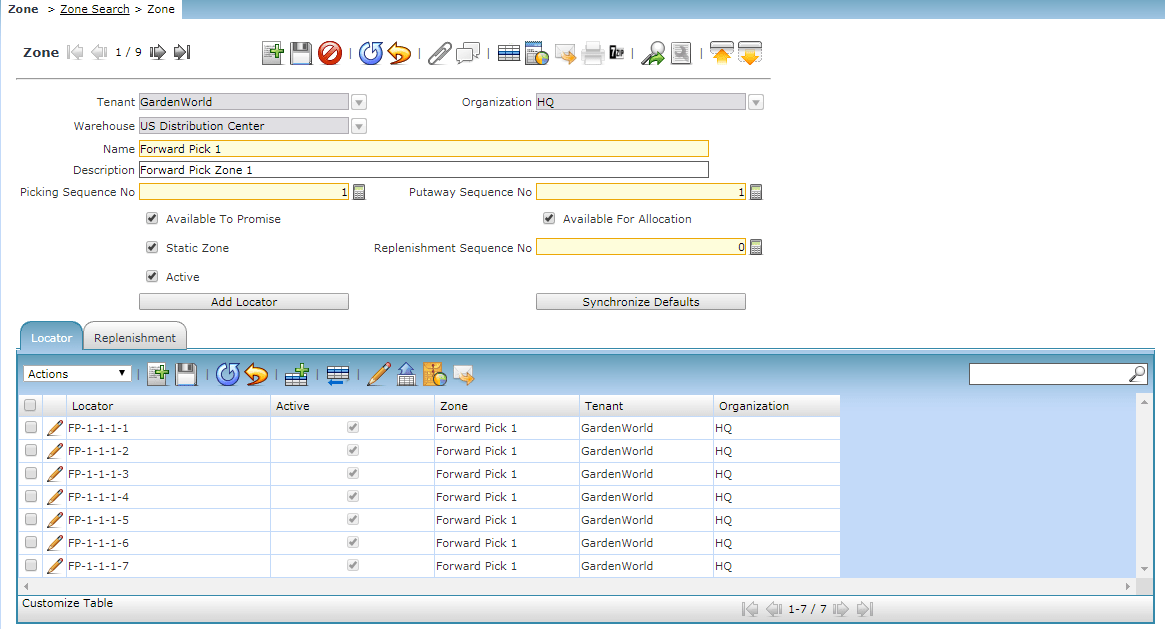

Zones

Zones are a grouping of locators. The Zone definition is not mandatory unless transactions requiring zones need to be performed.

![]()

Ware House Management-->Ware House Management Setup--> Zone

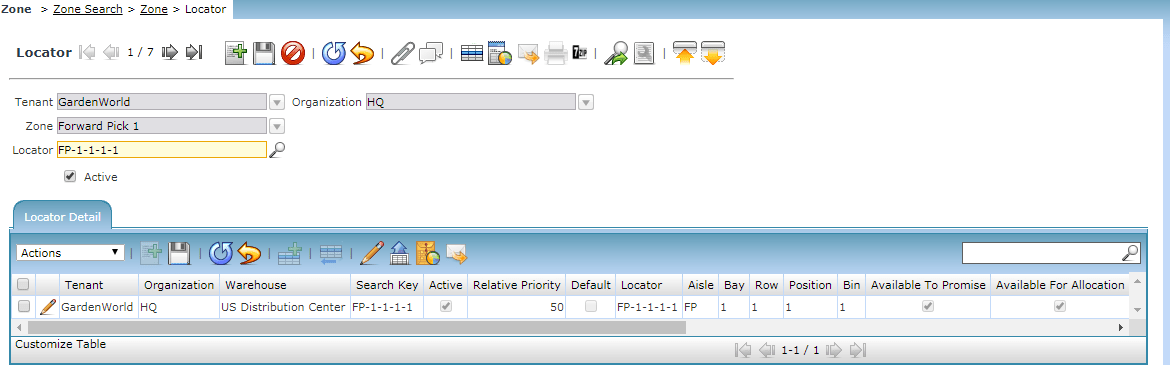

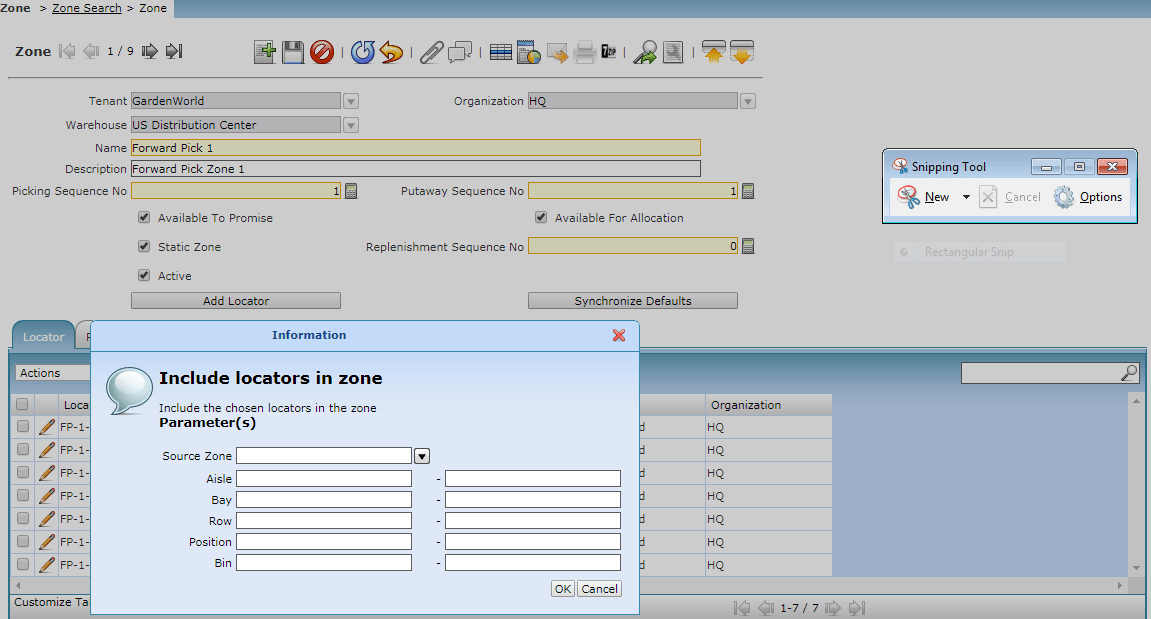

It is possible to add the locators manually in the zone screen. A button Add locator is available on the Zone screen to allow automation inclusion of locators into the zone.

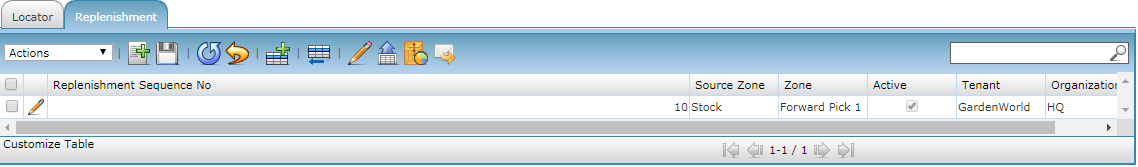

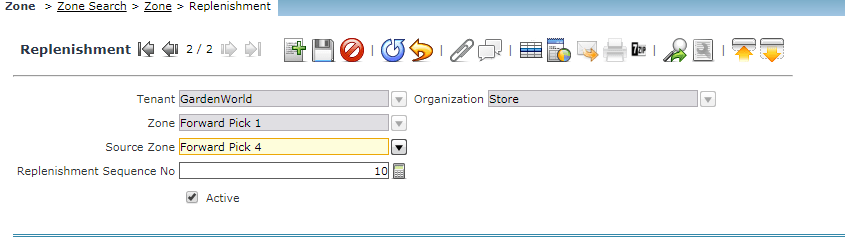

Locators in a Zone can be Replenishment from locators in a different zone when the quantity of a product in a locator falls below its minimum stocking quantity. Two type Zones can be defined

- Static Zone: These Zones are used for Replenishment Purpose.

