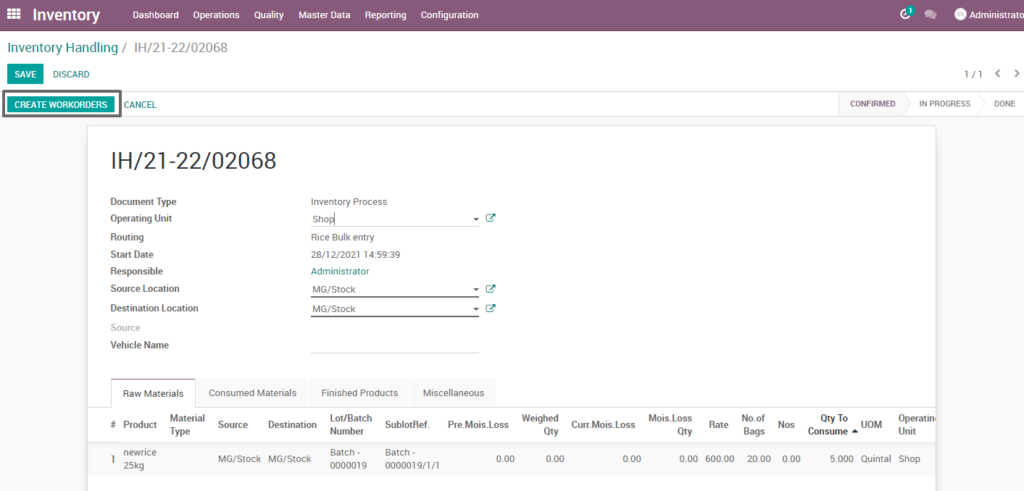

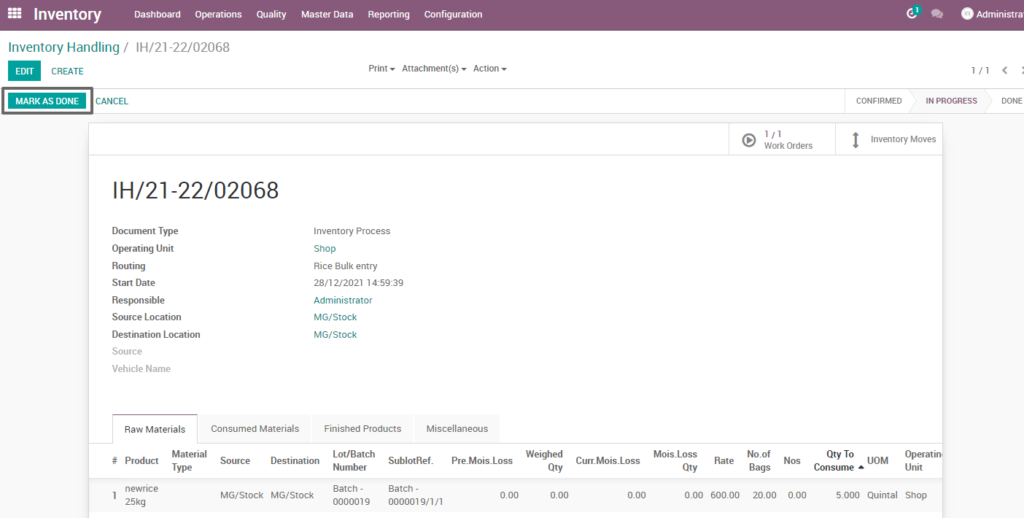

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

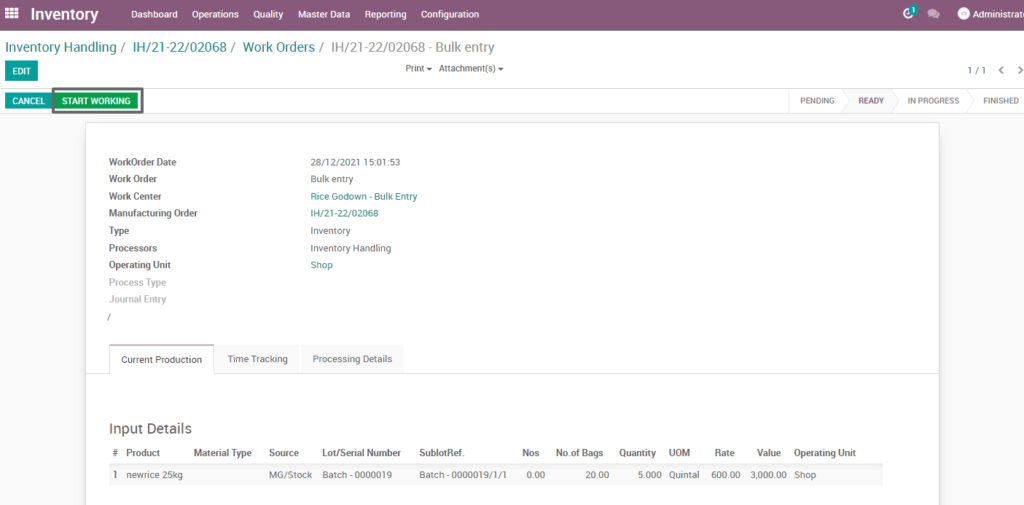

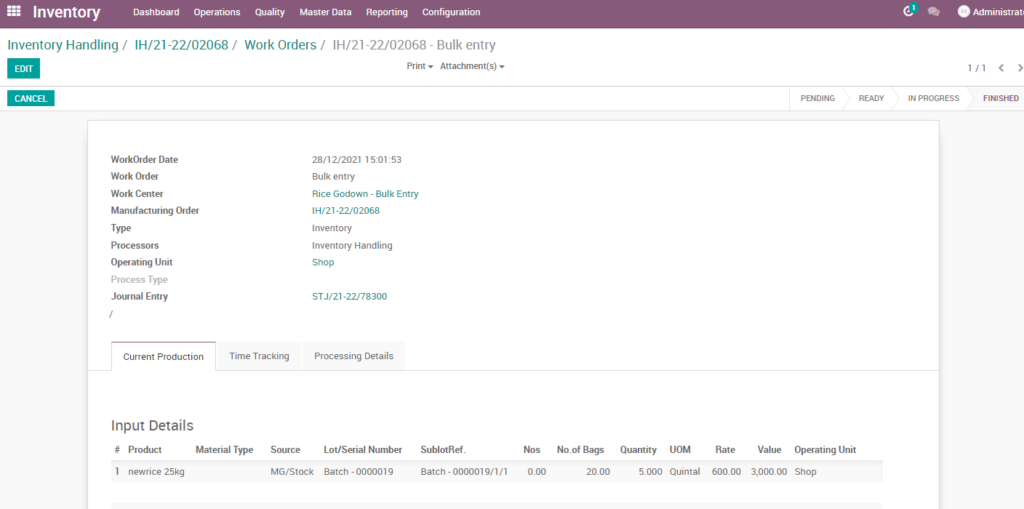

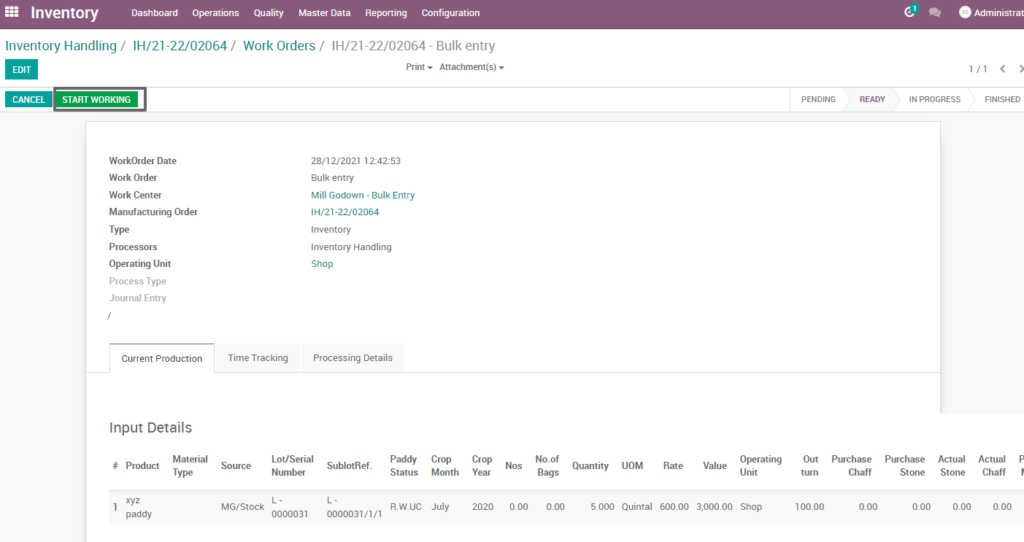

Open work order

Open work order to view the work order process of the rice bulk entry inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field Description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of rice bulk entry.

Field Description

- Start working – click on start work order button to start the process of work order

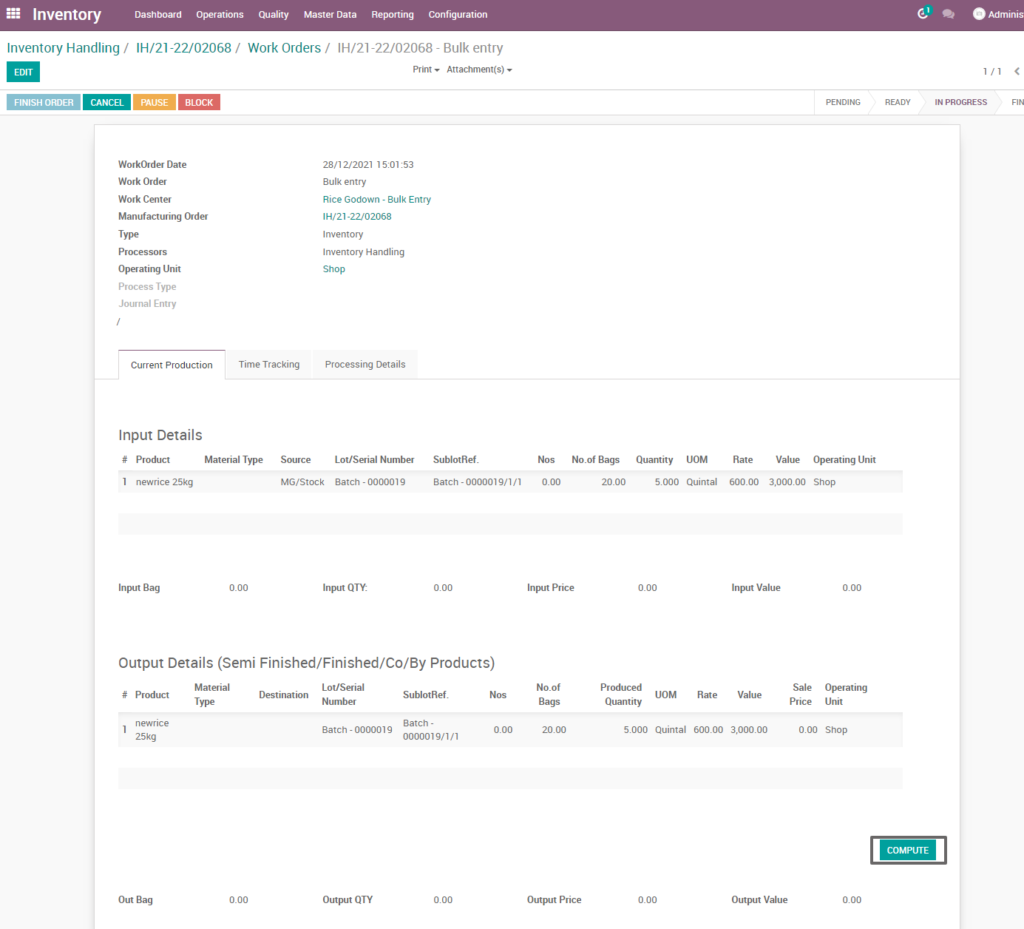

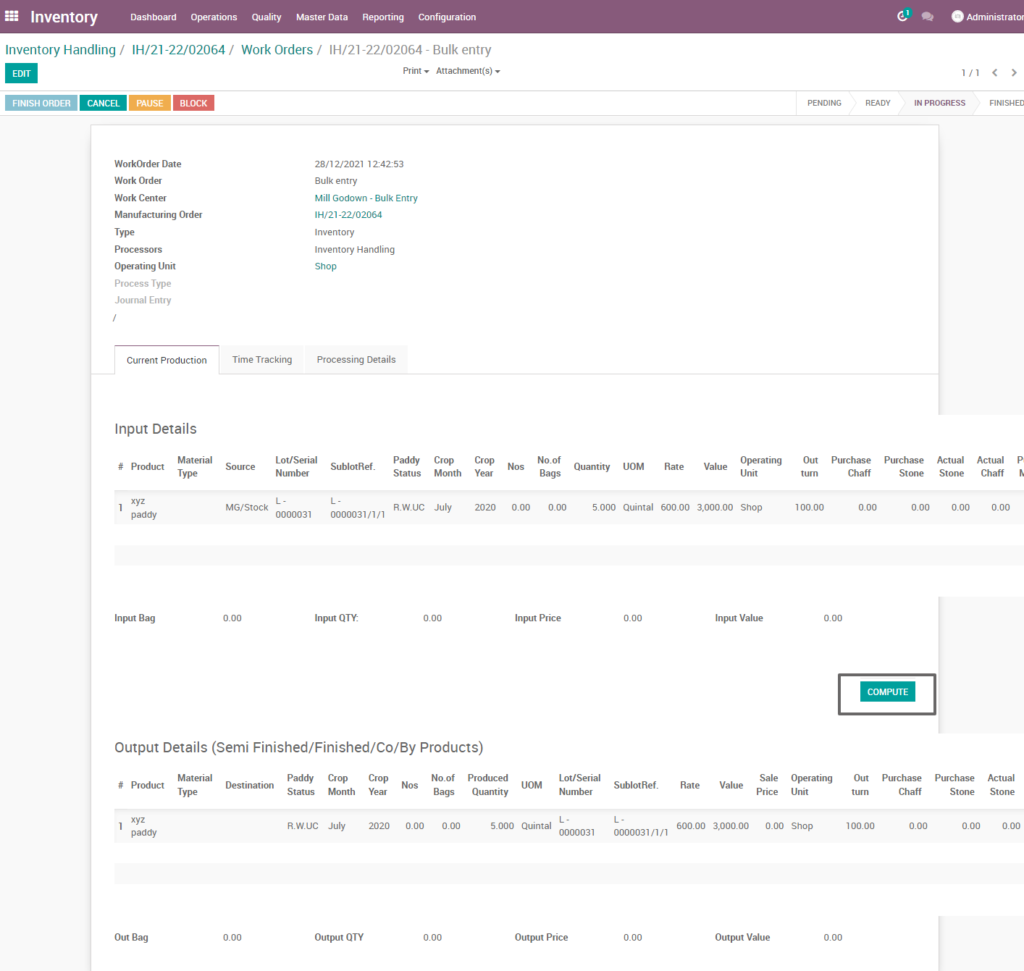

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process rice bulk entry.

Field Description

- Compute – Click on compute button to compute input and output details

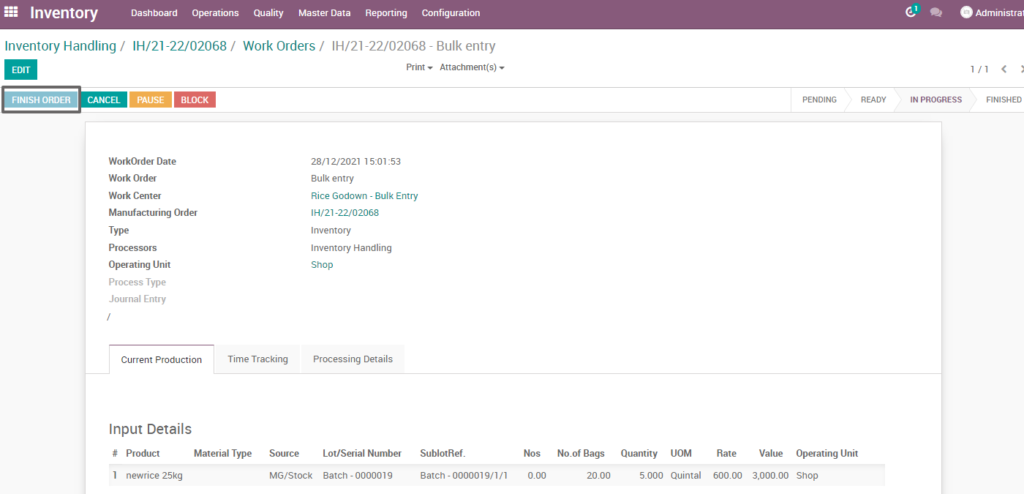

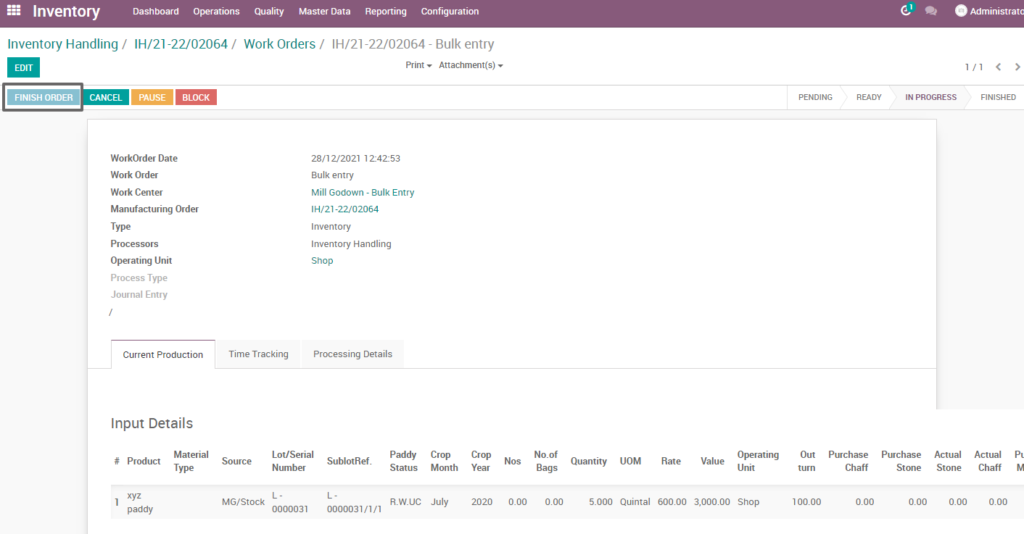

Finish process

After compute process, check on rice bulk entry of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of rice bulk entry from inventory process. State is changed in progress state into finished state.

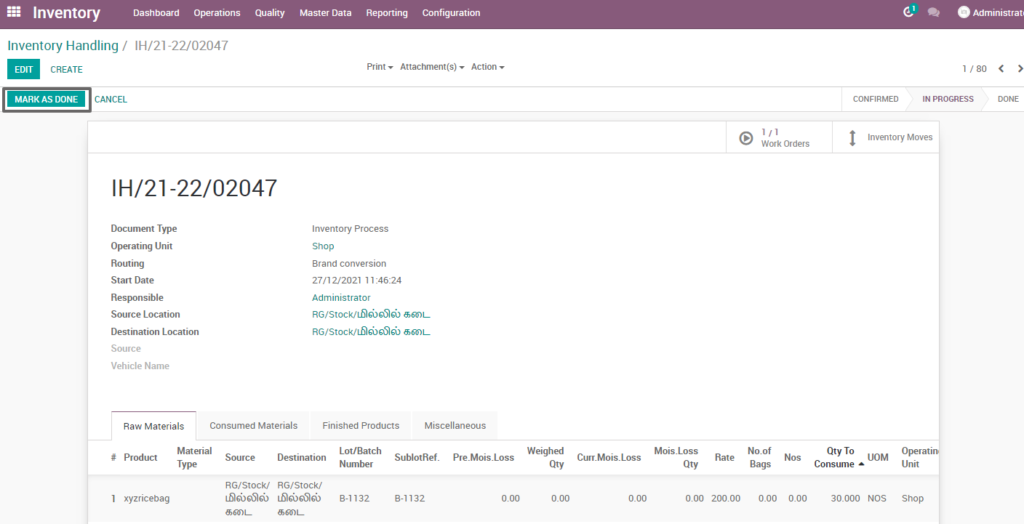

Work order-mark as done

Work order is finished the process then click on mark as done which shows the work order of rice bulk entry is done. State is changed in progress state into done state.

Field Description

- Mark as done : Click on mark as done button to complete the process (state-done)

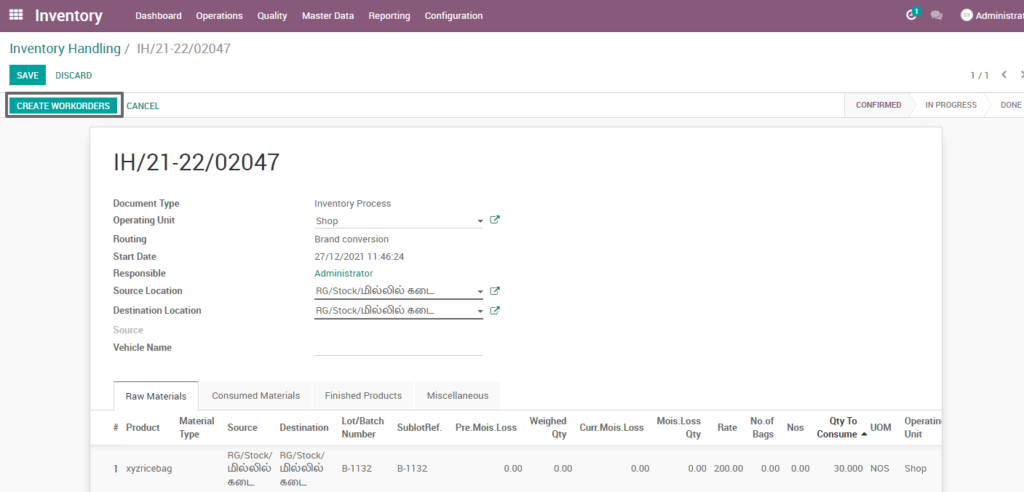

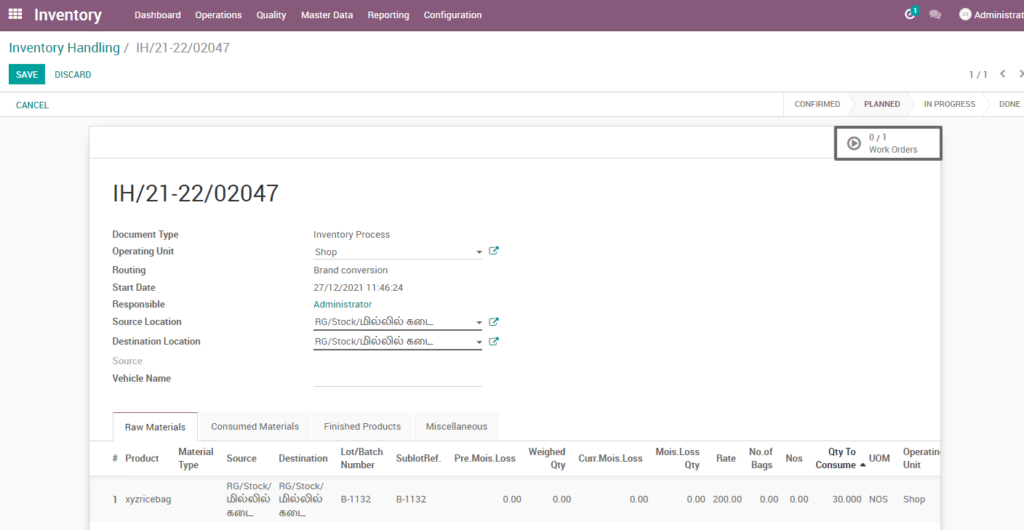

2. User scenario – Brand conversion

It is an inventory process which convert one brand set of rice product into other brand set of rice. As per business requirements, products can be converted into different brands with changes in the pricing, packing, etc.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Brand conversion, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No. Of bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

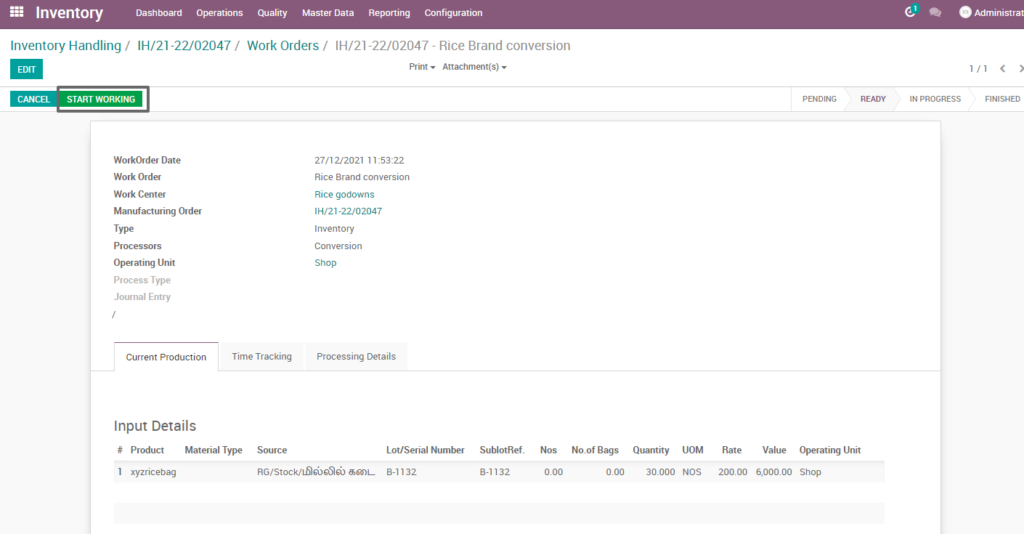

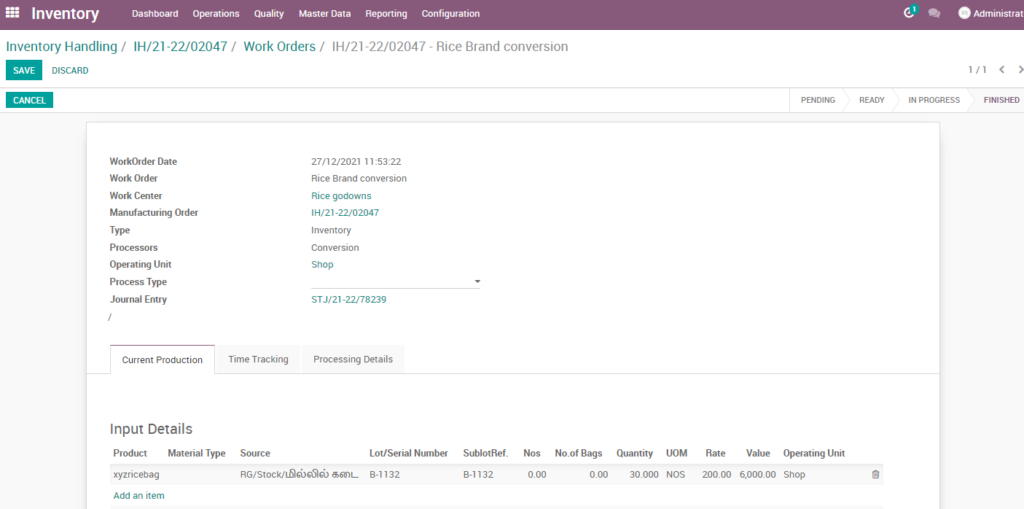

Open work order

Open work order to view the work order process of the brand conversion inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field Description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start .It shows input and output details of the brand conversion.

Field Description

- Start working – Click on start work order button to start the process of work order

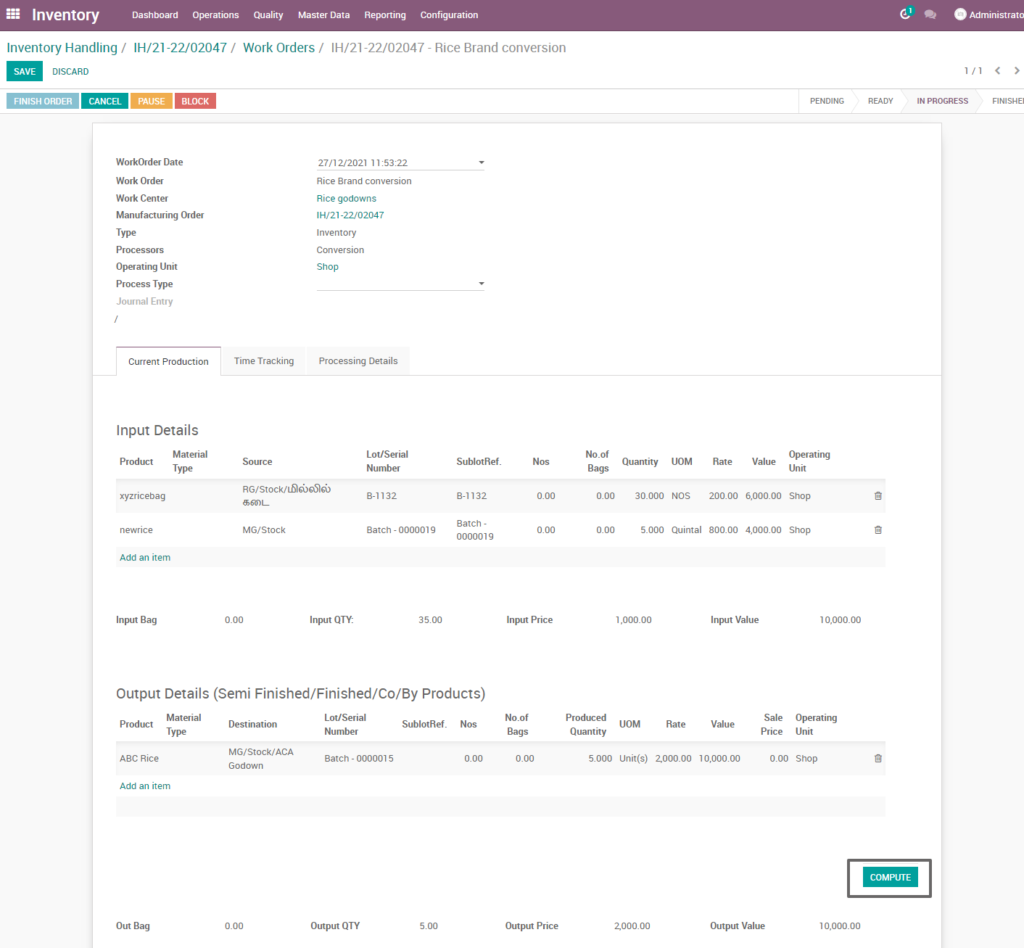

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process brand conversion.

Field Description

- Compute – Click on compute button to compute input and output details

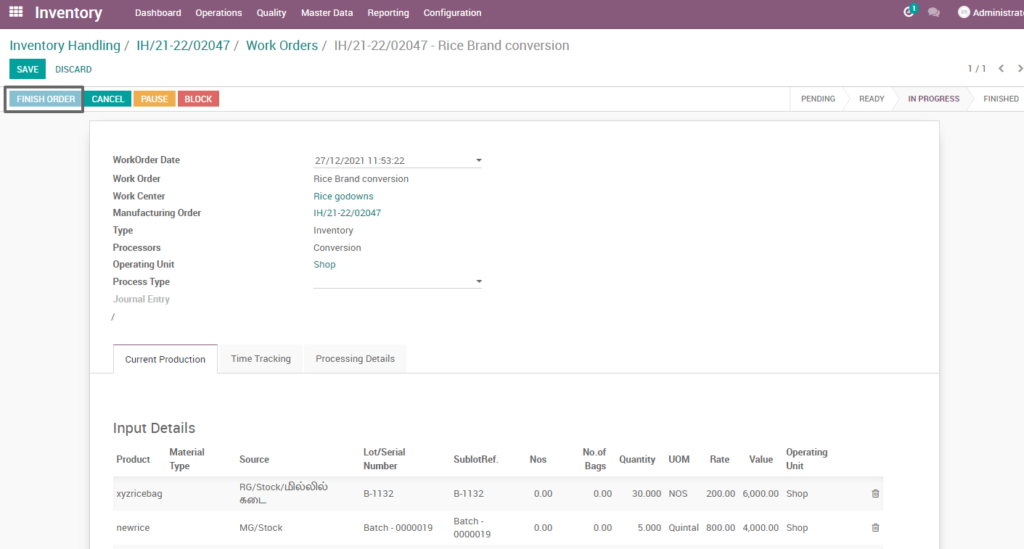

Finish process

After compute process, check on brand conversion of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of rice brand conversion of inventory process. State is changed in progress state into finished state.

