Rice Mill ERP Manufacturing Management

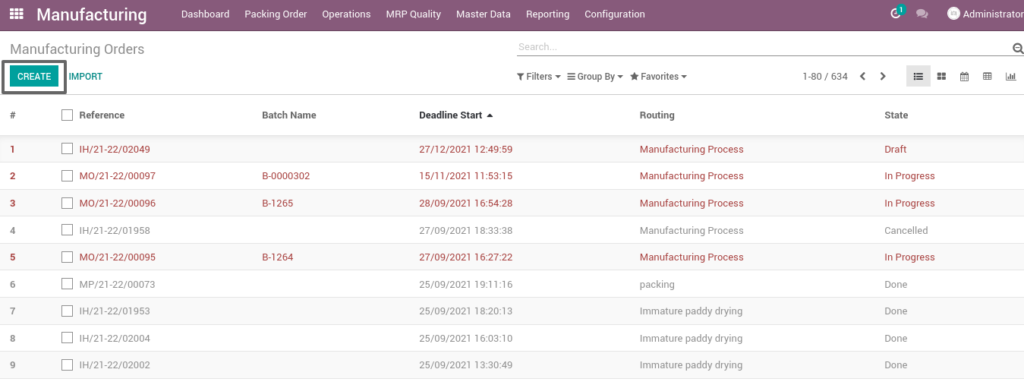

Go to Manufacturing → Click on Operations menu → Select Manufacturing order

Field Description

- Create : Click create button to create a new manufacturing order

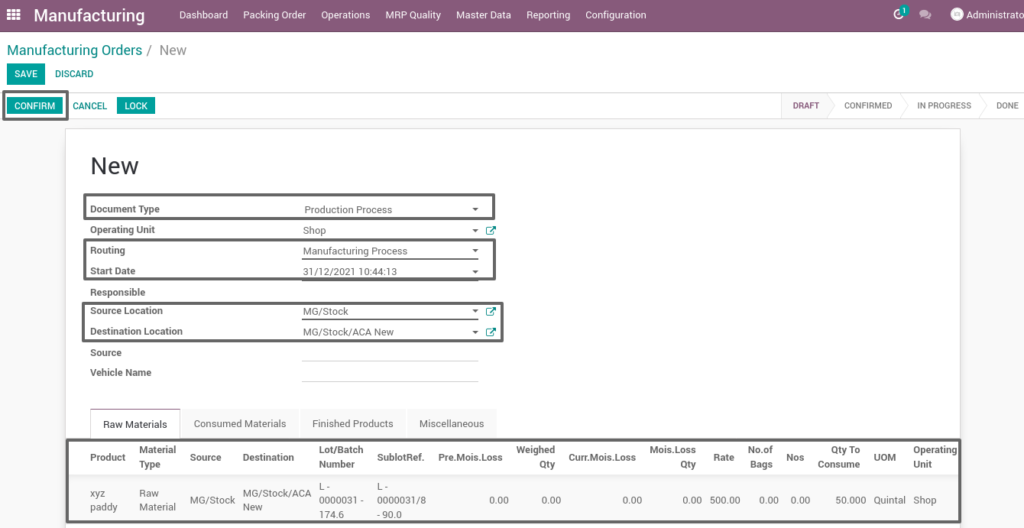

User scenario – Manufacturing Process

Manufacturing process management is a collection of technologies and methods used to define how products are to be manufactured. Select the production process and routing as manufacturing process which convert a raw material into finished product.

Field description

- Document type – Select the document type (i.e. Production process, move request, etc., ) (mandatory)

- Routing – Select routing for which to create the new manufacturing order(i.e. Manufacturing process, packing, immature paddy drying, etc., )(Mandatory)

- Source location – Choose the data for input location

- Destination location – Choose the data for output location

- Product – Add one or more products for processing

- Lot/batch number – Select lot no for chosen product

- Sub lot – Select sub lot no for chosen lot no

- No.of.bags – Choose no of bags to process quantity

- Quantity – Enter the required product quantity

- Confirm – Click on confirm button to create work order

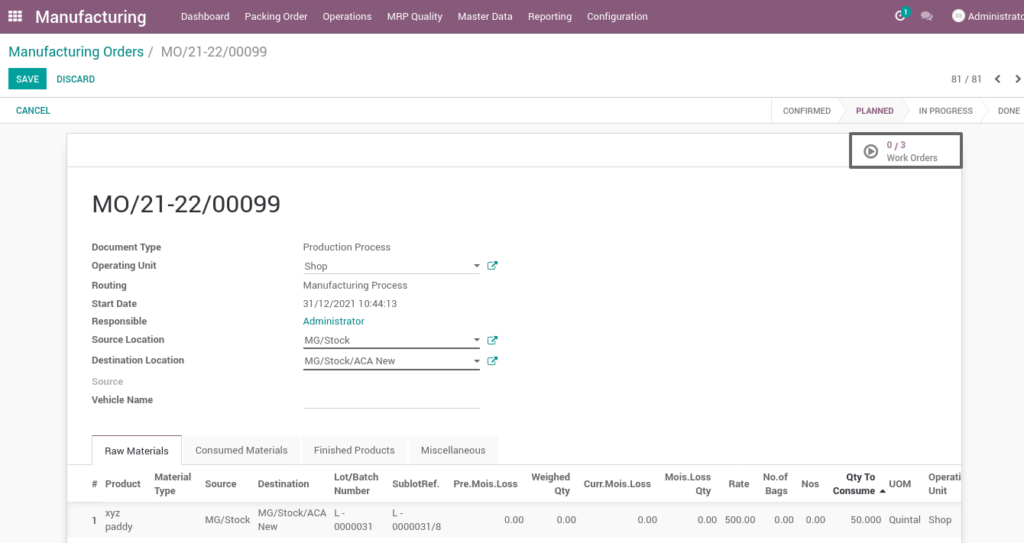

1. Create work order

Work orders are an authorization of maintenance, repair or operations work to be completed. Manufacturing Contains three work order such as soaking and cooking, boiled paddy drying and hulling.

Field Description

- Create work order – Click on create work order button to create work order

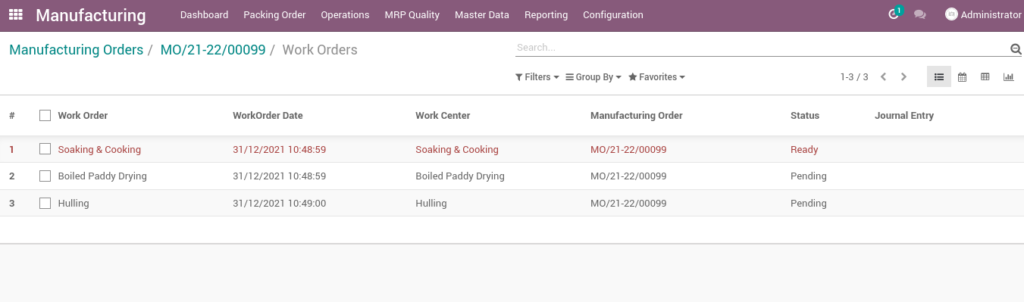

2. Open work order

Three work order are process, one by checking and transfer a raw material to finished product. It displays a well-defined layout of work order with entry details and input output session.

Field Description

- Work order – Click on work orders to open work order

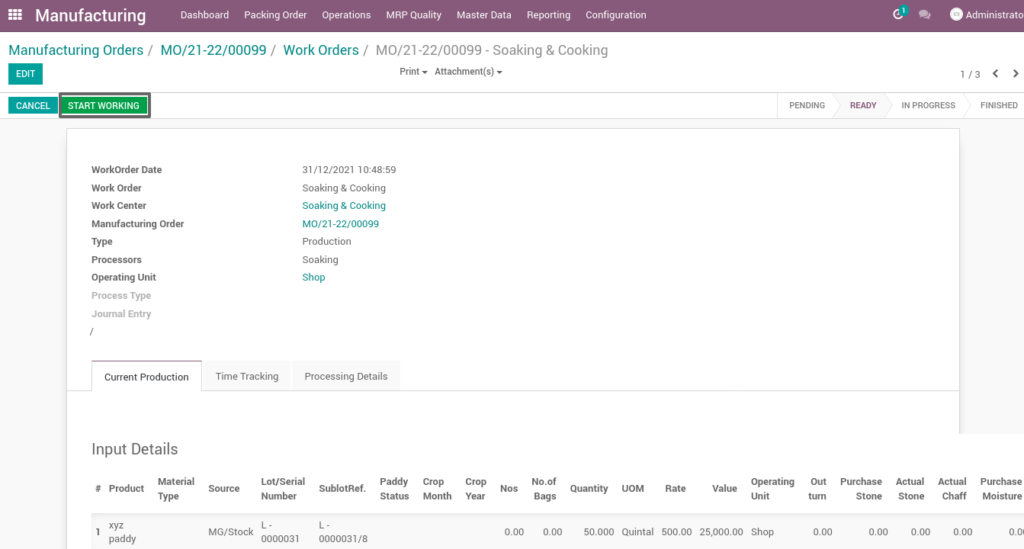

3. Start work order process – Soaking & Cooking

Soaking is a process of soaking a paddy in water after that cooking process is partial boiling of the paddy before milling in order to increase its nutritional value.