- Non Static Zones: These are floating zones, they can have overlapping locators with other zones.

Compiere Warehouse Management Execution Steps

- Go to the “Warehouse Management Rule” window and setup putaway and allocation/picking rules.

- Go to the “Warehouse Management Strategy” window and create strategies and place the rules created you want them to be executed.

- Go to the “Warehouse Management Workbench” window and create strategy sets by placing the strategies created in step 2 in the sequence you want them to be executed

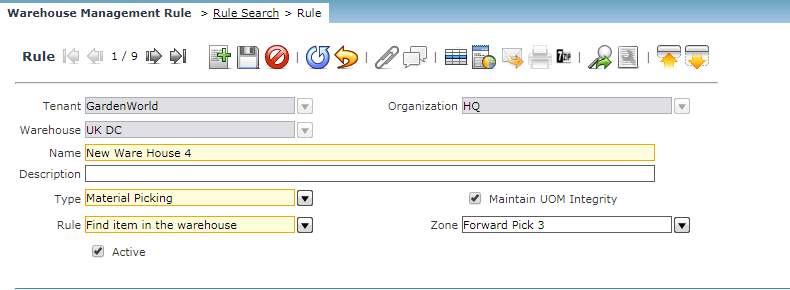

Warehouse Management Rule

Warehouse Management-->Warehouse Management Setup-->Warehouse Management Rule

We can set up the allocation and the picking rules on this particular screen. STK zone putaway – same product.

Rules for the Putaway Sequence.

- To find a Fixed Locator in a Warehouse eg: FP zone 1 putaway – fixed locator

- To find a fixed Locator in a Zone eg: Allocate from FP zone 2

- To find a non-static locator in the warehouse with the same product

- To find a non-static locator in a zone with the same product eg: SP zone putaway – same product

- To find any empty non-static locator in the warehouse

- To find any empty non-static locator in a zone

- To find any locator with available capacity in the warehouse

- To find any locator with available capacity in the zone

- To find any locator with available capacity in a zone

Put away and Allocation/Picking

At the rule level, we can select the flag to Maintain UOM Integrity. This will control the handling of the Unit of Measurement during pick away and allocation/Picking.

If Maintain UOM integrity is checked, the allocation of product picking is done in multiples of the picking UOM of the locator. For eg: if the stocking UOM of the locator is 10 pack then the rule has Maintain UOM integrity checked. Then only product receipts with a UOM of 10-pack can be put away into that locator.

If Maintain UOM Integrity is checked, allocations of products for picking are done in multiples of the picking UOM on the locator. For eg: if the picking UOM of a locator is 10-pack and the required quantity on the sales order is 40 Eaches, and the rule has maintained UOM integrity checked, the system will allocate 1 4-packs from this locator.

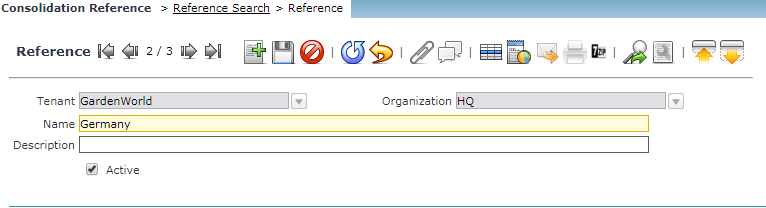

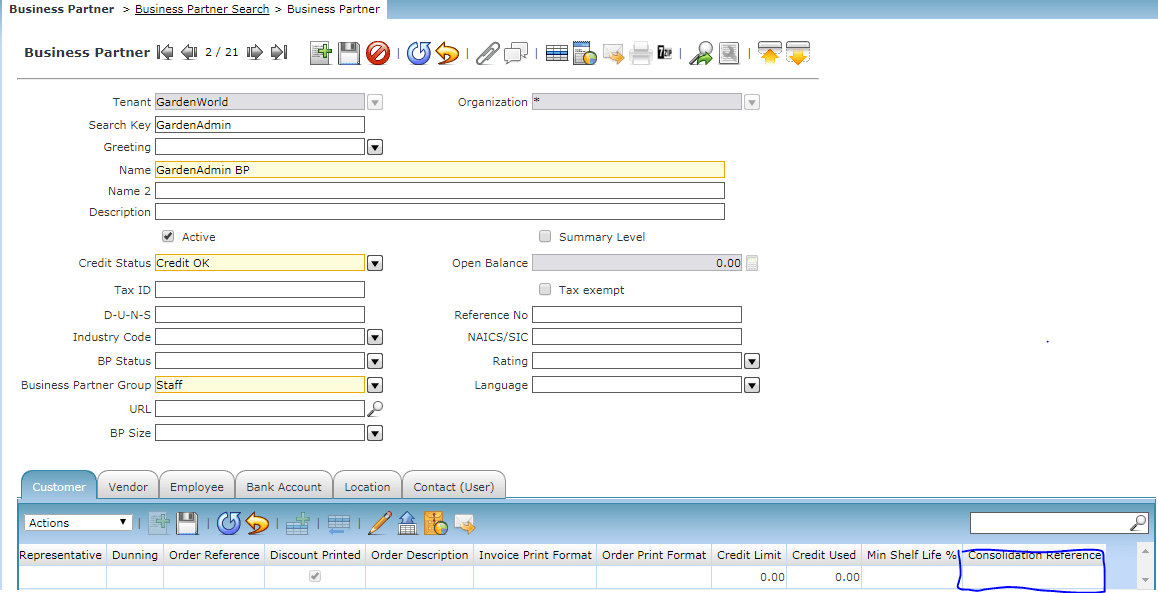

Consolidation Reference

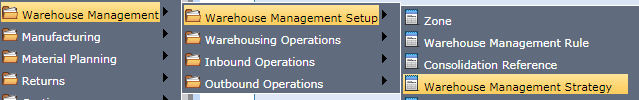

Warehouse Management-->Warehouse Management Setup-->Consolidation Reference

Sometimes shipments may need to be consolidated. For example, a number of shipments with a common country of destination may be consolidated on a single palette and then shipped.

You can create a Consolidation Reference to represent such consolidations.