Work order-mark as done

Work order is finished the process then click on mark as done which shows the work order of rice brand conversion is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

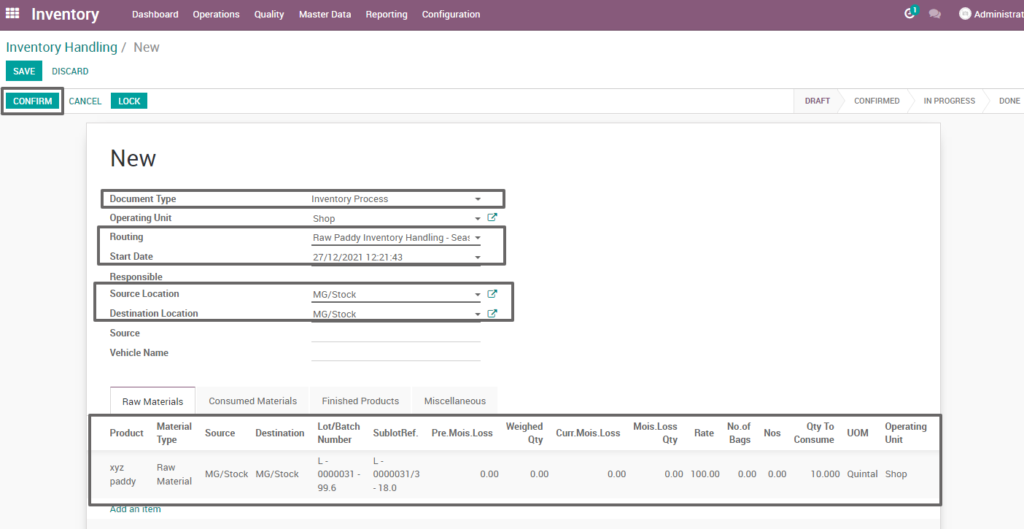

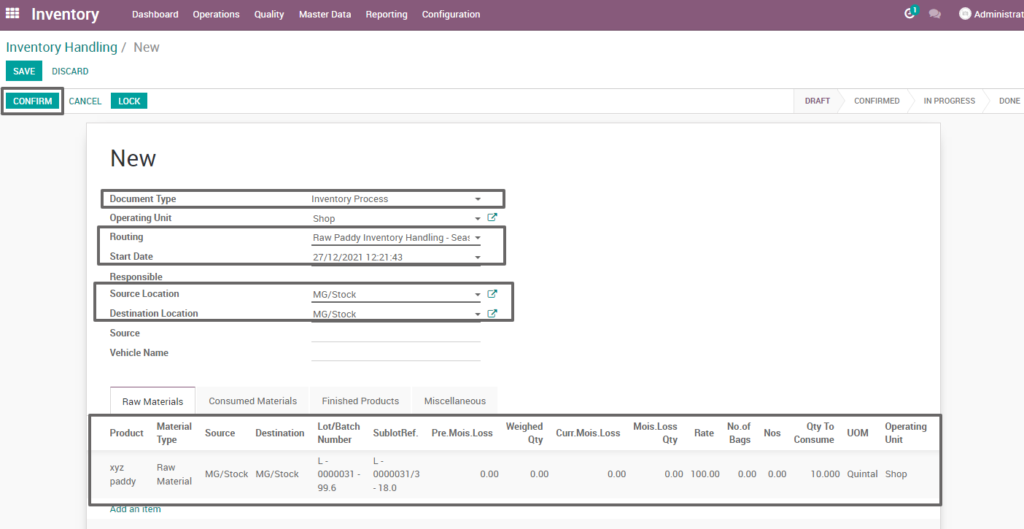

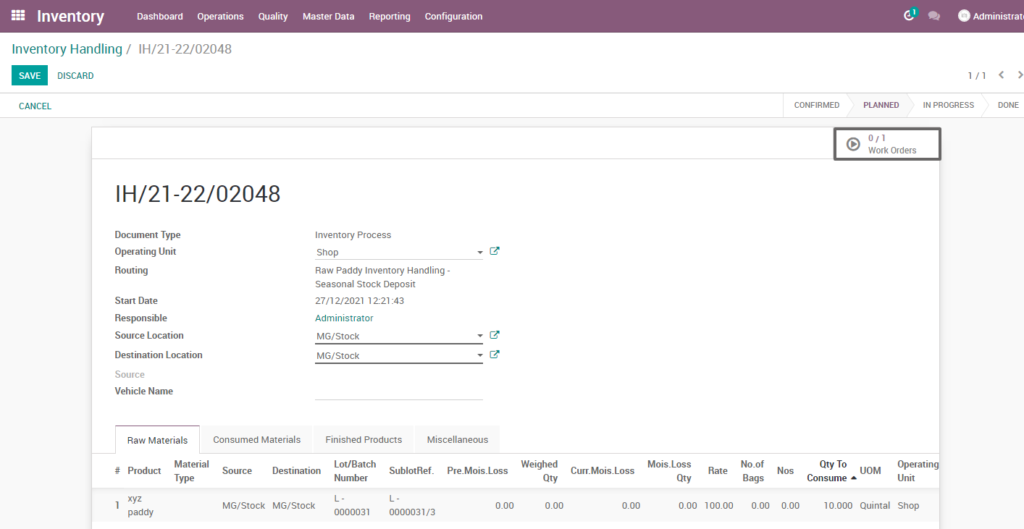

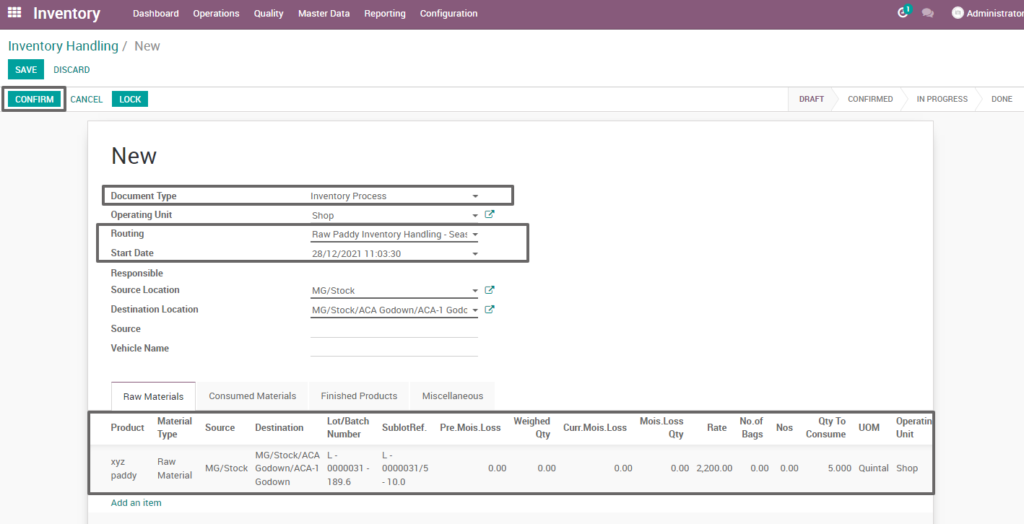

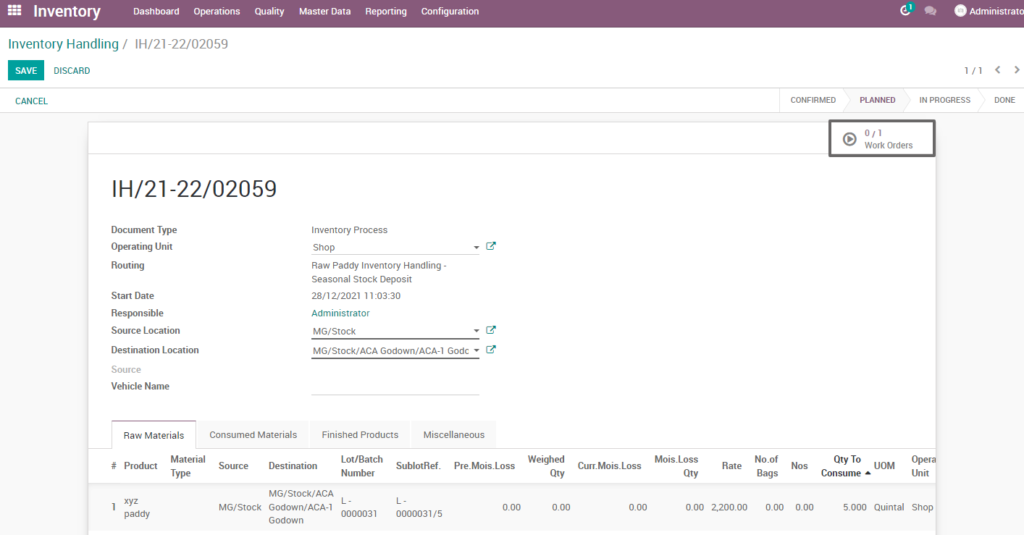

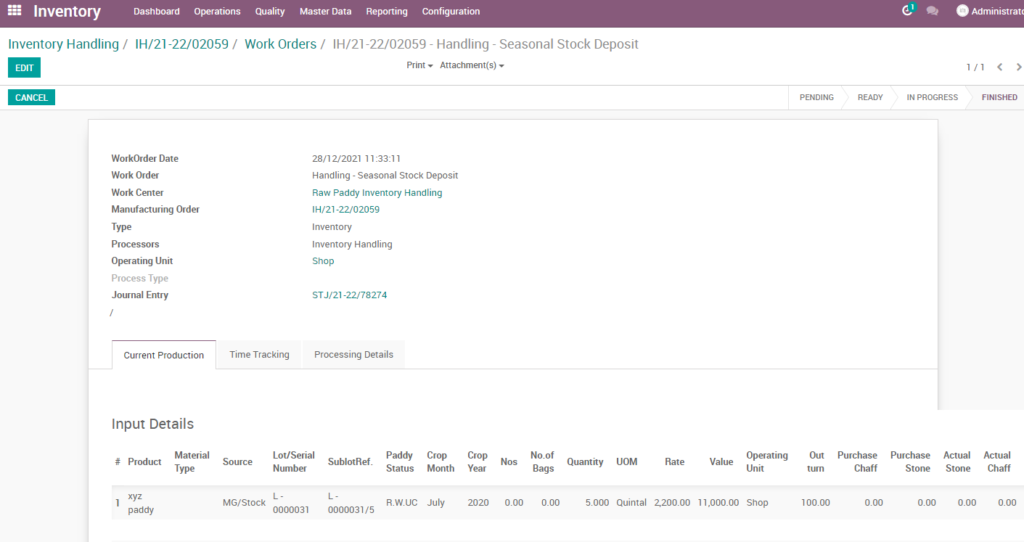

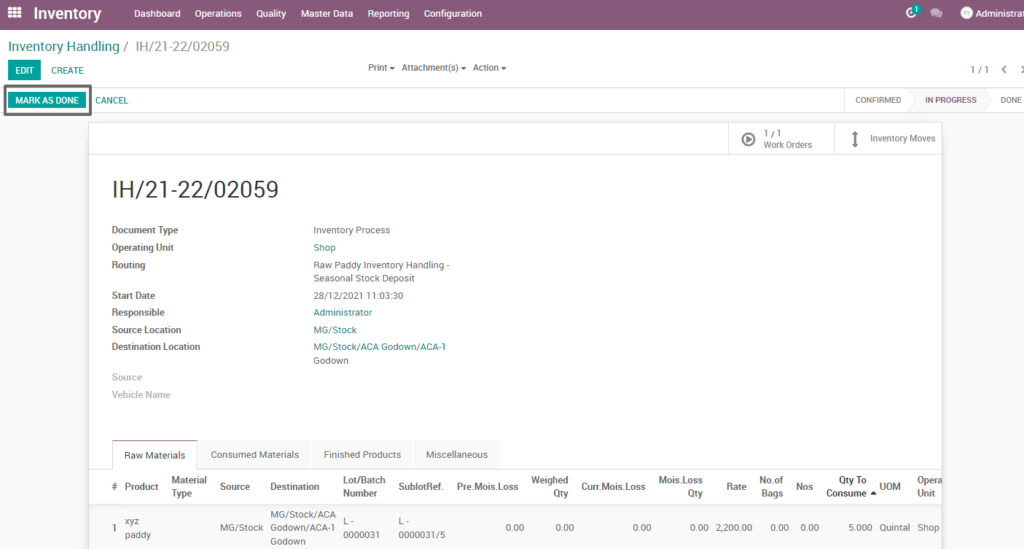

3. User scenario – Raw Paddy Inventory Handling – Seasonal Stock Deposit

Raw paddy inventory handling is the process of managing and tracking, seasonal stock deposit, stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – Select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – Select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – Choose the data for input location

- Destination location – choose the data for output location

- Product – Add one or more products for processing

- Lot/batch number – Select lot no for chosen product

- Sub lot – Select sub lot no for chosen lot no

- No.of.bags – Choose no of bags to process quantity

- Quantity – Enter the required product quantity

- Confirm – Click on confirm button to create work order

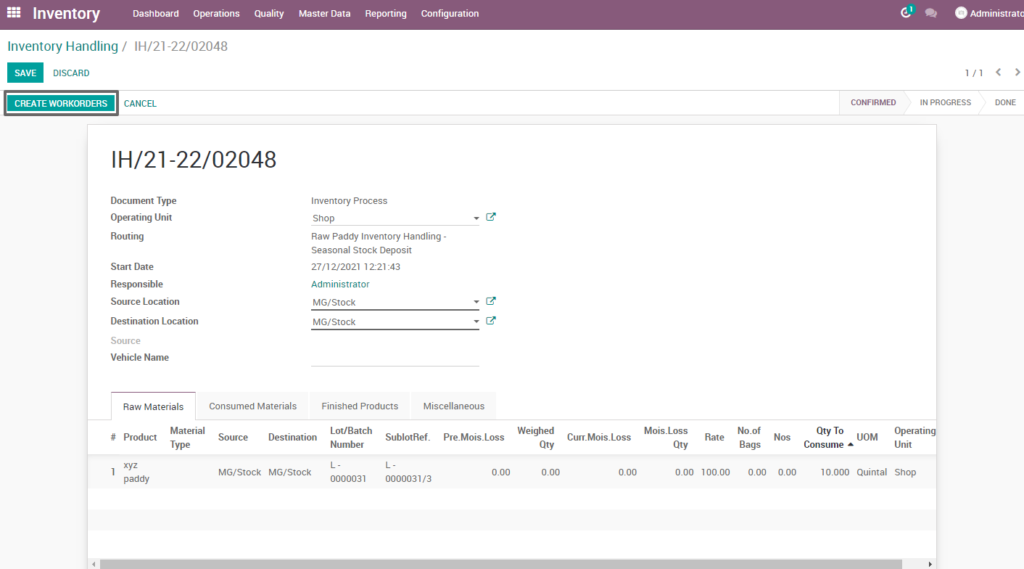

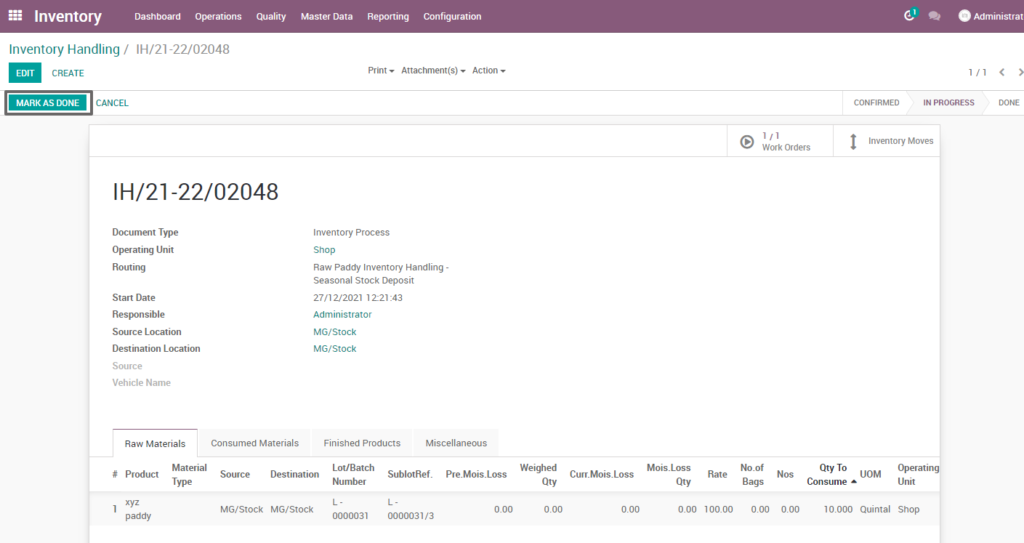

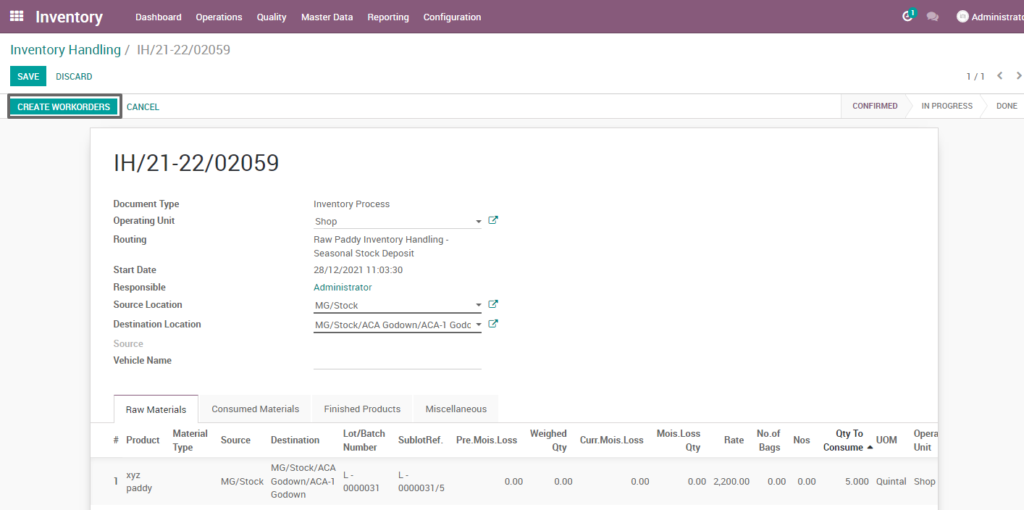

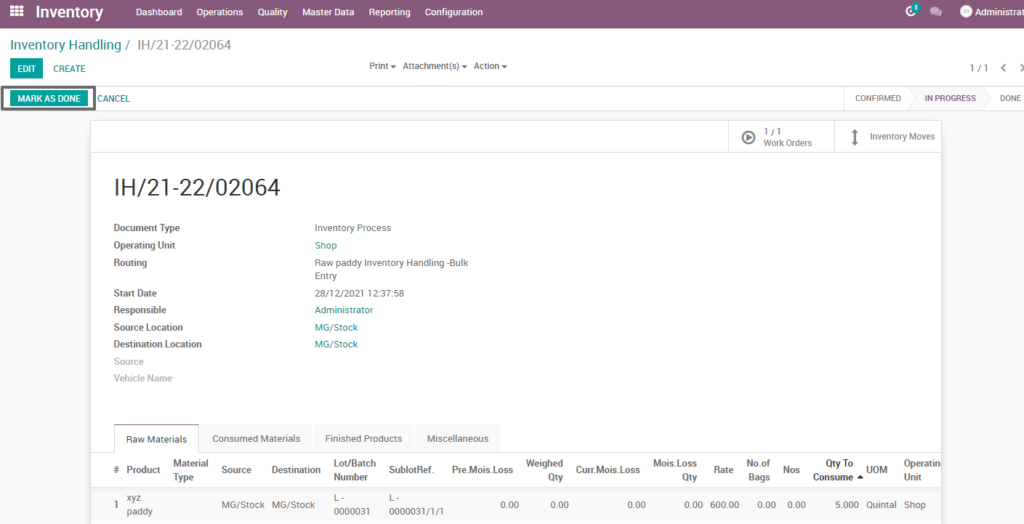

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

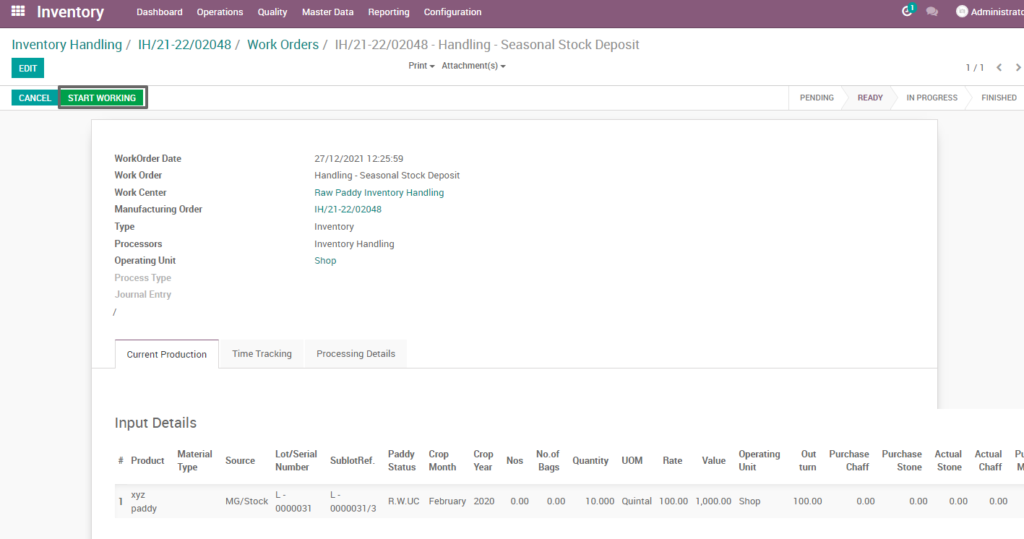

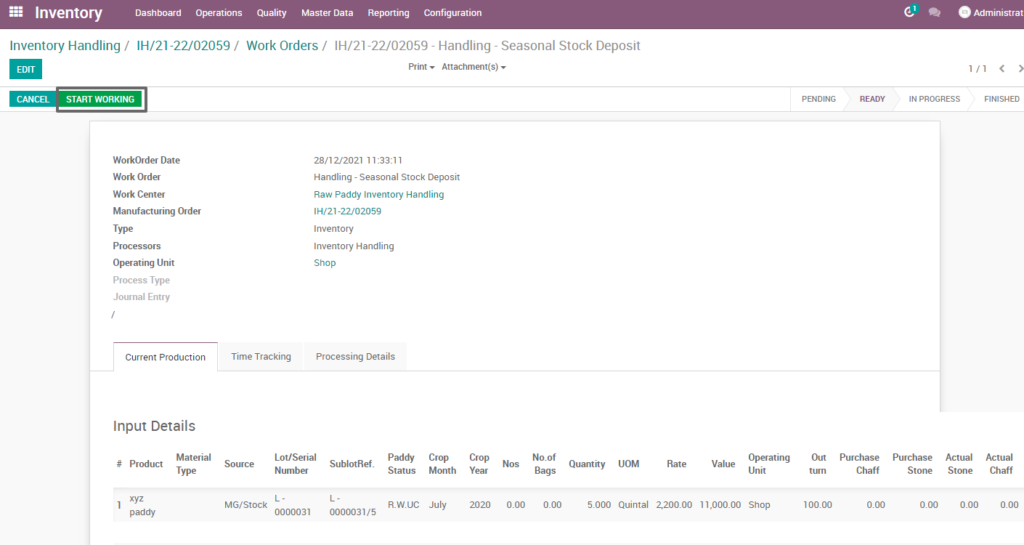

Open work order

Open work order to view the work order process of the raw paddy inventory handling seasonal stock deposit inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

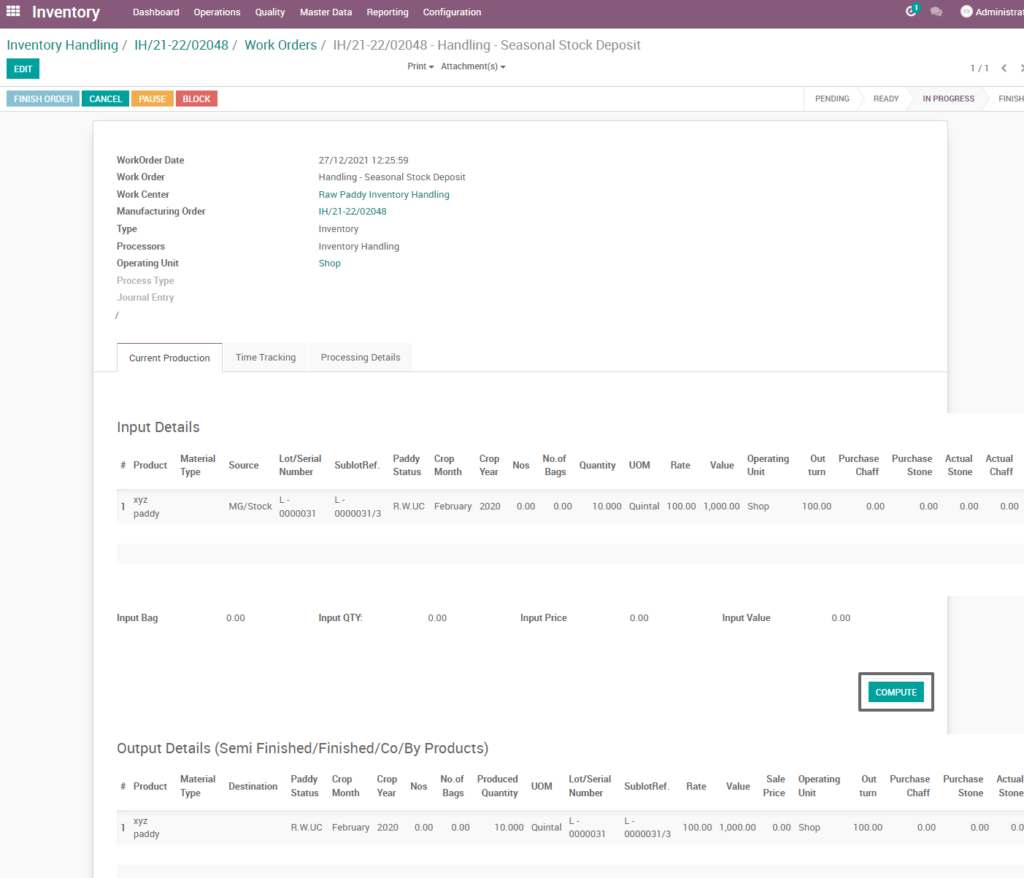

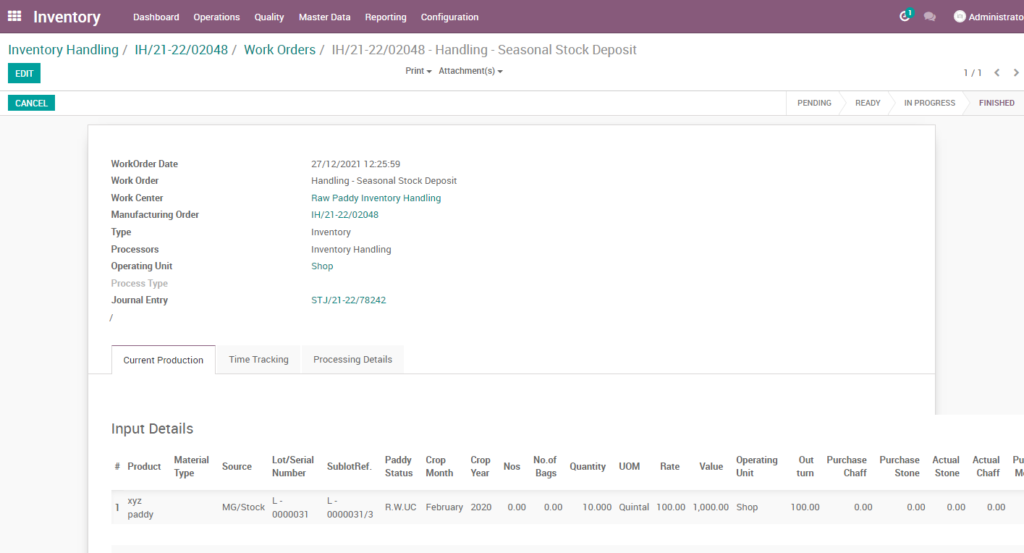

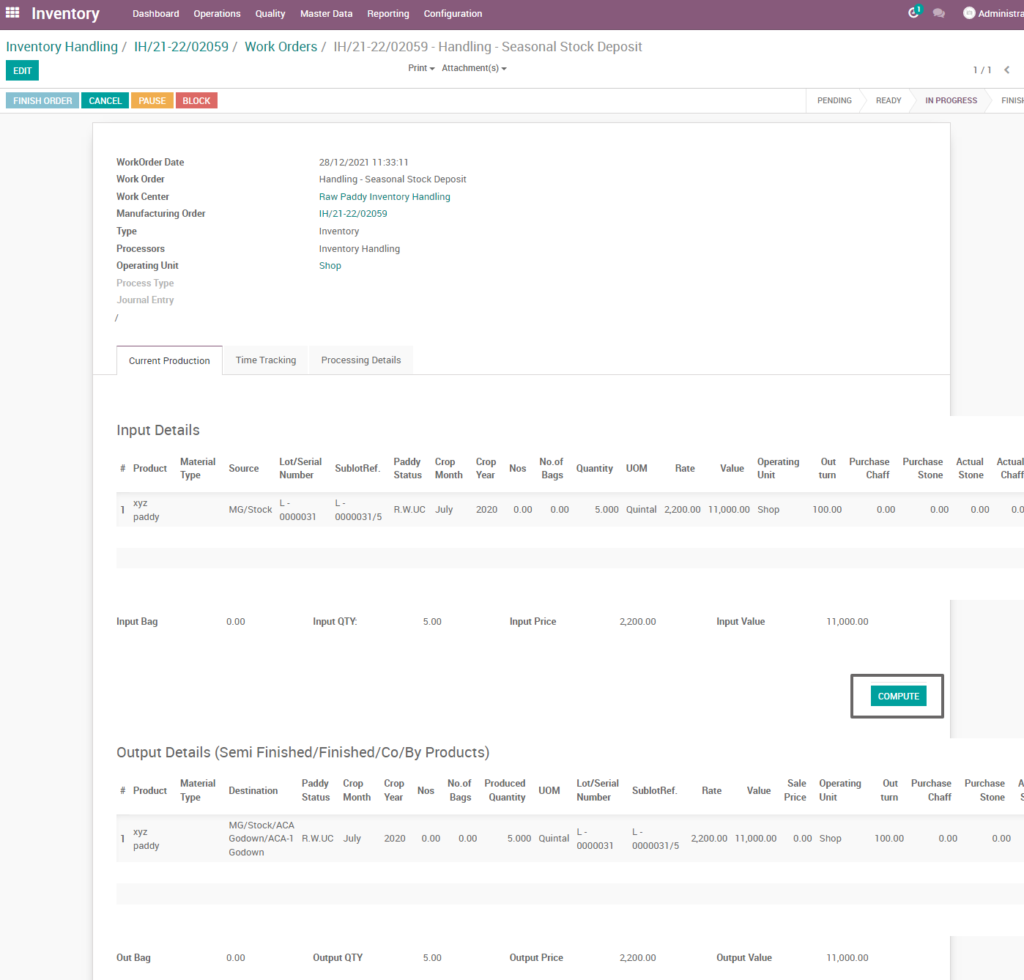

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start .It shows input and output details of the raw paddy inventory handling seasonal stock deposit .

Field Description

- Start working – Click on start work order button to start the process of work order

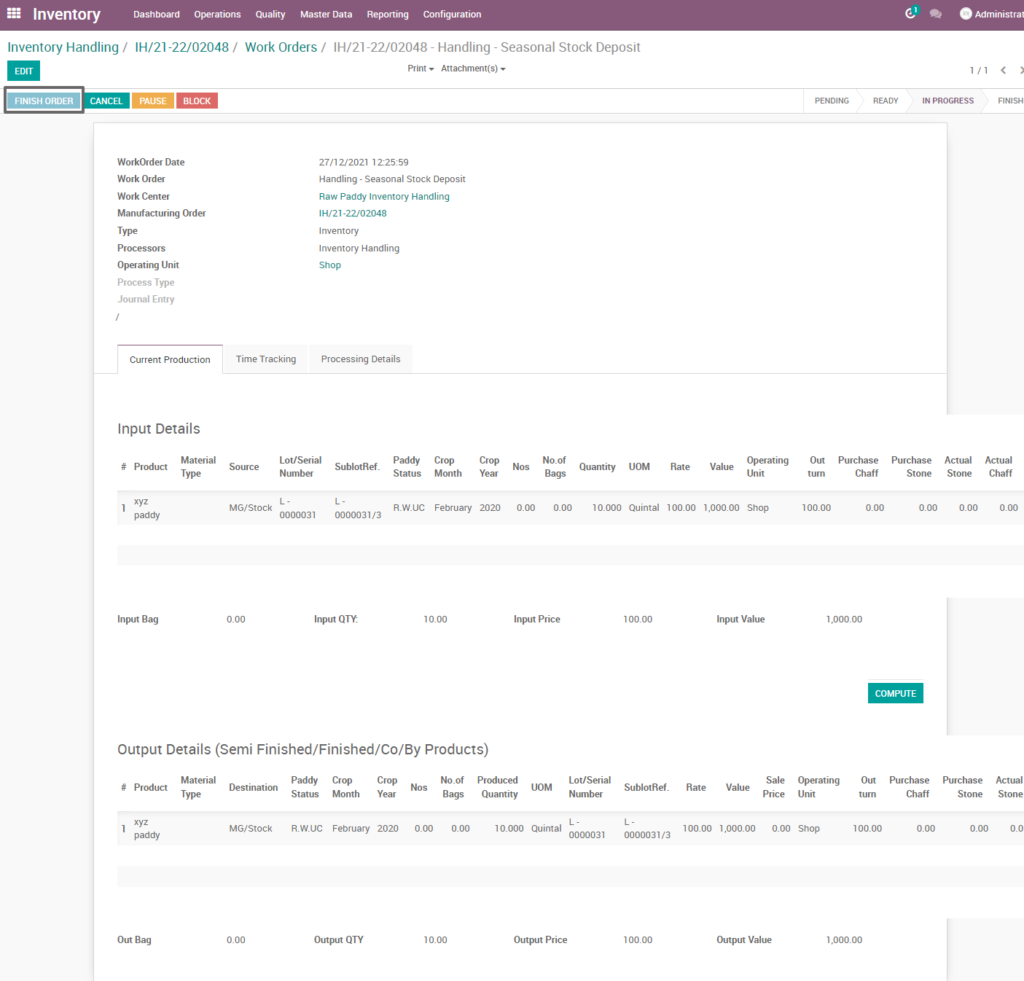

Compute process

Clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules.

Field Description

- Compute – Click on compute button to compute input and output details

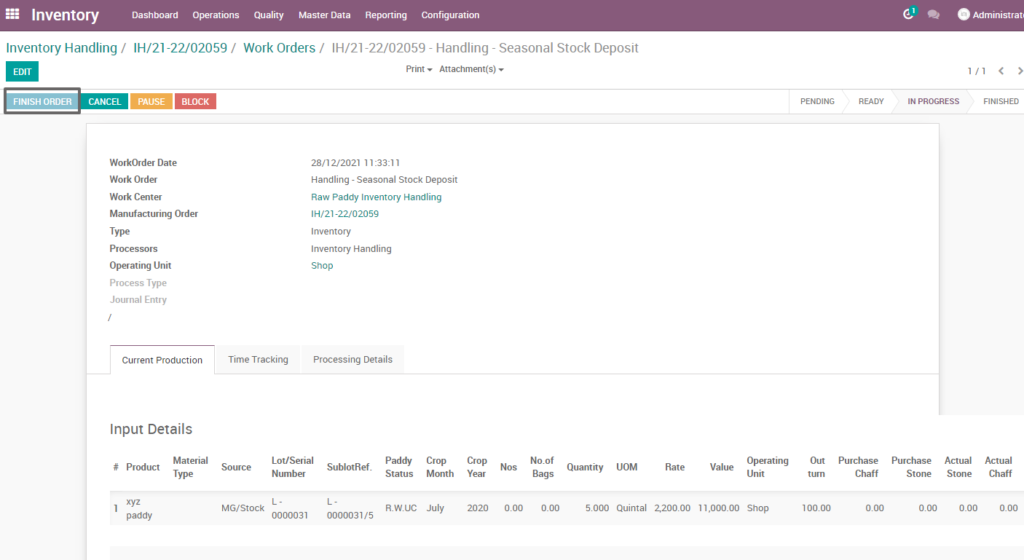

Finish process

After completing the compute process, the order can be marked as finished by clicking “finish order” .Then Work order will be set to completed state.

Field Description

- Finish order – click on finish order button to complete the work order

Finished work order

Here shows the finished work order of raw paddy inventory handling seasonal stock deposit of inventory process. State is changed in progress state into finished state.

