Compiere Manufacturing Module

Compiere Manufacturing Module provides functionality to support the manufacturing requirements of the tenant Garden World. For eg, the tenant garden world Manufacturers small scale equipment, Fertilizers, and solutions for plants, herbs, and bushes. It enables you to manufacture items, sub-assemblies and finished goods requiring multiple mandatory and optional manufacturing operations. This module also helps us to track the moves and costs related to labor, material, and scrap at each step.

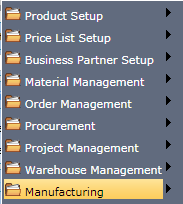

Main Menu-->Manufacturing

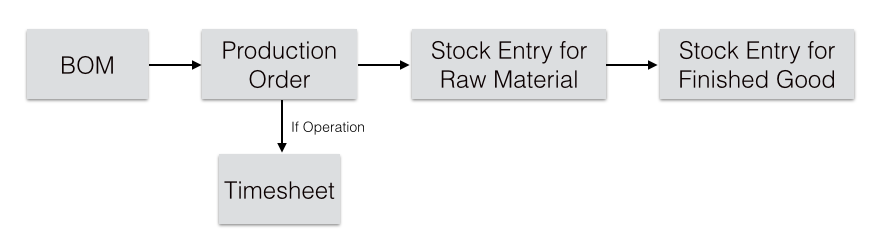

Manufacturing Steps/Workflow to be followed

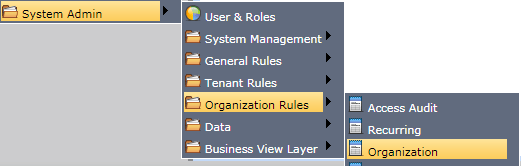

1. Create a New Organization

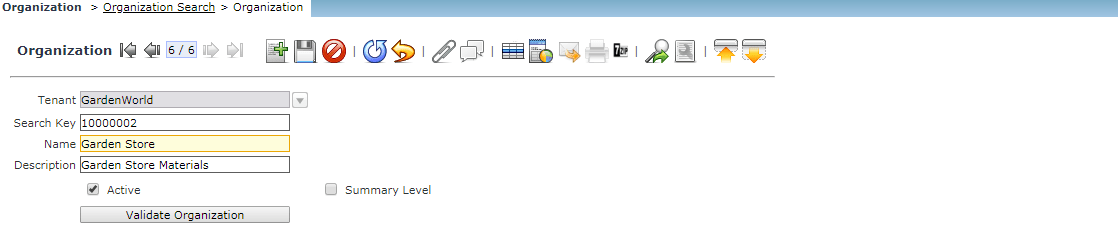

System Admin -->Organization Rules -->Organization

Ensure that once the organization Garden Store is created, the Application will prompt to Restart.

Log in with the New Organization

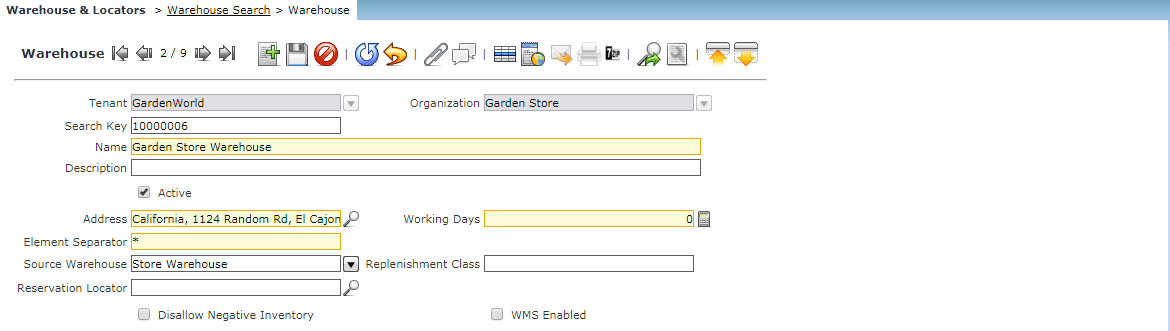

Creating a New Warehouse for the Organization and Marking the source warehouse as the existing Store WareHouse.