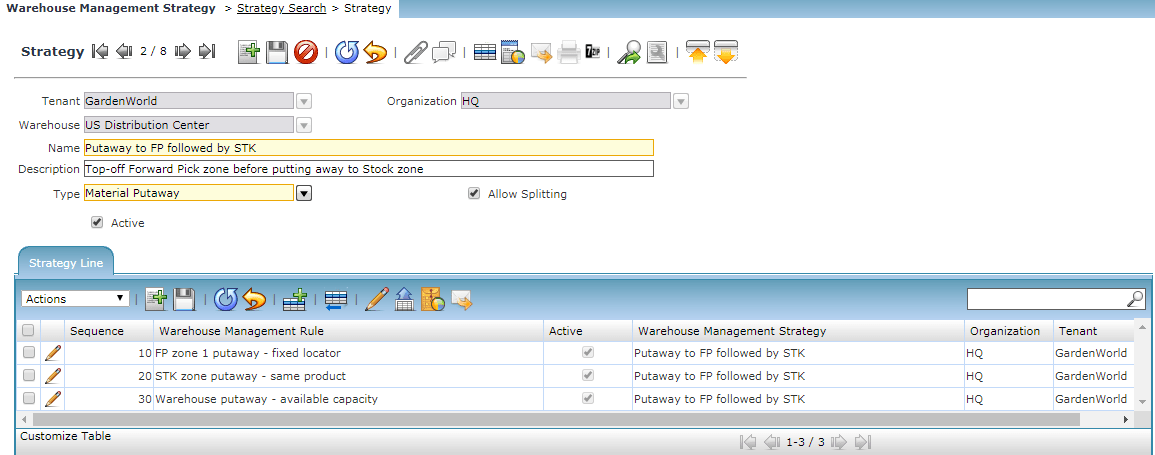

Warehouse Management Strategy

A strategy is a collection of rules that are laid out in sequence for execution one after the other.

Warehouse Management-->Warehouse Management Setup-->Warehouse Management Strategy

We can set up a Putaway and Allocation/Picking Strategies. eg: Top of forwarding pick zone before putting away to the stock zone.

We can select a flag Allow Splitting

Putaway: If Allow Splitting is checked, a certain quantity of a product in the receipt UOM cannot be putaway entirety into a single locator with the same stocking UOM, the system will split the quantity of the product in multiples of the receipt UOM and attempt to find another locator with the same stocking UOM as the receipt UOM.

For example, if 6 7-packs of a product were received and only 4 7-packs can be put away into a locator with a stocking UOM of 7-pack, the system will attempt to find another locator with a stocking UOM of 7-pack for the remaining 2 7-pack of this product.

If Allow Splitting is unchecked, the system will attempt to find a single locator that has the same stocking UOM as the receipt UOM that can stock the quantity of the product.

Allocation/Picking: After orders have been selected for release and prioritized for allocation, the rules engine makes the allocations. If Allow Splitting is checked, a certain quantity of a product cannot be allocated in the picking UOM setup on the locator, the system will split the quantity up to the quantity available in multiples of the picking UOM in this locator and then attempt to find another locator for the remaining quantity.

For example, if the picking UOM defined for a locator was 6-pack and 20 Eaches (ideally 3 6-packs and 2 Eaches) of a product existed in it and if the sales order required 20 Eaches of the product, the system will allocate 3 6-packs (18 Eaches) from this locator and move on to a different locator to allocate the remaining 2 Eaches.

If Allow Splitting is unchecked, the system will attempt to find a single locator from which the quantity of the product can be allocated.

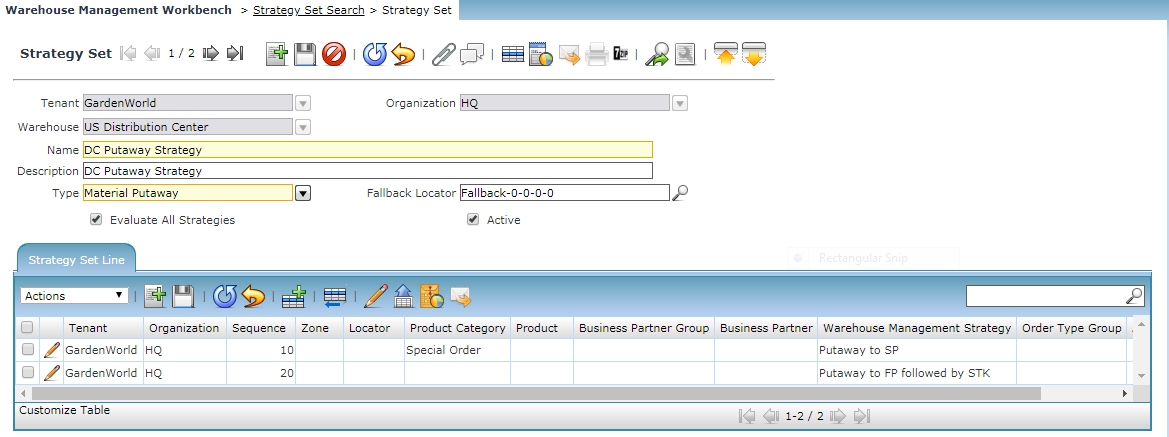

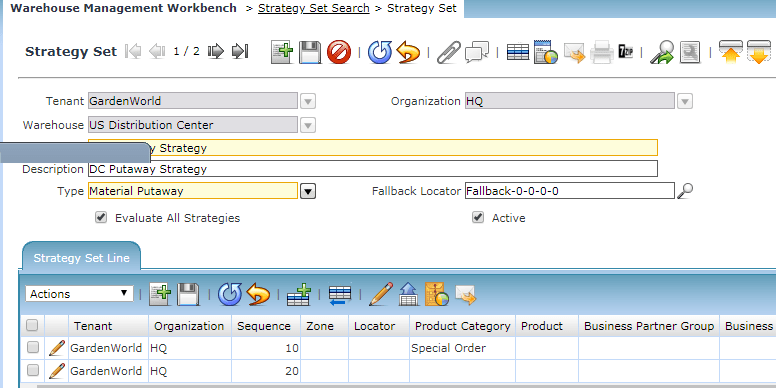

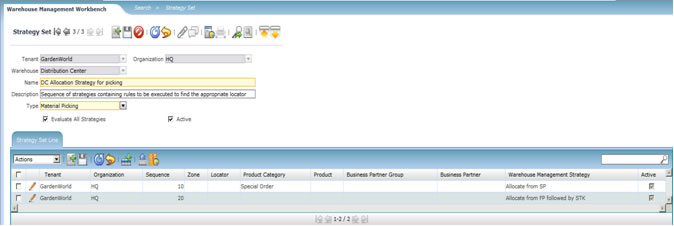

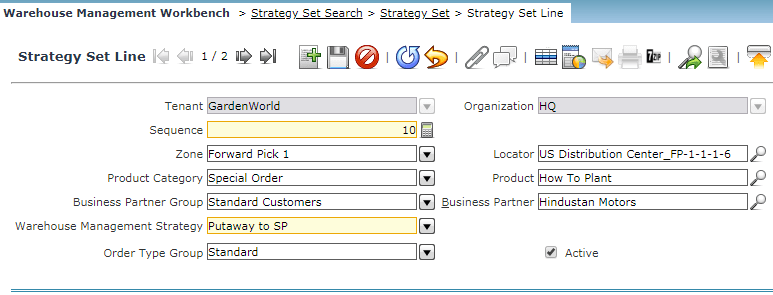

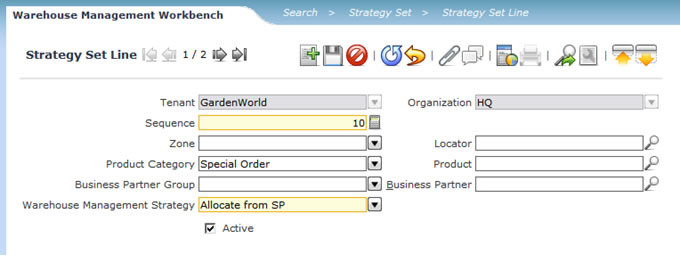

Warehouse Management Work Bench

Warehouse Management-->Warehouse Management Setup-->Warehouse Management Workbench

This is the screen where all the strategies are defined, consolidated and are used for the final execution in the WMS process.