Field Description

- Start working – Click on start work order button to start the process of work order

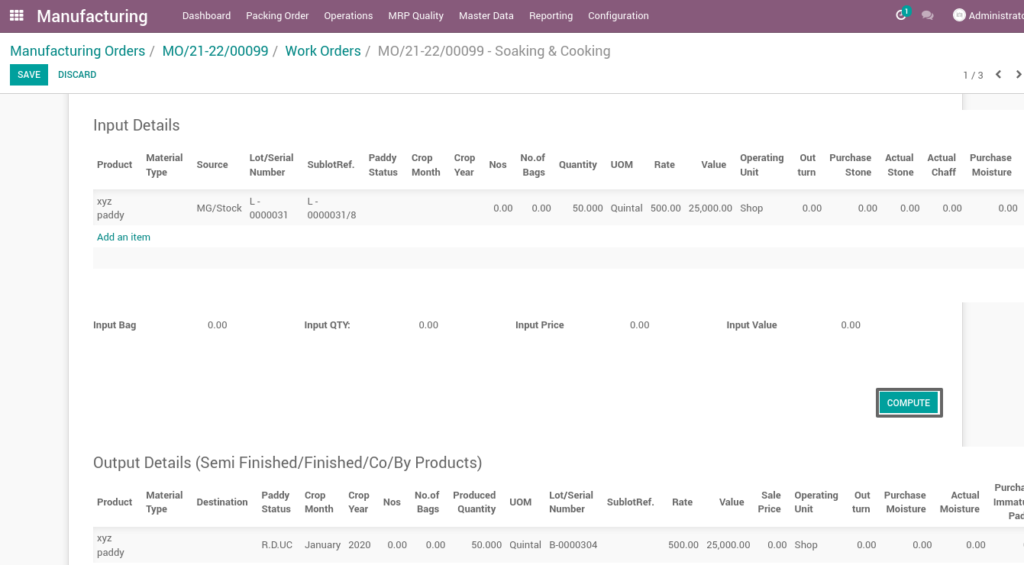

4. Compute process

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process manufacturing of soaking and cooking.

Field Description

- Compute – Click on compute button to compute input and output details

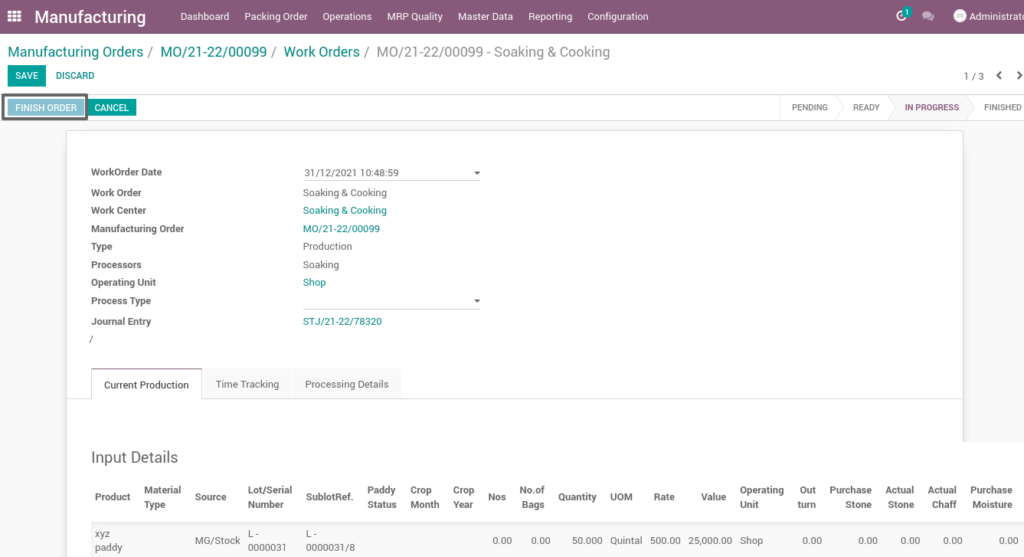

5. Finish process

After compute process, check on soaking and cooking of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

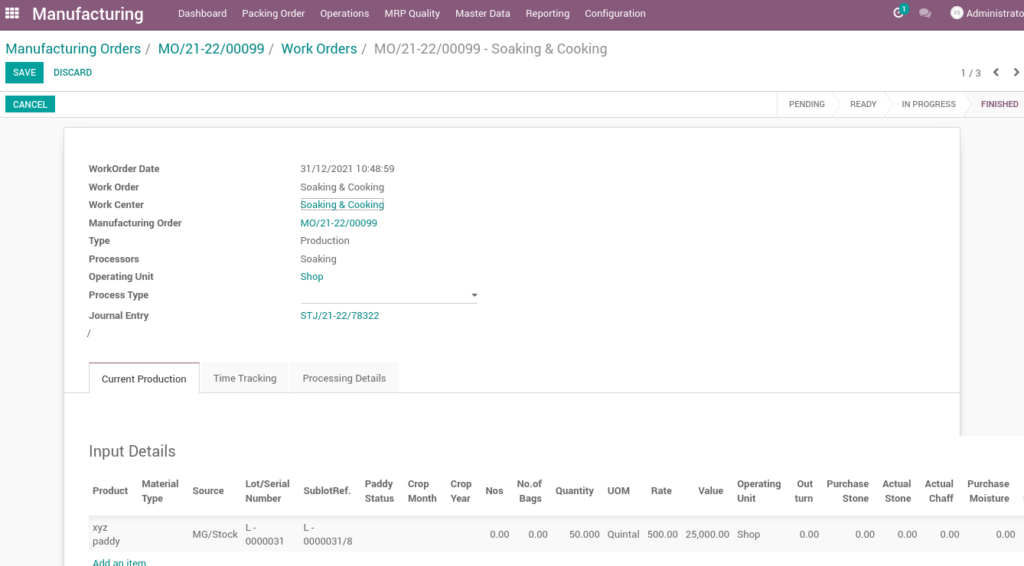

6. Work order

Here shows the finished work order of soaking and cooking from manufacturing process. State is changed in progress state into finished state.

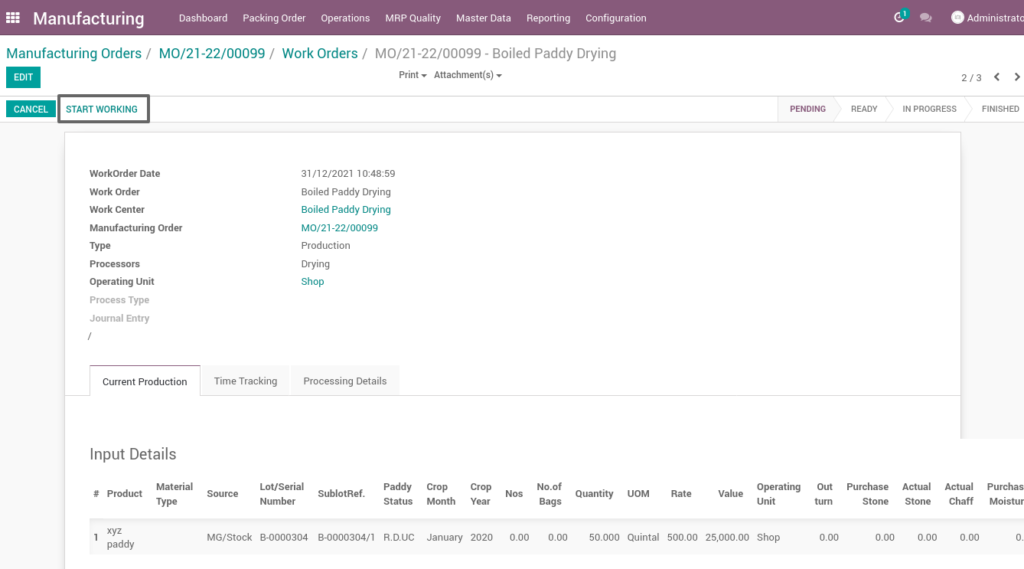

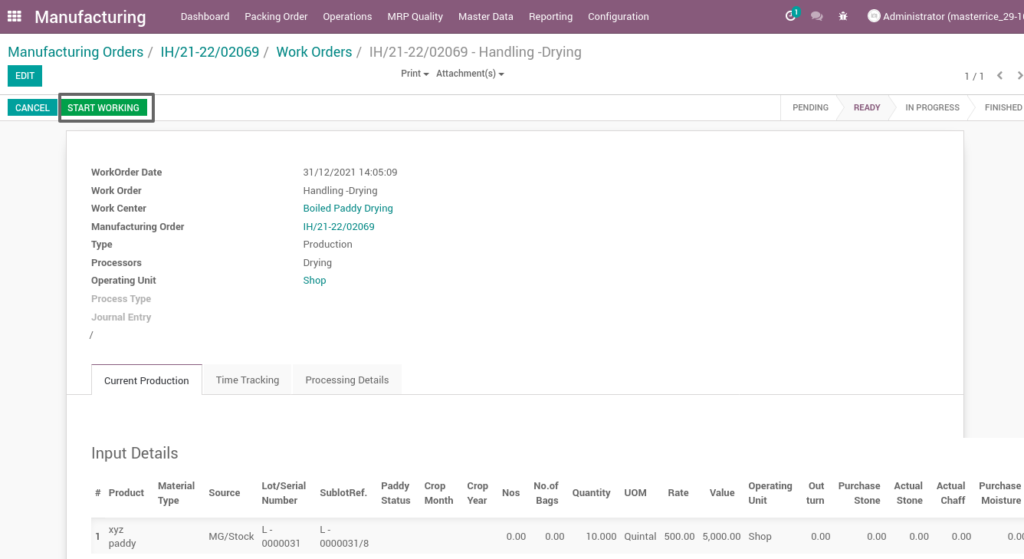

7. Start work order process – boiled paddy drying

Boiled paddy drying is the process of drying reduces grain moisture content to a safe level for storage and further proceed hulling process.