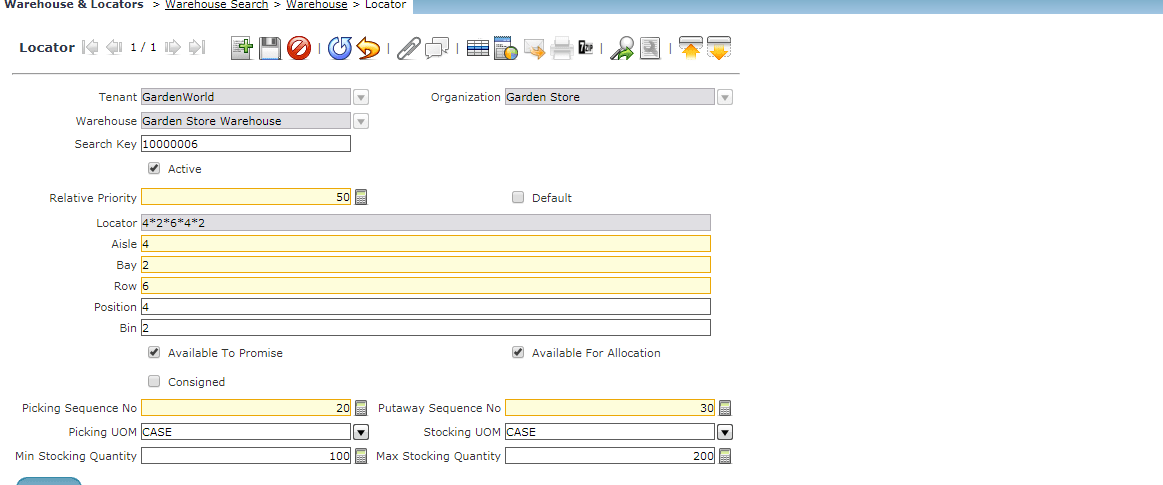

Next is creating the Locator for the New Ware House

Create a Bill of Materials for the Product

Use the Bill of Materials to specify the components that are required to manufacture the product assembly, and how many of each component is required. You can define Bills of Material with any number of levels.