Two types of strategies are defined on this screen.

Material Picking

Material Putaway

Strategy (set line) selection criteria

For each strategy, we would define selection criteria that would be used to select one strategy over the other when validated.

Putaway: Product, product category, source zone, source locator, business partner, business partner group

Picking/Allocation: Product, product category, destination zone, destination locator, business partner, business partner group.

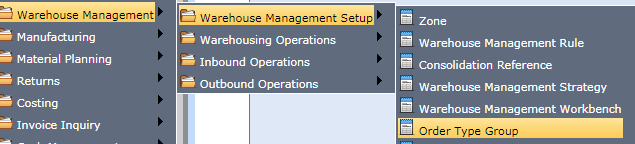

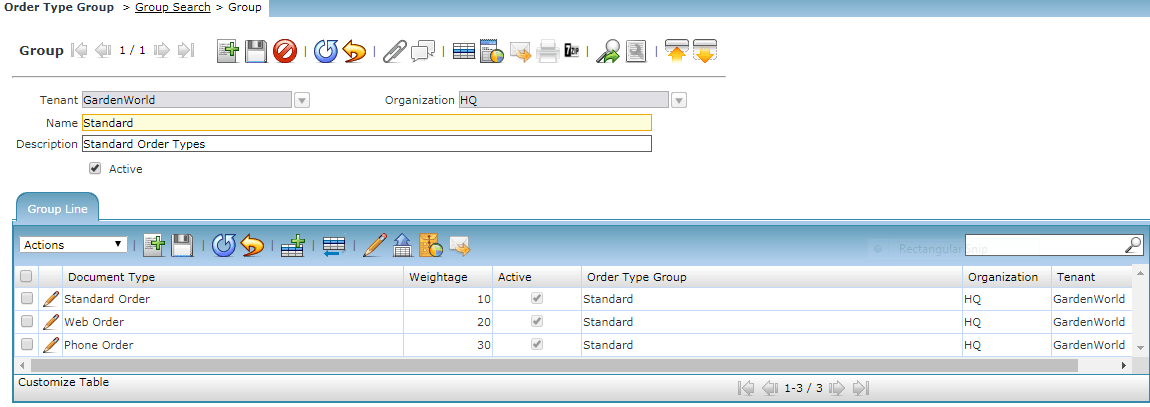

Order Type Group

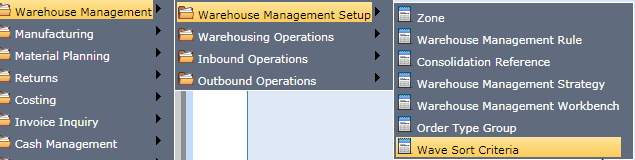

Warehouse Management-->Warehouse Management Setup-->Order Type Group

This screen where we can group the orders together. All order types within this Group are processed for ordering

We can provide Weightage for each order type in this group. During wave planning, if the wave sort criteria have weight as an option in it, the order lines are sorted by it. we will see the wave planning on the next screen.

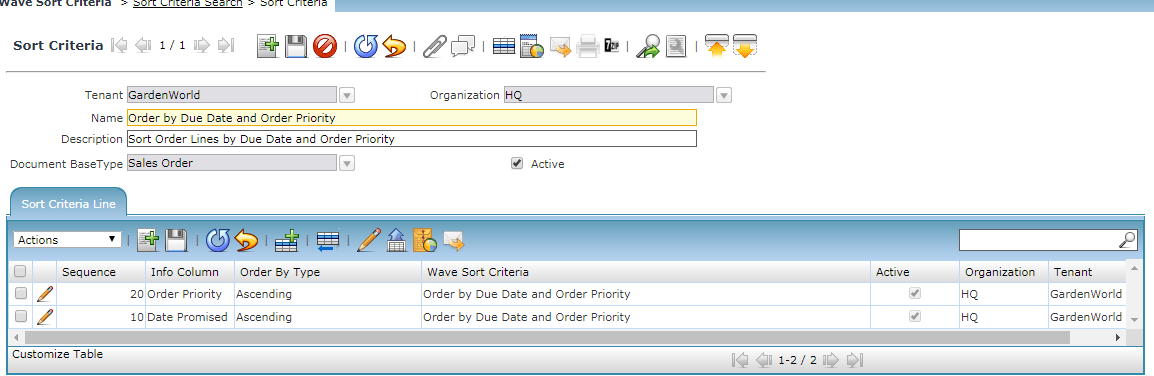

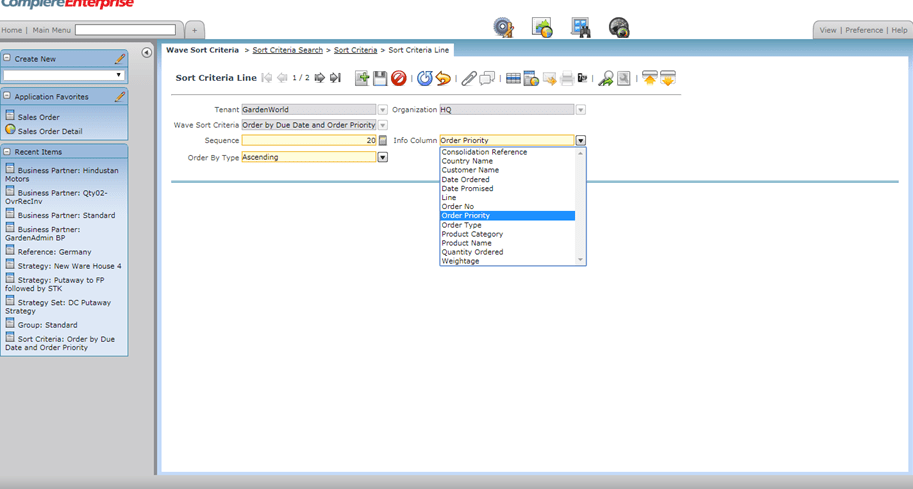

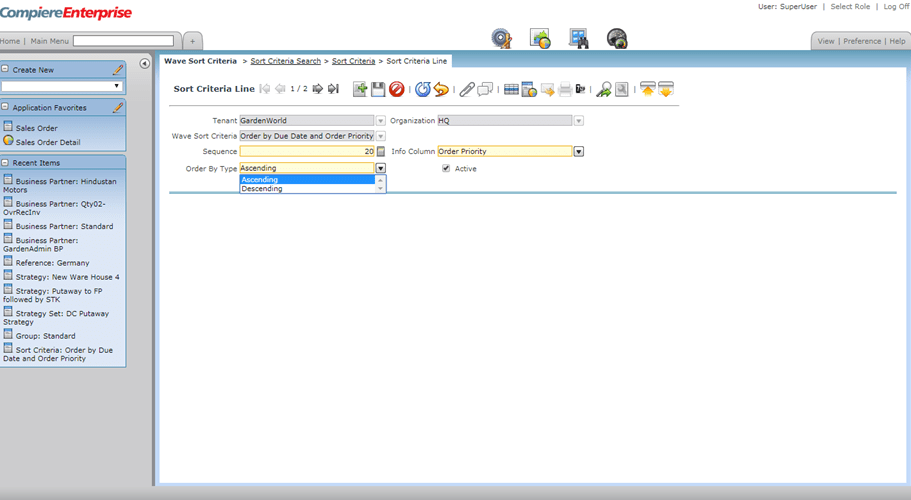

Wave Sort Criteria

Warehouse Management-->Warehouse Management Setup-->Wave Sort Criteria

We can create various combinations of sort criteria for order lines to be processed in a wave.