Field Description

- Start working – Click on start work order button to start the process of work order

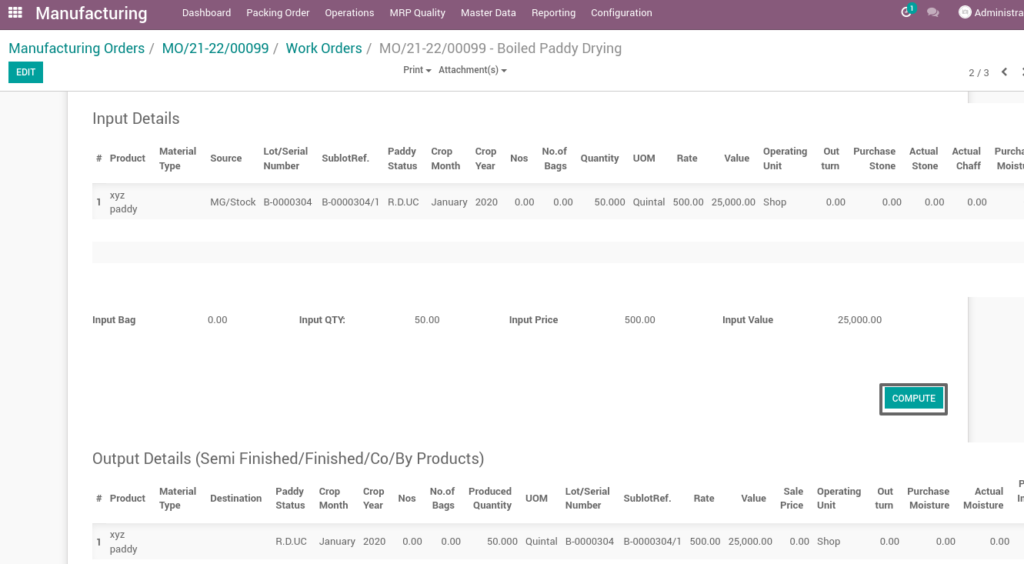

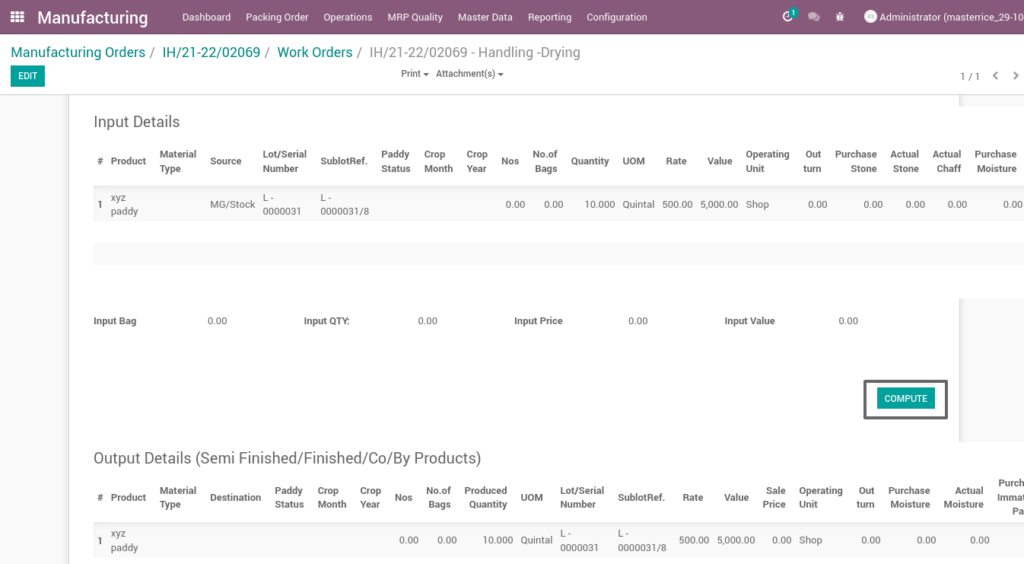

8. Compute work order

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process manufacturing of boiled paddy drying.

Field Description

- Compute – Click on compute button to compute input and output details

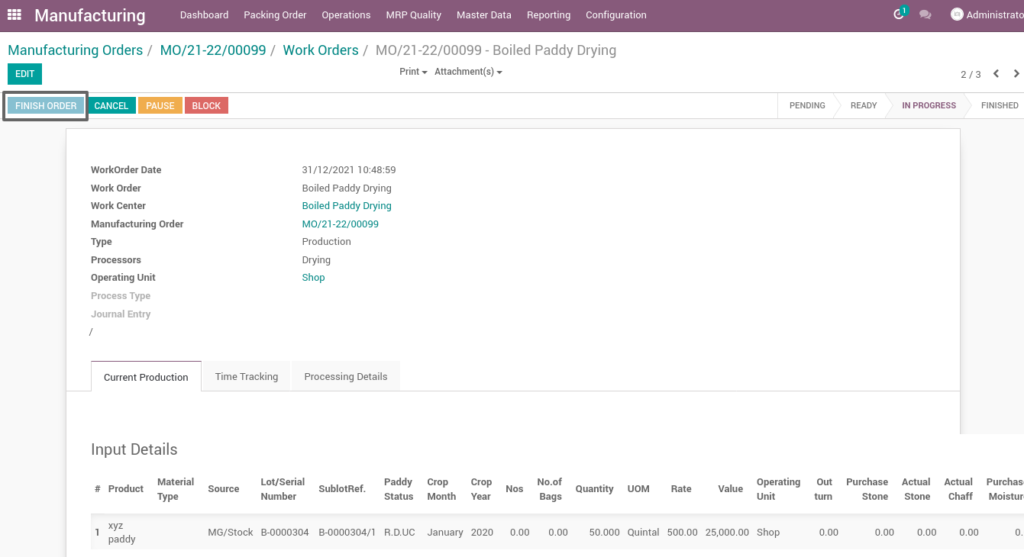

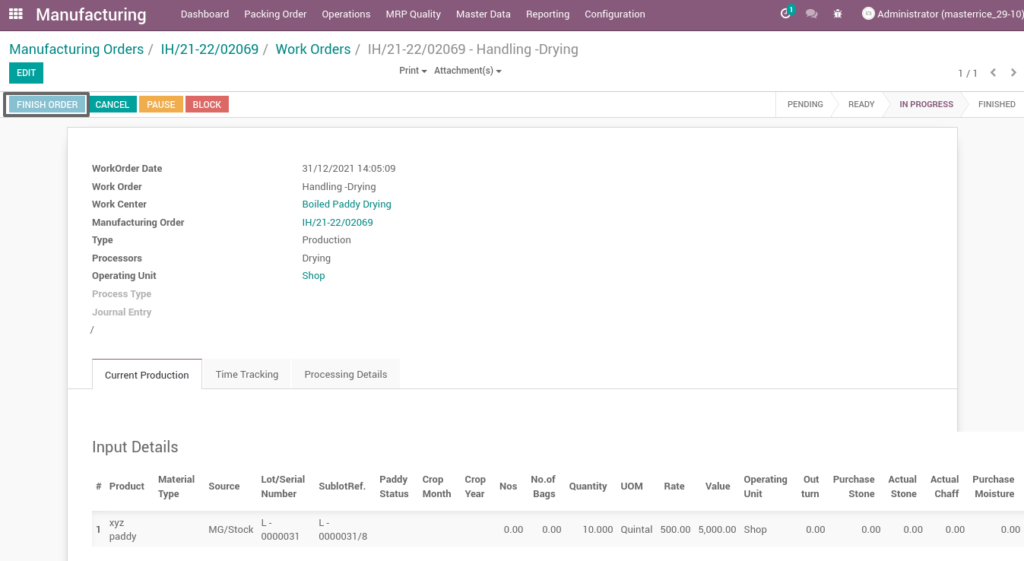

9. Finish process

After compute process, check on boiled paddy drying of the product and click finish order, then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

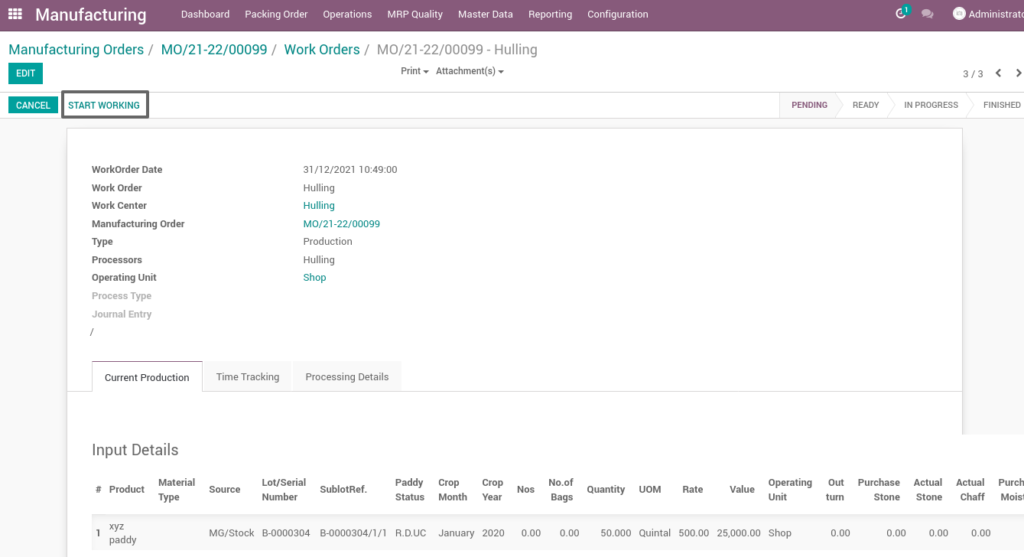

10. Start work order – Hulling

Hulling is the process of removing the chaff (the outer husks) of grains of rice, and it converted into finished rice product.