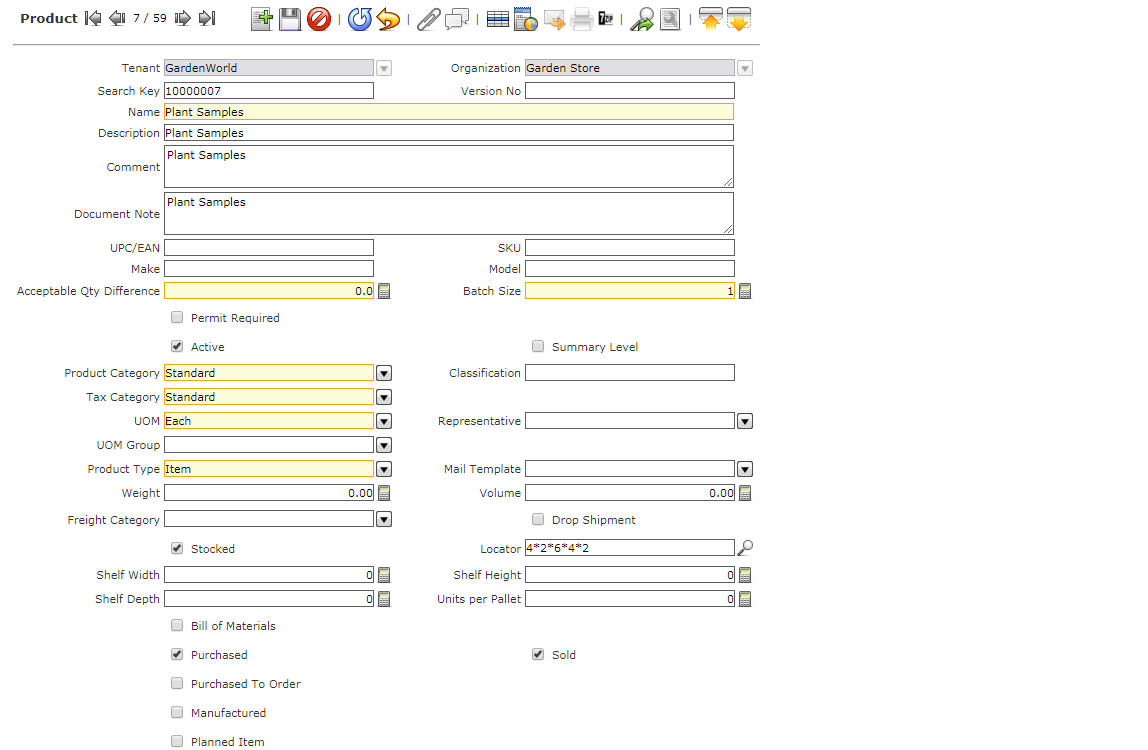

Create two products

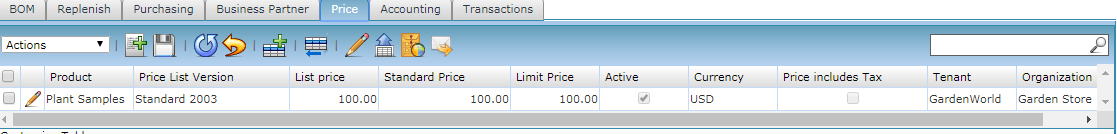

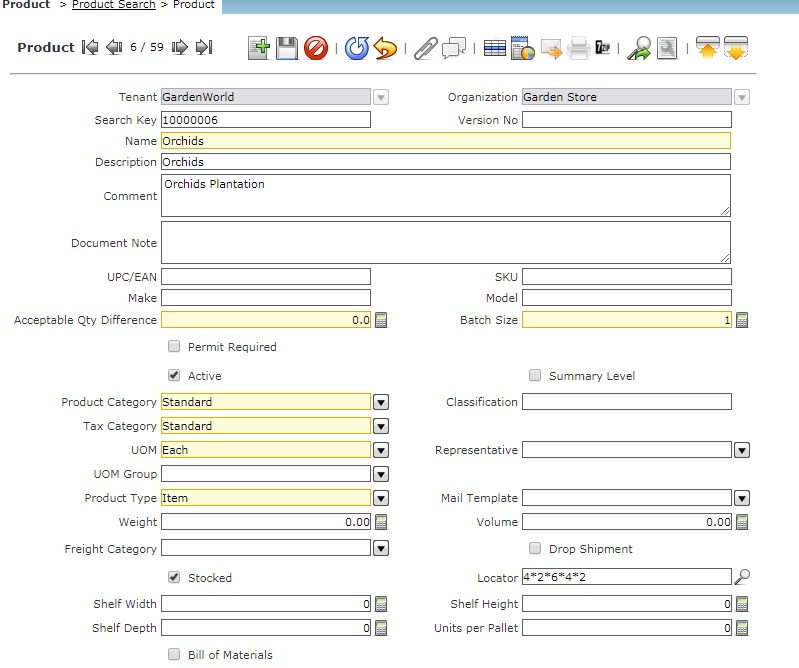

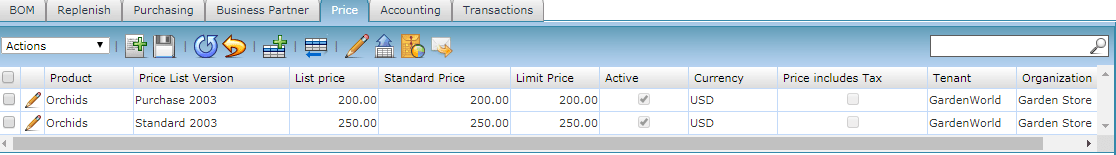

Plant Samples and Orchids. Define the price for the Products.