Work order-mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy inventory handling seasonal stock deposit is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

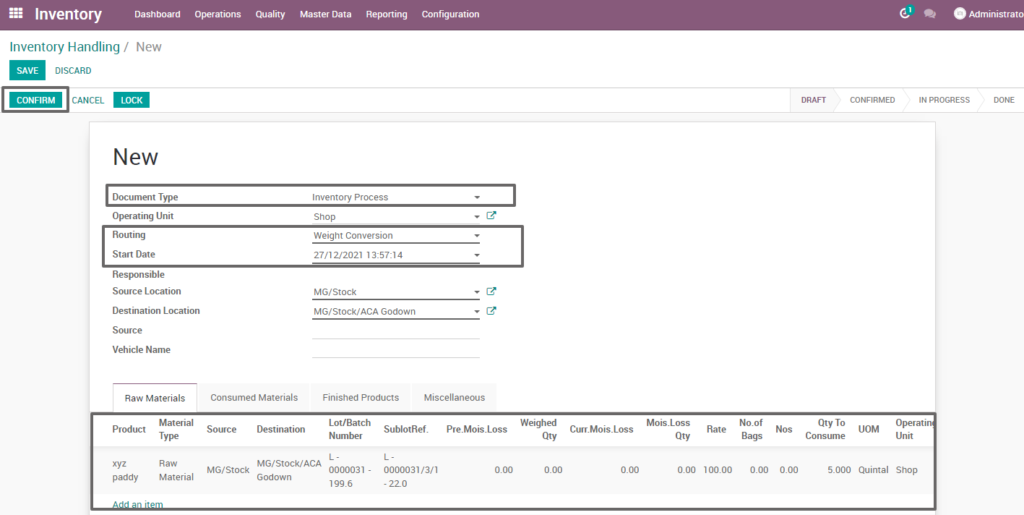

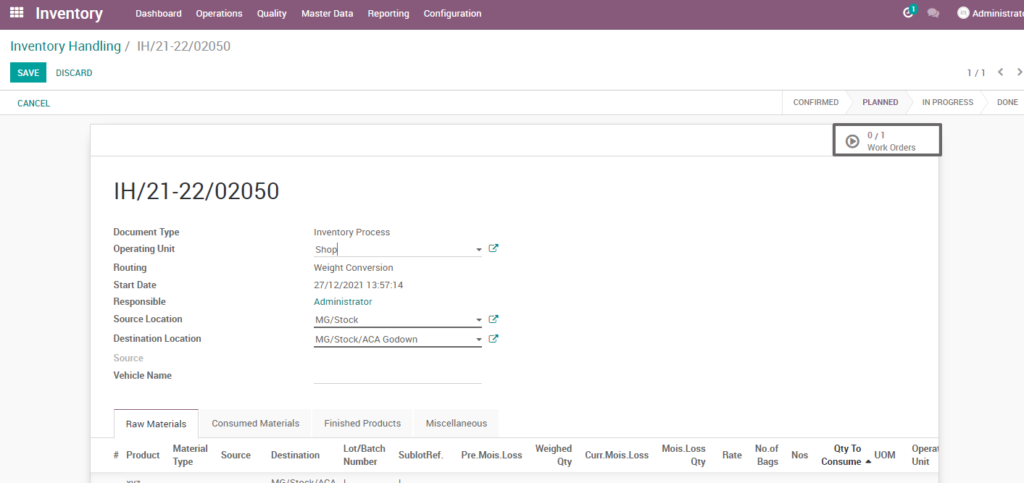

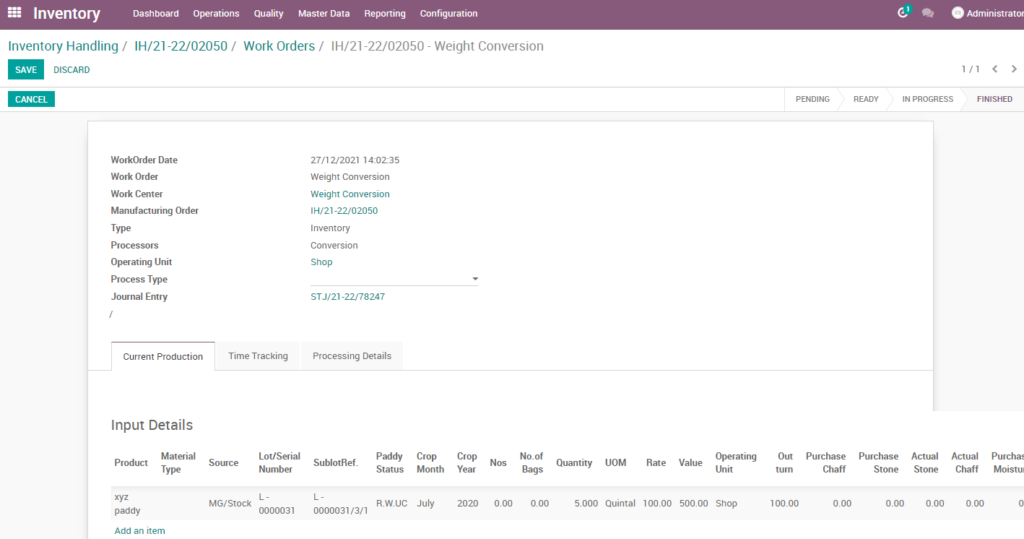

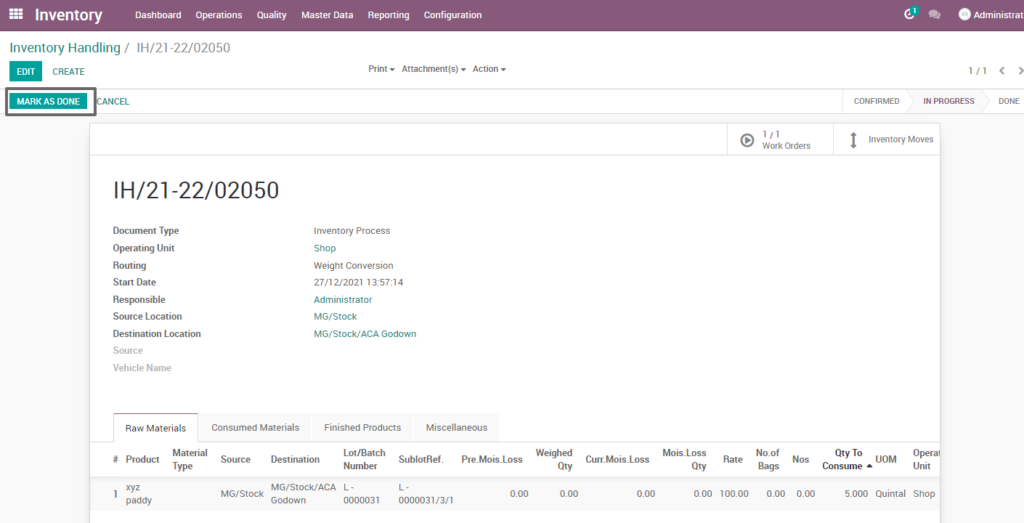

4. User scenario – Weight conversion

Weight conversion is the process of converting one quantity of product into another quantity weight product due to some loss of weight or any other inventory loss scenario in the inventory process.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc.,) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

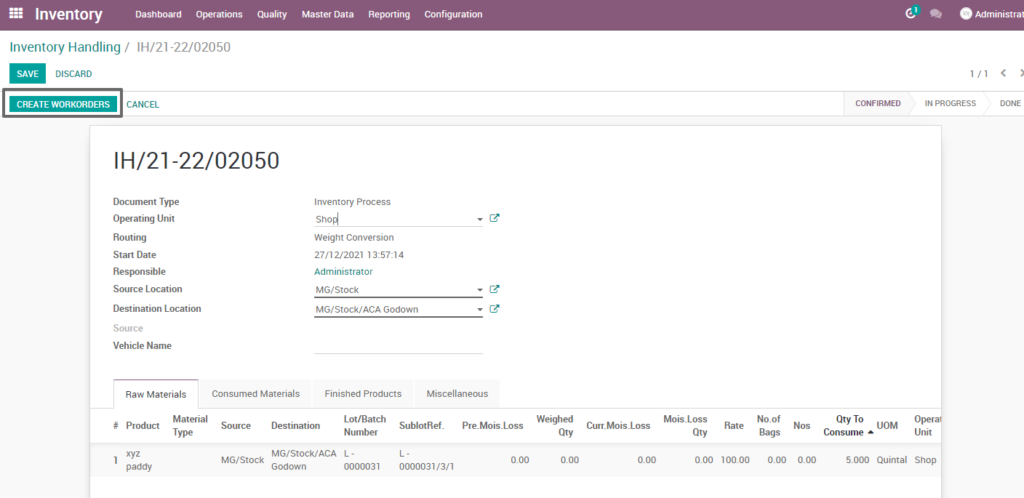

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

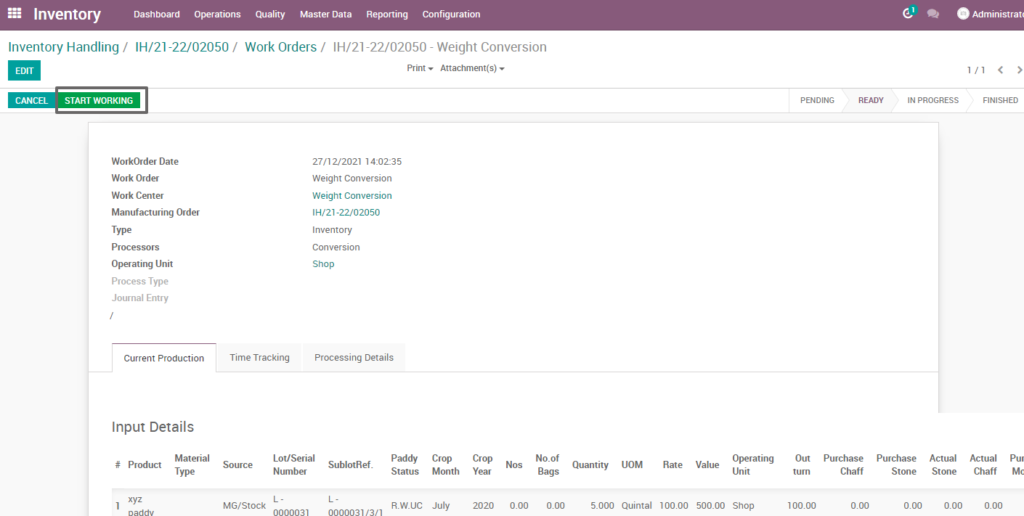

Open work order

Open work order to view the work order process of the weight conversion process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of weight conversion is start. It shows input and output details of the weight conversion.

Field Description

- Start working – Click on start work order button to start the process of work order

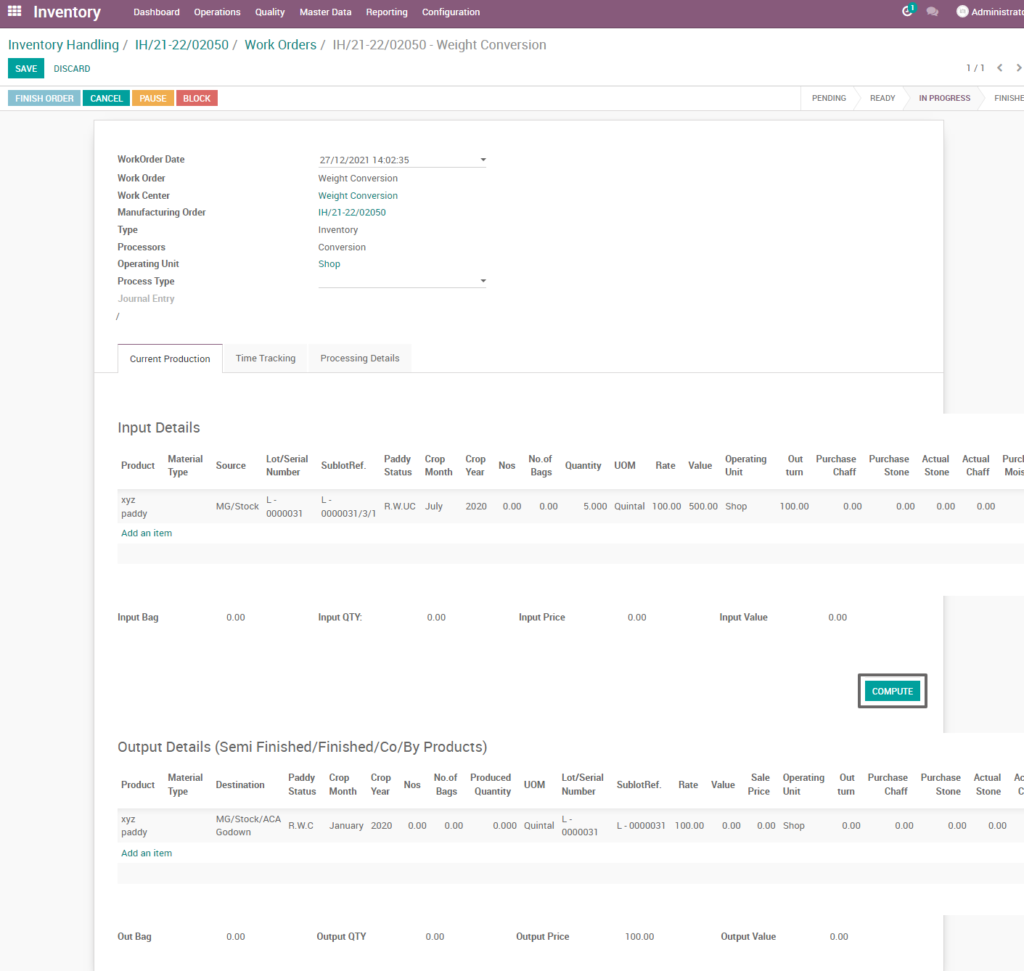

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules.

Field Description

- Compute – Click on compute button to compute input and output details

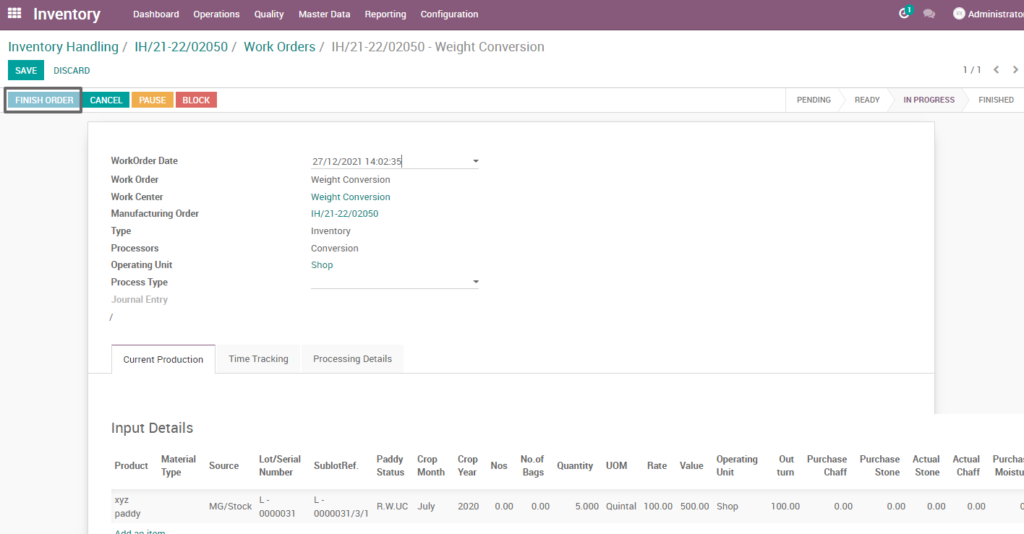

Finish process

After compute process, check on weight conversion of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of weight conversion of inventory process. State is changed in progress state into finished state.

Work order-mark as done

Work order is finished the process then click on mark as done which shows the work order of weight conversion is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

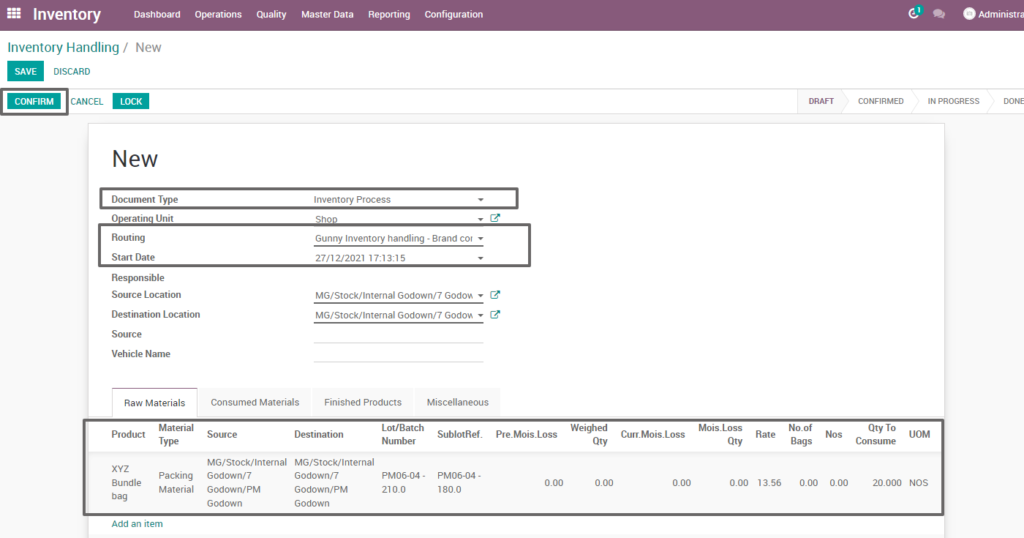

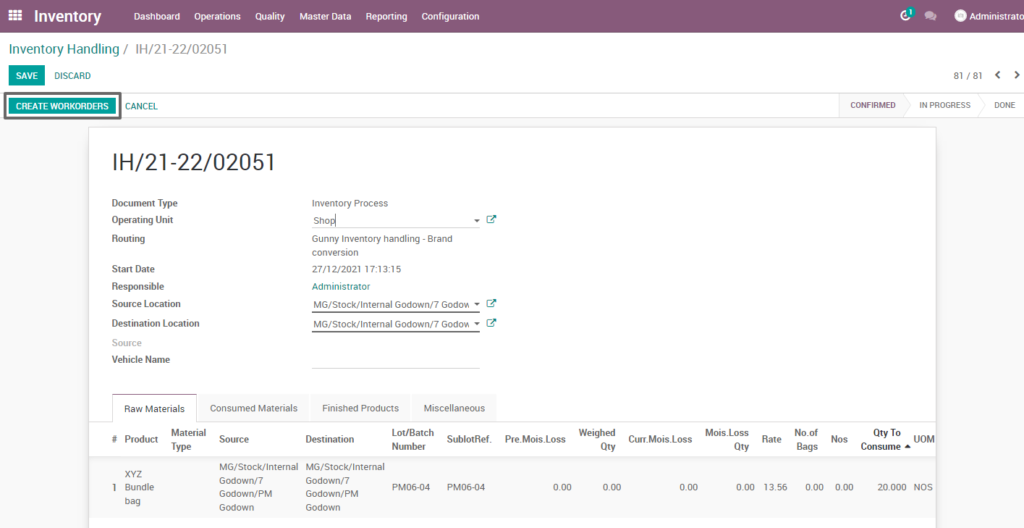

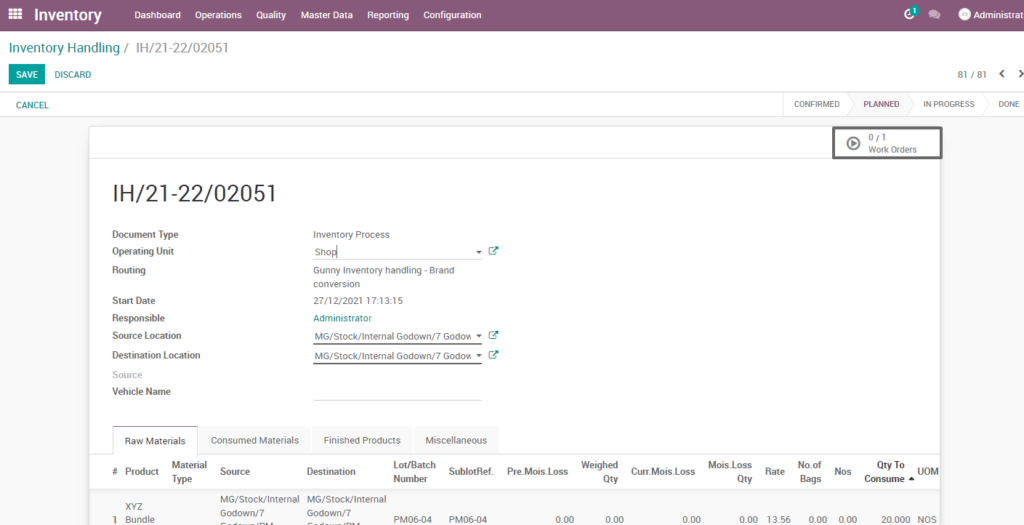

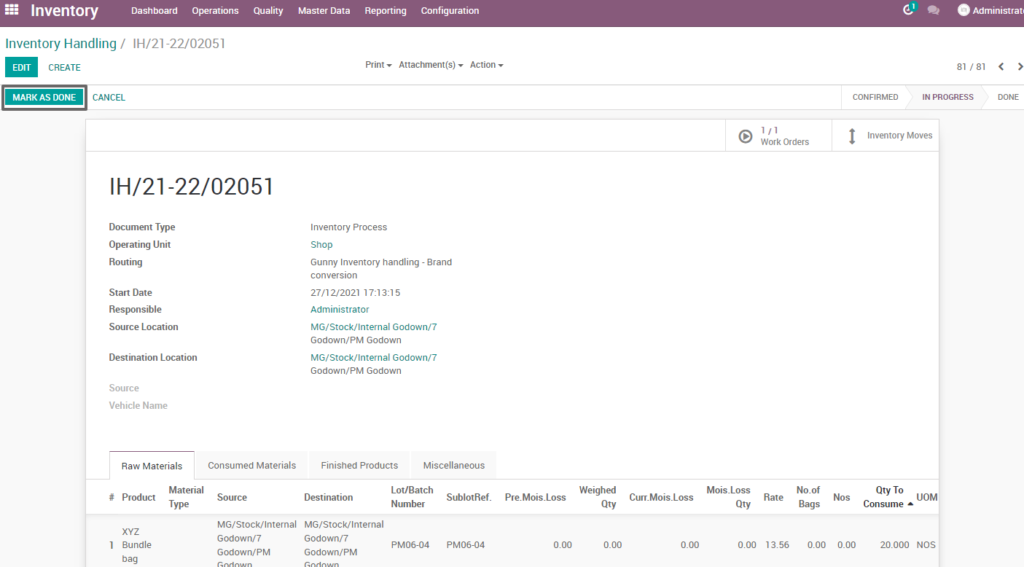

5. User scenario – Gunny inventory handling – Brand conversion

Gunny inventory handling is the process of managing and tracking brand conversion, stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – Select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – Select routing for which to create the inventory handling(i.e. Gunny inventory handling-brand conversion, weight conversion, etc., )(Mandatory)

- Source location – Choose the data for input location

- Destination location – Choose the data for output location

- Product – Add one or more products for processing

- Lot/batch number – Select lot no for chosen product

- Sub lot – Select sub lot no for chosen lot no

- No.of.bags – Choose no of bags to process quantity

- Quantity – Enter the required product quantity

- Confirm – Click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

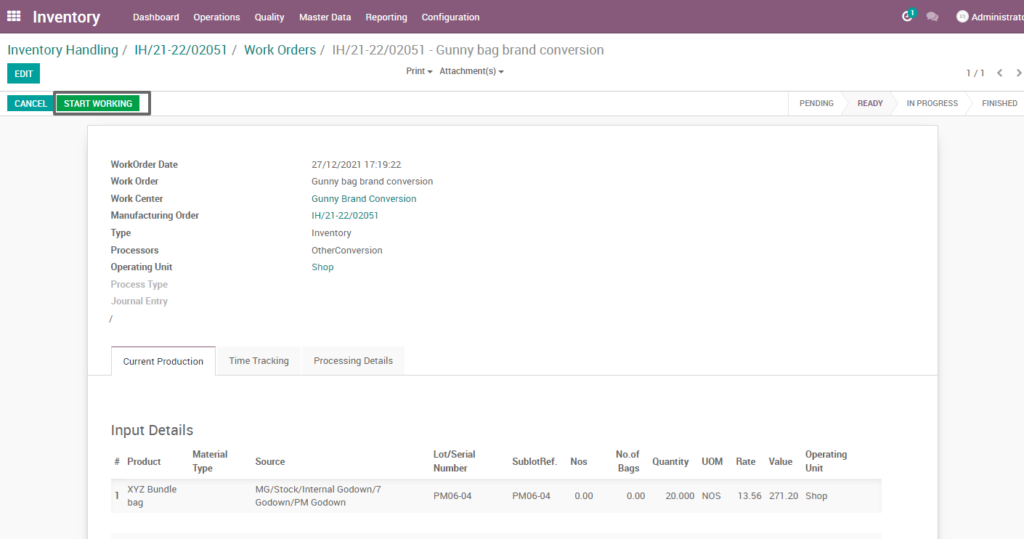

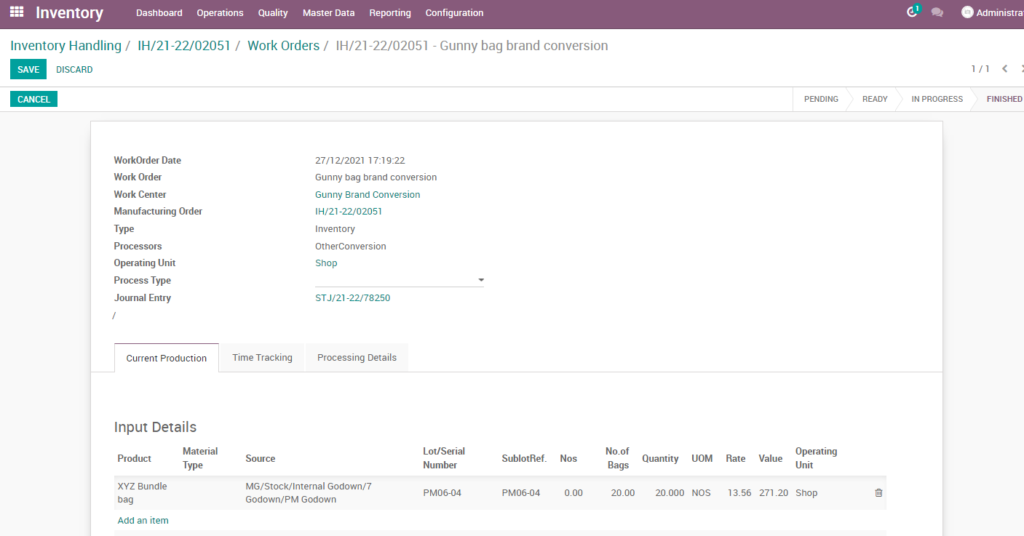

Open work order

Open work order to view the work order process of the gunny inventory handling brand conversion of inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of the gunny inventory handling brand conversion.

Field Description

- Start working – Click on start work order button to start the process of work order

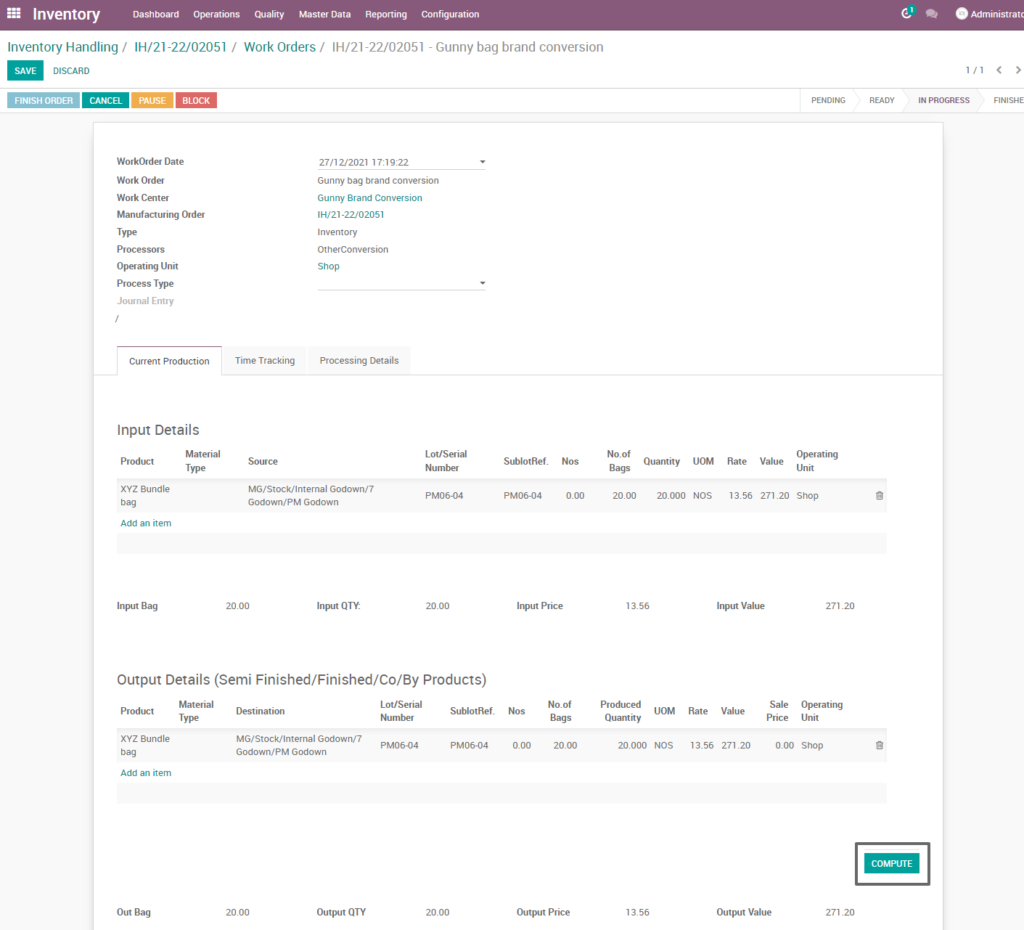

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules.

Field Description

- Compute – Click on compute button to compute input and output details

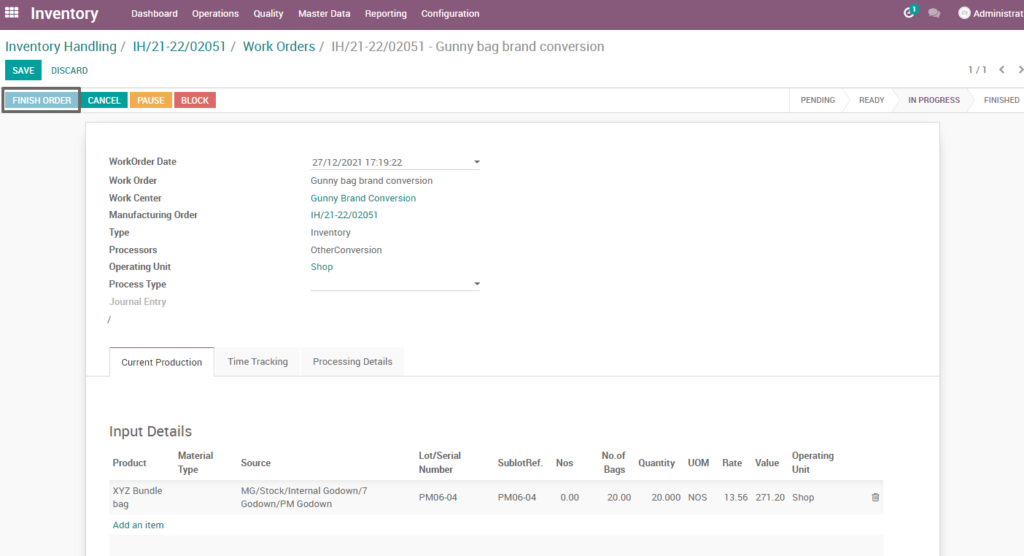

Finish process

After compute process, check on gunny inventory handling of brand conversion of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Work order

Here is the work order of gunny inventory handling of brand conversion of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of gunny inventory handling of brand conversion is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

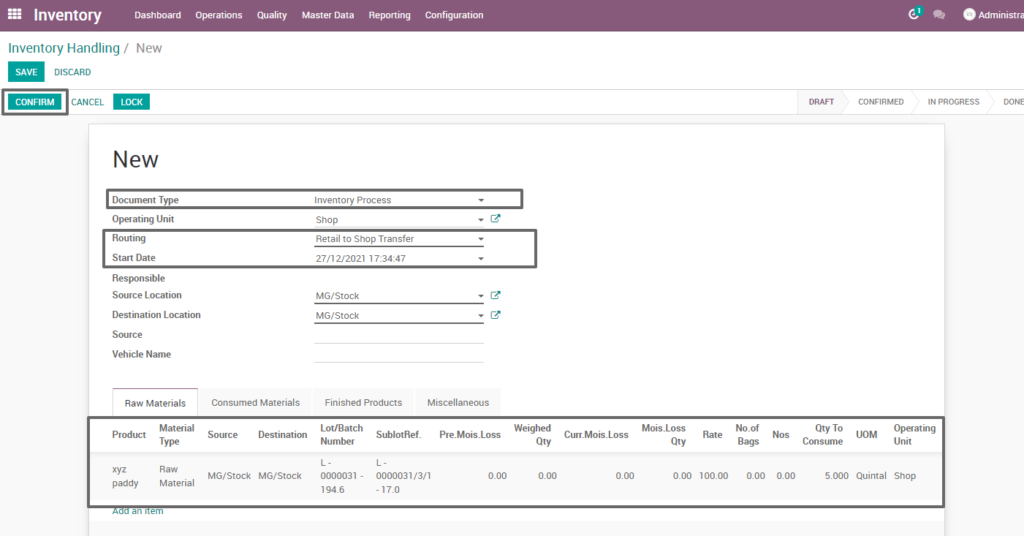

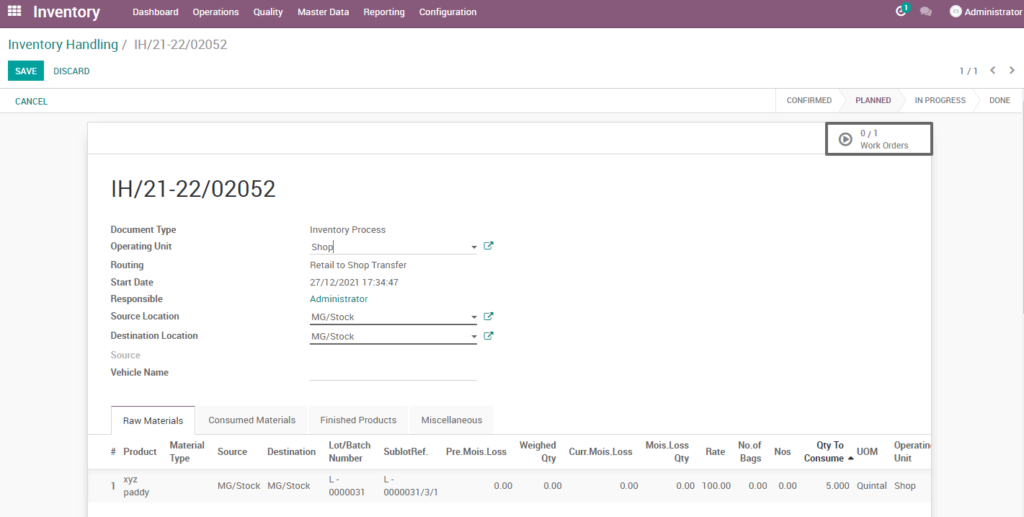

6. User scenario – Retail to shop transfer

It is process to transfer the products from retail center to shop which make to sale the products. Only transfer of products happen here. There Will be no changes in the quality or other properties of the product.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc.,) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Retail to shop transfer, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

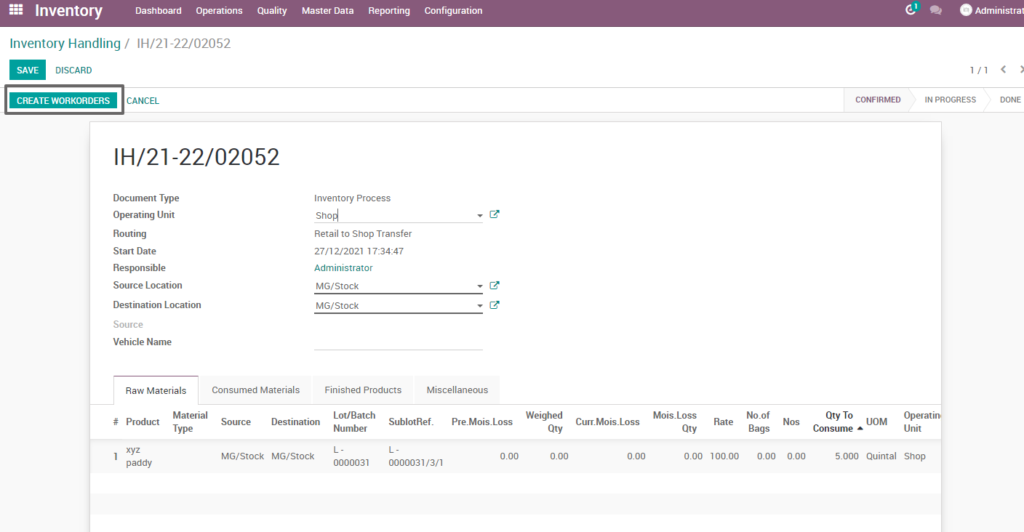

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

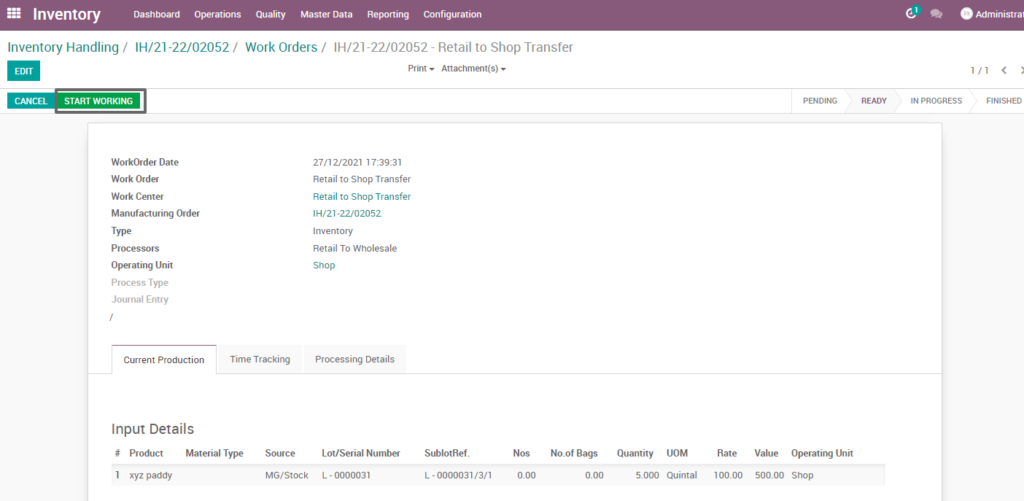

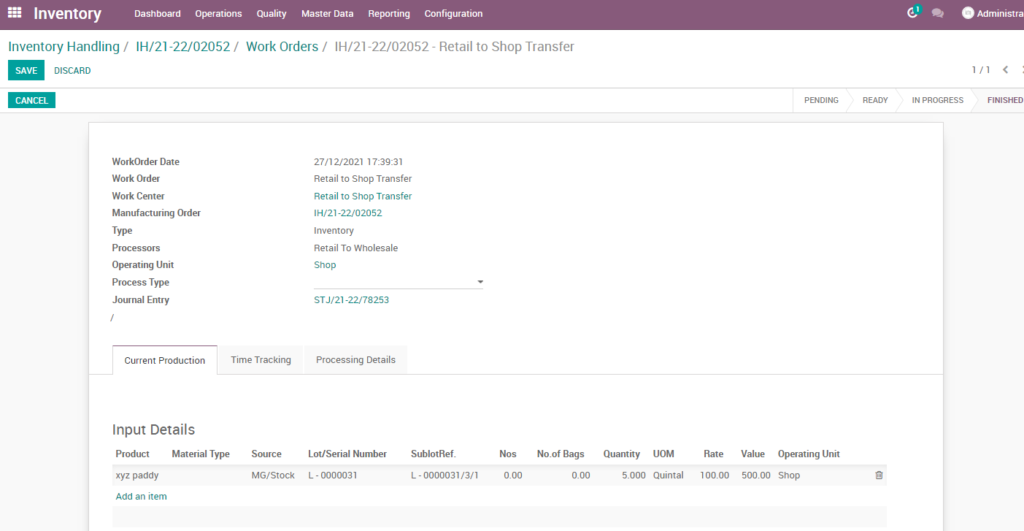

Open work order

Open work order to view the work order process of the retail to shop transfer inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of the retail to shop transfer.