Field Description

- Start working – Click on start work order button to start the process of work order

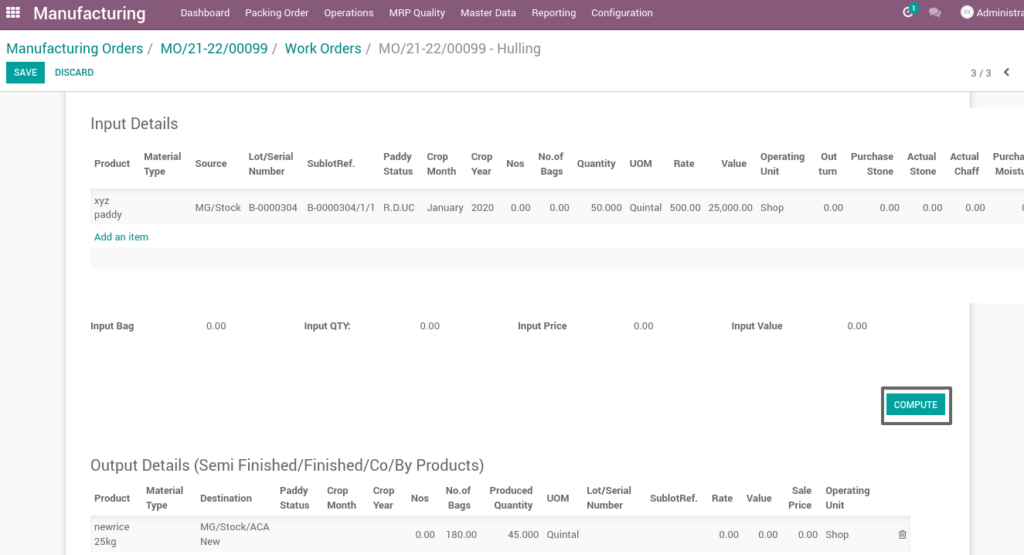

11. Compute work order

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process manufacturing of hulling.

Field Description

- Compute – Click on compute button to compute input and output details

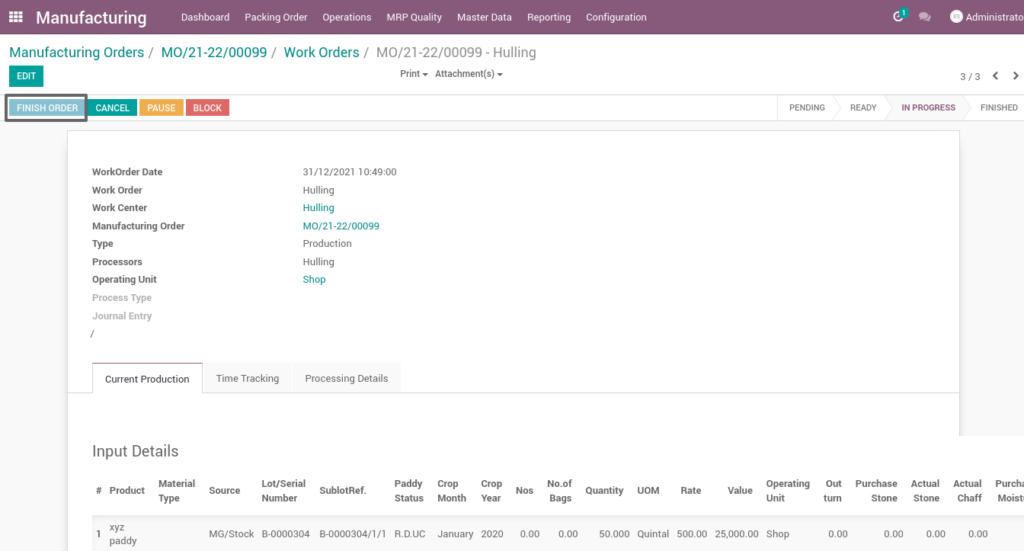

12. Finish work order

After compute process, check on hulling of the product and click finish order then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

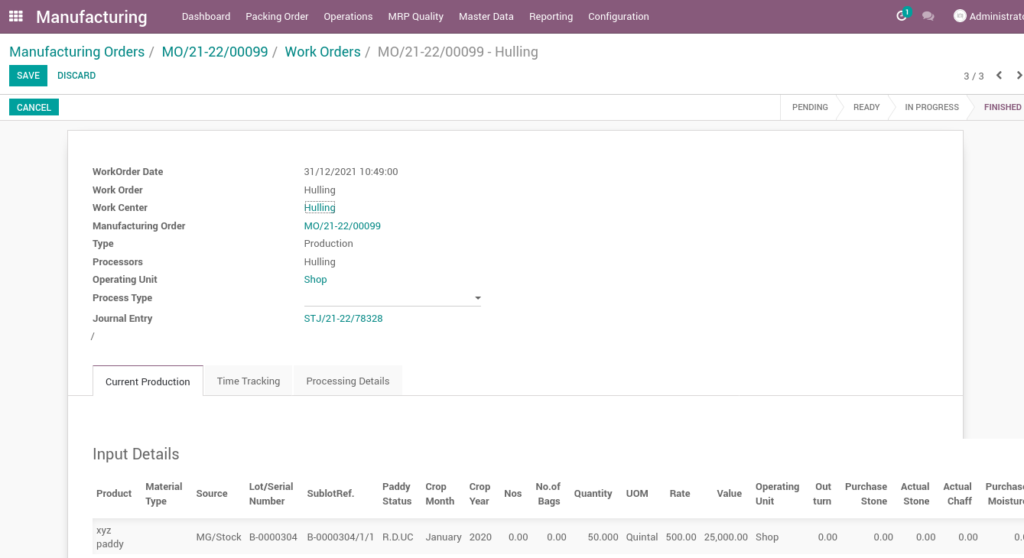

13. Work order

Here shows the finished work order of hulling from manufacturing process. State is changed in progress state into finished state.

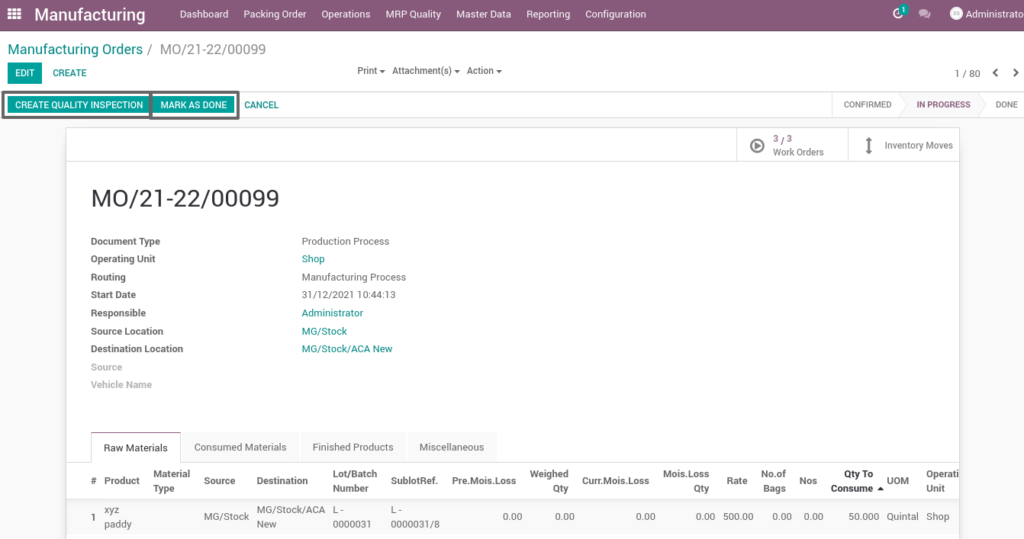

14. Validation

Validation is the process of check quality parameters of converted paddy into finished rice product.

Field Description

- Create quality inspection – Click on create quality inspection button to create the quality inspection

- Mark as done – Click on mark as done button to complete the process(state-done)

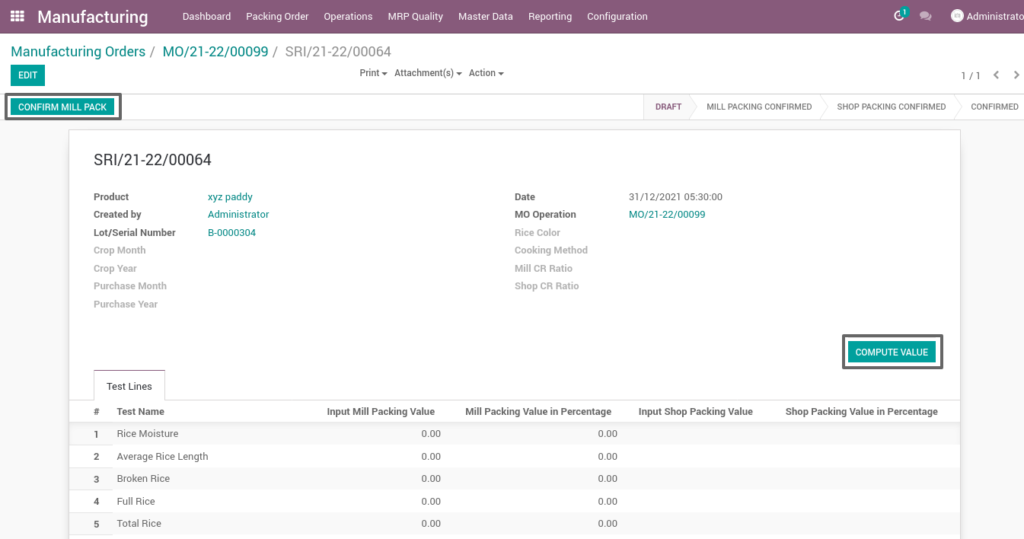

15. Quality inspection compute

Field Description

- Confirm mill pack – Click on confirm mill pack button to confirm the mill packs