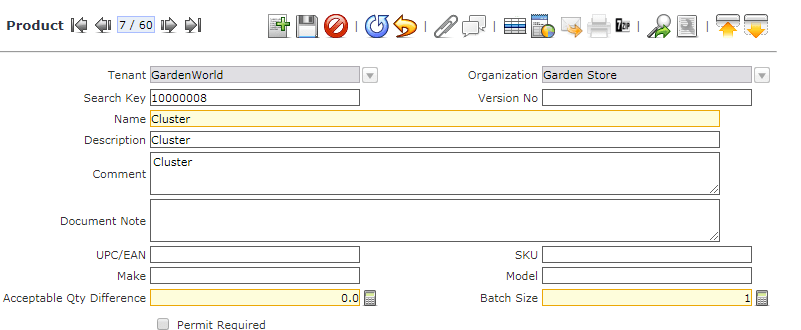

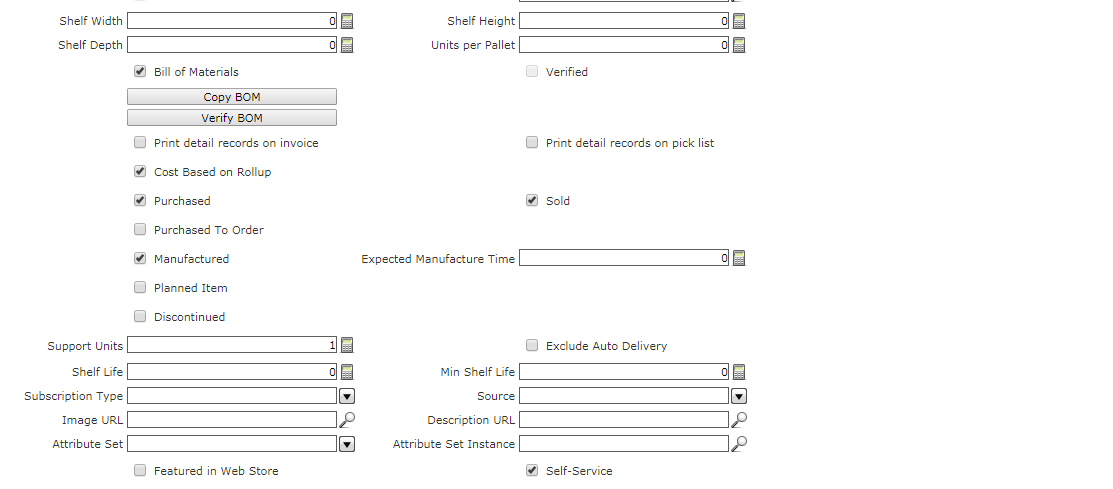

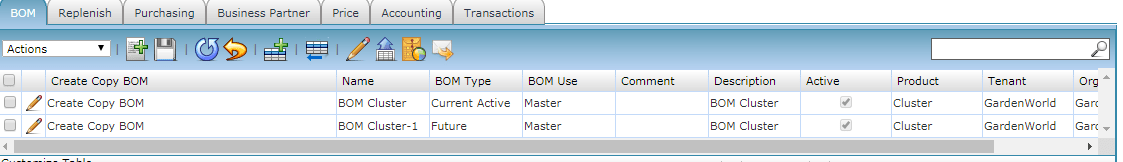

Create a Final Product Cluster

- Check the Bill of Material CheckBox. It indicates if this product consists of a bill of materials.

- Check Manufactured CheckBox. Only manufactured products will be produced using Work Orders. Cost Rollup will run only for manufactured products