Field Description

- Start working – Click on start work order button to start the process of work order

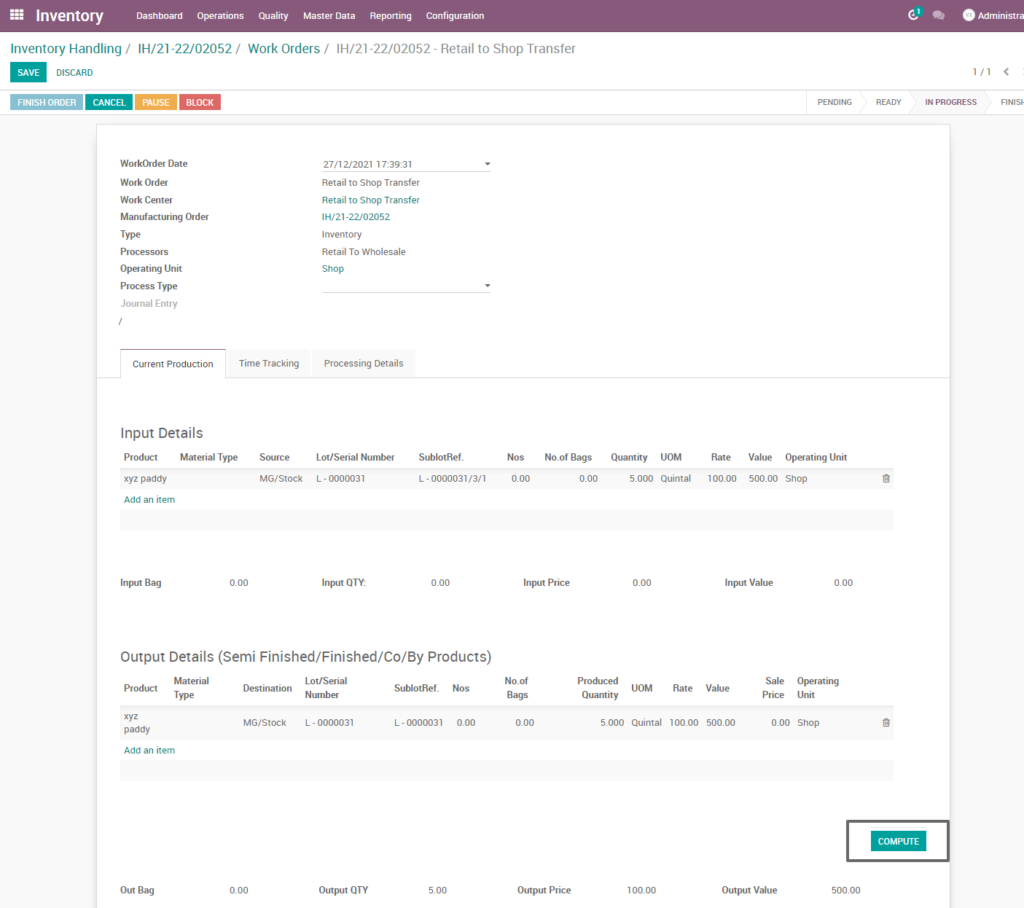

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process retail to shop transfer.

Field Description

- Compute – Click on compute button to compute input and output details

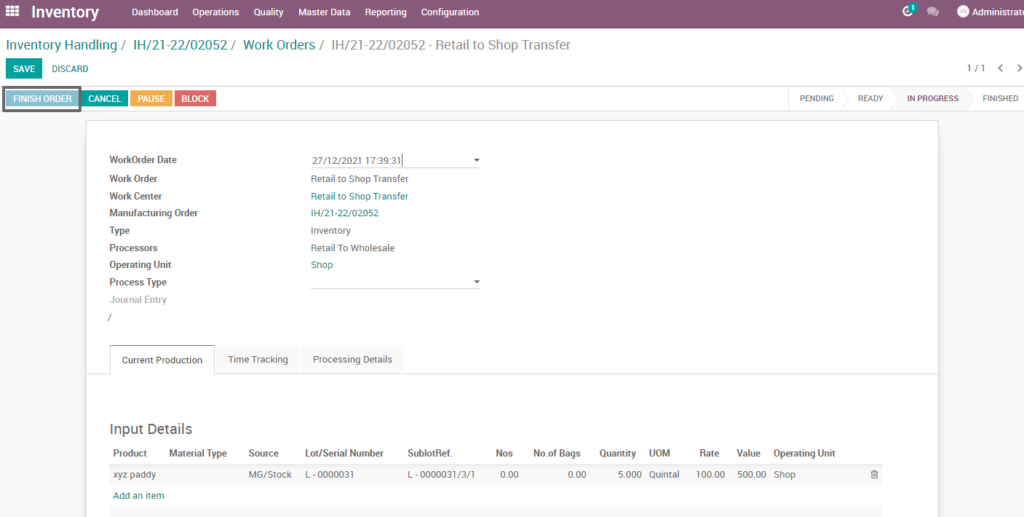

Finish process

After compute process, check on retail to shop transfer of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

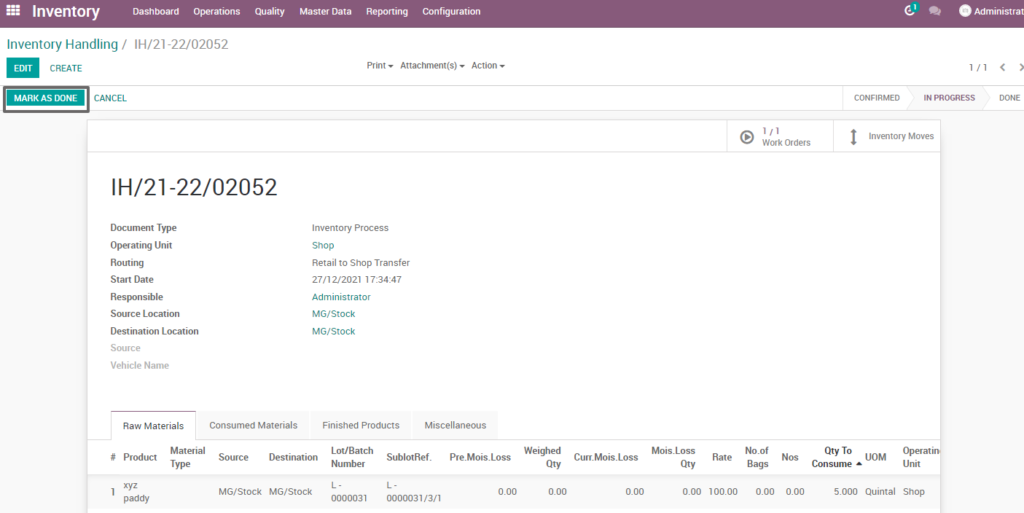

Finished work order

Here shows the work order of retail to shop transfer of inventory process. State is changed in progress state into finished state. State is changed in progress state into done state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of retail to shop transfer is done.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

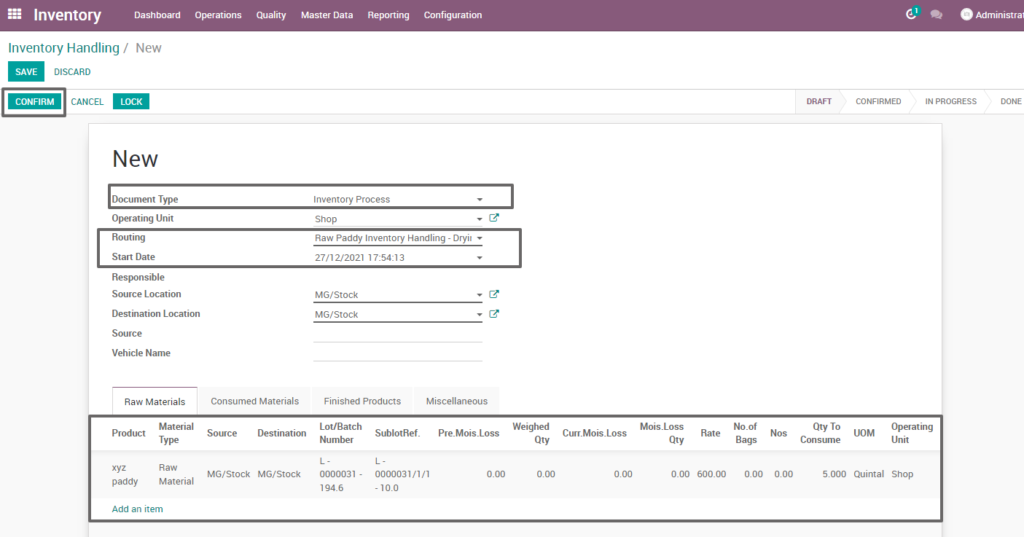

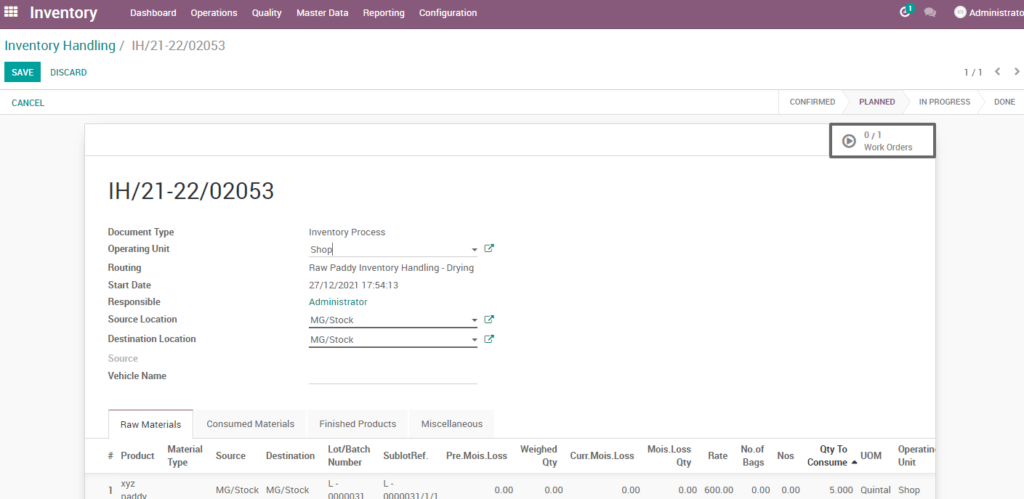

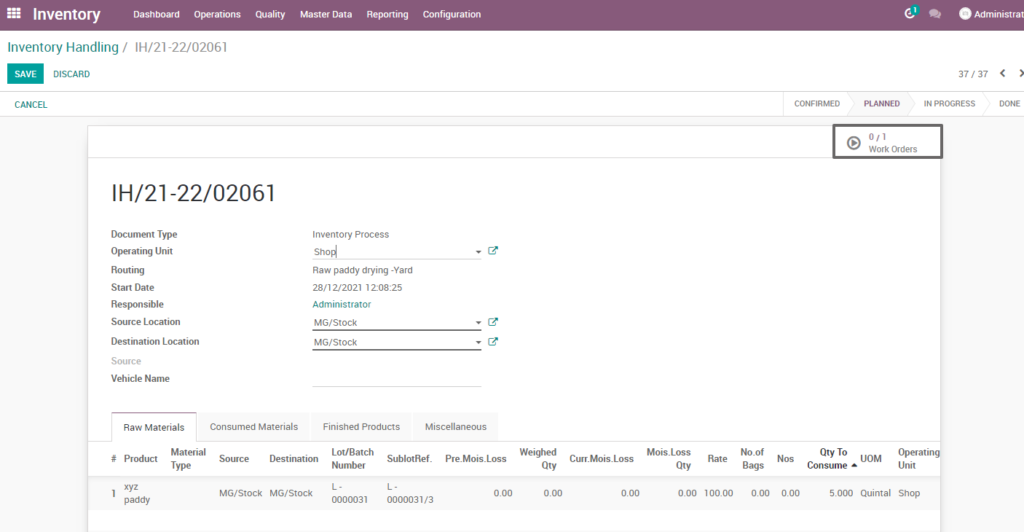

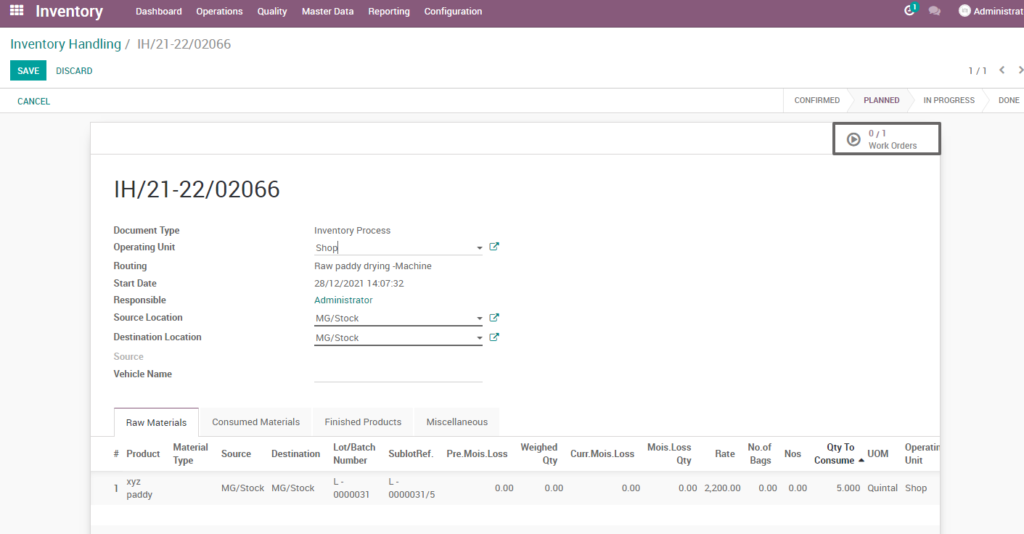

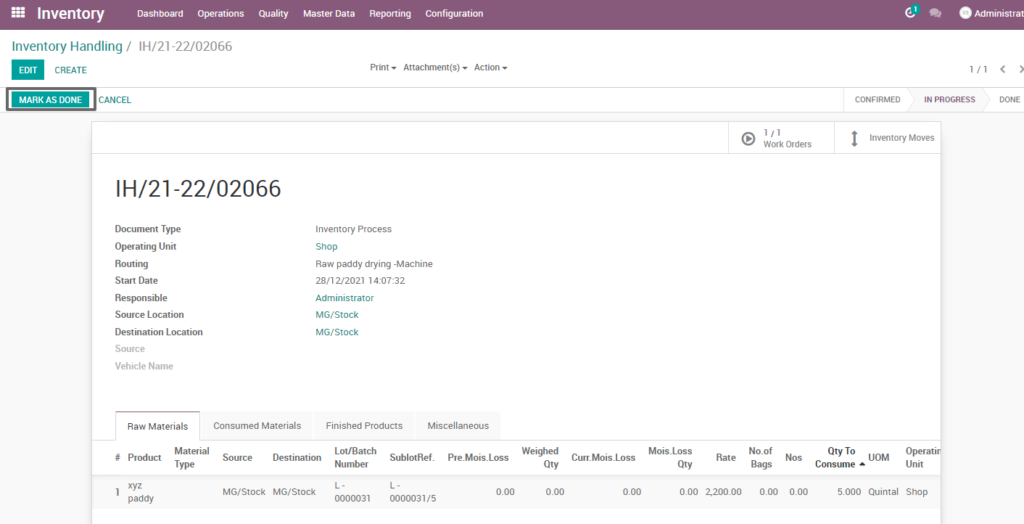

7. User scenario – Raw paddy inventory handling – Drying

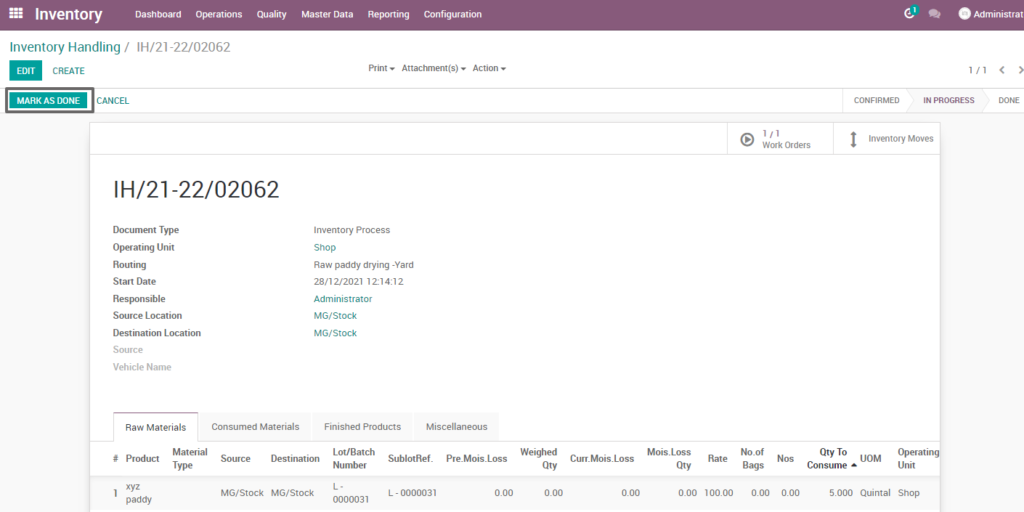

Raw paddy inventory handling is the process of managing and tracking drying paddy, stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Raw paddy inventory handling-drying, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

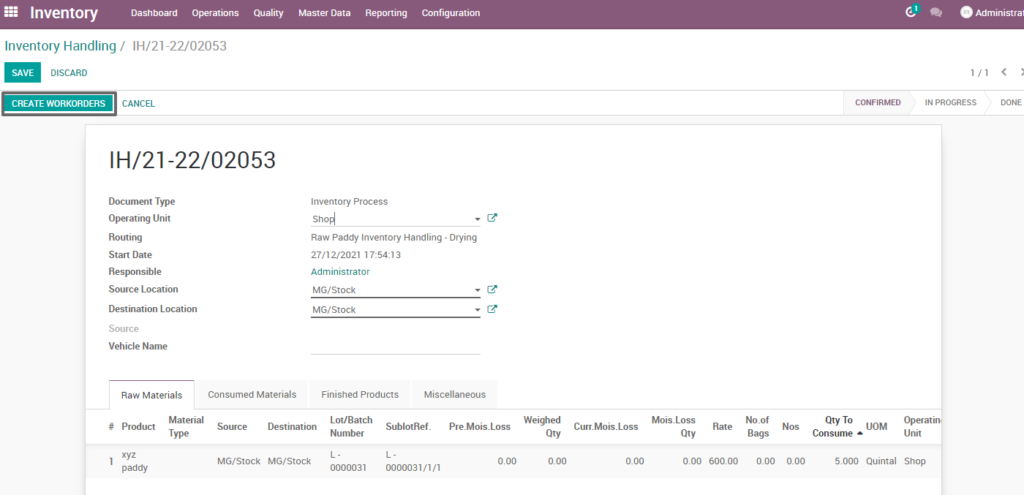

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

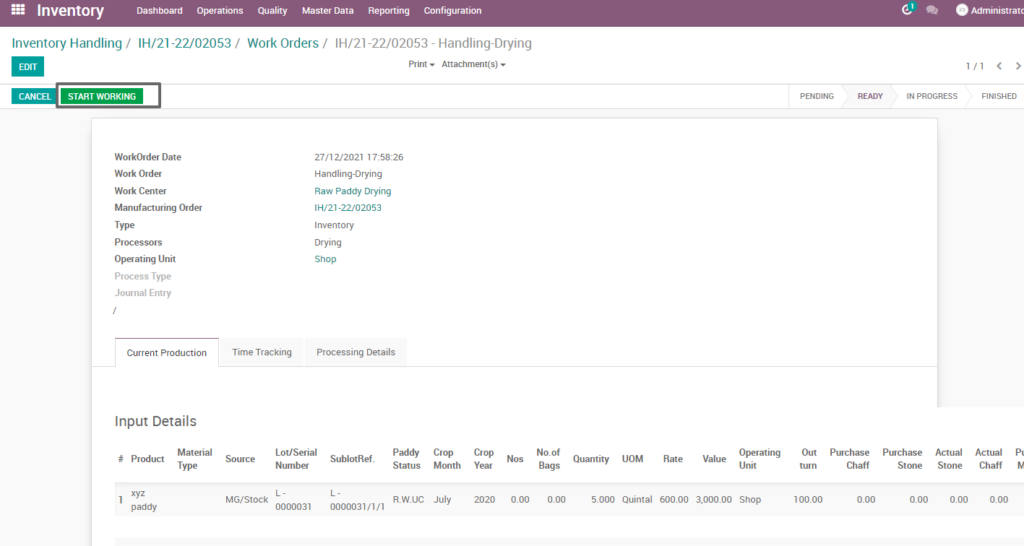

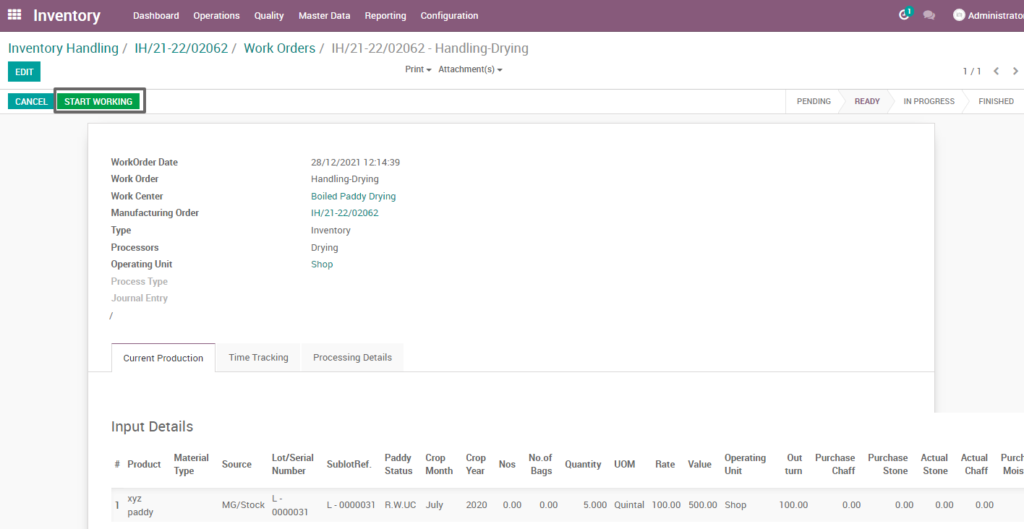

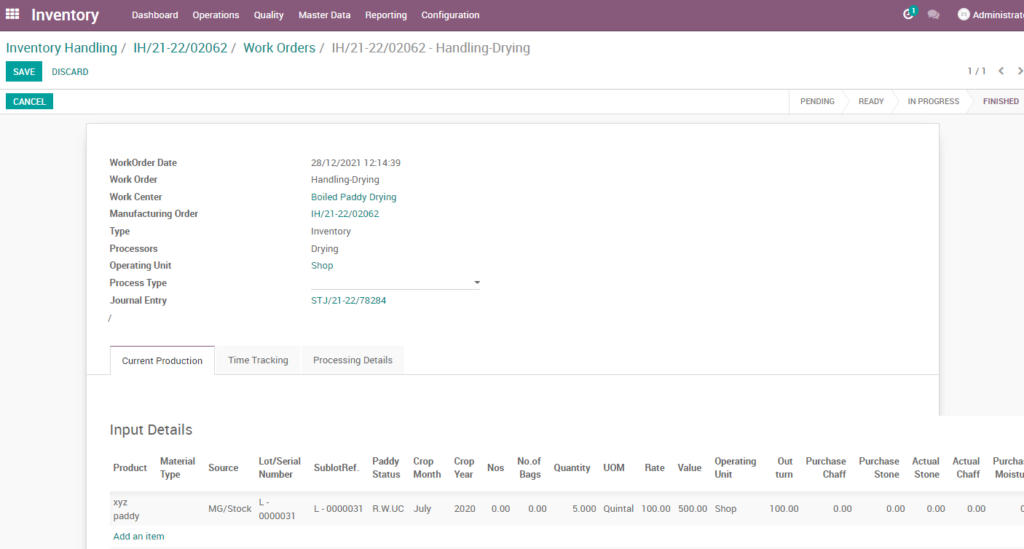

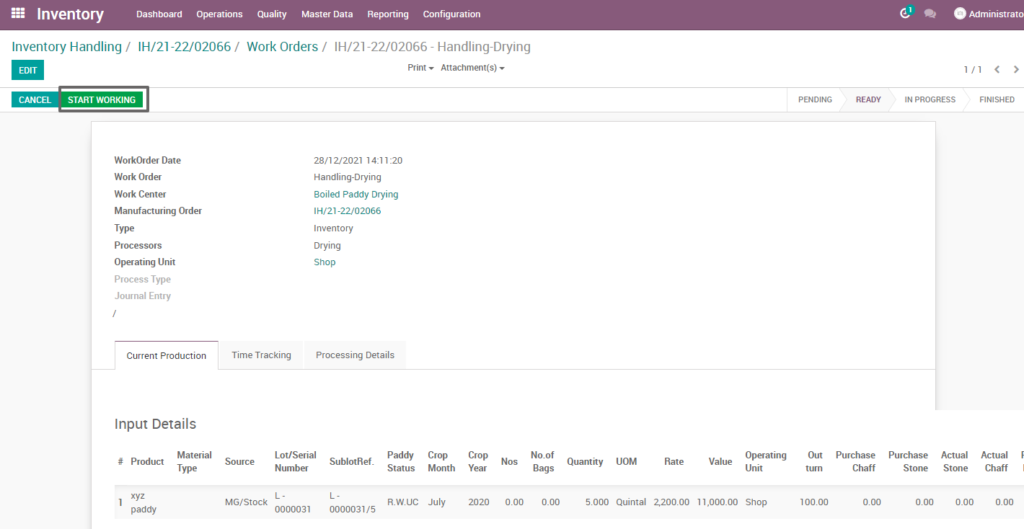

Open work order

Open work order to view the work order process of the raw paddy inventory handling drying inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling drying is start . It shows input and output details of the raw paddy inventory handling seasonal stock deposit.

Field Description

- Start working – Click on start work order button to start the process of work order

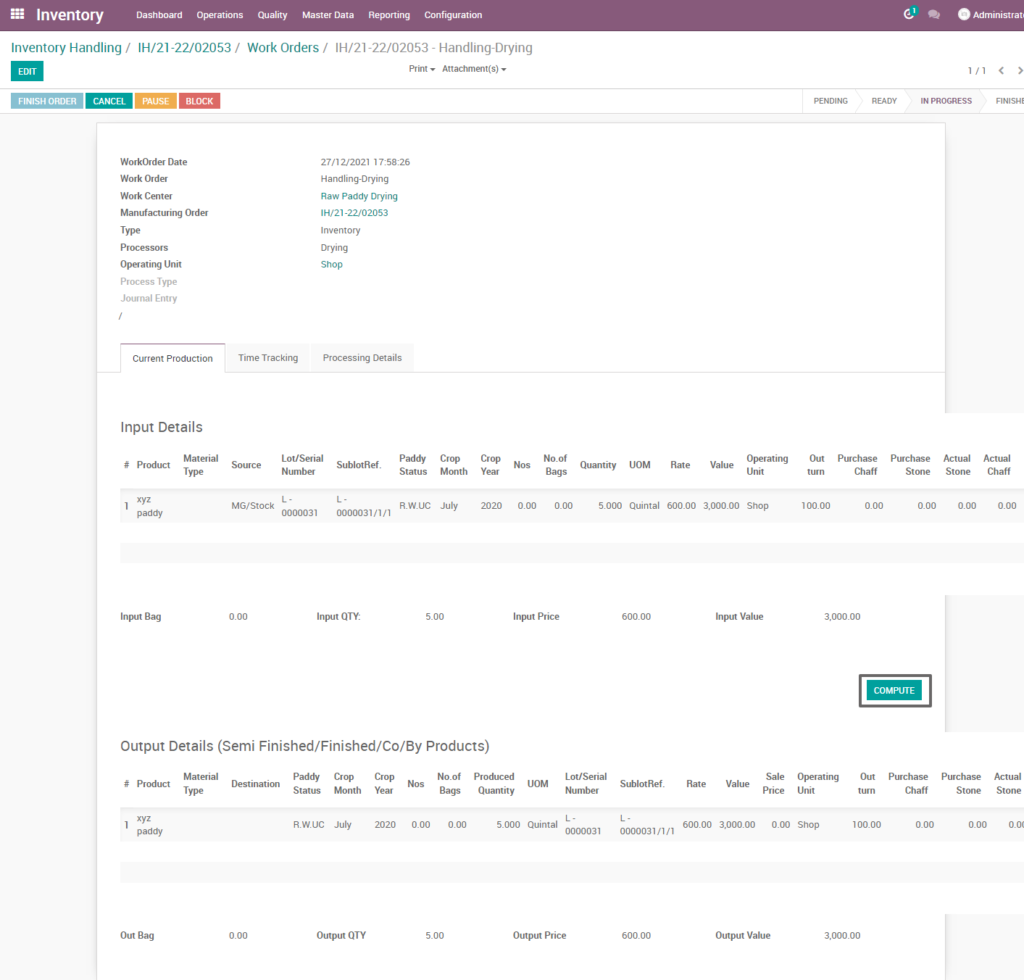

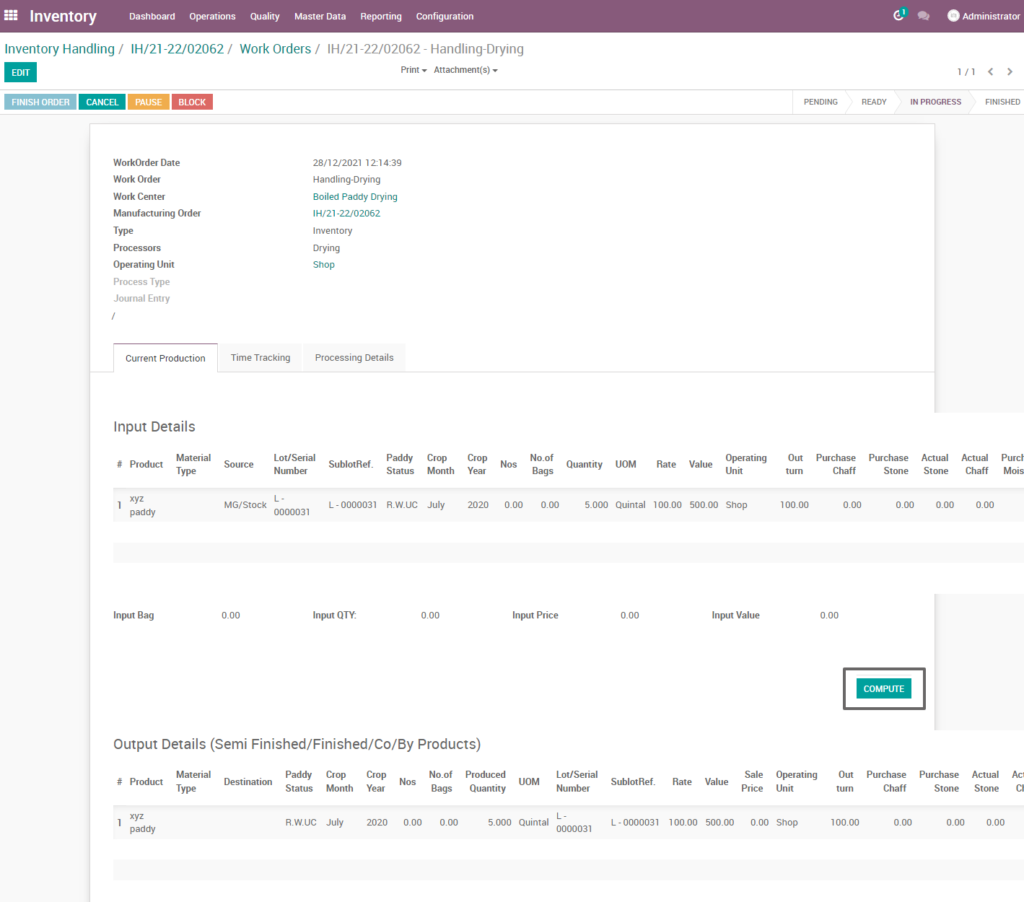

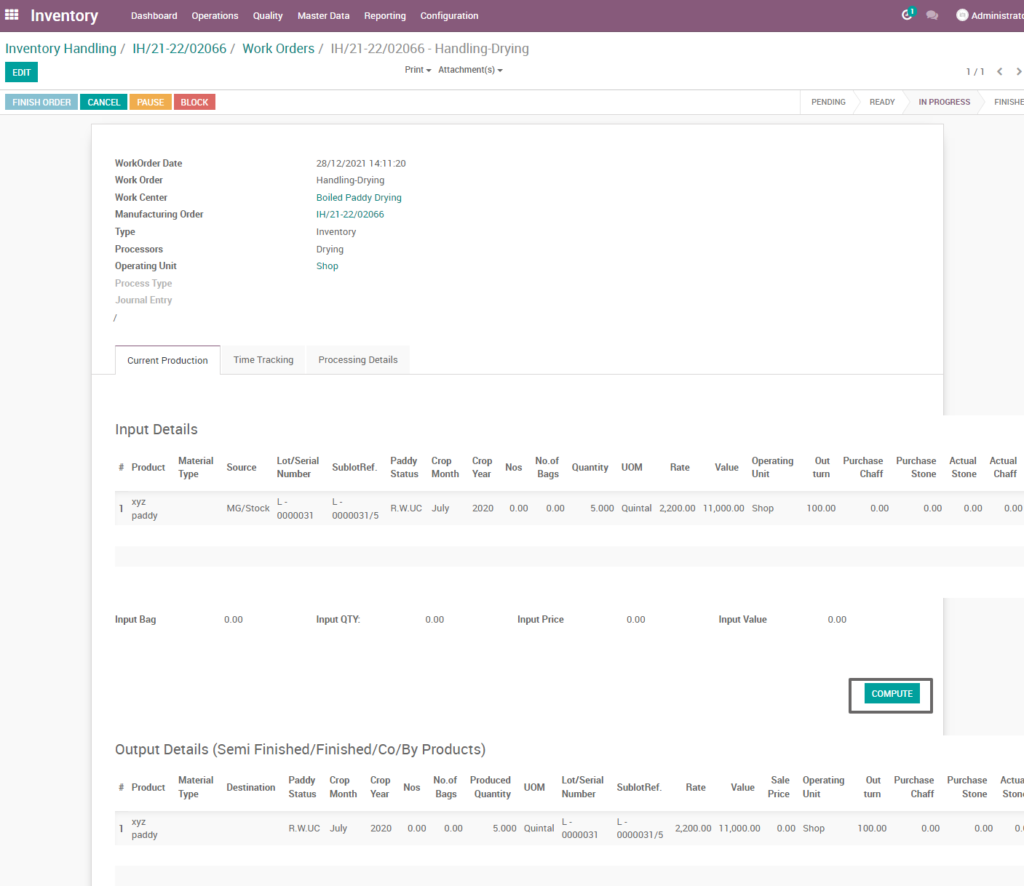

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules.