- Compute value – Click on compute value button to compute values

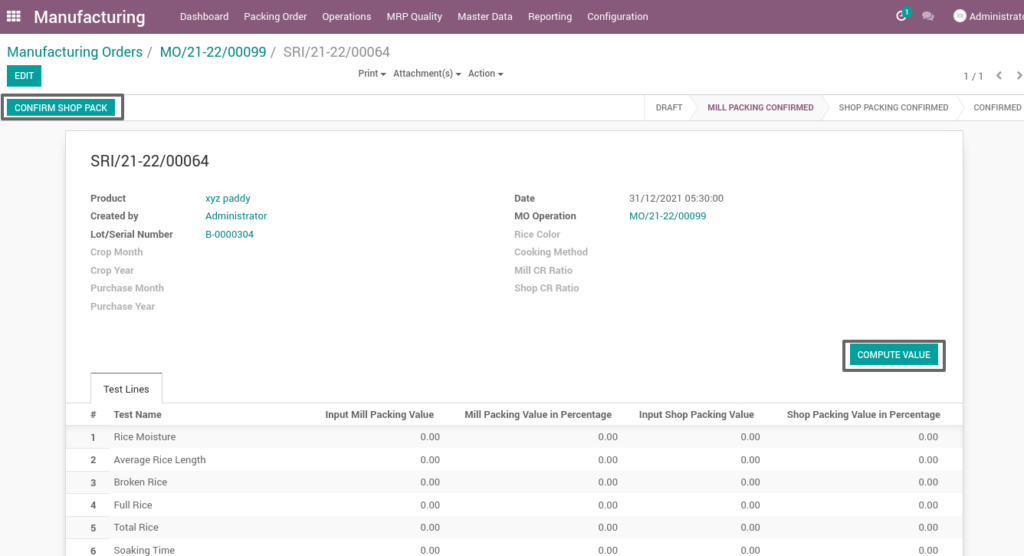

16. Quality inspection compute

Field Description

- Confirm shop pack – Click on confirm shop pack button to confirm the shop packs

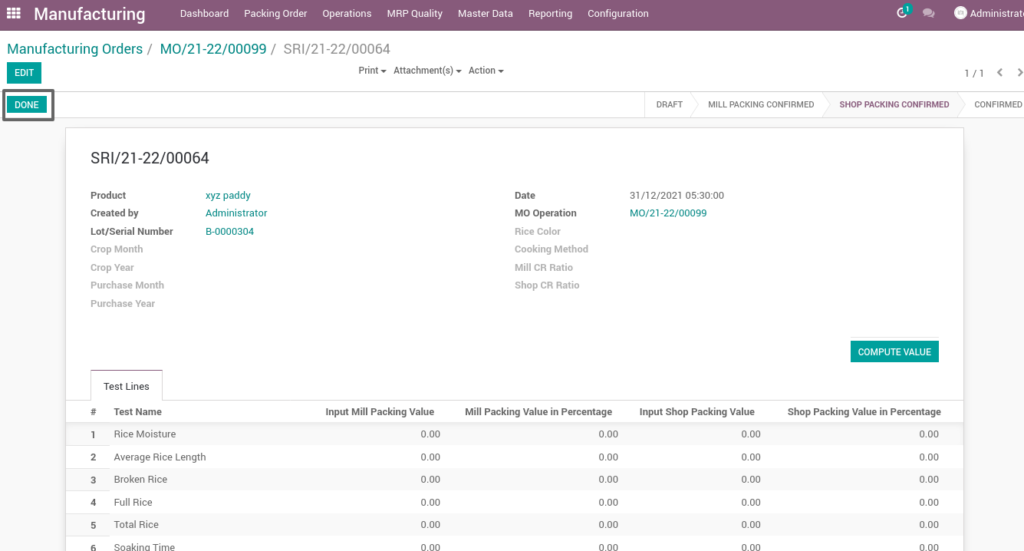

Quality inspection

- Done – Click on done button to complete the process

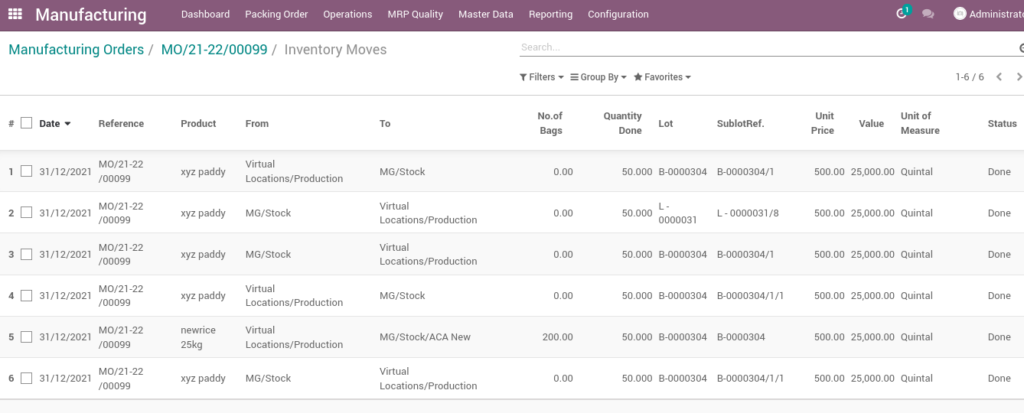

17. Inventory moves

A stock move is a movement of any particular product from a source location to a destination location, a stock move is a collection of stock move lines. Records are not saved as stock input, output, or transformation; instead, all operations are stock moves between locations.

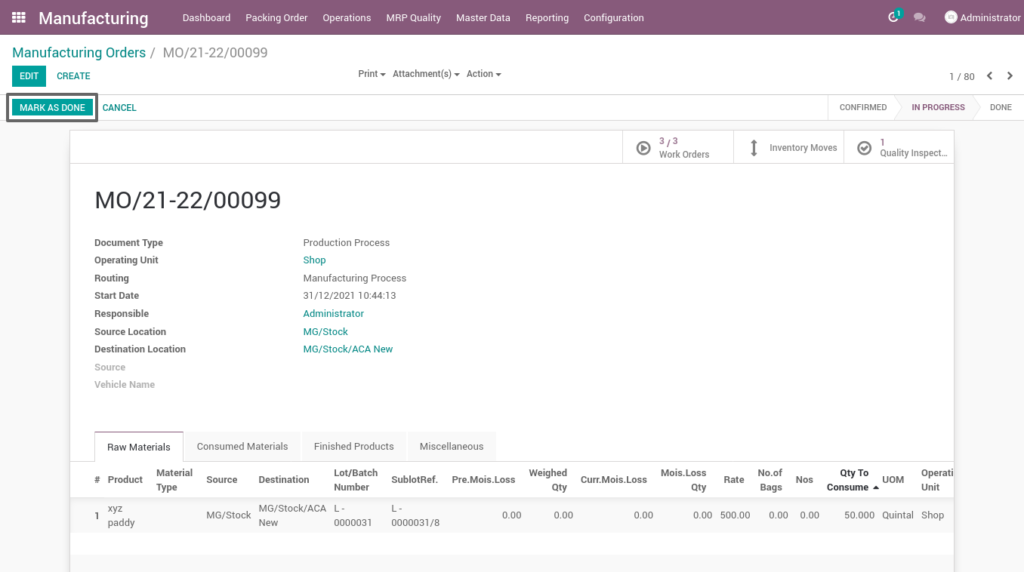

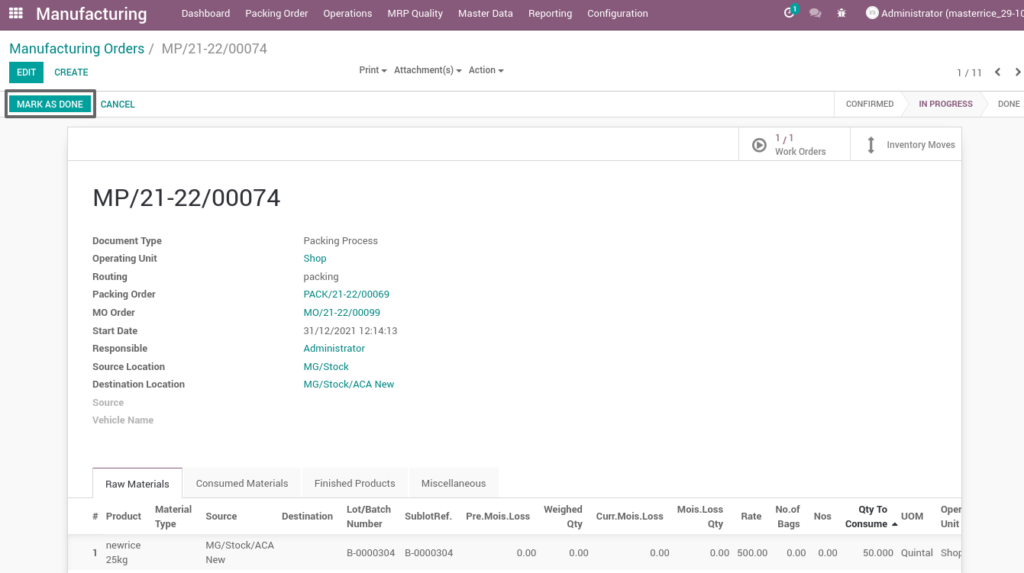

18. Work order – mark as done

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

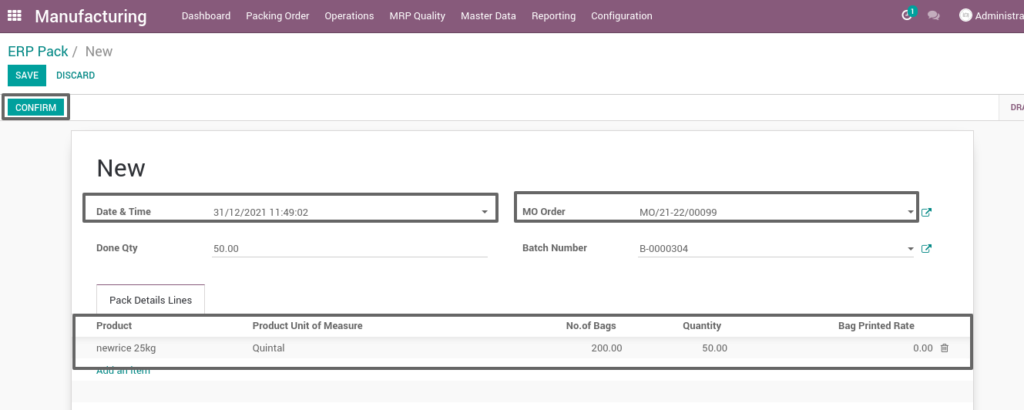

19. Creation of ERP packing request

Packing is the process to sell out the same product in distinctive quantity and allocate a group of products to a package, thus simplifying the sales and the delivery operations of the company.