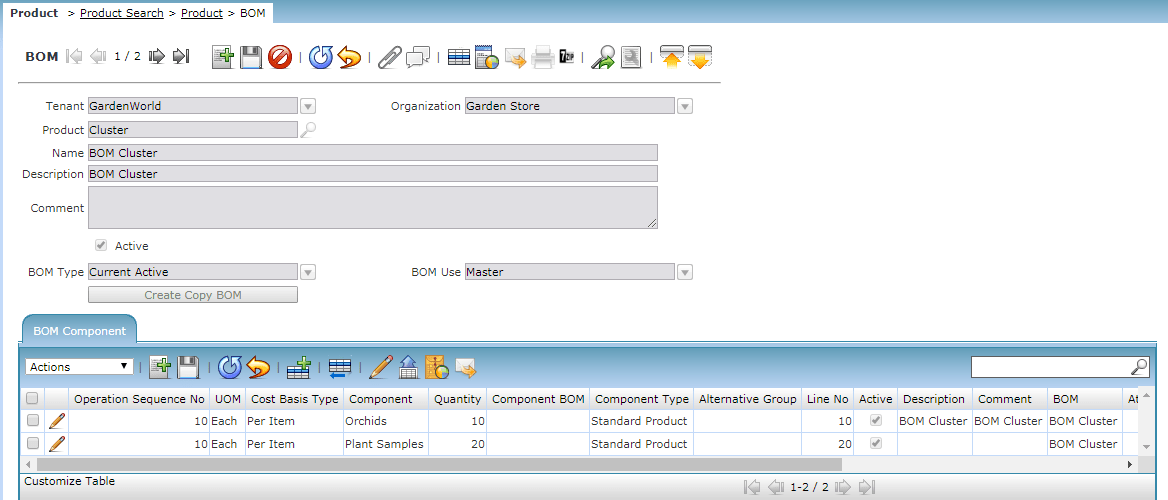

- After saving the Record, Add previously created products Sample Plant, Orchids as BOM Product in BOM tab.

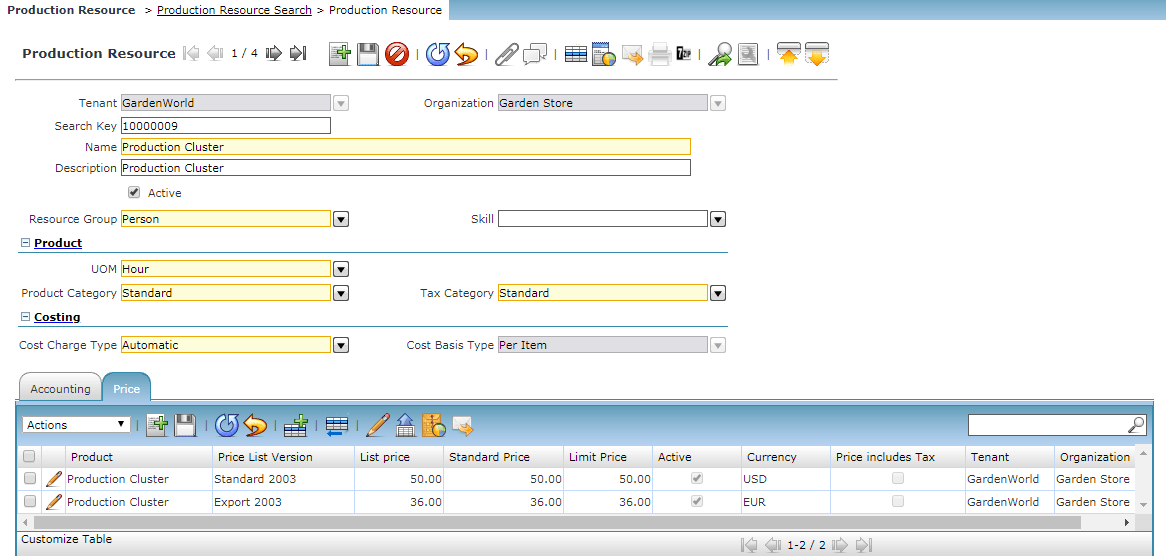

The Next Step will be Creating the Production Resource for the tenant Garden world

Create a New Production resource as Production Cluster for the Tenant GARDEN WORLD. Define the Price for the New Production Resource.