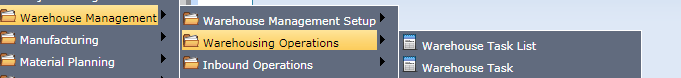

Warehouse Operations

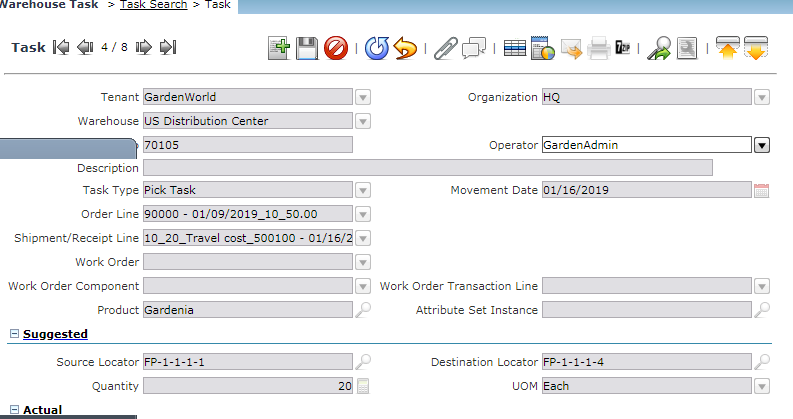

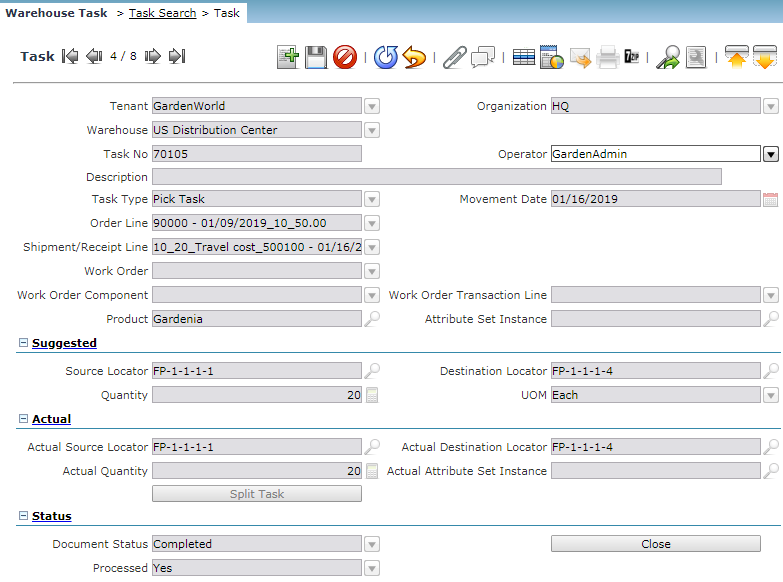

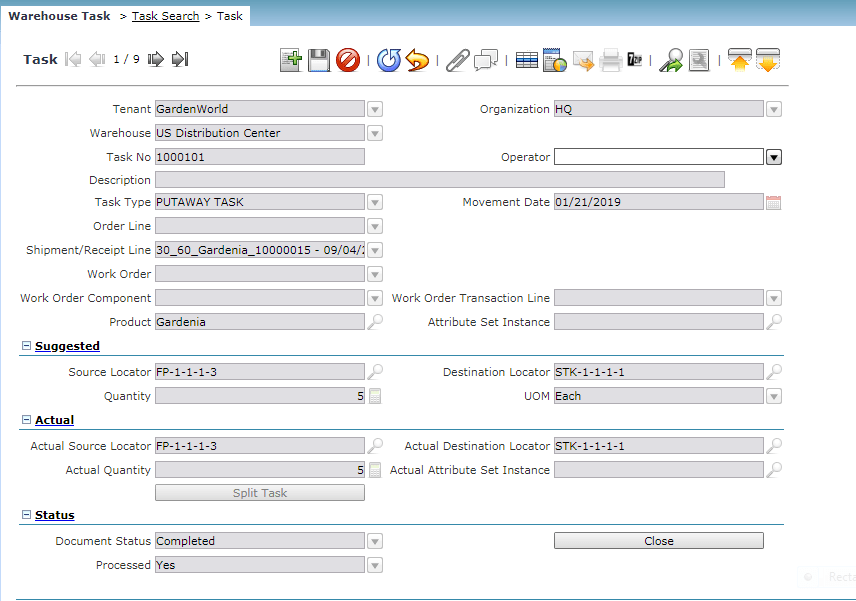

Warehouse Management-->Warehouse Operations-->Warehouse task, Warehouse Tasklist

Ware House Management generates three types of tasks

Inbound operations: putaway tasks are generated

Outbound operations: picking tasks are generated

Replenishment: Replenishment tasks are generated

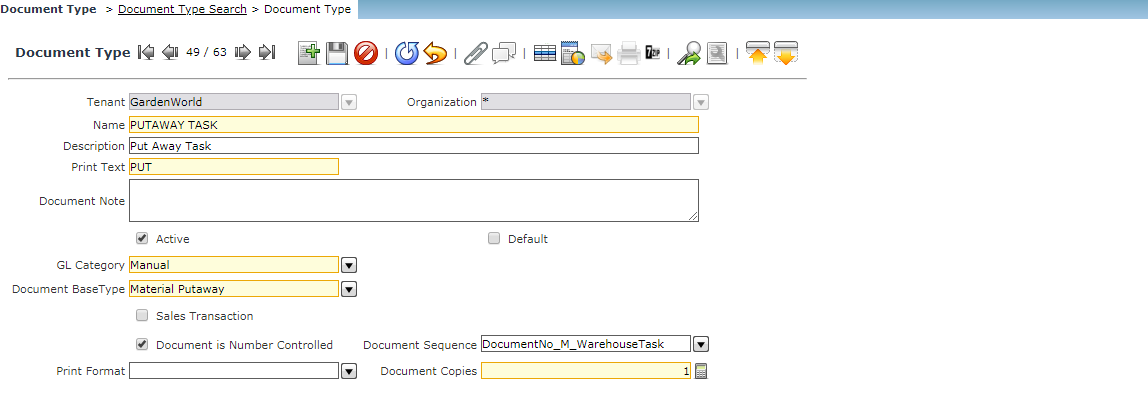

First Step is to create a Document type for Material Pick, Material Putaway and Material Replenish

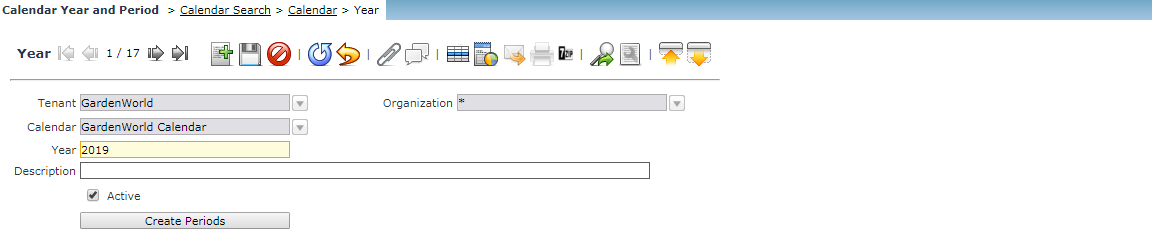

The second step is to create a Calendar Year period for the current year. The Calendar Year and the Period window allow you to define the Calendars that will be used for Reporting and Period Control. Each Tenant has one or more Calendars.