Field Description

- Date & time – Select the date and time for packing(mandatory)

- Mo order – Select mo order field for packing request based on manufacturing order(mandatory)

- Product – Add one or more products for processing

- No.of.bags – Choose no of bags to process quantity

- Quantity – Enter the required product quantity

- Confirm – Click on confirm button to create work order

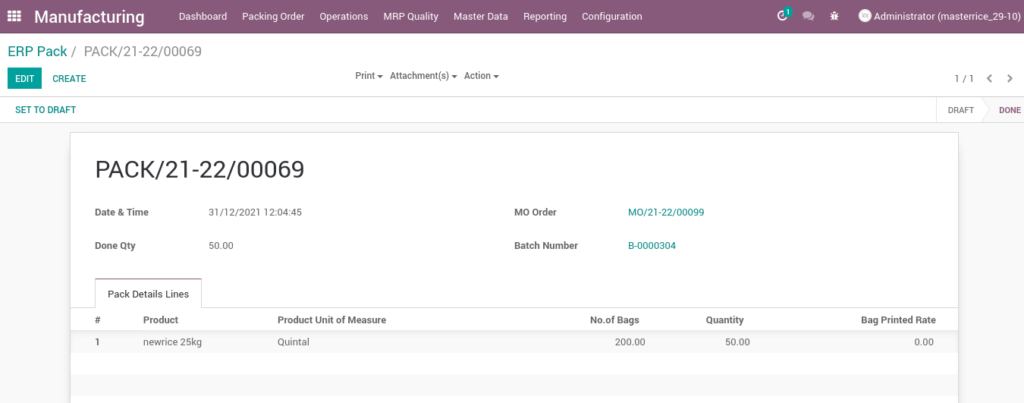

20. ERP packing request order

Packing request order is created to pack the product in the required quantity.

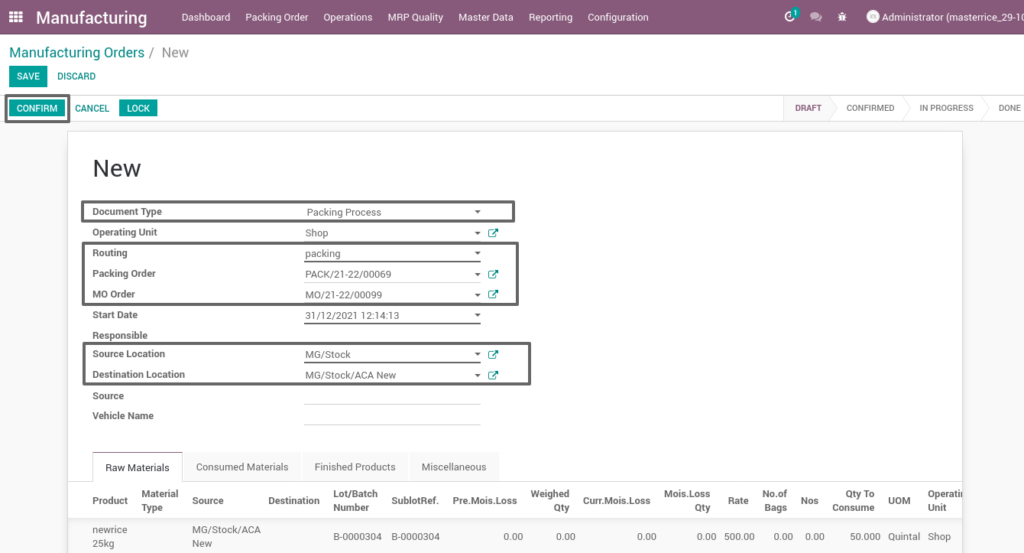

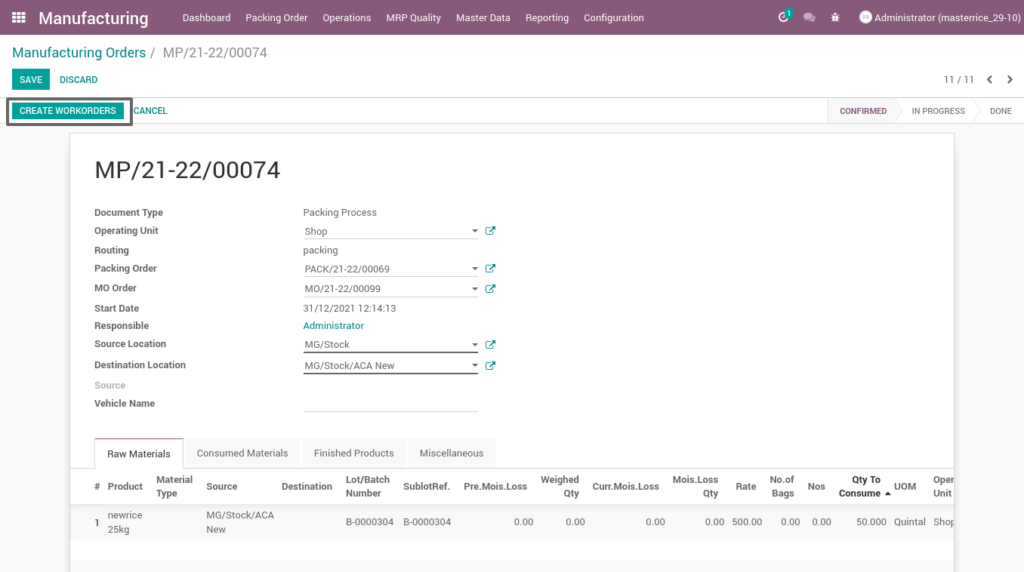

21. Packing creation

Packing is created by using the manufacture order , assign source and destination of the product for packing process.

Field Description

- Document type – Select the document type (i.e. Inventory process, production process, move request, etc., ) (mandatory)

- Routing – Select routing for which to create the new manufacturing order(i.e. Manufacturing process, packing, immature paddy drying, etc., )(Mandatory)

- Packing order – Select packing order number for packing based on packing request(mandatory)

- Mo order – Select mo order field for packing based on manufacturing order(mandatory)

- Source location – Choose the data for input location

- Destination location – Choose the data for output location

22. Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

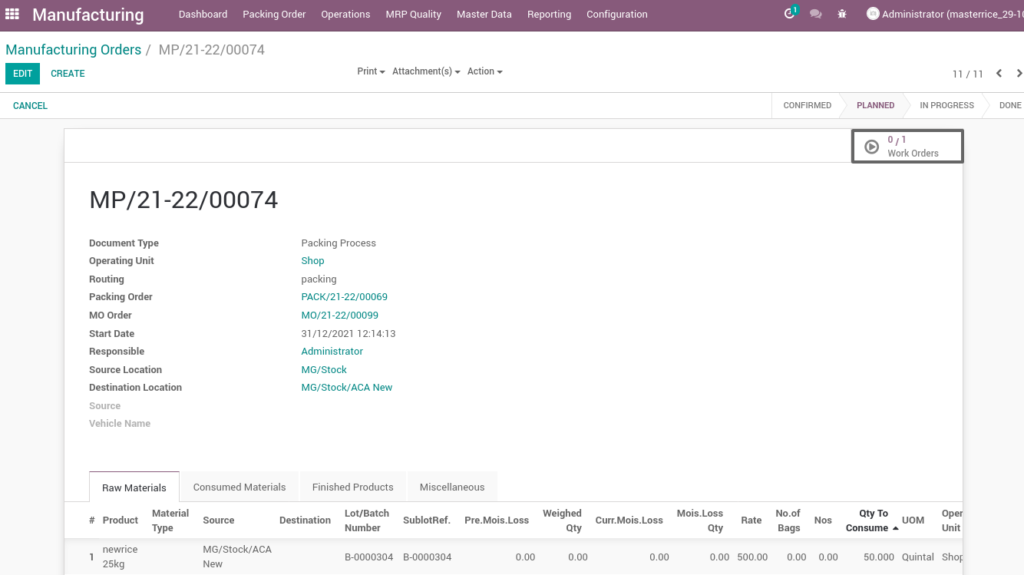

23. Open work order

Open work order to view the work order process of the packing process. It displays a well-defined layout of work order with entry details and input output session.