Field Description

- Compute – Click on compute button to compute input and output details

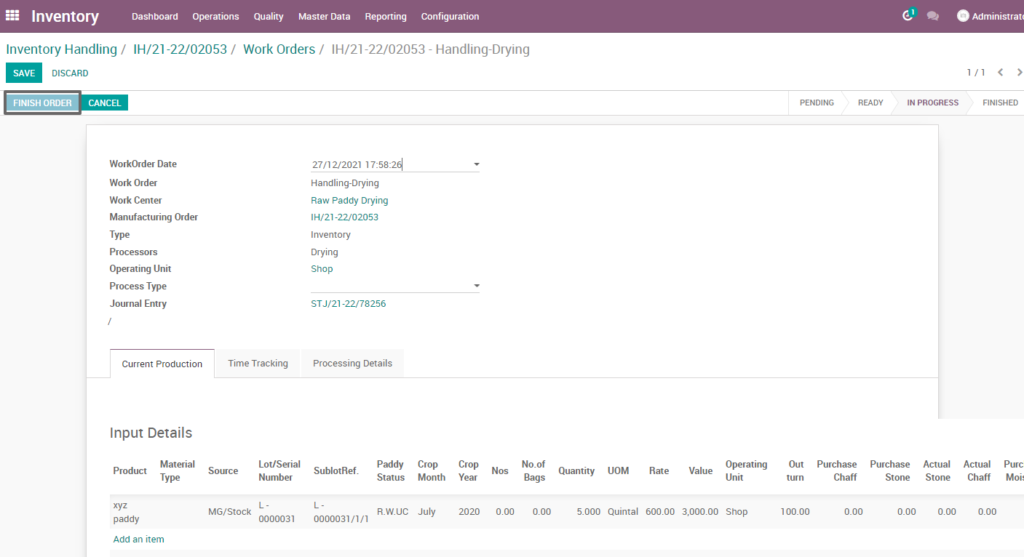

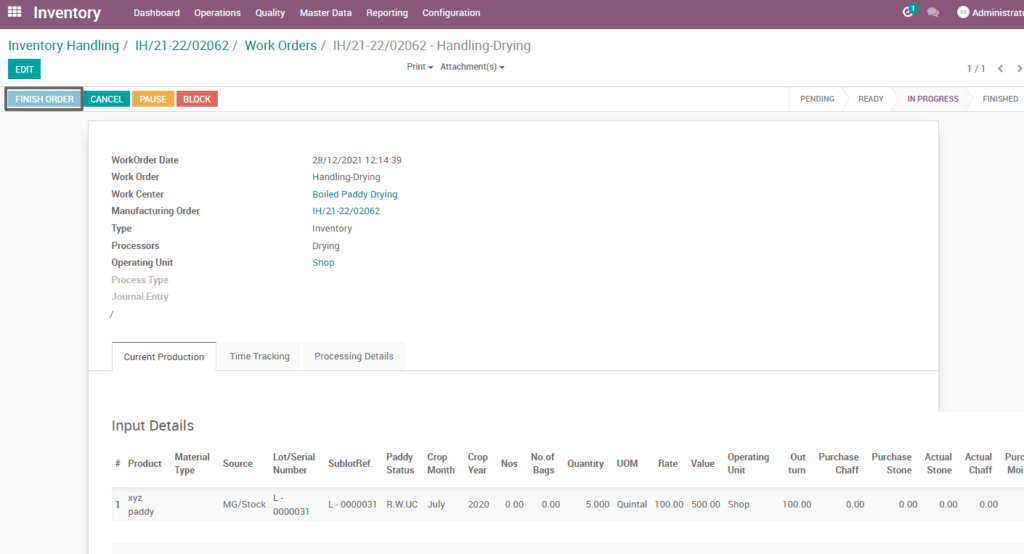

Finish process

After compute process, check on raw paddy inventory handling drying of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

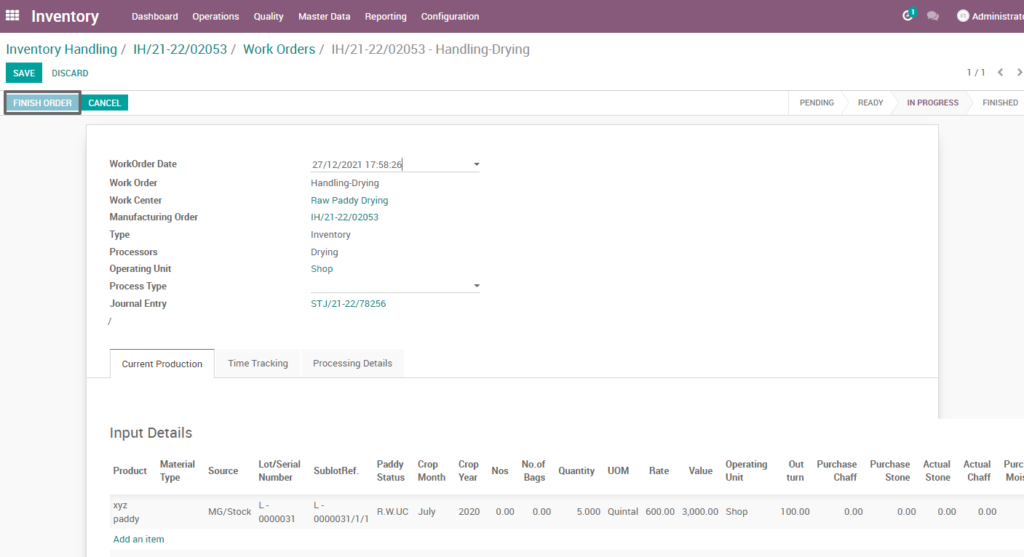

Finished work order

Here shows the finished work order of raw paddy inventory handling, drying of inventory process. State is changed in progress state into finished state.

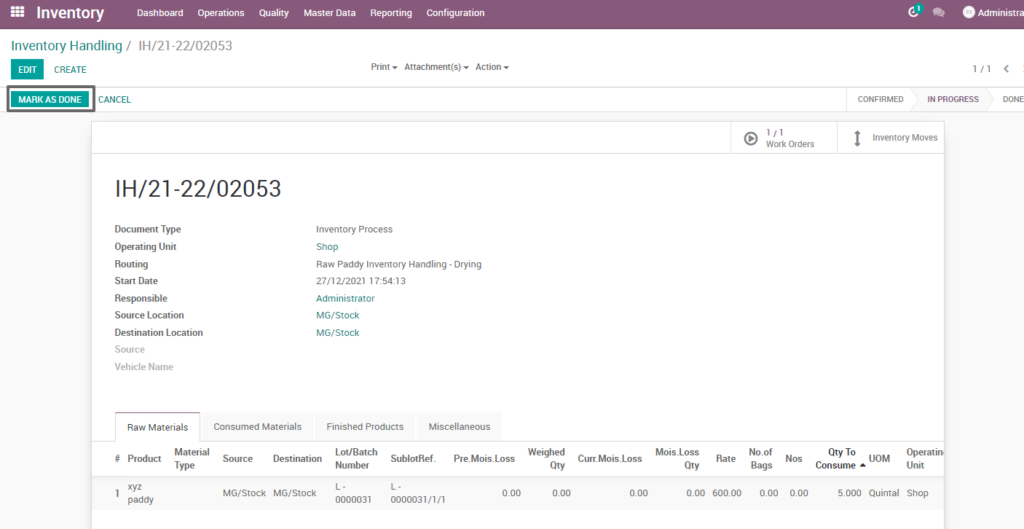

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy inventory handling drying is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

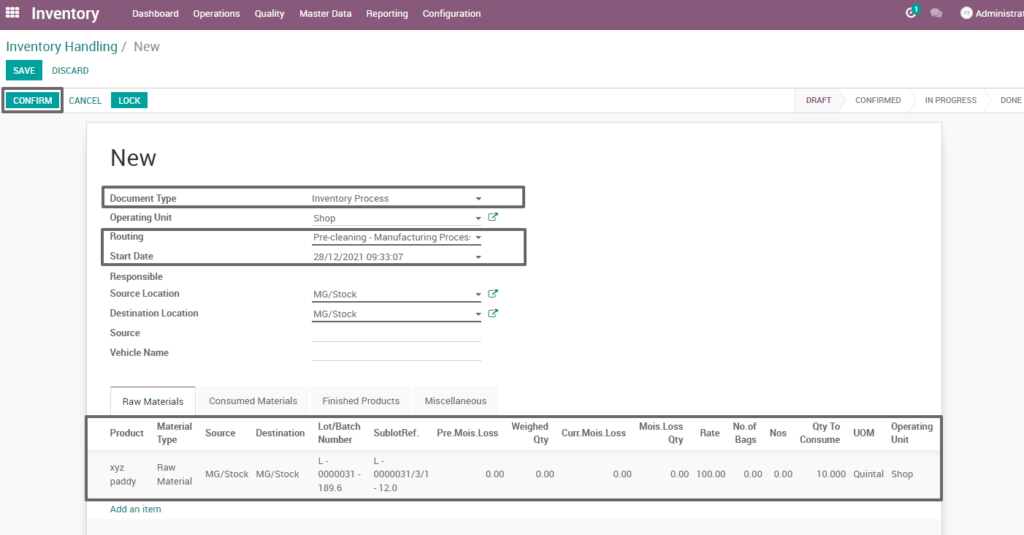

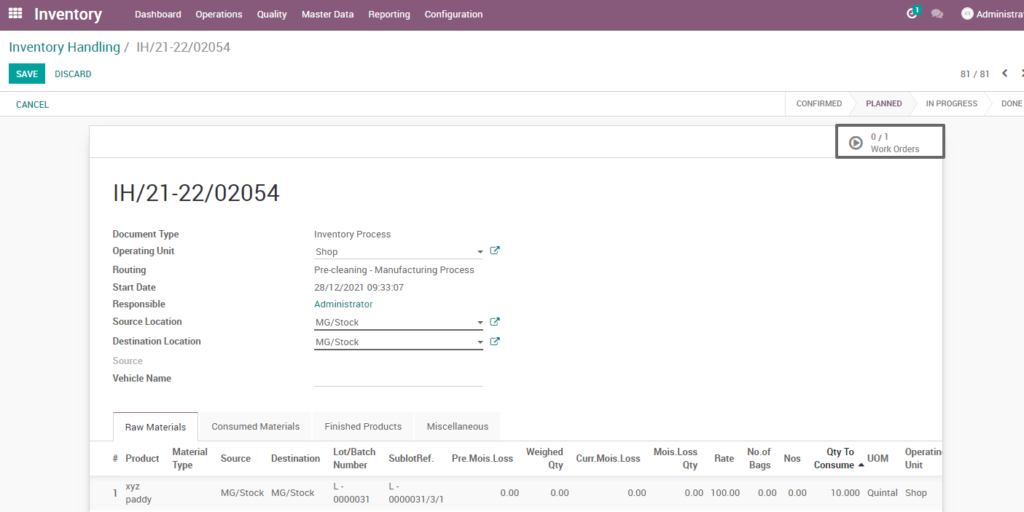

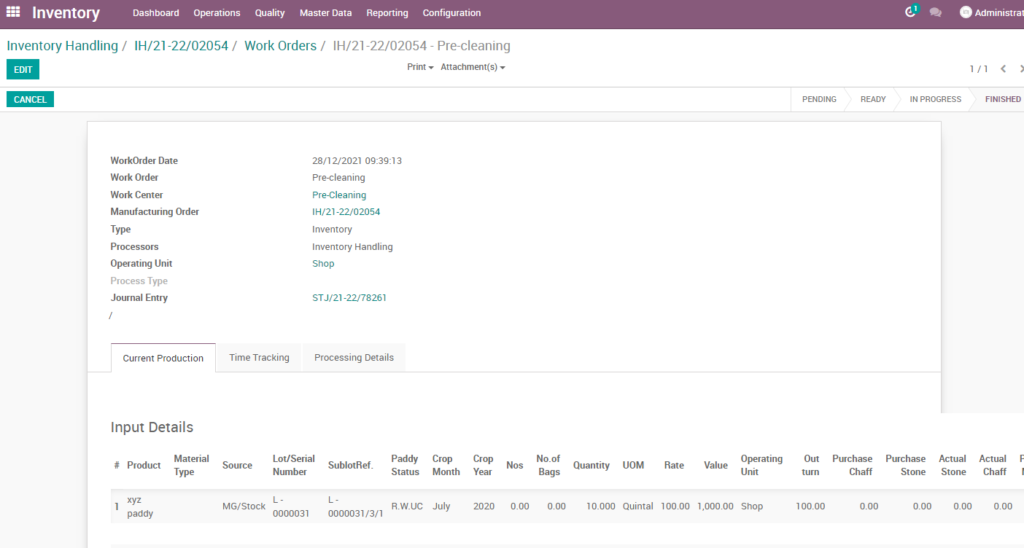

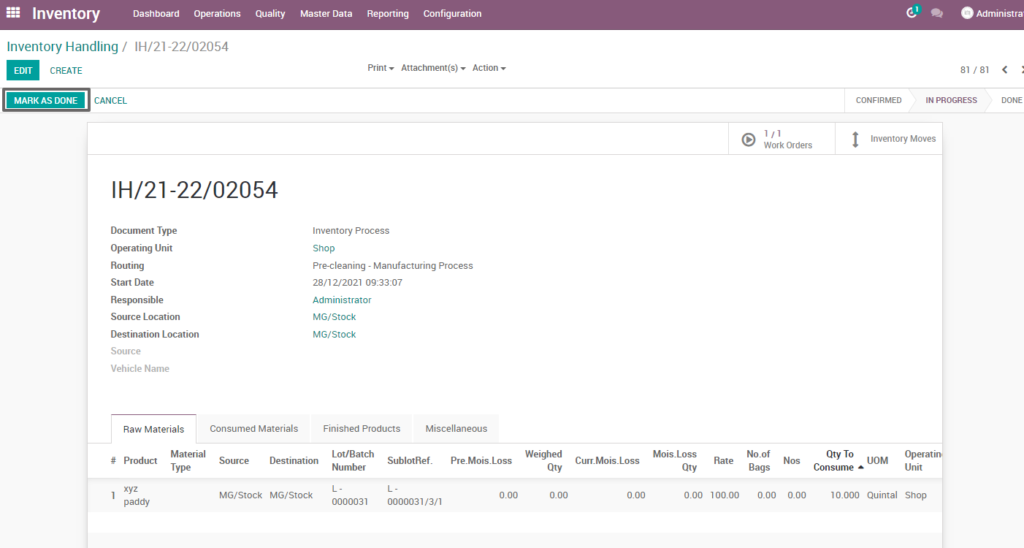

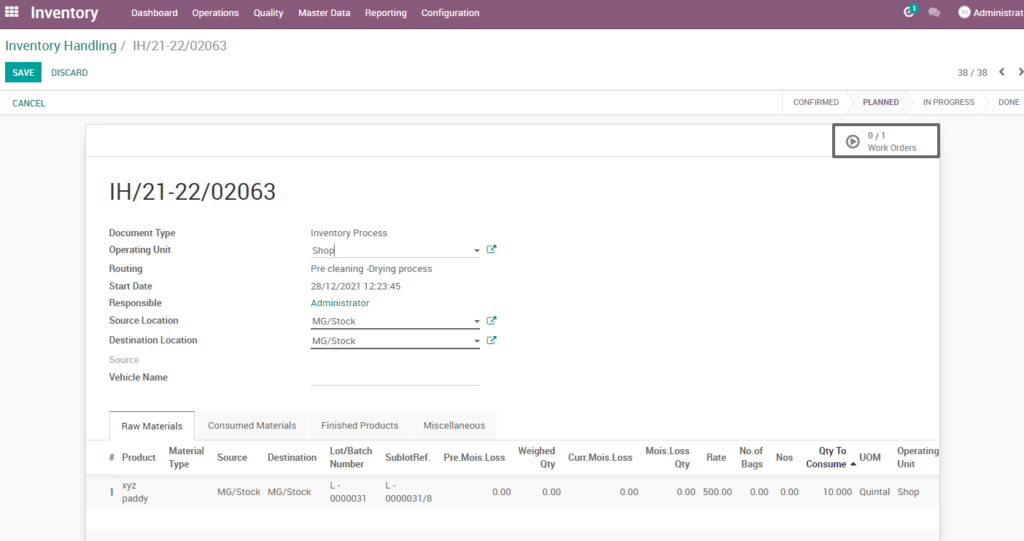

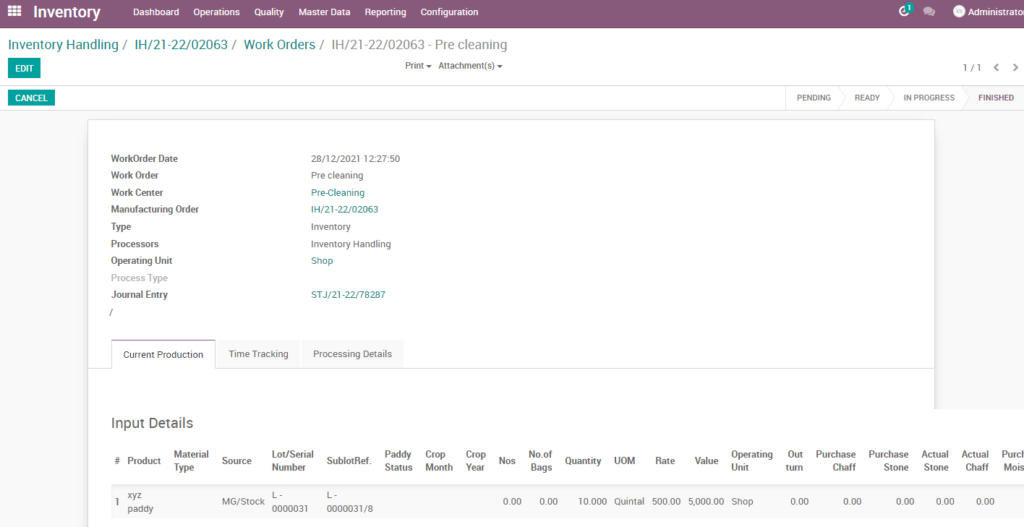

8. User scenario – Pre – Cleaning – Manufacturing Process

Pre-cleaning is the process of cleaning before manufacture to product. In This stage the product will be allowed to be separate from foreign particles like dust, stone, chaff, etc.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Pr-cleaning-manufacturing process, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

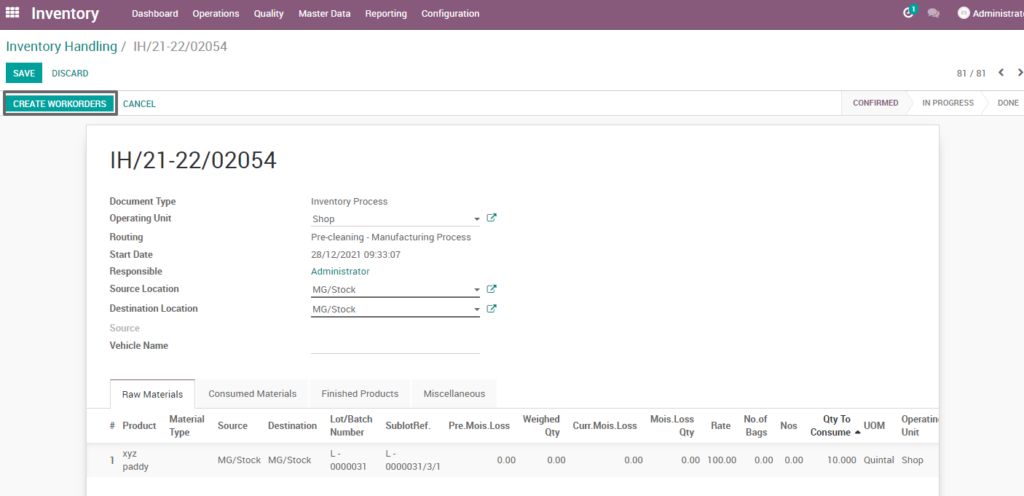

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

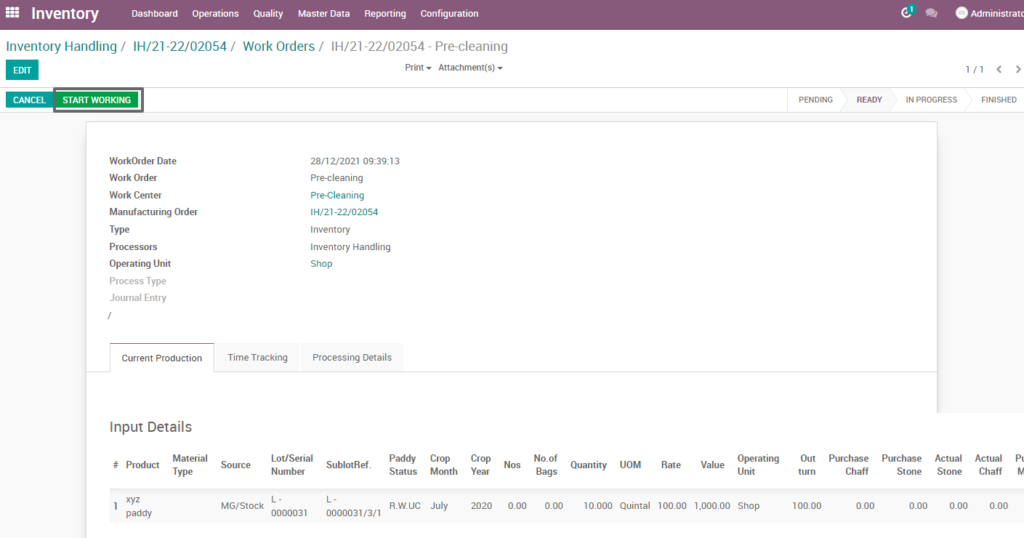

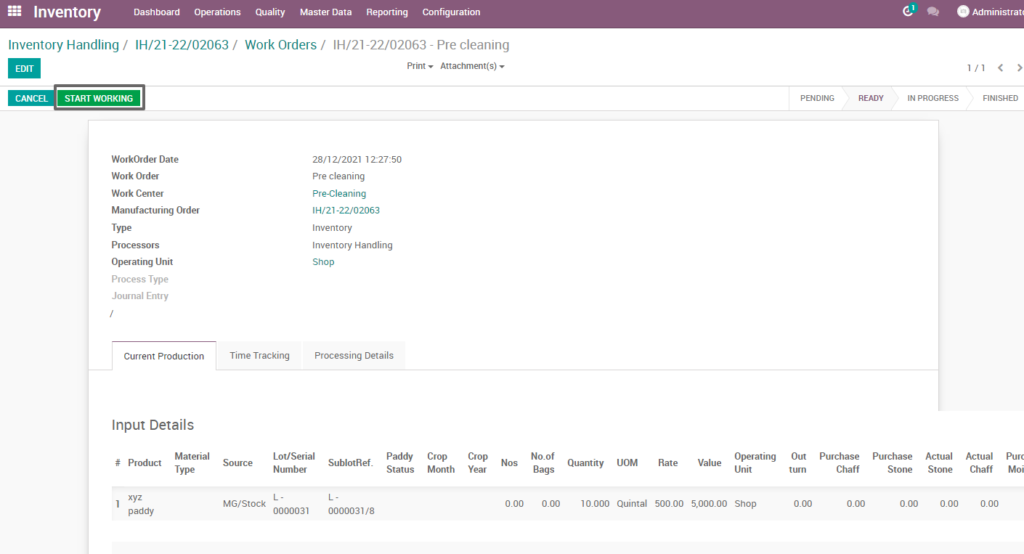

Open work order

Open work order to view the work order process of the pre-cleaning manufacturing process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start .It shows input and output details of pre-cleaning manufacturing process.

Field Description

- Start working – Click on start work order button to start the process of work order

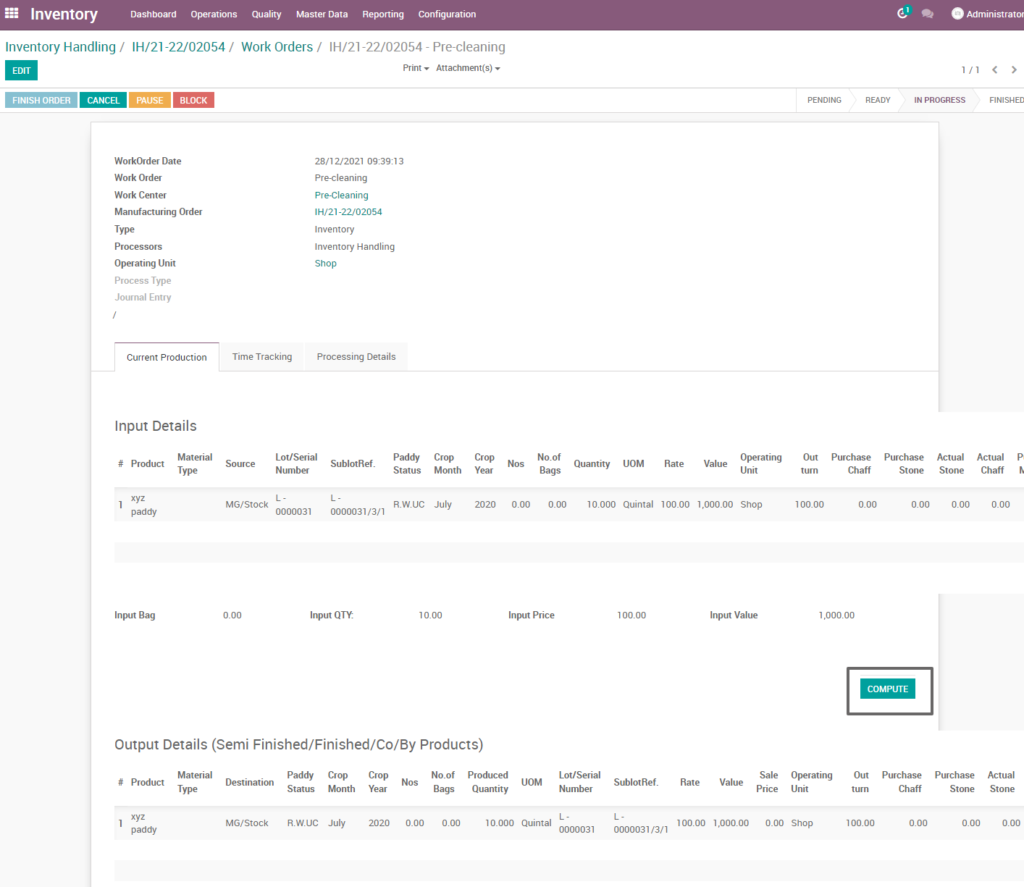

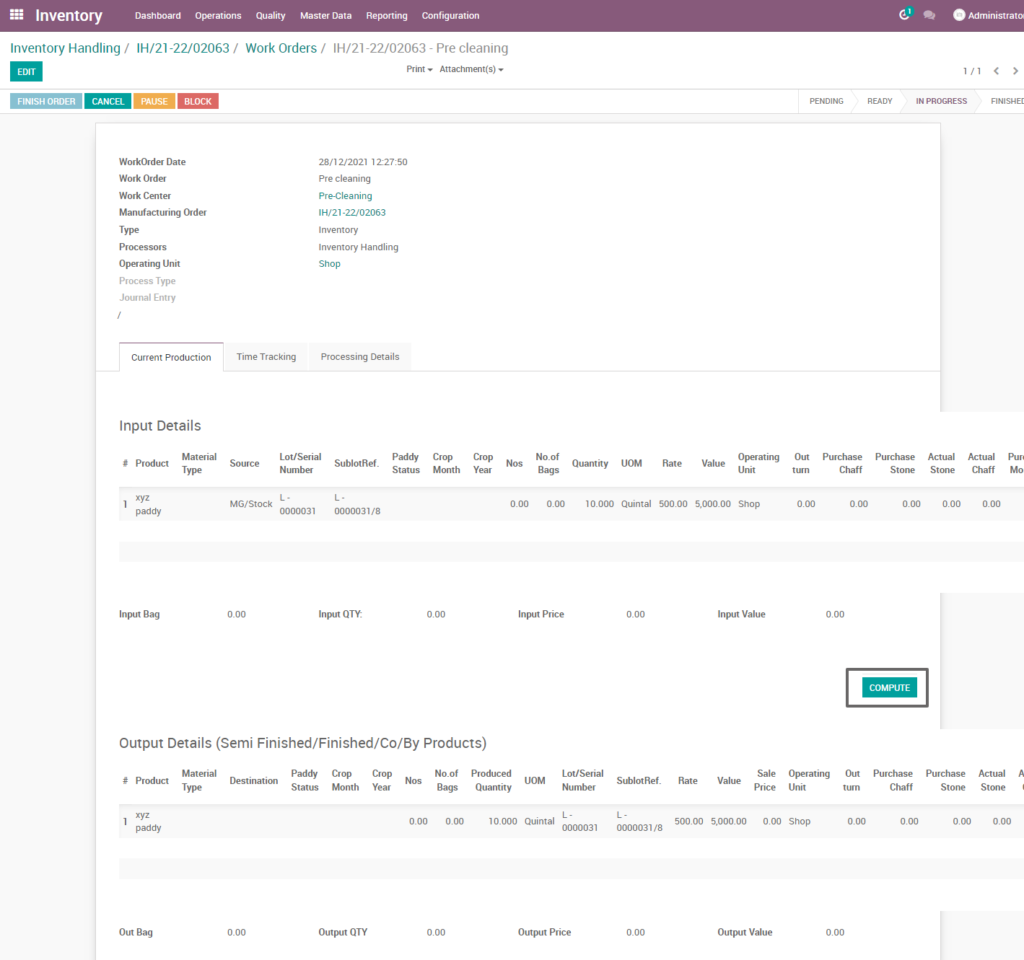

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules.

Field Description

- Compute – Click on compute button to compute input and output details

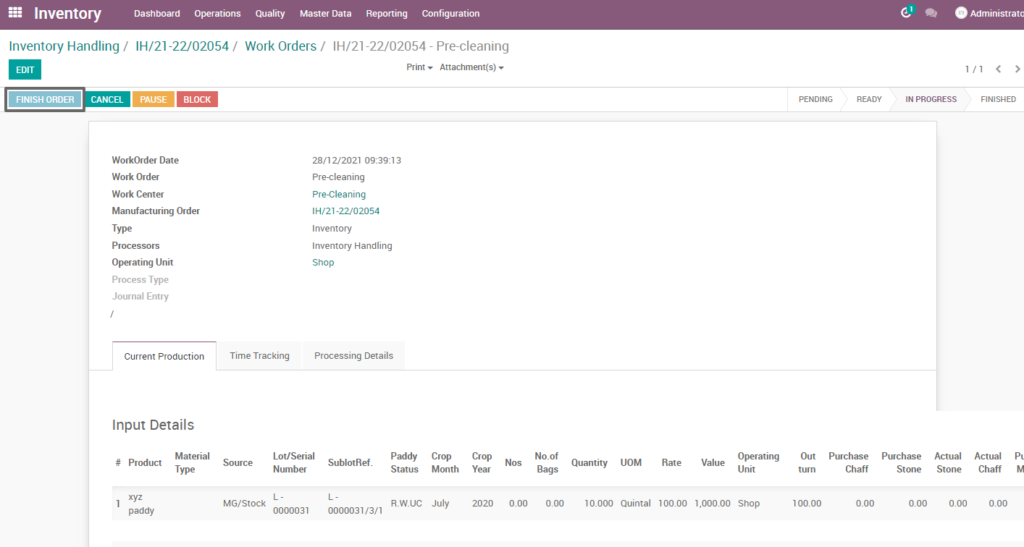

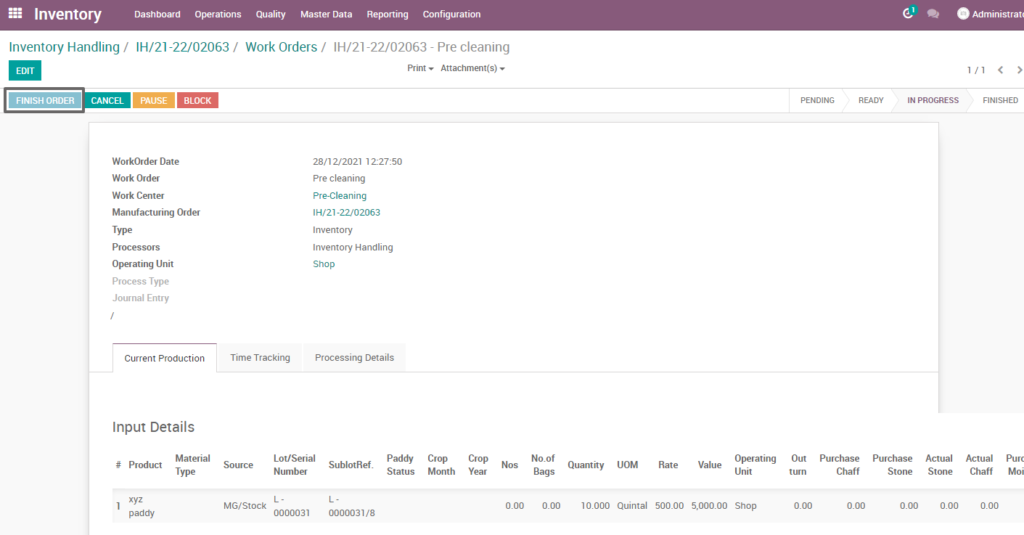

Finish process

After compute process, check on pre-cleaning manufacturing process of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the work order of pre-cleaning manufacturing process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of pre-cleaning manufacturing process is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