Each task is basically a move operation with a product, a source locator, a destination locator and the quantity to be moved and the UOM associated with the quantity. The document type will indicate whether the task is a putaway task, a pick task or a replenishment task. The Source Locator, Destination Locator, and Quantity fields are populated by the “Generate Putaway”, “Release Wave” and “Generate Replenishment” processes. These fields cannot be updated by the user. The movement quantity is derived from the actual quantity in the product UOM.

When a task is completed, the quantity entered is depleted from the source locator and added to the destination locator.

If the quantity entered is less than the actual quantity, then the additional allocated quantity needs to be unallocated.

If there is an open shipment for the order associated with the task, there will be a new line added to it for the order line. If there is no open shipment for the order, a new one will be created.

Tasks can be grouped into Warehouse Task Lists. Each task list is basically a group of tasks that can be printed and assigned to an operator.

Warehouse Task lists will be automatically generated as part of the “Generate Putaway”, “Release Wave” and “Generate Replenishment” processes. You can print/re-print these task lists.

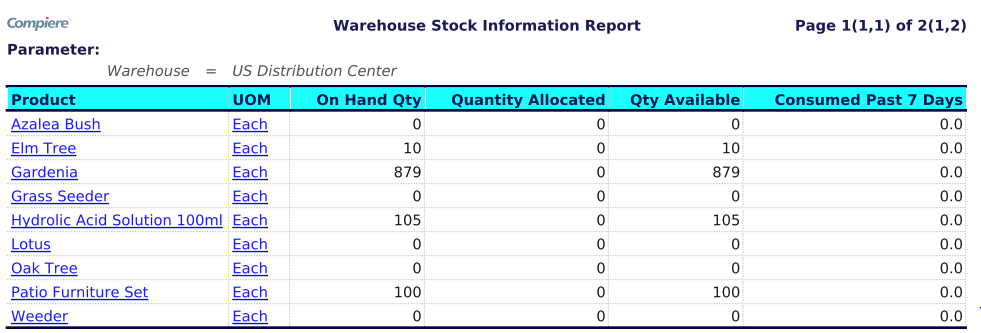

Ware House Stock report

Product, UOM, On hand quantity, Quantity allocated, Quantity Available, Consumed Past 7 days.

Print Address Labels

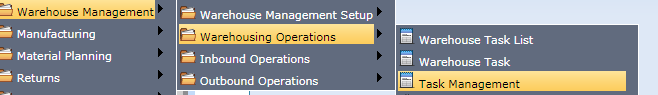

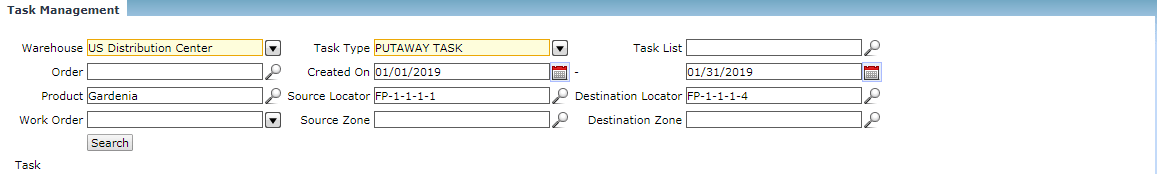

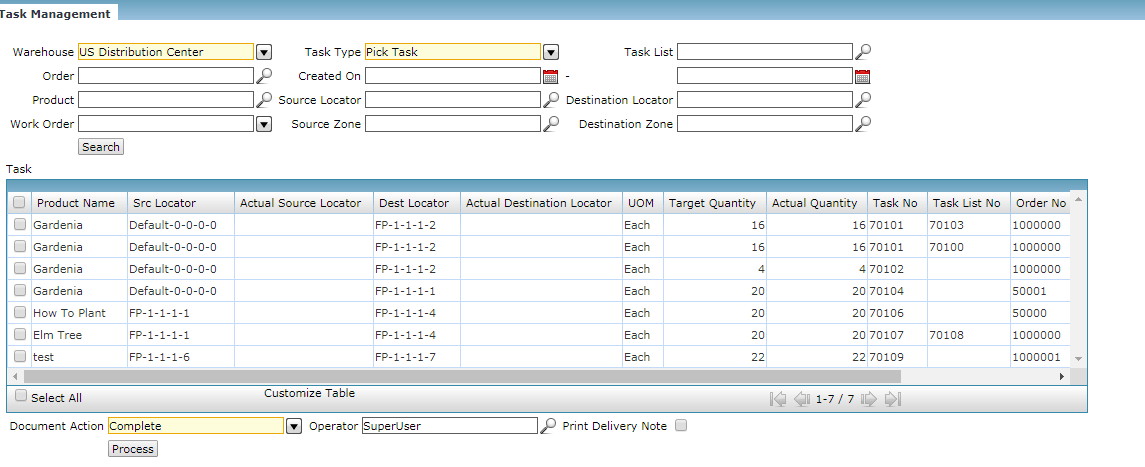

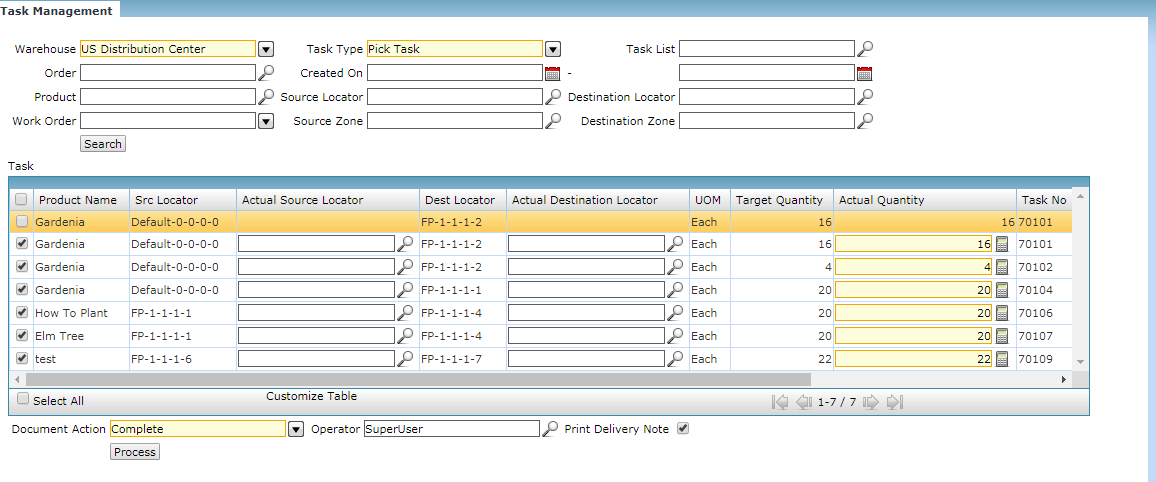

Task Management

Warehouse Management-->Warehousing Operations-->Task Management

The “Task Management” screen essentially helps you complete a group of tasks rather than having to complete each individual task.