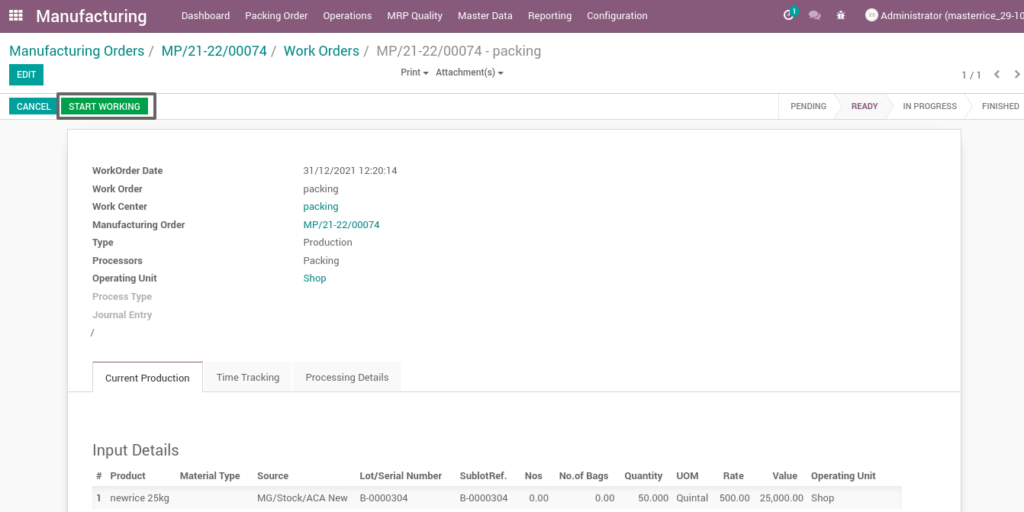

24. Start work order process

By clicking “start working” button, the work order of packing is start. It shows input and output details of the packing.

Field Description

- Start working – Click on start work order button to start the process of work order

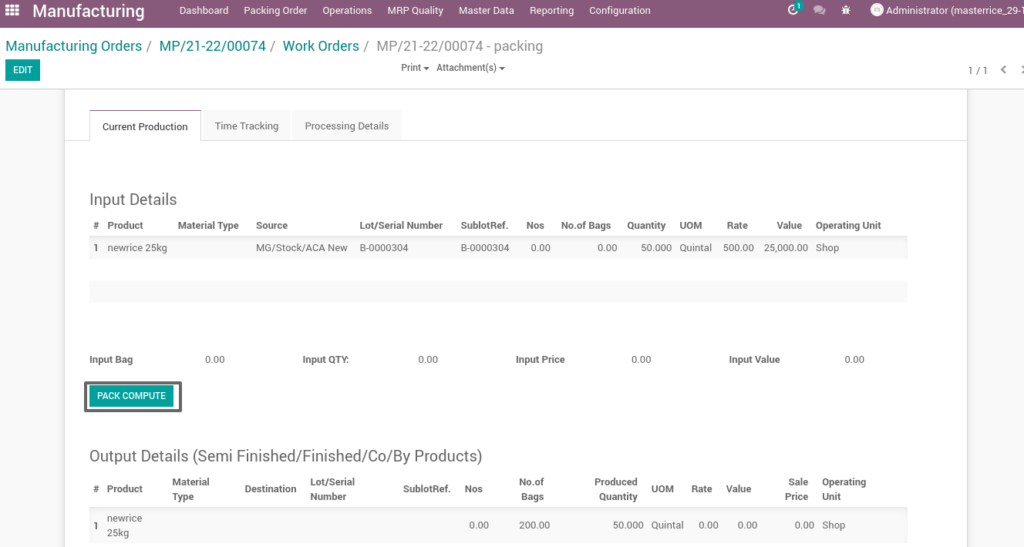

25. Compute work order

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process packing.

Field Description

- Pack compute – Click on compute button to compute input and output details

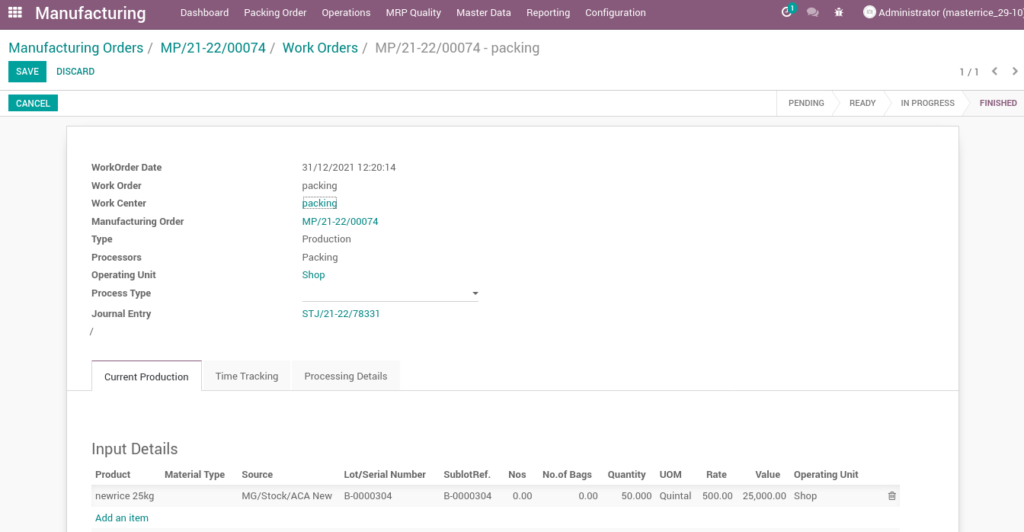

26. Finished work order

Here shows the finished work order of packing. State is changed in progress state into finished state.

27. Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of packing is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

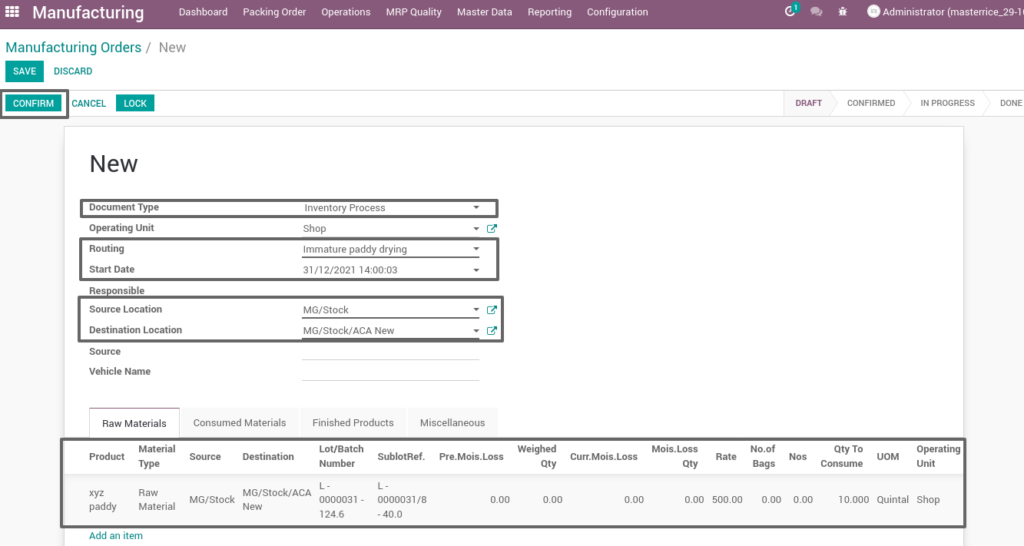

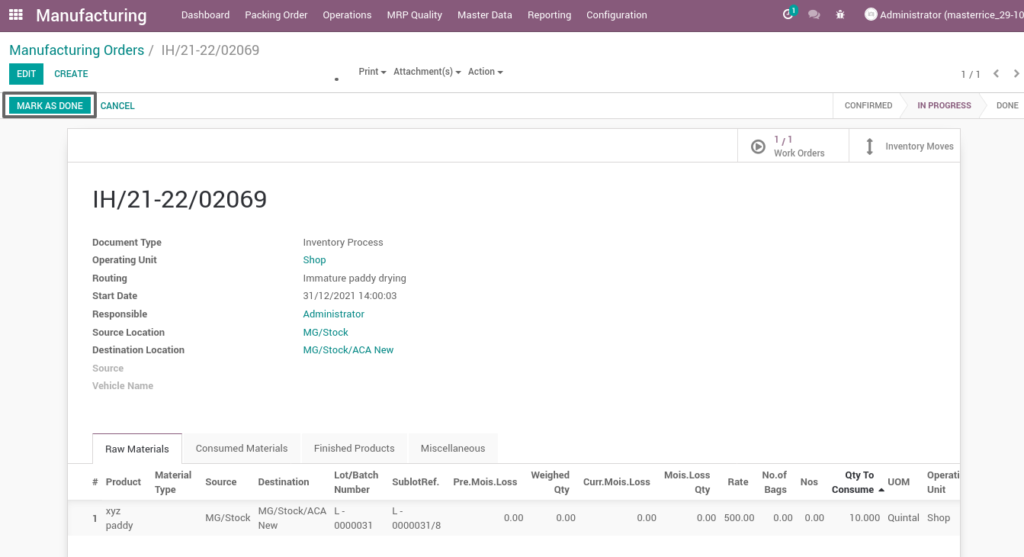

28. User scenario – Manufacturing process

Immature paddy will produce high percentage of broken rice, poor grain quality and to cure that drying process which dry and remove the broken rice and increase good grain quality.