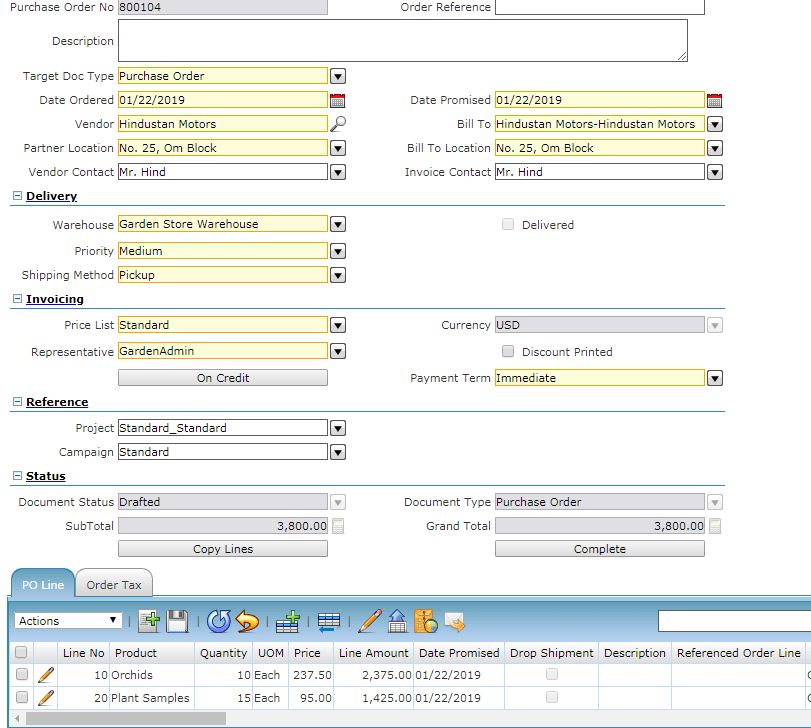

Next Step will be the Purchasing the BOM components [BOM cluster]

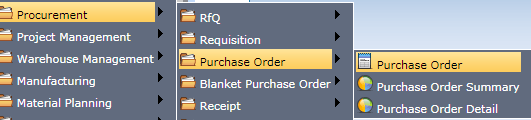

Procurement --> Purchase Order --> Purchase Order

The Purchase Order is created for the BOM components Orchids and Plant Samples.