If the print Delivery Note has to be printed please check the box. once the required tasks are selected the system will pop up for the Actual source locator and the Actual Destination Locator.

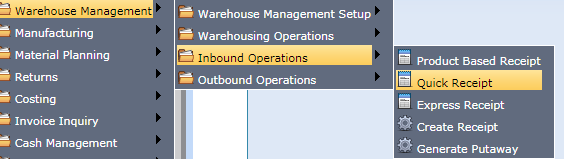

Inbound Operations

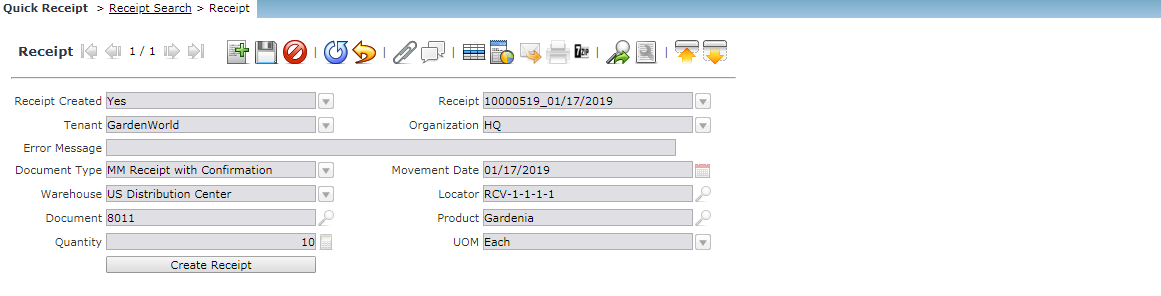

Warehouse Management-->Inbound Operations-->Quick Receipt

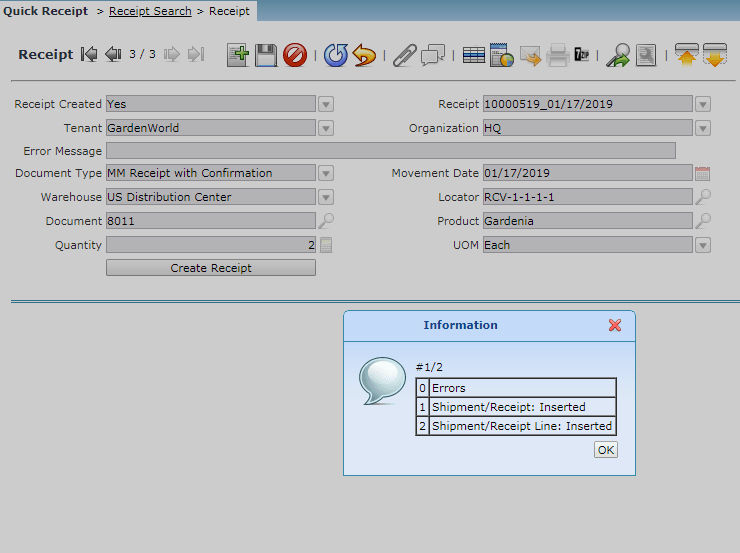

Once all entries are complete, simply click the “Create Receipt” button. This will create the Material Receipt document.

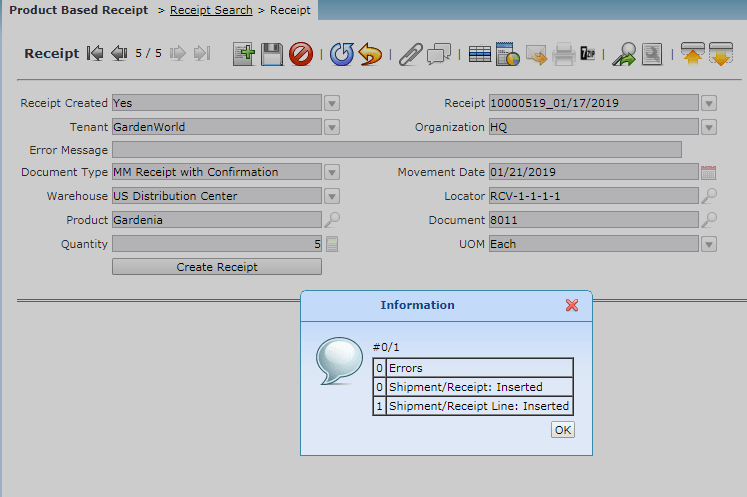

Product Based Receipts

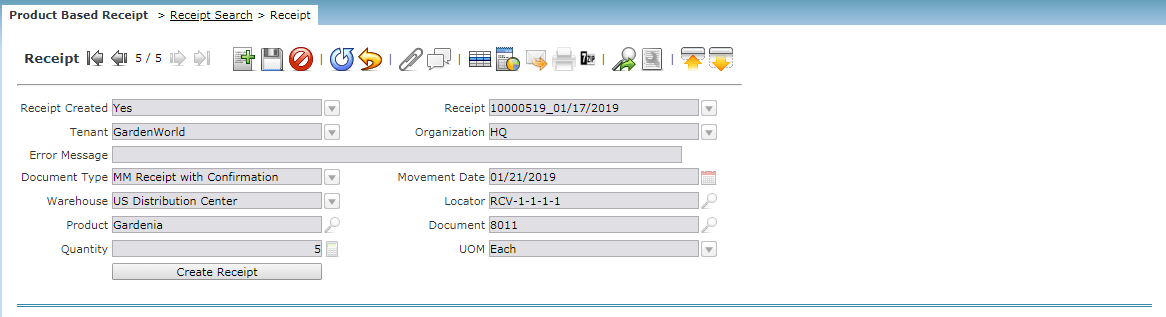

Warehouse Management-->Inbound Operations-->Product Based Receipt

The product receipt is the streamlined receiving with the product as the starting point. Please select the Document type as Material Management with Confirmation receipt. The expected quantity will not default. Instead, the application will be prompted to enter the quantity received. Enter the quantity for the product Gardenia to ensure that the selected product on hand quantity is available. Once all entries are complete, simply click the “Create Receipt” button. This will create the Material Receipt document for the tenant Garden World. The below screenshot confirms the shipment/receipt line is 1.

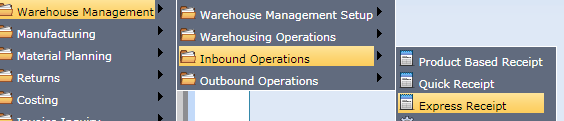

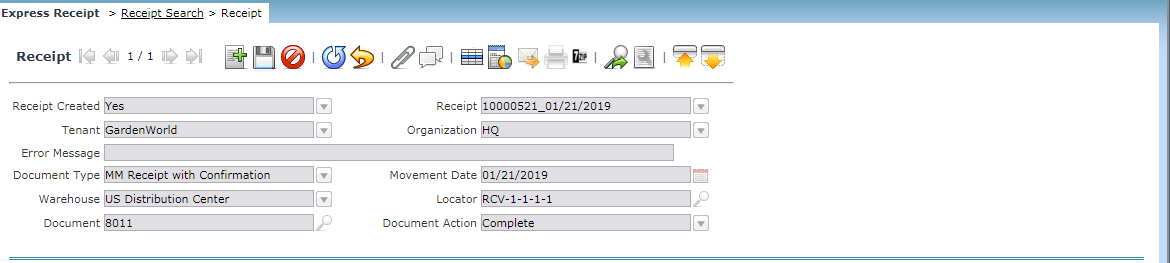

Express Receipt

Warehouse Management-->Inbound Operations-->Express Receipt

This menu is the place where it is possible to perform all the blanket receipts for all products. We can complete the receipt by processing all the records at once. Below is the screen which showcases the express receipt for the single record.