Field Description

- Document type – select the document type (i.e. Production process, move request, etc., ) (mandatory)

- Routing – select routing for which to create the new manufacturing order(i.e. Manufacturing process, packing, immature paddy drying, etc.,)(Mandatory)

- Source location – choose the data for input location

- Destination location – choose the data for output location

- Product – add one or more products for processing

- Lot/batch number – select lot no for chosen product

- Sub lot – select sub lot no for chosen lot no

- No.of.bags – choose no of bags to process quantity

- Quantity – enter the required product quantity

- Confirm – Click on confirm button to create work order

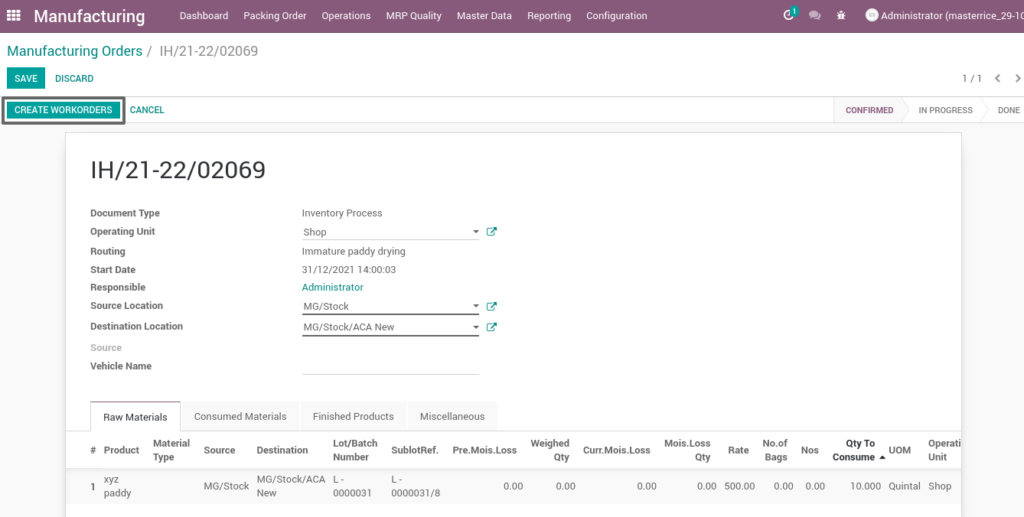

29. Create work order

Create a work order by clicking “create work orders” button and update start date and enter the source location, destination location and quantity to consume.

Field Description

- Create work order – Click on create work order button to create work order

30. Start work order process – boiled paddy drying

Boiled paddy drying is a process that reduces grain moisture content to a level where it is safe for storage, making it the most critical operation after harvesting a rice crop.

Field Description

- Start working – Click on start work order button to start the process of work order

31. Compute work order

By clicking “compute” button, some calculated fields in output will be updated based on the calculations given. It also compares a set of fields which are mandatory in output and shows warning if they are not updated. It shows input and output details like input value, input quantity, input and output price where input and output details must be as per the predefined rules, which process of boiled paddy drying.

Field Description

- Compute – click on compute button to compute input and output details

32. Finish work order

After compute process, check on boiled paddy drying of the product and click finish order ,then work order set to be completed.

Field Description

- Finish order – Click on finish order button to complete the work order

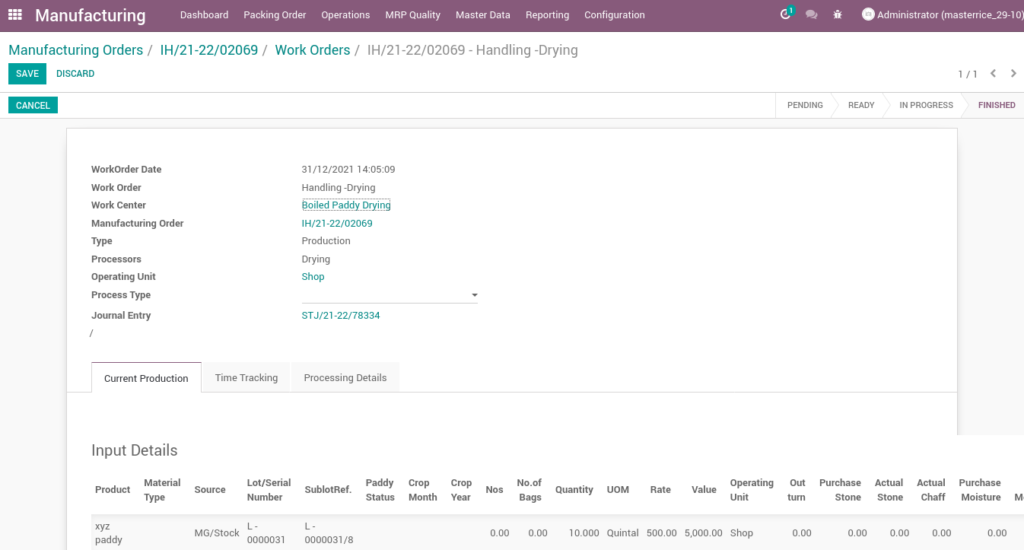

33. Work order

Here shows the finished work order of boiled paddy drying from manufacturing process. State is changed in progress state into finished state.

34. Work order – mark as done

Work order is finished the process then click on mark as done which shows the work order of immature paddy drying is done. State is changed in progress state into done state.

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

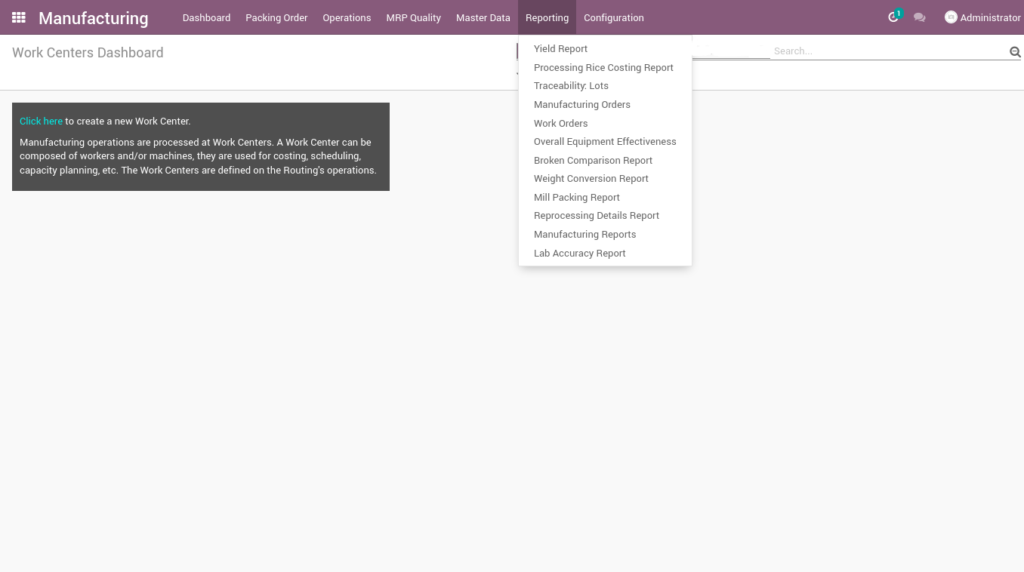

35. Manufacturing Reports

It is a document that helps a business to monitor the sales performance for a fixed period of time. A manufacturing report can be generated for a week, month, or year.

Go to Manufacturing → Click on Reporting menu

Field Description

- Mark as done – Click on mark as done button to complete the process(state-done)

User scenario:

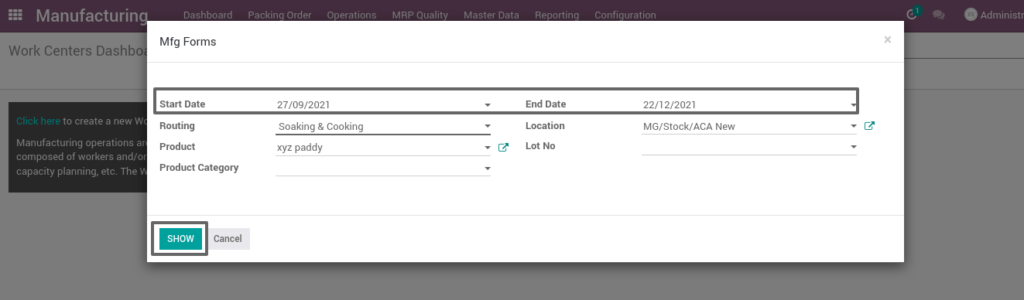

36. Manufacturing Report

Go to Manufacturing → Click on Reporting menu → Manufacturing report

Field description

- Date from: choose the start date from which the data has to be extracted (mandatory)

- Date to: choose the end date up to which the data has to be extracted (mandatory)

- Routing: select a routing to fetch the data for a particular routing

- Location: select the type of location to view the report of particular location

- Show: click on show button to view the report

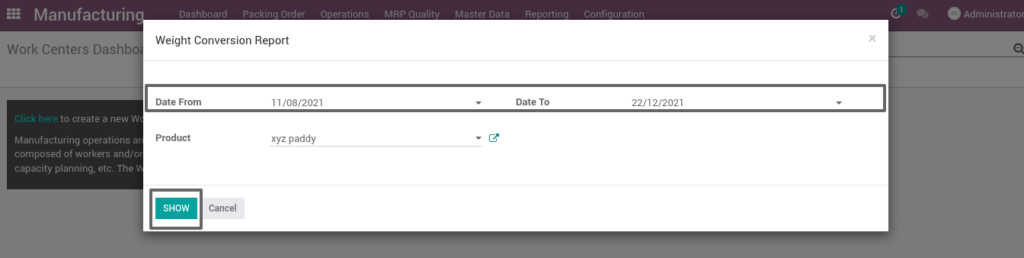

37. Weight Conversion report

Go to Manufacturing → Click on Reporting menu → Weight conversion report

Field Description

- Date from: choose the start date from which the data has to be extracted (mandatory)

- Date to: choose the end date up to which the data has to be extracted (mandatory)

- Product: select the type of product to view the report of a particular product

- Show: click on show button to view the report

-

Pingback: 10 Tips to Choose the Right ERP for Your Rice Mill Industry - TenthPlanet Technologies