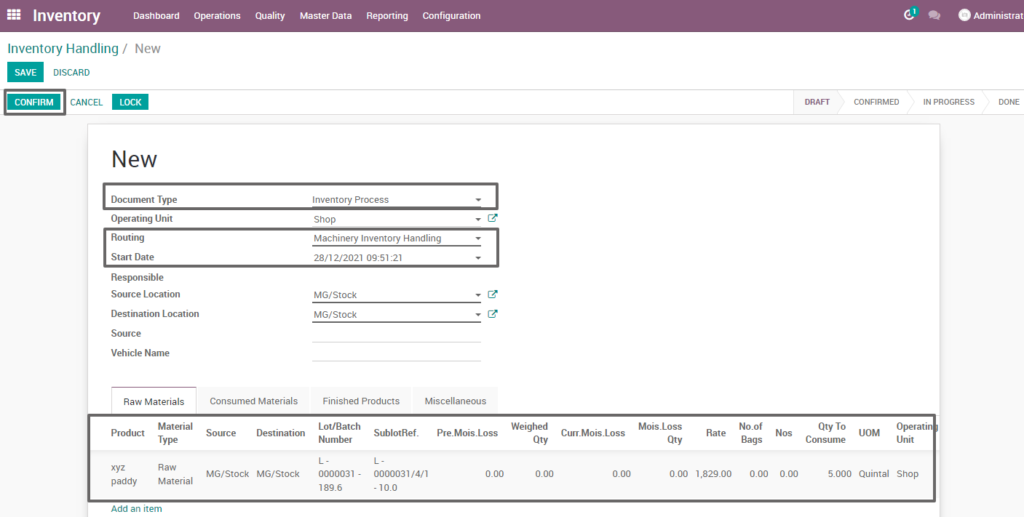

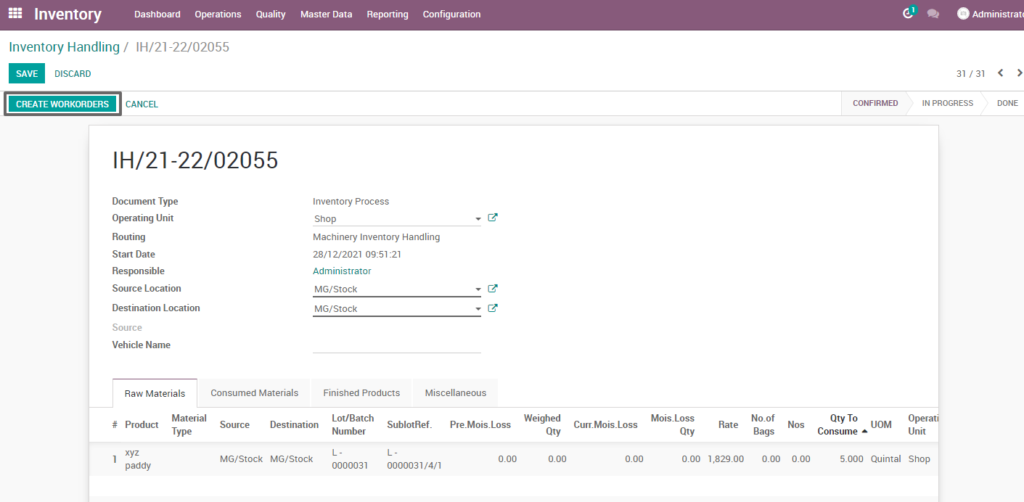

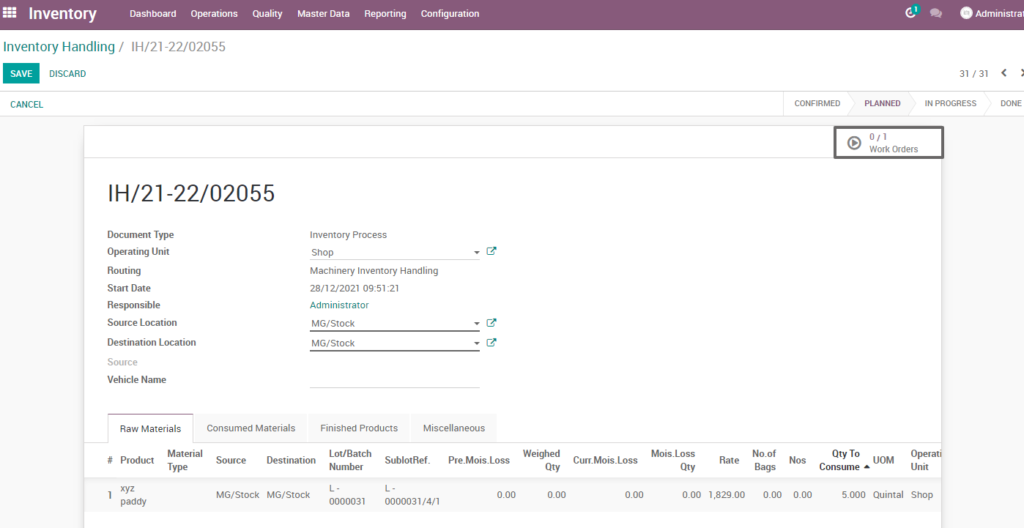

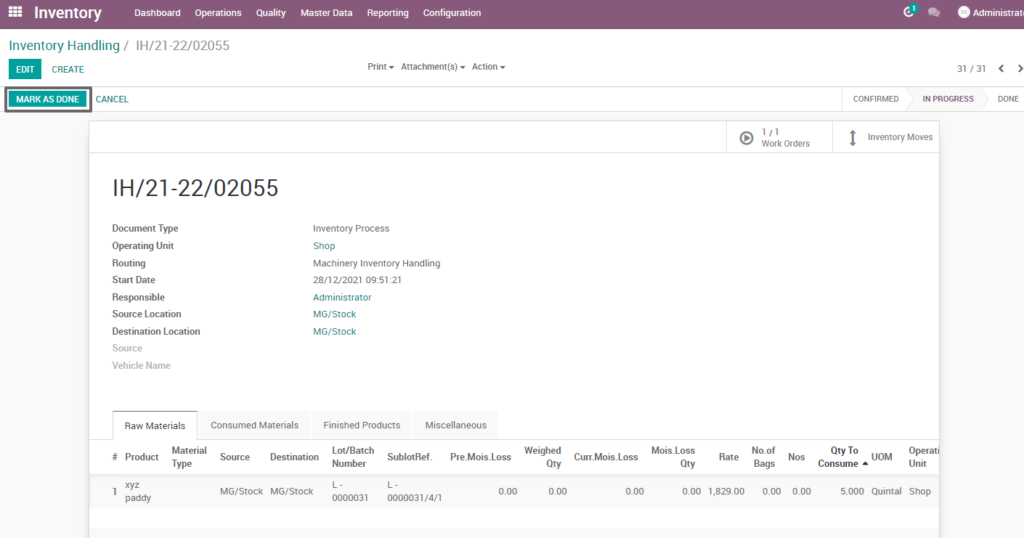

9. User scenario – Machinery Inventory Handling

Machinery inventory handling is the process of managing and tracking stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Machinery inventory handling, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

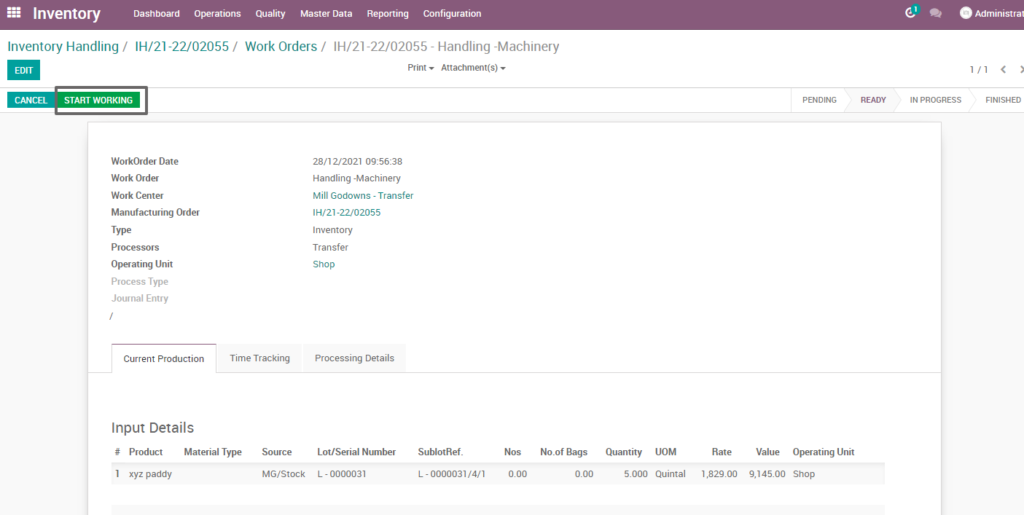

Open work order

Open work order to view the work order process of the machinery inventory handling process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of the machinery inventory handling.

Field Description

- Start working – Click on start work order button to start the process of work order

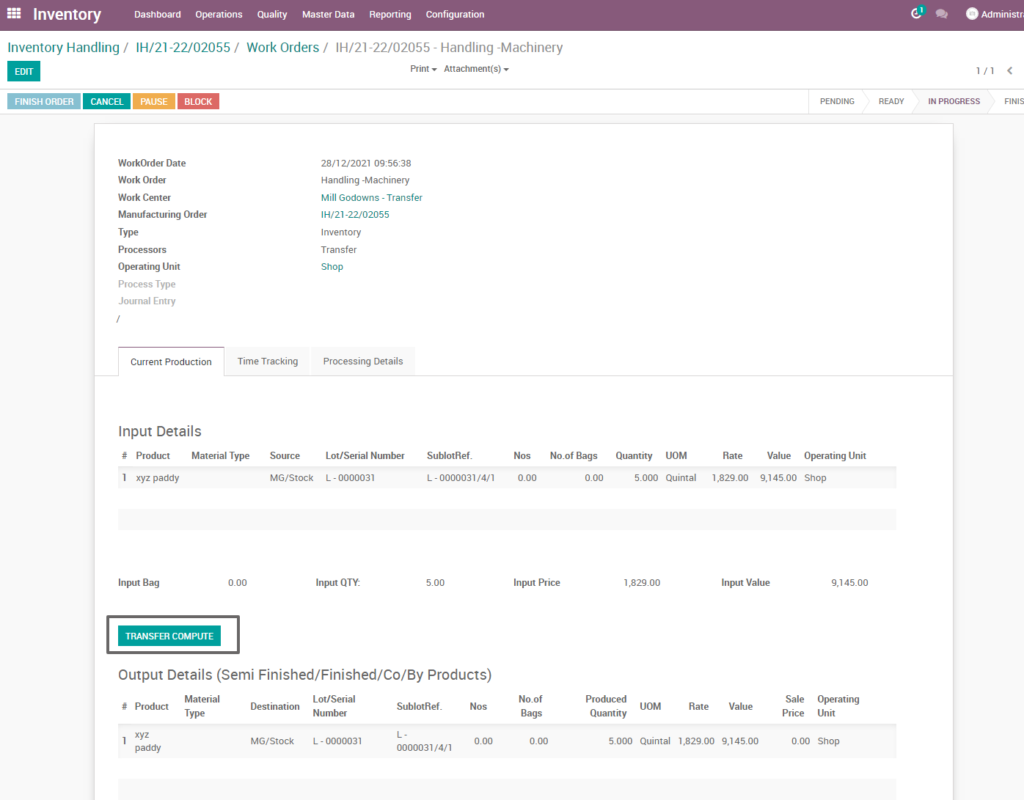

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process machinery inventory handling.

Field Description

- Compute – Click on compute button to compute input and output details

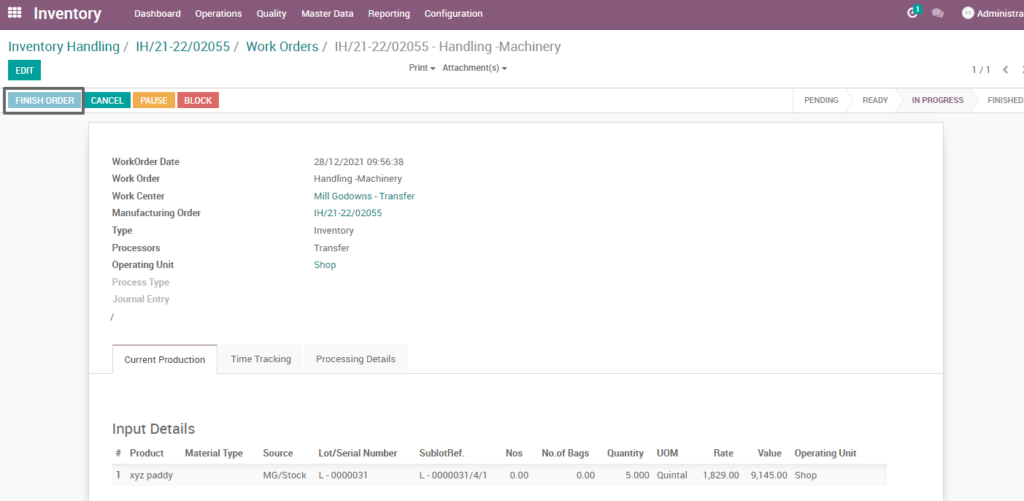

Finish process

After compute process, check on machinery inventory handling of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

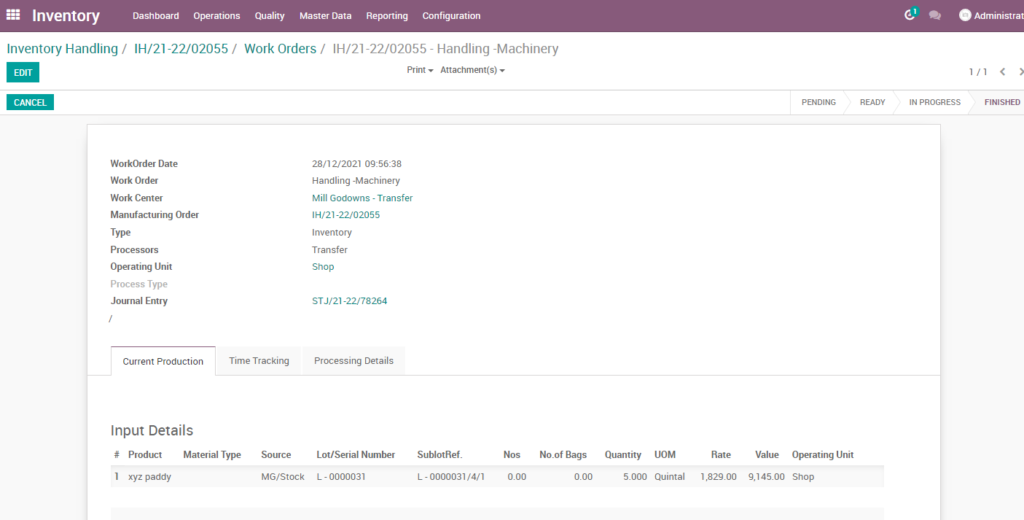

Finished work order

Here shows the finished work order of machinery inventory handling of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of machinery inventory handling is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

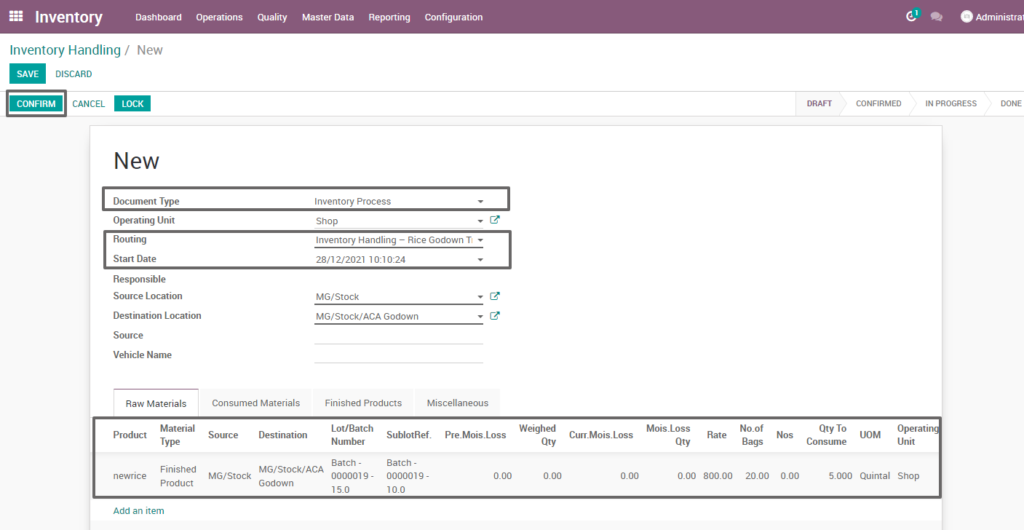

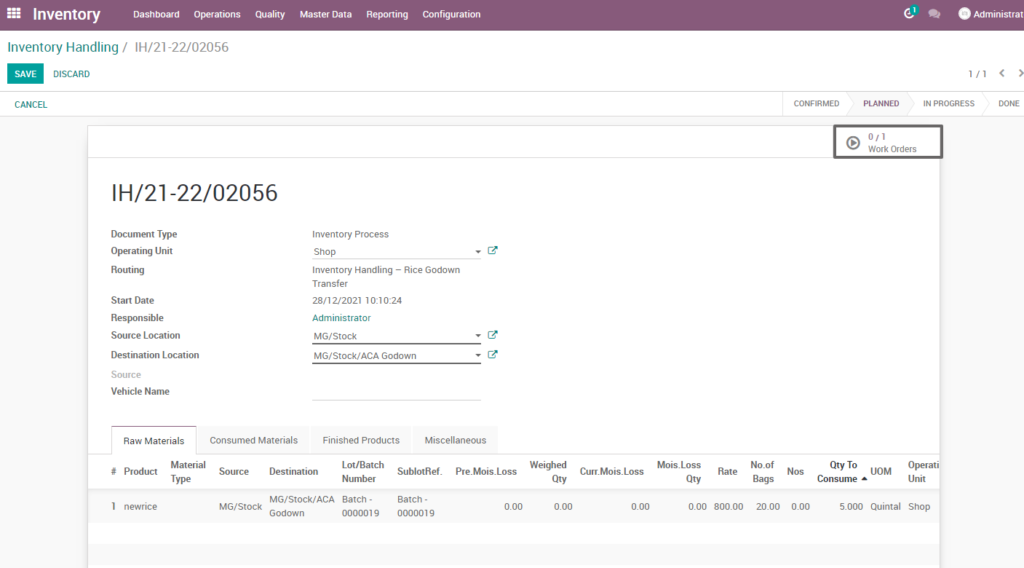

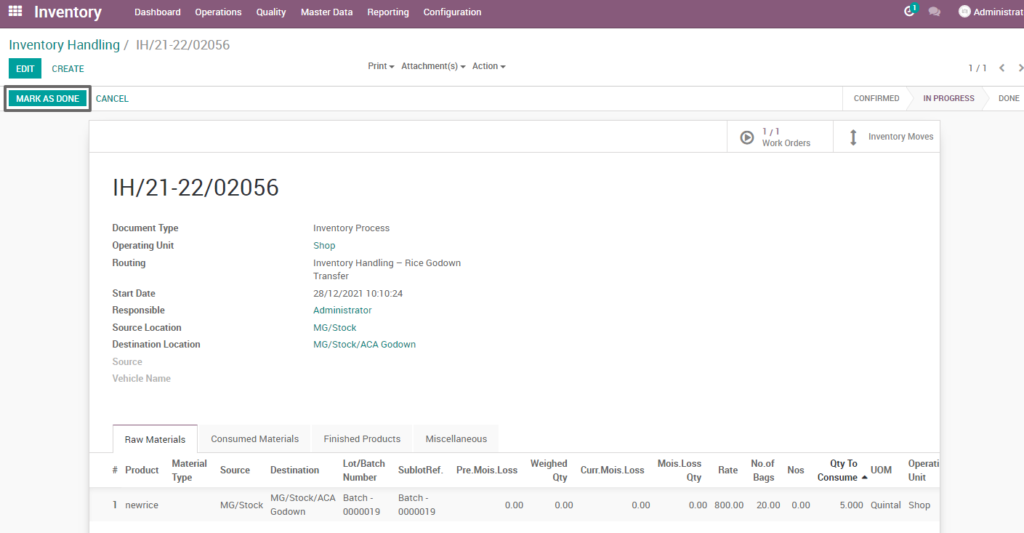

10. User scenario – Inventory Handling – Rice godown transfer

Inventory handling rice go down transfer is the process of managing and transfer rice stock, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

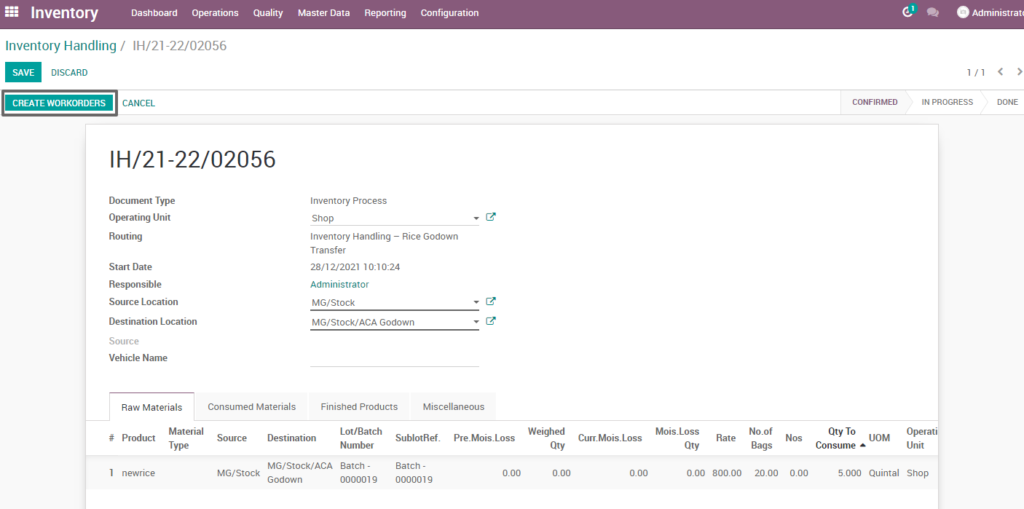

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

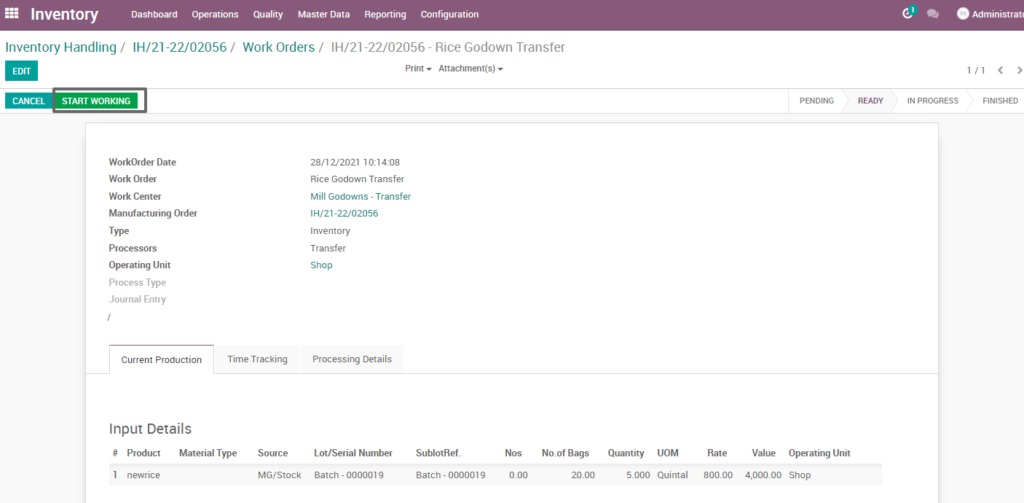

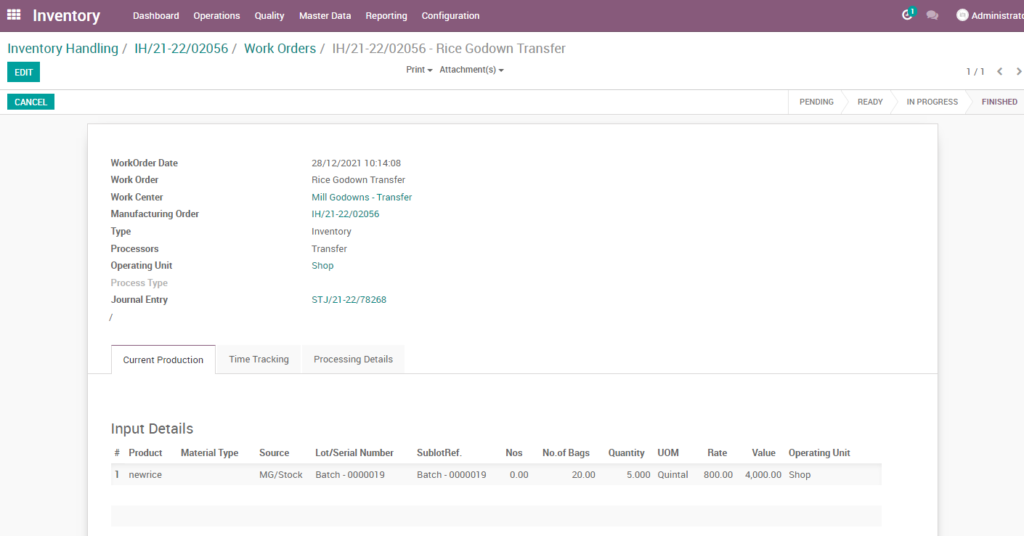

Open work order

Open work order to view the work order process of the inventory handling rice go down transfer. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

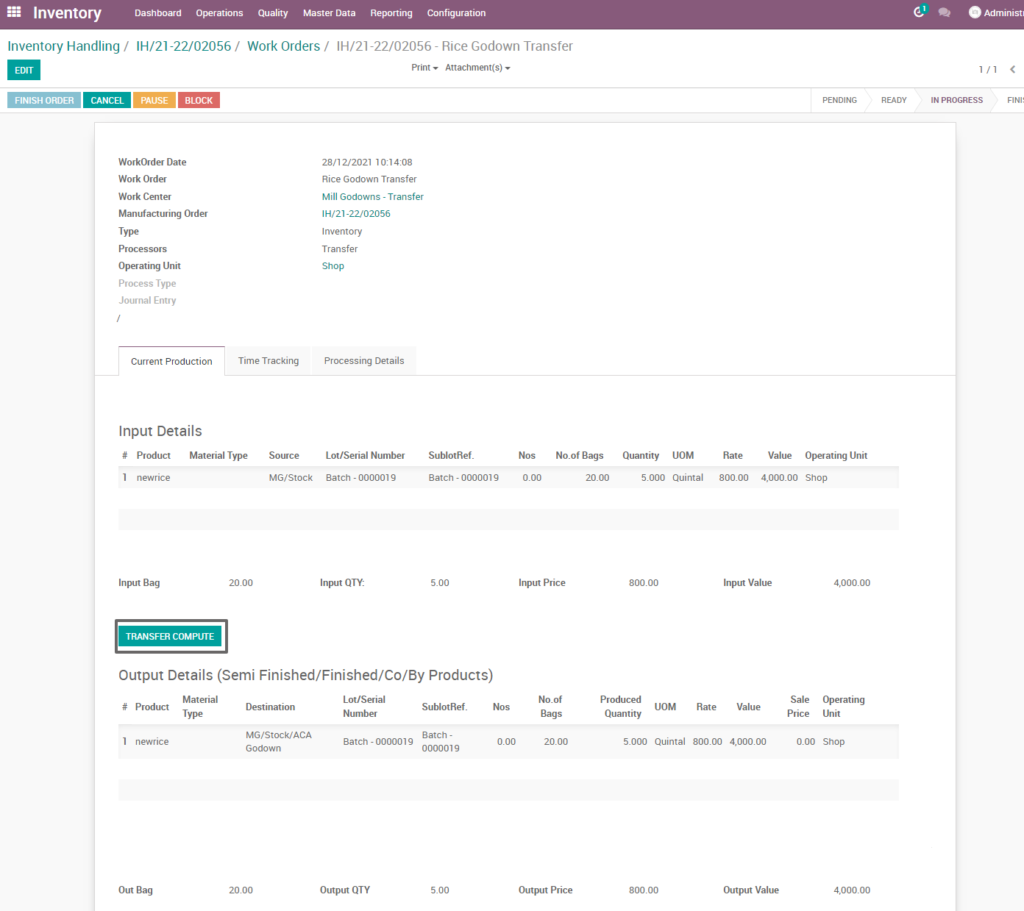

Start work order process

By clicking “start working” button ,the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of the inventory handling rice go down transfer.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process inventory handling rice godown transfer.

Field Description

- Transfer Compute – Click on compute button to compute input and output details

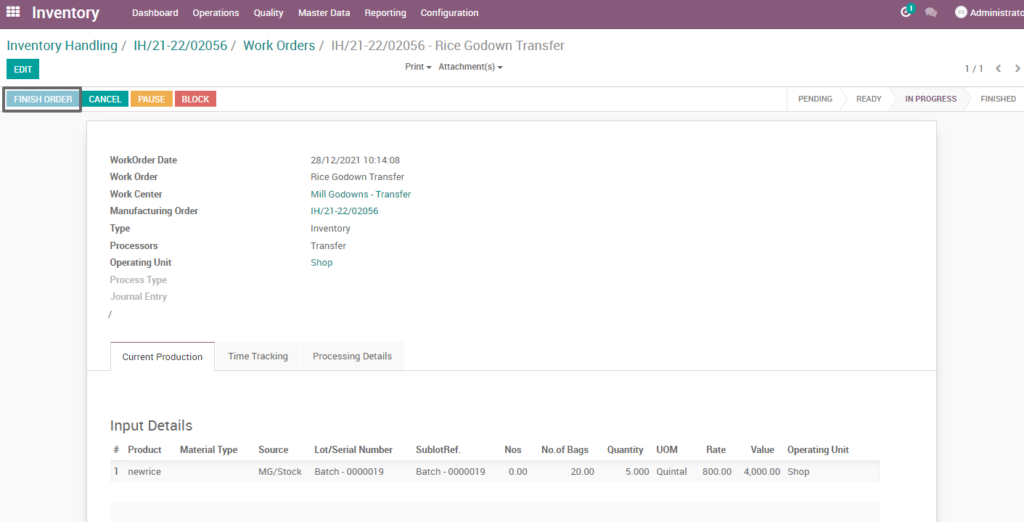

Finish process

After compute process, check on inventory handling rice godown transfer of the product and click “finish order”, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of inventory handling, godown transfer of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of inventory handling rice godown transfer is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

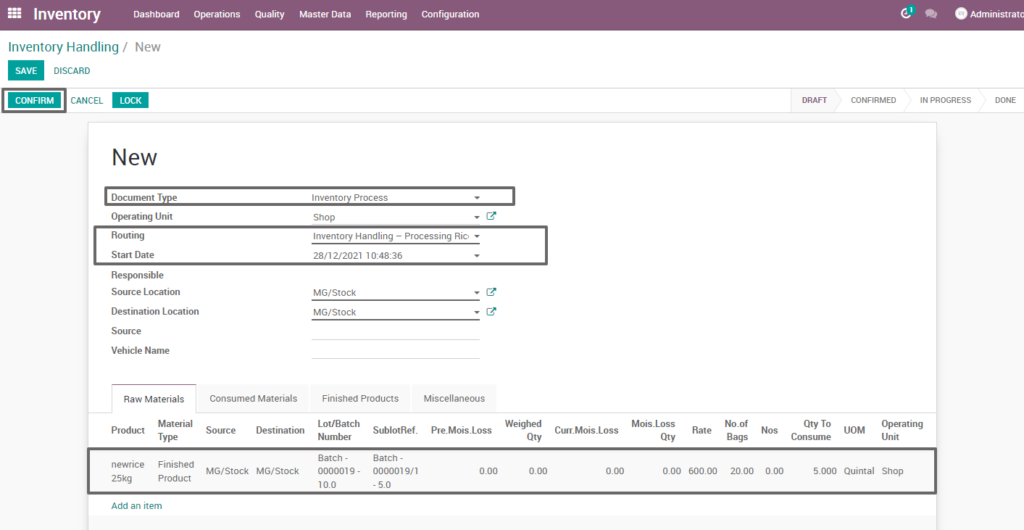

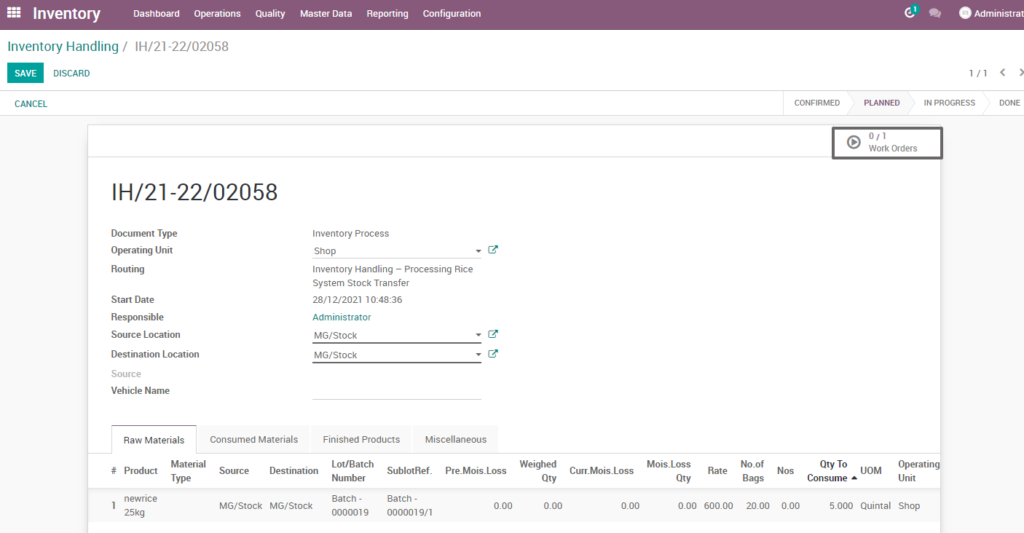

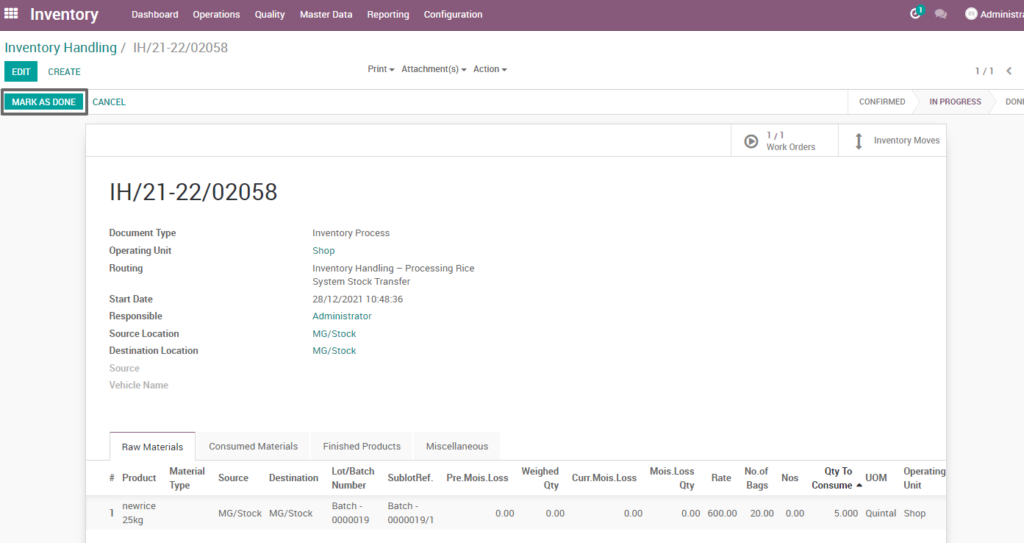

11. User scenario – Inventory handling – Processing Rice System Stock Transfer

Rice system stock transfer inventory handling is the process of managing and transfer rice system stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Processing rice system stock transfer, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

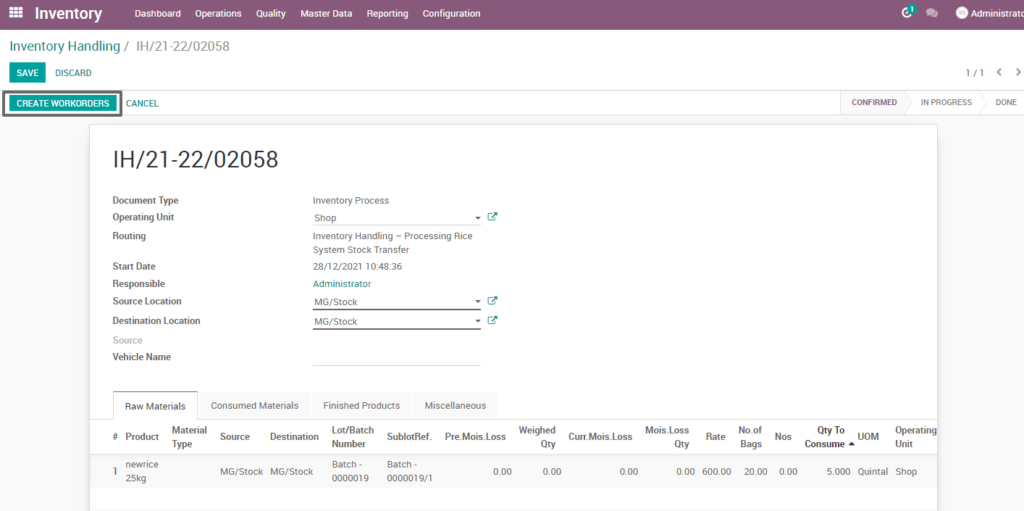

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

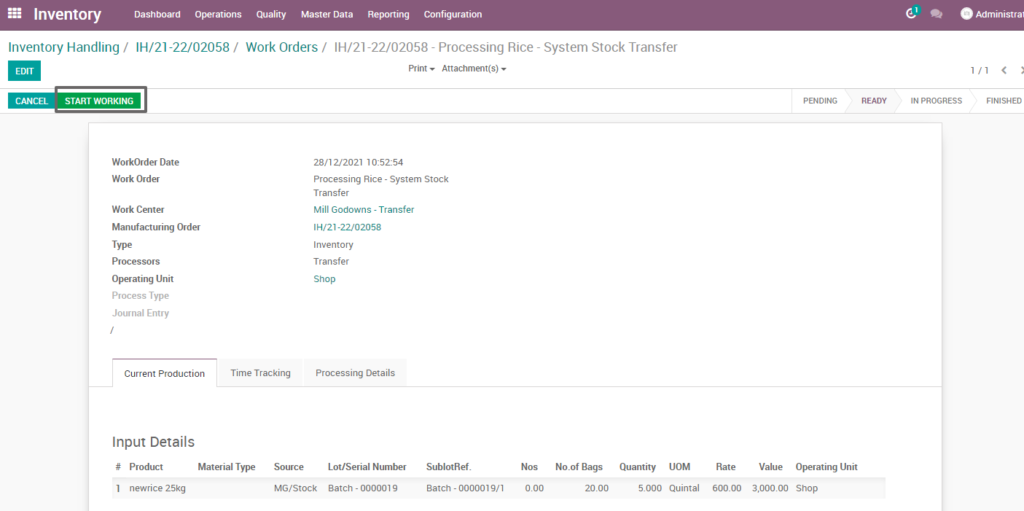

Open work order

Open work order to view the work order process of the inventory handling processing rice system stock transfer. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of inventory handling processing rice system stock transfer is start . It shows input and output details of the inventory handling processing, rice system stock transfer.