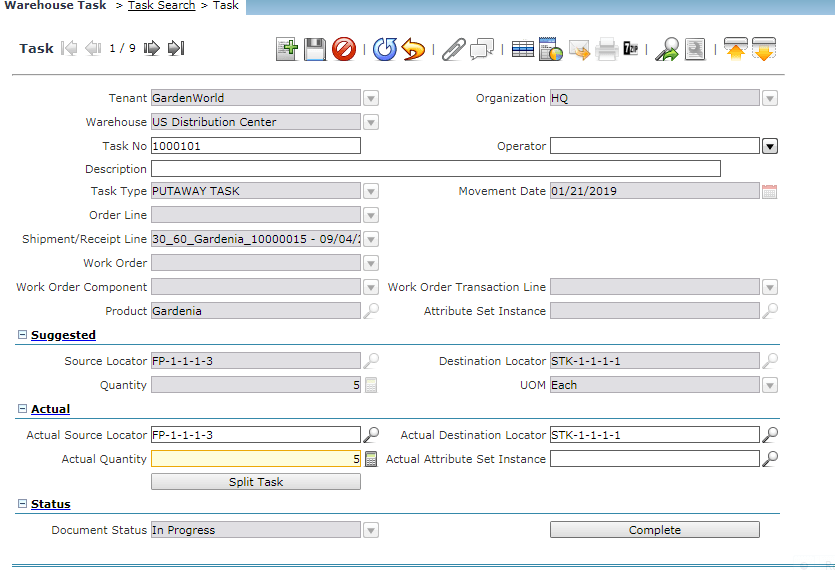

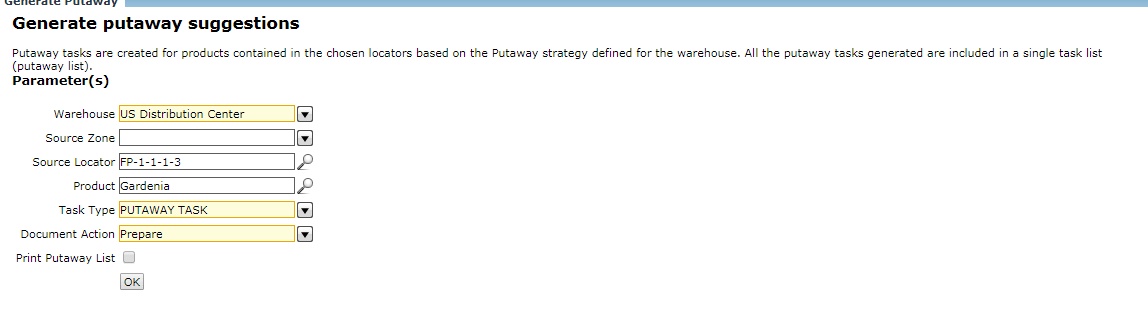

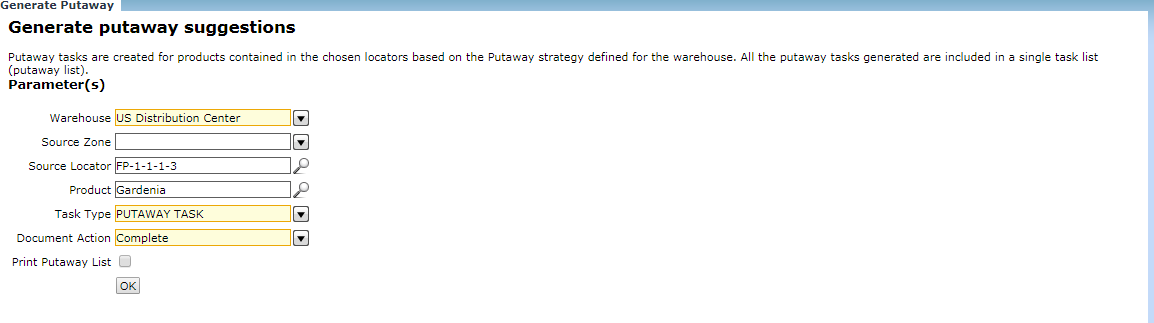

Ability to Generate Putaway Suggestions

As goods are being received at the receiving dock, you can choose to perform a putaway once sufficient goods have been received. The “Generate Putaway” process is available for this purpose. The input to this process is a source Receiving locator zone or locator.

In addition, a product or product category can be provided as input. This process will consider all the products in the source zone/locator, and evaluate the appropriate plan for those products. If a product or product category is chosen, then only the specified products are considered.

It will generate a list of Warehouse Tasks that are grouped into a Task List (Putaway list). There is a Warehouse Task for each product with the suggested putaway location. The tasks are in “Prepared” status, by default. You can choose to even complete the task using the document action parameter. You can take a print out of the Task List (Putaway list) and perform the putaway. Once the putaway is completed by the operator, they can make any corrections if necessary using the Task Management screen.

They can then complete the tasks, which will make the necessary adjustments in Inventory. While generating the warehouse tasks, the Generate Putaway process will look for any open tasks for the product. If there are any open tasks, it will not regenerate the task. If you want to regenerate Putaway Tasks (for example, if the Putaway rules have changed since the last time the Putaway list was generated), they will have to void the original tasks using the Task Management window.

During the putaway, the operator may find two kinds of exceptions.

- They had to choose a different locator (for example, if there was insufficient space in the suggested locator).

- The quantity that was putaway is different from the quantity on the putaway list. In either situation, the operator must update the Warehouse task with the actual locator and quantity before completing it. For eg if the product Gardenia quantity is 5 and the product quantity on the putaway list is 4 this will be an exception. then we should update the warehouse task with the actual quantity of the product.

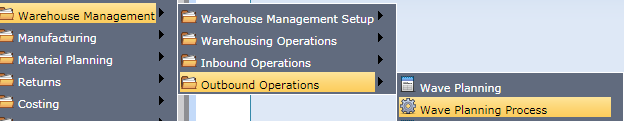

Warehouse Outbound Operations

The below selection criteria

Warehouse Management-->Outbound Operations-->Wave Planning Process.

- Warehouse: This is the warehouse where the allocation and picking are to be performed.

- Order No: This can be used to query a specific Sales Order. This can be used under special circumstances where you want to pick and ship only a specific Sales Order.

- Order Type: This can be used to query a specific Order Type.

- Order Type Group: Order type groups can be defined to group a number of order types.

- Order Priority: This can be used to query orders based on the priority setup on the Order header.

- Customer: This can be used to query all orders for a specific customer

- Date Ordered Range: This can be used to query all orders that were entered in a specified date range.

- Date Promised Range: This can be used to query all orders that were promised to be delivered in a specified date range.

- Freight Carrier: This can be used to query all orders with a specific freight carrier.

- Product: This can be used to query all orders for a specific product.

- Product Category: This can be used to query all orders for a specific product category

- Country: This is the country where the product is being shipped.