Field Description

- Start working – Click on start work order button to start the process of work order

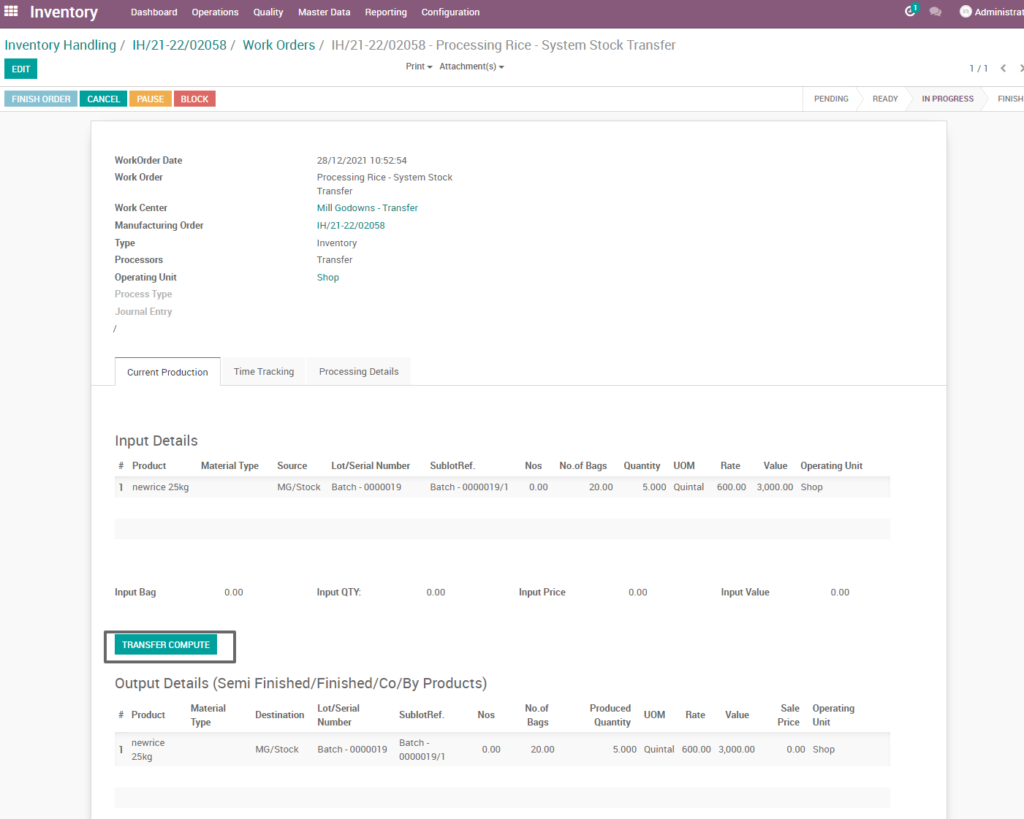

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process inventory handling rice system stock transfer.

Field Description

- Transfer Compute – Click on compute button to compute input and output details

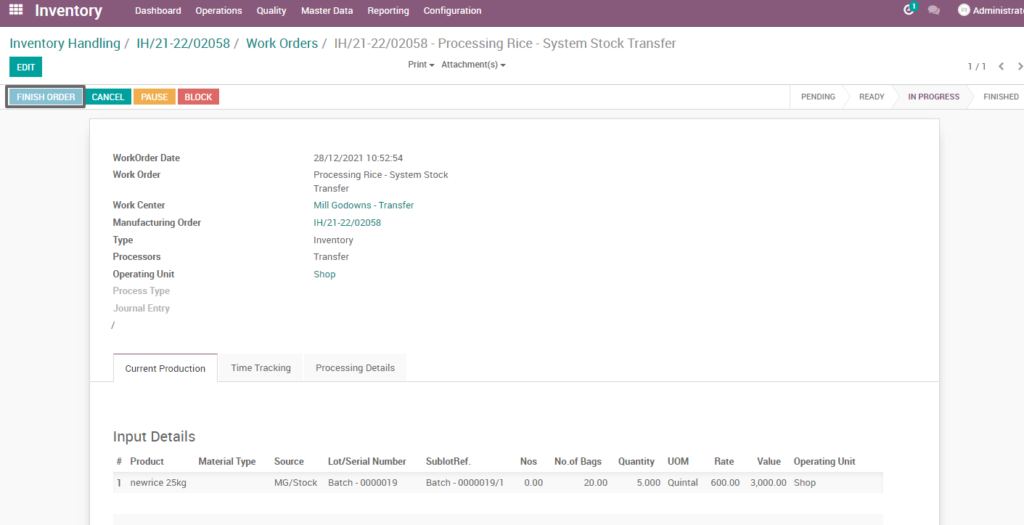

Finish process

After compute process, check on rice system stock transfer of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

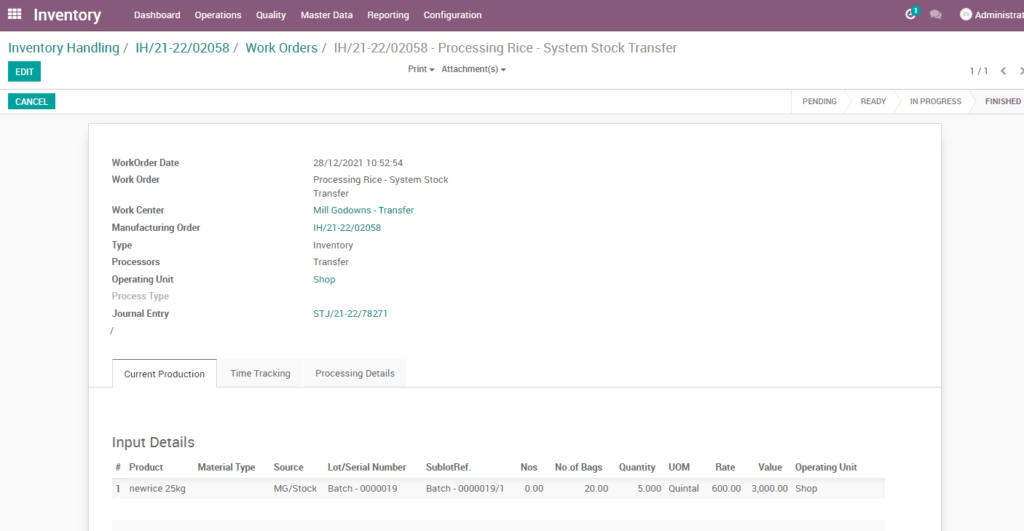

Finished work order

Here shows the finished work order of inventory handling rice system stock transfer of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of inventory handling rice system stock transfer is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

12. User scenario – Raw paddy inventory handling – Seasonal stock release

Raw paddy inventory handling is the process of managing and tracking stock levels, seasonal stock release, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Raw paddy inventory handling-seasonal stock release, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

Open work order

Open work order to view the work order process of the raw paddy inventory handling seasonal stock release. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start. It shows input and output details of the raw paddy inventory handling seasonal stock release.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process raw paddy inventory handling seasonal stock release.

Field Description

- Compute – Click on compute button to compute input and output details

Finish process

After compute process, check on raw paddy inventory handling seasonal stock release of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of raw paddy inventory handling seasonal stock release of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy inventory handling seasonal stock release is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

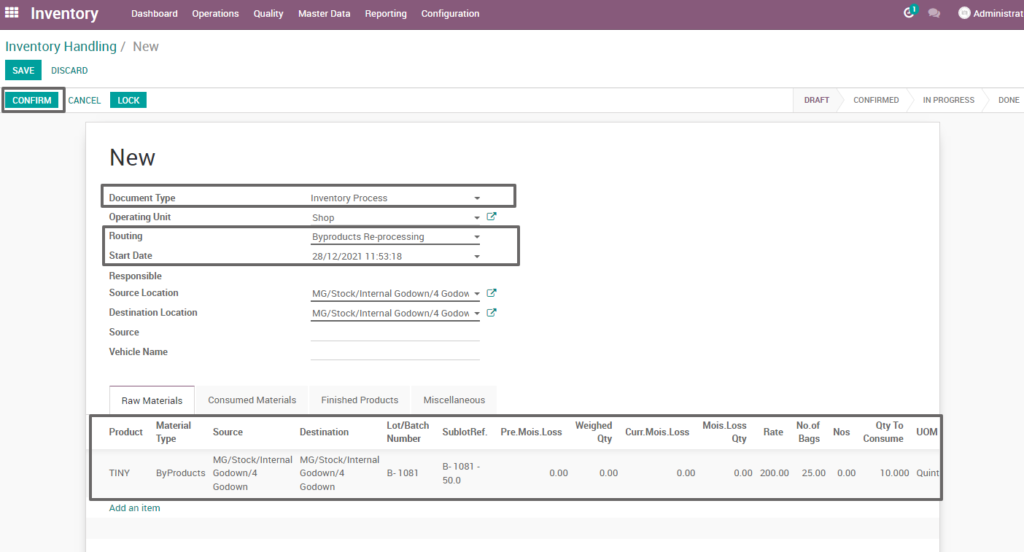

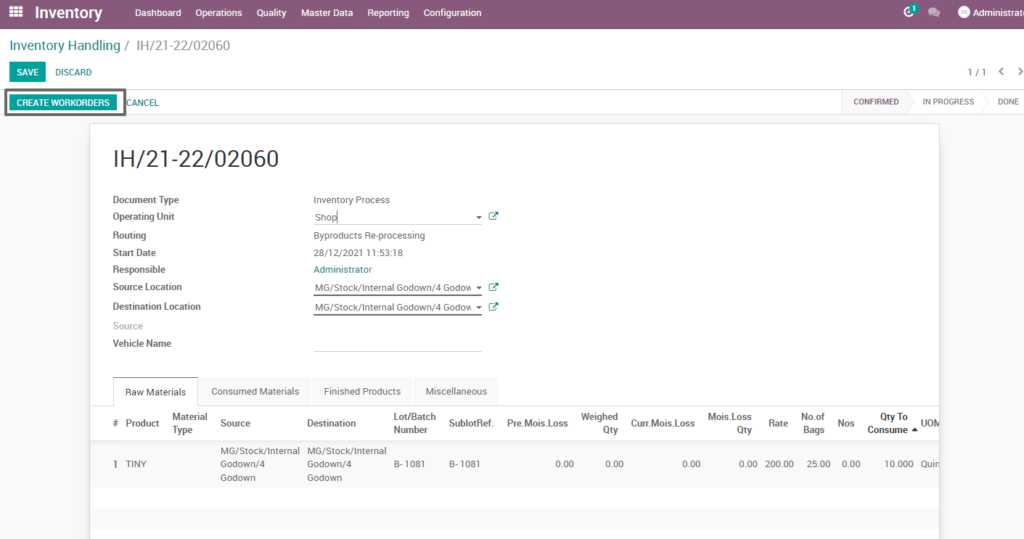

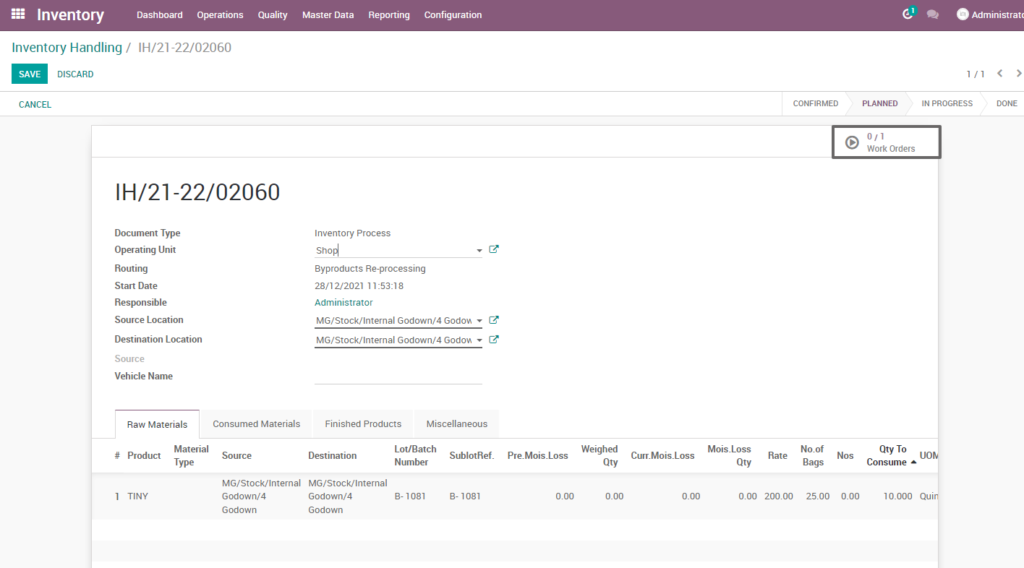

13. User scenario – Byproducts Re-processing

By product re-processing is the process of converting byproducts into a product which make into sale the product.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

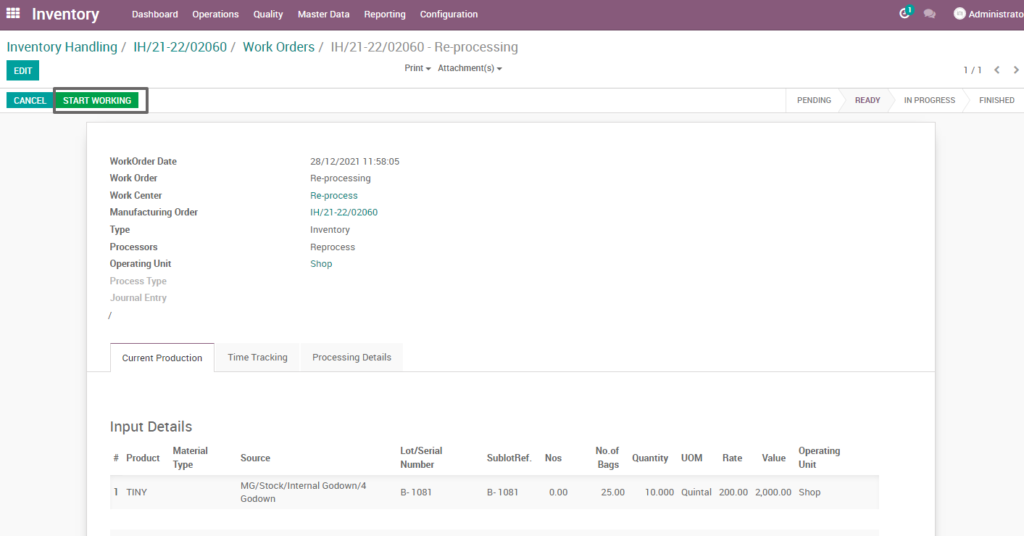

Open work order

Open work order to view the work order process of the by-product reprocessing. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

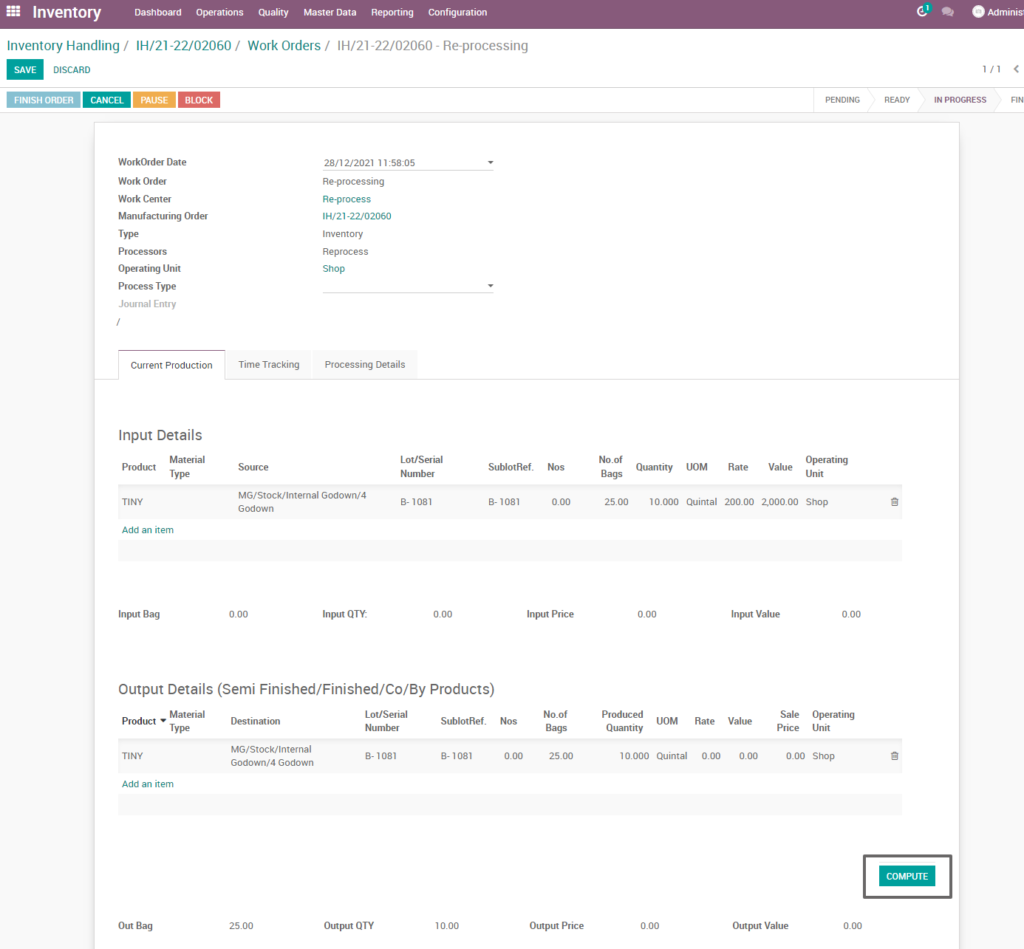

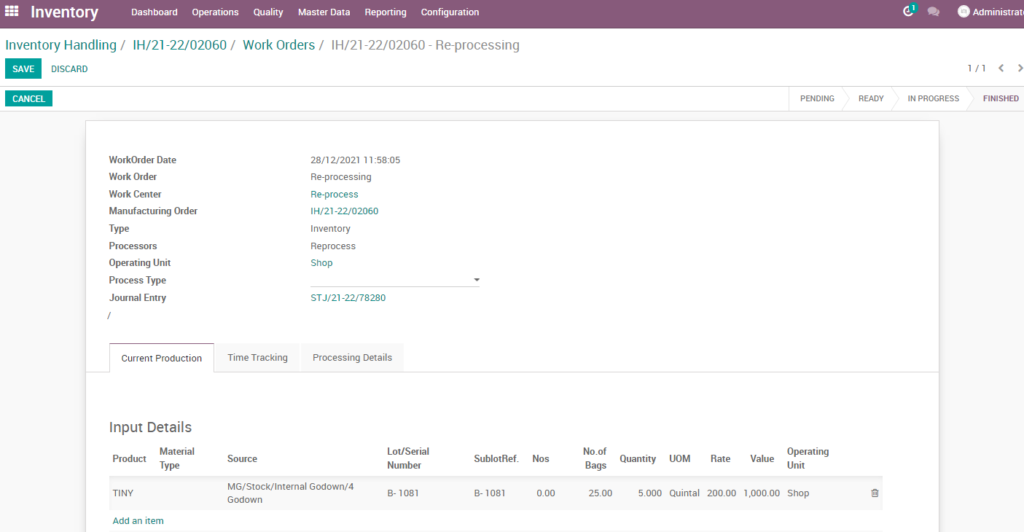

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start. It shows input and output details of by-product reprocessing.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process by-product reprocessing.

Field Description

- Compute – Click on compute button to compute input and output details

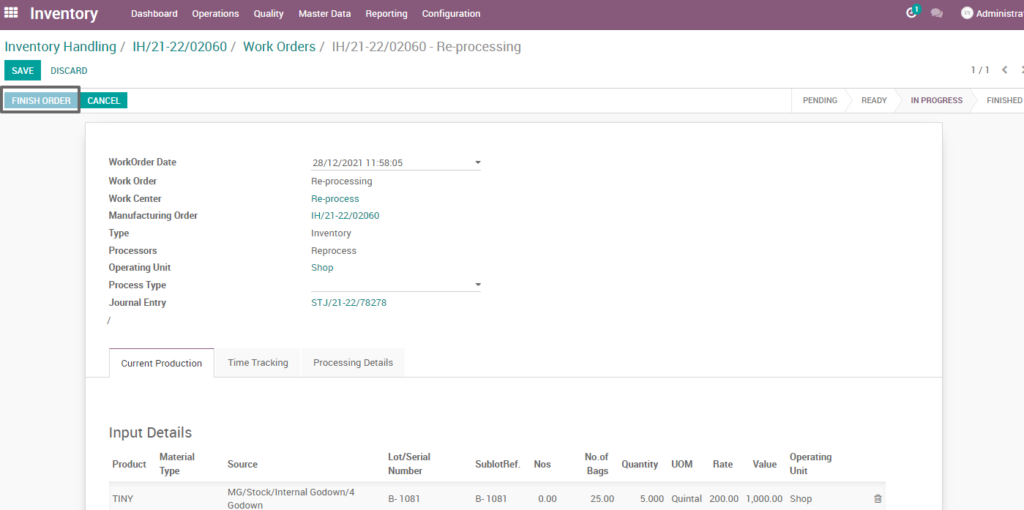

Finish process

After compute process, check on by-product reprocessing of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here show the work order of by-product reprocessing of inventory process. State is changed in progress state into finished state.

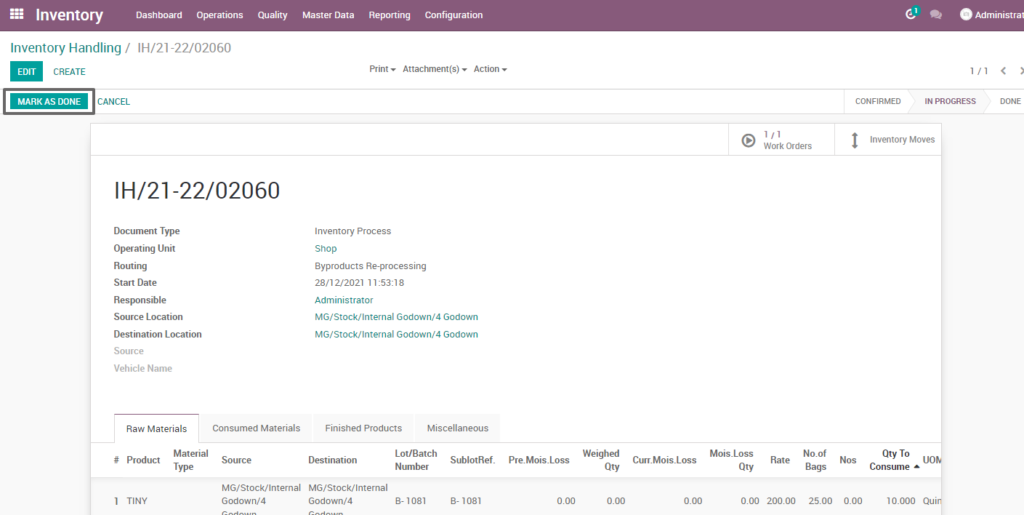

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of by-product reprocessing is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

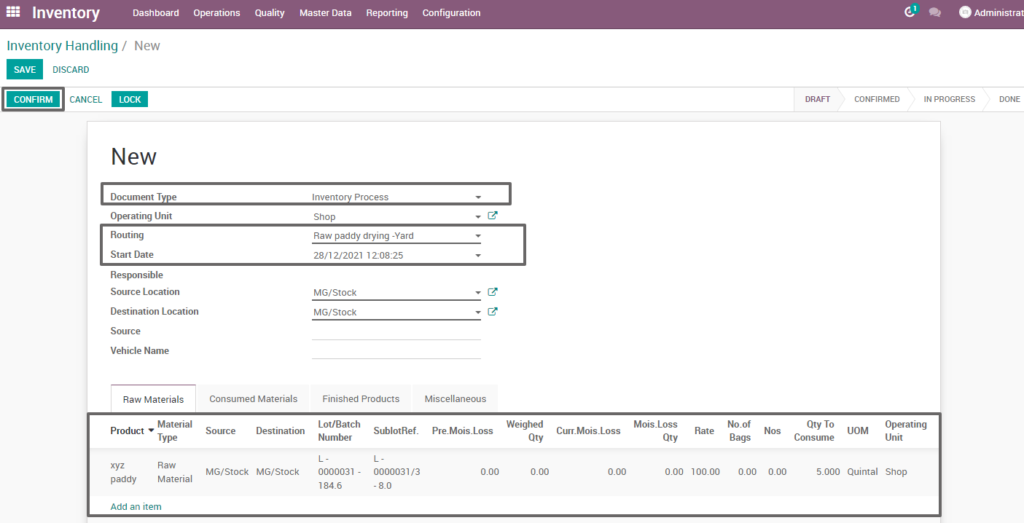

14. User scenario – Raw paddy drying – Yard

It is the processing, drying the wet paddy into dry paddy product in the yard. Here there will be moisture loss from the paddy, which will be treated as a separate product in the output line.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc.,) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Raw paddy drying yard, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

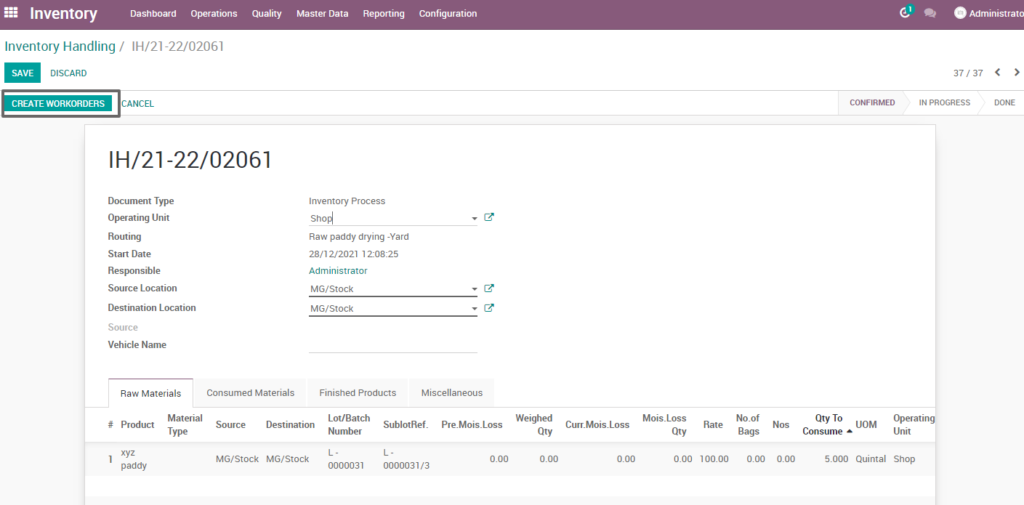

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

Open work order

Open work order to view the work order process of the raw paddy drying yard inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy drying yard is start. It shows input and output details of the raw paddy drying yard.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process raw paddy drying yard.

Field Description

- Compute – Click on compute button to compute input and output details

Finish process

After compute process, check on raw paddy drying yard of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Work order

Here shows finished work order of raw paddy drying yard of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy drying yard is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

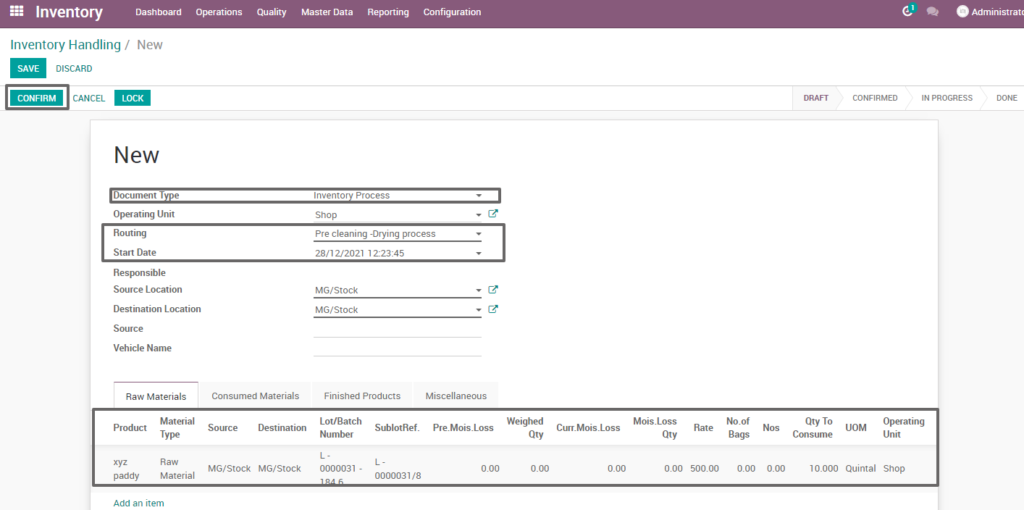

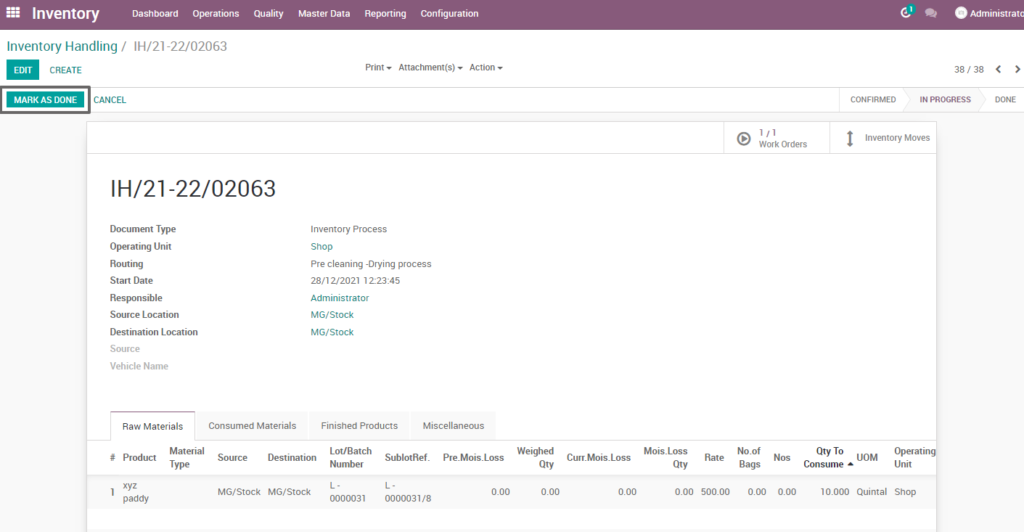

15. User scenario – Pre-cleaning – Drying process

It is the process of pre-cleaning the paddy which remove moisture and dry the paddy which reduces grain moisture content to a safe level for storage.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Pre-cleaning drying process, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

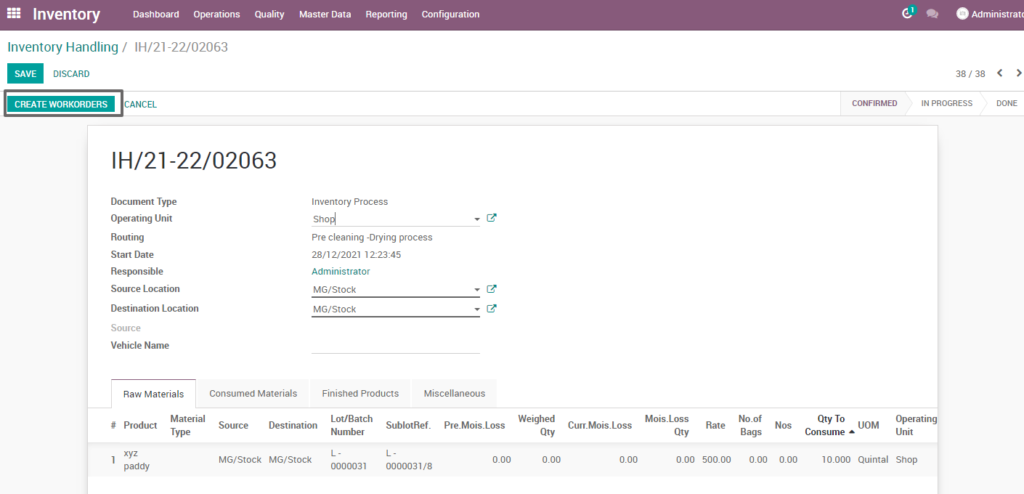

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

Open work order

Open work order to view the work order process of the pre-cleaning drying inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start. It shows input and output details of the pre-cleaning drying process.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process pre-cleaning drying process.

Field Description

- Compute – Click on compute button to compute input and output details

Finish process

After compute process, check on pre-cleaning drying process of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of pre-cleaning drying of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the pre-cleaning drying process is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

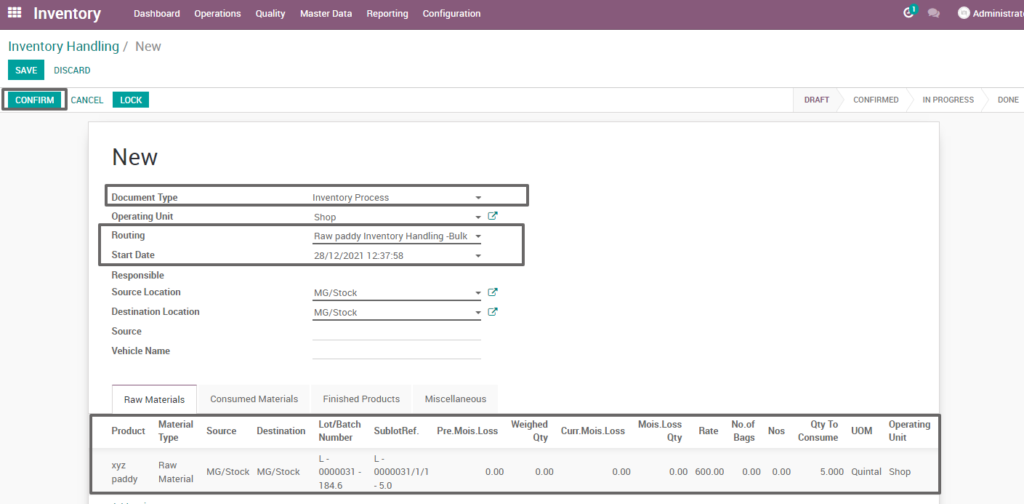

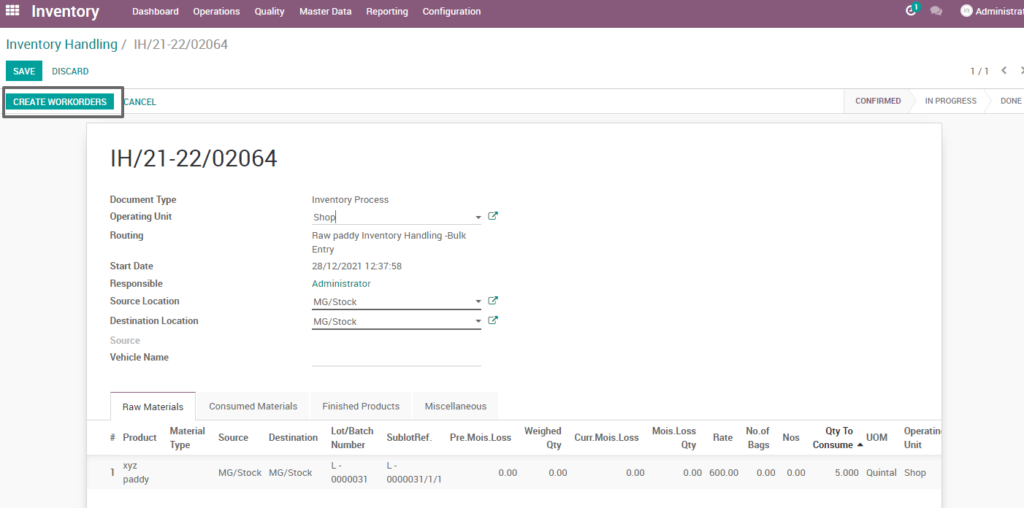

16. User scenario – Raw paddy inventory handling – Bulk entry

Raw paddy inventory handling is the process of managing and tracking bulk entry stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc.,) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

Open work order

Open work order to view the work order process of the raw paddy inventory handling bulk entry. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start. It shows input and output details of the raw paddy inventory handling bulk entry.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process raw paddy inventory bulk entry.

Field Description

- Compute – Click on compute button to compute input and output details

Finish process

After compute process, check on raw paddy bulk entry of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

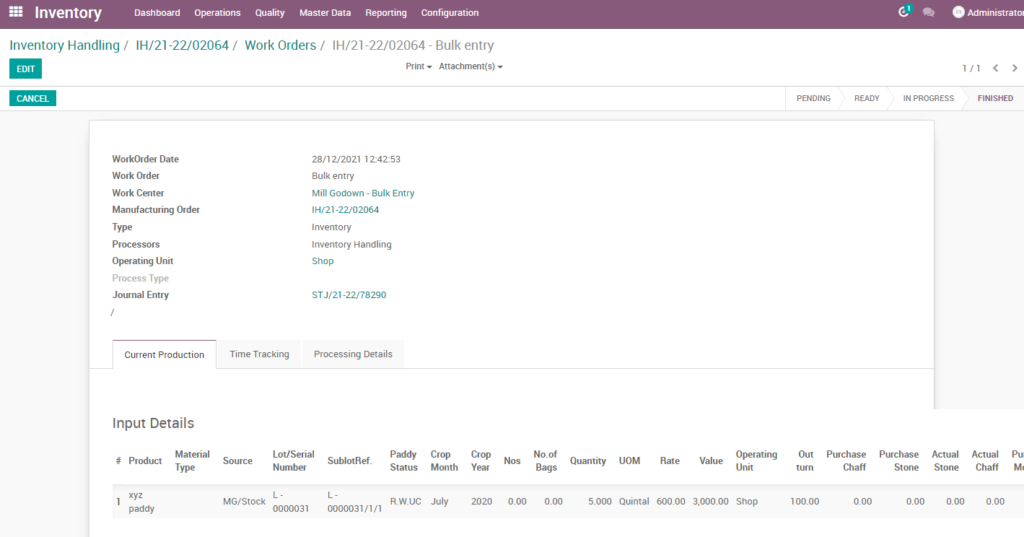

Finished work order

Here shows the finished work order of raw paddy inventory handling bulk entry of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy inventory handling bulk entry is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

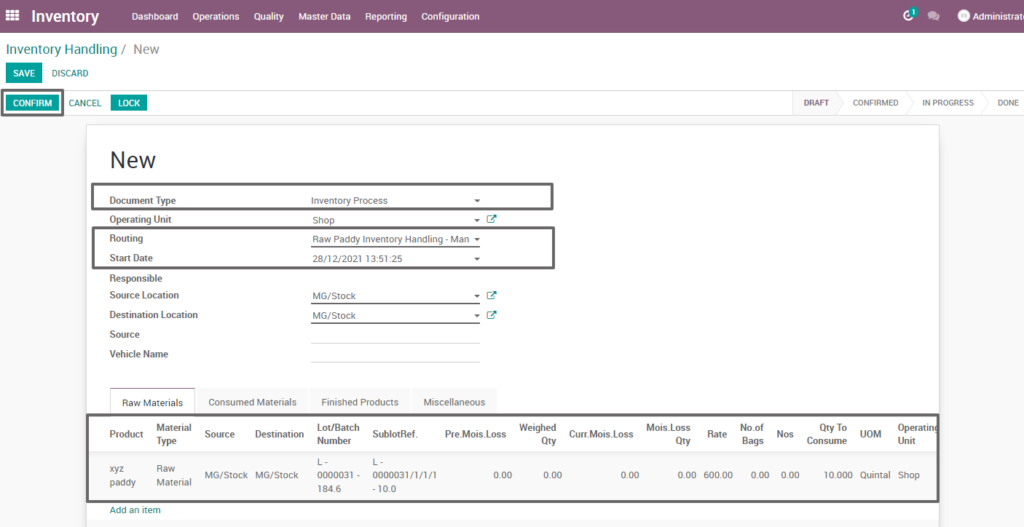

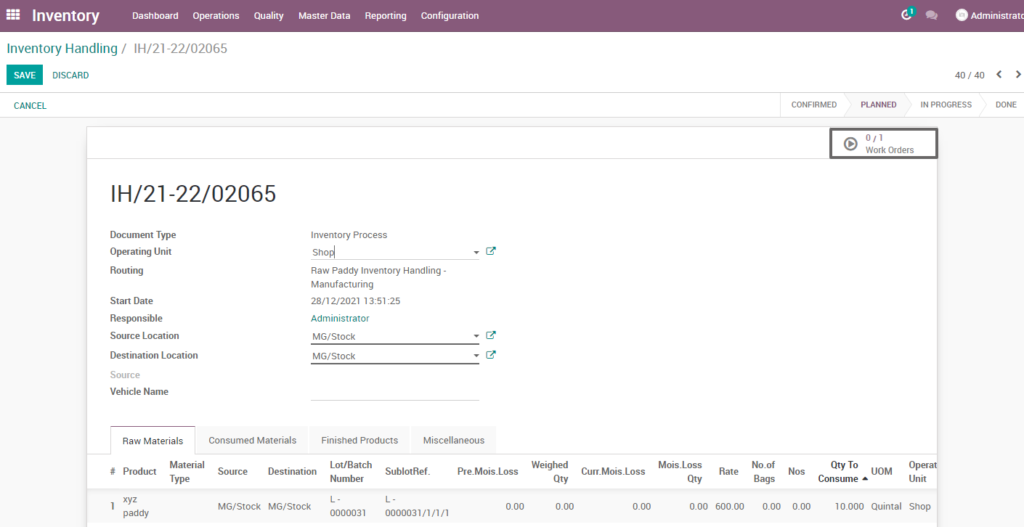

17. User scenario – Raw Paddy inventory handling – Manufacturing

Raw paddy inventory handling is the process of manufacturing and tracking stock levels, directing productivity and efficiency competently to regulate all necessary tasks.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Rice bulk entry, weight conversion, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm –click on confirm button to create work order

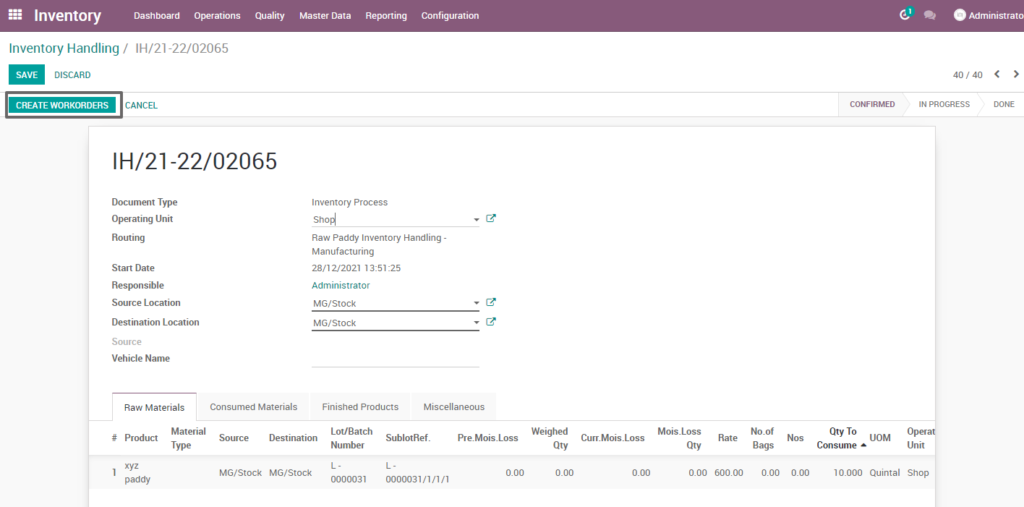

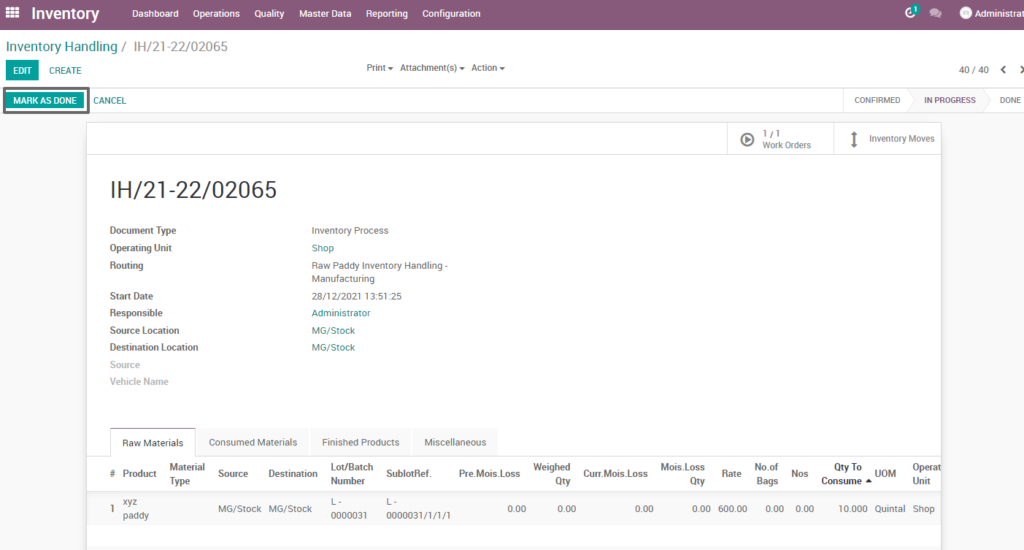

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

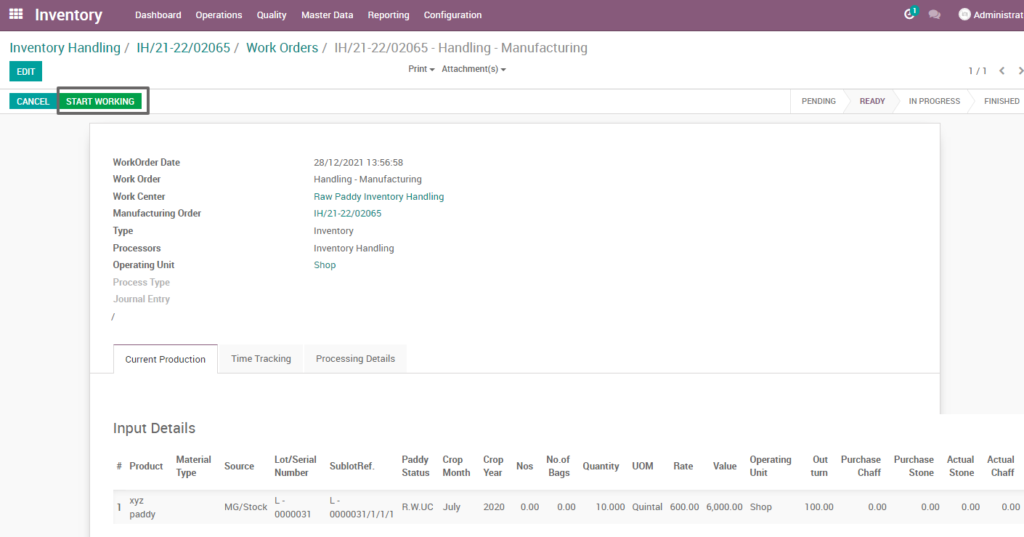

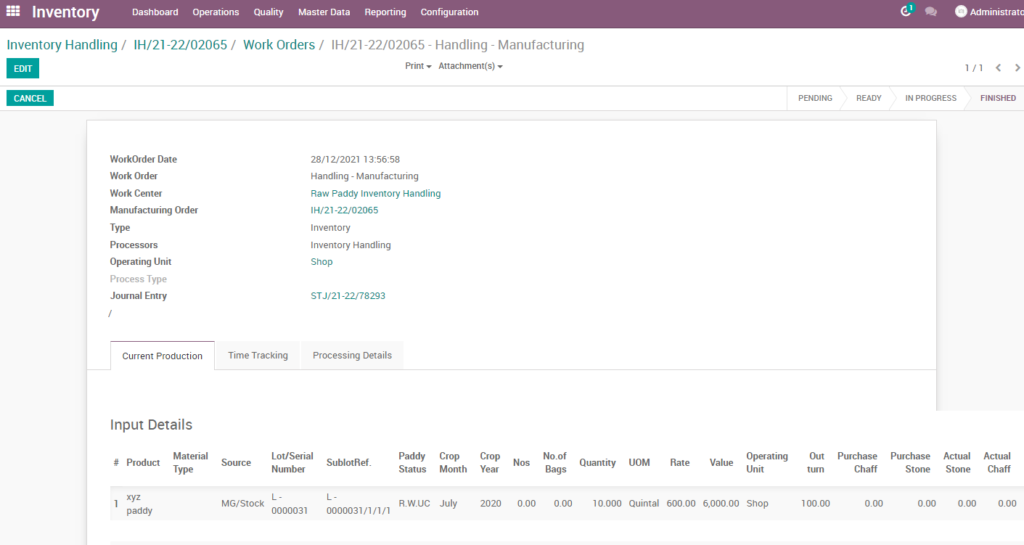

Open work order

Open work order to view the work order process of the raw paddy inventory handling manufacturing of inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling seasonal stock deposit is start . It shows input and output details of the raw paddy inventory handling manufacturing.

Field Description

- Start working – Click on start work order button to start the process of work order

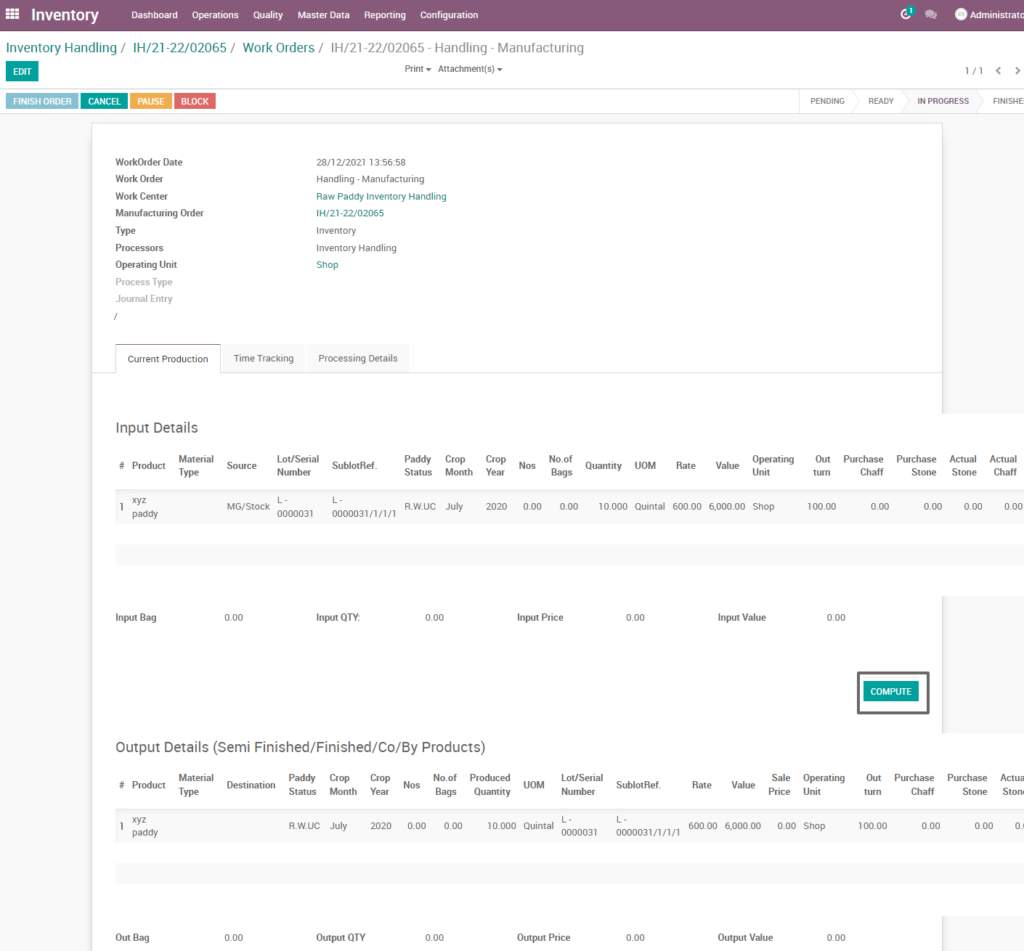

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process raw paddy inventory handling manufacturing.

Field Description

- Compute – Click on compute button to compute input and output details

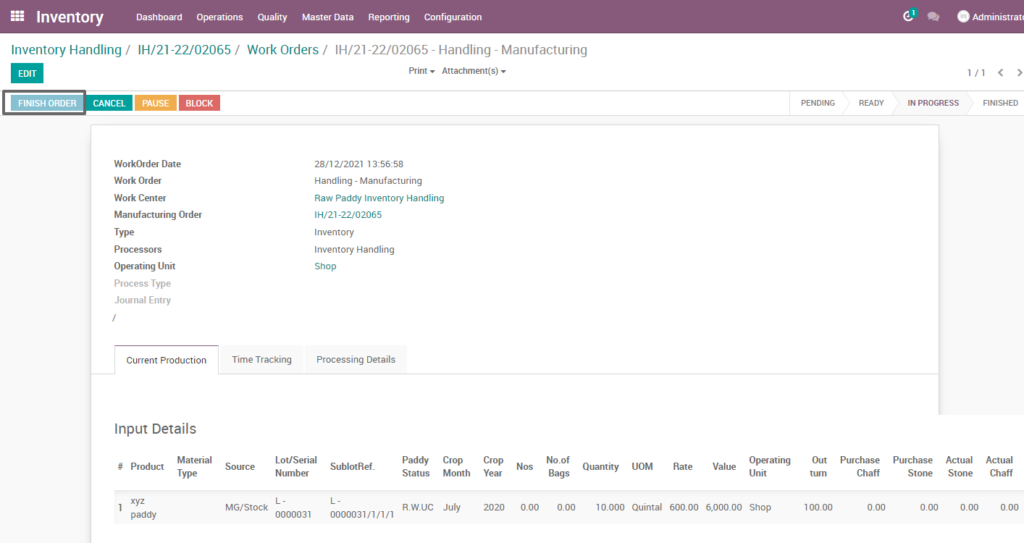

Finish process

After compute process, check on raw paddy inventory handling manufacturing of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Finished work order

Here shows the finished work order of raw paddy inventory handling manufacturing of inventory process. State is changed in progress state into finished state.

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy inventory handling manufacturing is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

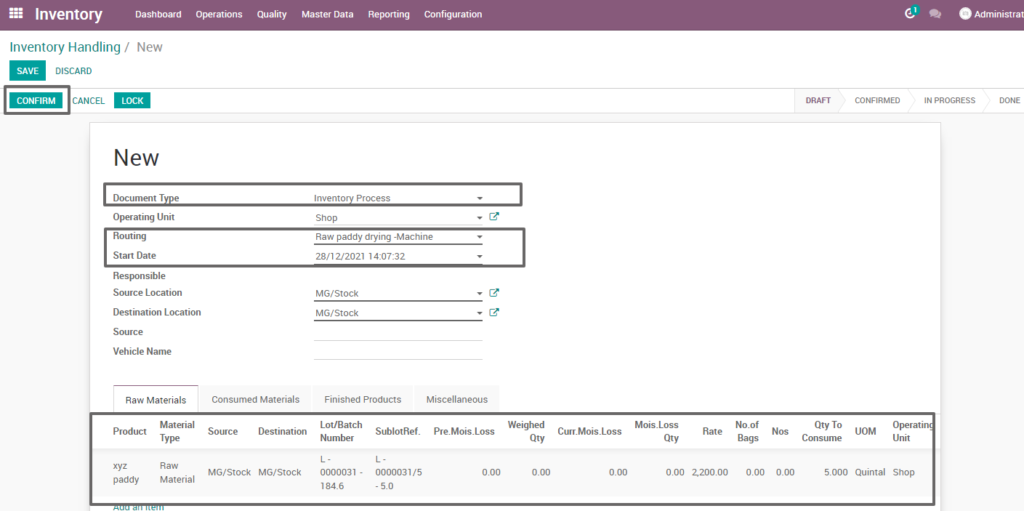

18. User scenario – Raw paddy drying – Machine

Raw paddy drying machine is the process of that reduces grain moisture content to a level where it is safe for storage, making it the most critical operation after harvesting a rice crop.

Field Description

- Document type – select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the inventory handling(i.e. Raw paddy drying machine, weight conversion, etc., )(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm – click on confirm button to create work order

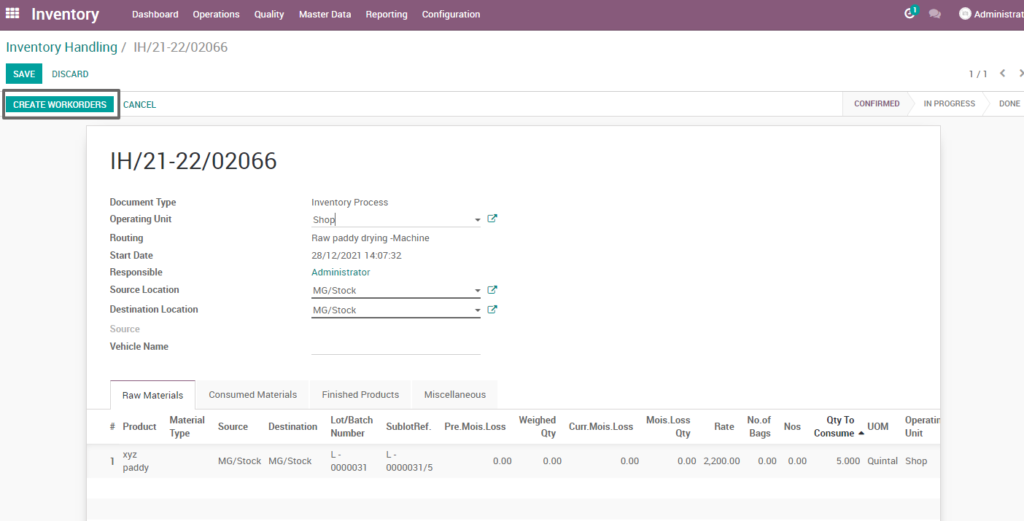

Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

Open work order

Open work order to view the work order process of the raw paddy drying machine inventory process. It displays a well-defined layout of work order with entry details and input output session.

Field description

- Work order – Click on work order button to open work order

Start work order process

By clicking “start working” button, the work order of raw paddy inventory handling drying machine is start. It shows input and output details of the raw paddy inventory handling drying machine.

Field Description

- Start working – Click on start work order button to start the process of work order

Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process raw paddy inventory handling drying machine.

Field Description

- Compute – Click on compute button to compute input and output details

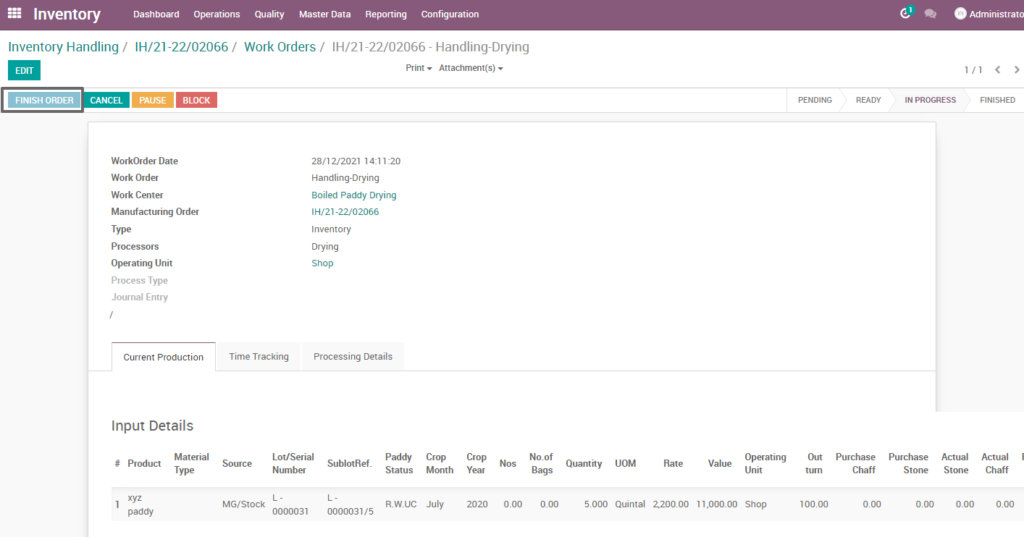

Finish process

After compute process, check on raw paddy inventory handling drying machine of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of raw paddy drying machine is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

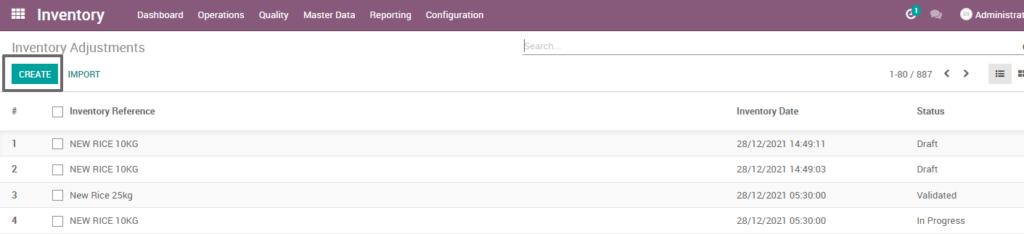

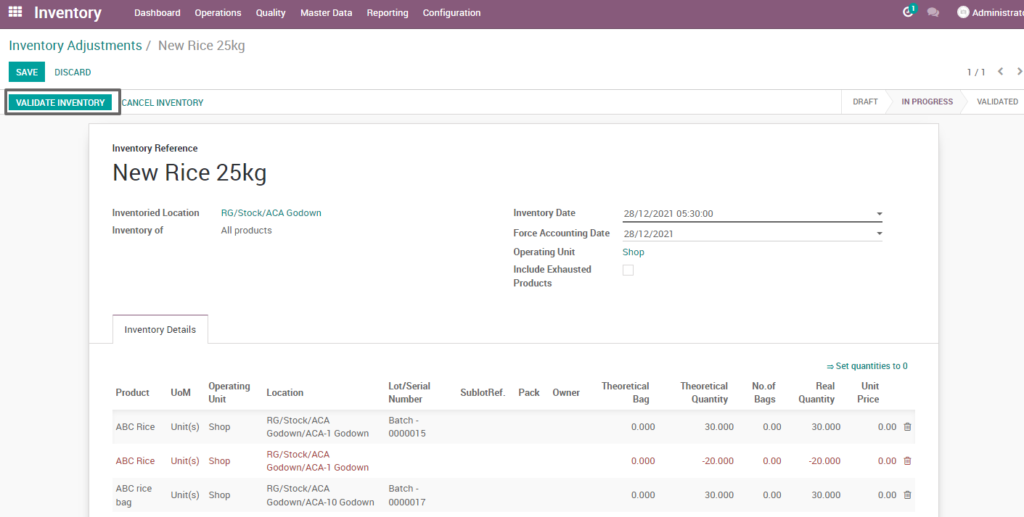

Inventory Adjustment

Inventory adjustment is users to change the product quantity or update the quantity by verifying the physical quantity, which will be reflected in the stock quantity of the product.

Inventory adjustment – Creation

Go to Inventory → Click on Operations → Select Inventory adjustment

Field Description

- Create – click create button to create rfq

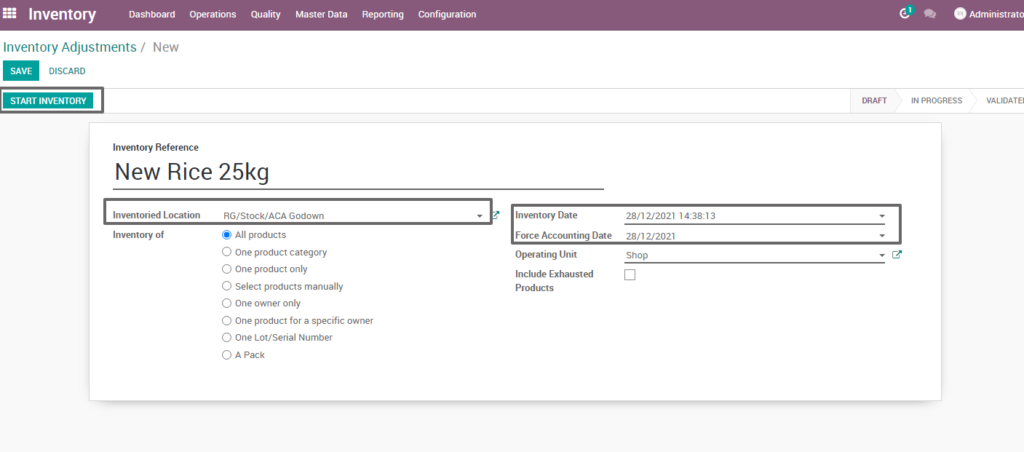

Inventory adjustment creation

Inventory adjustment is created by add inventoried location, date and accounting date then start inventory.

Field Description

- Start inventory – click the button to start the inventory adjustment process

- Inventory reference – enter the inventory reference detail(mandatory)

- Inventory location –choose the location based on product

- Inventory date –choose the date for inventory adjustment

- Operating unit – select the operating unit for inventory adjustment(i.e. Shop, retail 1,retail 2,retail 3,mill)

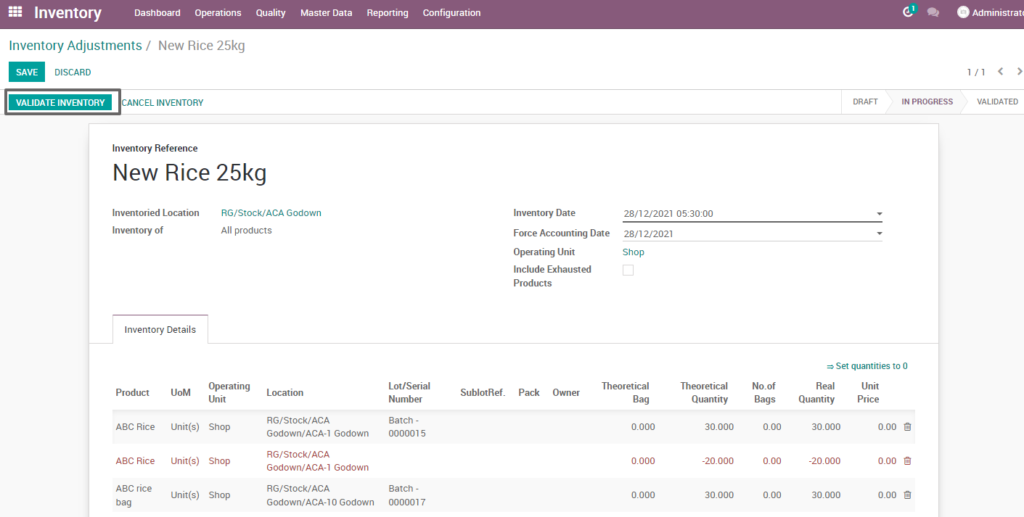

Validate – Inventory adjustment

Validate inventory adjustments are the manual adjustment of an item’s inventory by a store user for a given reason. Inventory adjustments change inventory positions based upon a reason code which is associated to a disposition.

Field Description

- Validate inventory – Click the button to validate the inventory details

18. Inventory adjustment

Inventory adjustment is users to change the product quantity or update the quantity by verifying the physical quantity, which will be reflected in the stock quantity of the product.

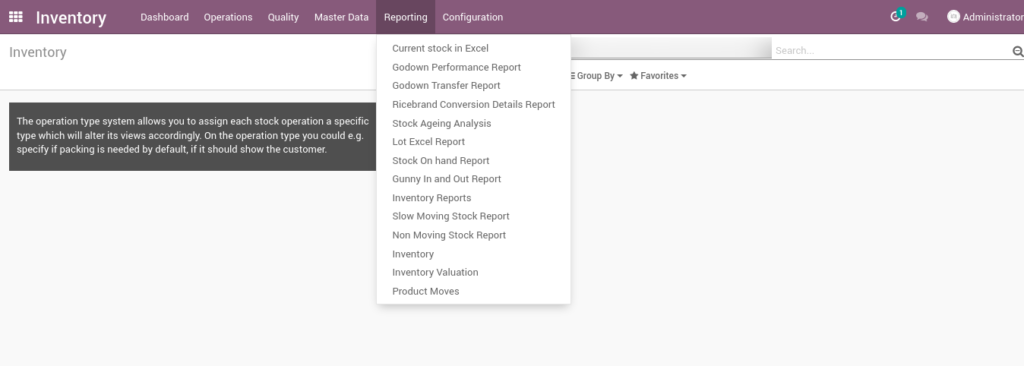

19. Inventory reports

It is a document that helps a business to monitor the sales performance for a fixed period of time. A inventory report can be generated for a week, month, or year.

Go to Inventory → Click on Reporting menu

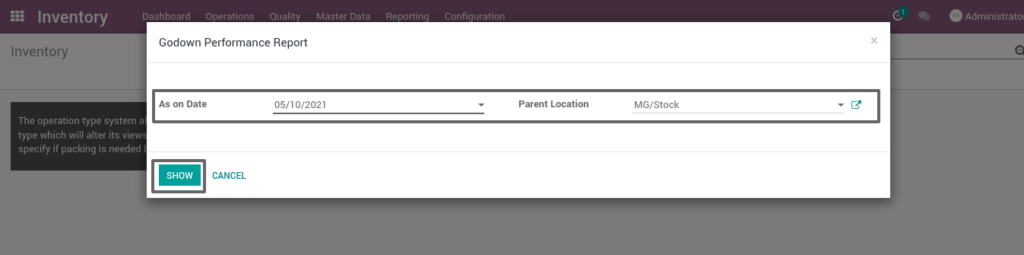

GODOWN Performance report

It is report which shows a godown performance by choosing the date and location which can view a performance of godown reports.

Go to Inventory → Click on reporting menu → Godown performance report

Field Description

- As on date: choose the as on date from which the data has to be extracted (mandatory)

- Parent location: select a parent location to view data for the selected godown

- Show: click on show button to view the report

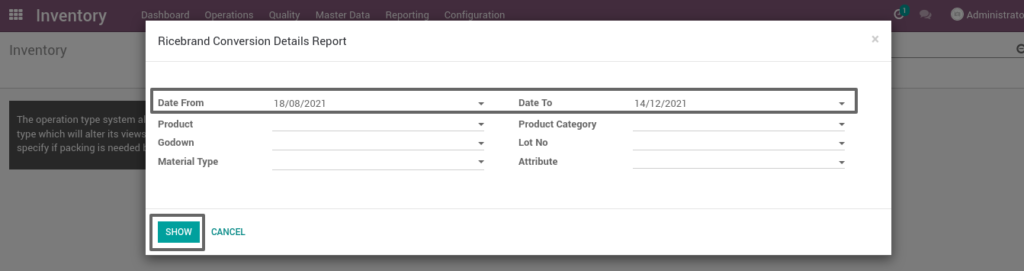

Rice brand conversion details report

It is report which shows a rice brand conversion by choosing from and to date, product, godown, lot no which can view a rice brand conversion product reports.

Go to Inventory → Click on Reporting menu → Rice brand conversion details report

Field Description

- Date from: choose the start date from which the data has to be extracted (mandatory)

- Date to: choose the end date up to which the data has to be extracted (mandatory)

- Show: click on show button to view the report

-

Pingback: 10 Tips to Choose the Right ERP for Your Rice Mill Industry - TenthPlanet Technologies

-

Pingback: 3 tips to manage your Rice Mill accounting system easily with Odoo - TenthPlanet Technologies