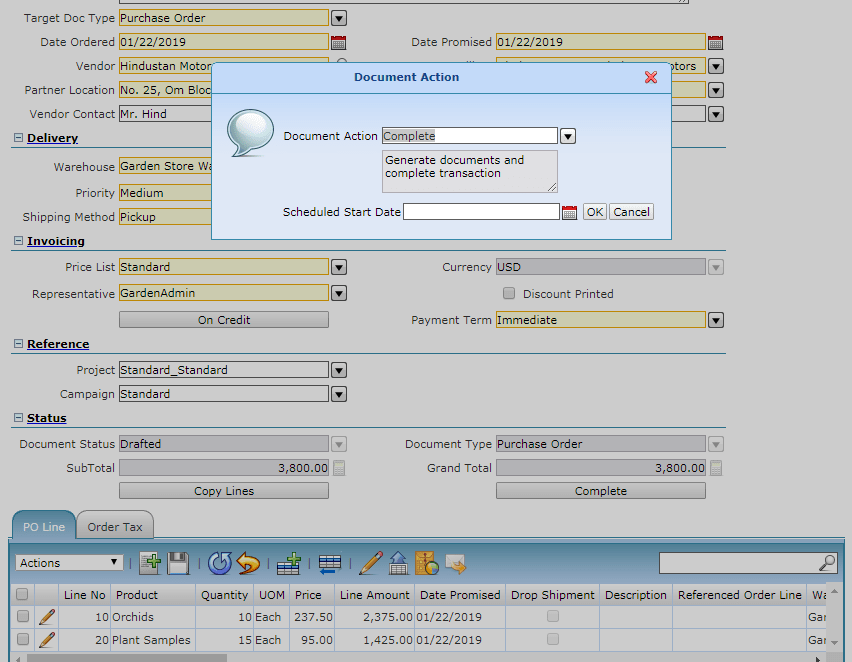

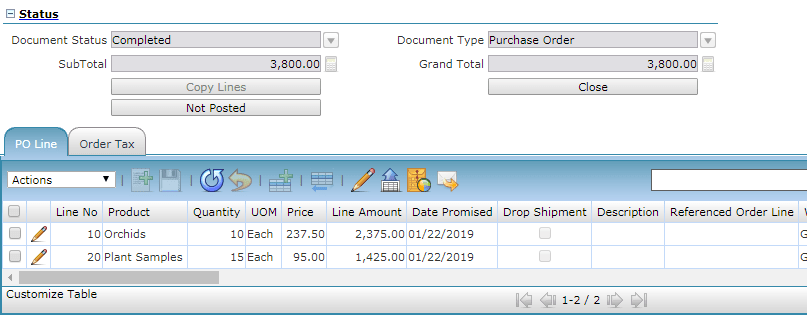

Complete the Purchase Order

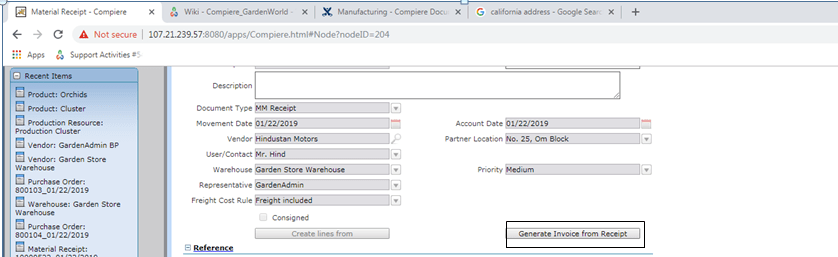

The Next Step will be the Material receipt Creation.

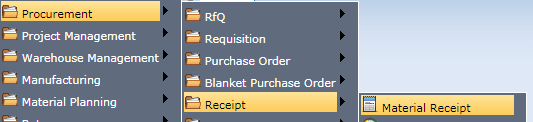

Procurement --> Receipt --> Material Receipt

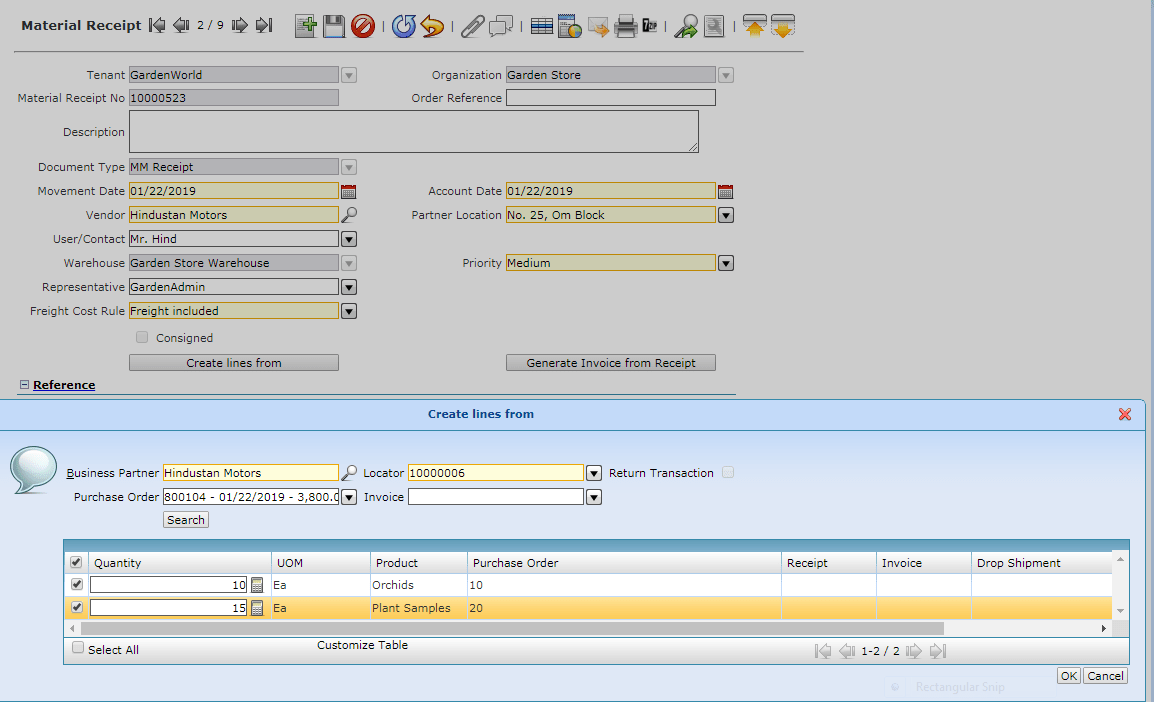

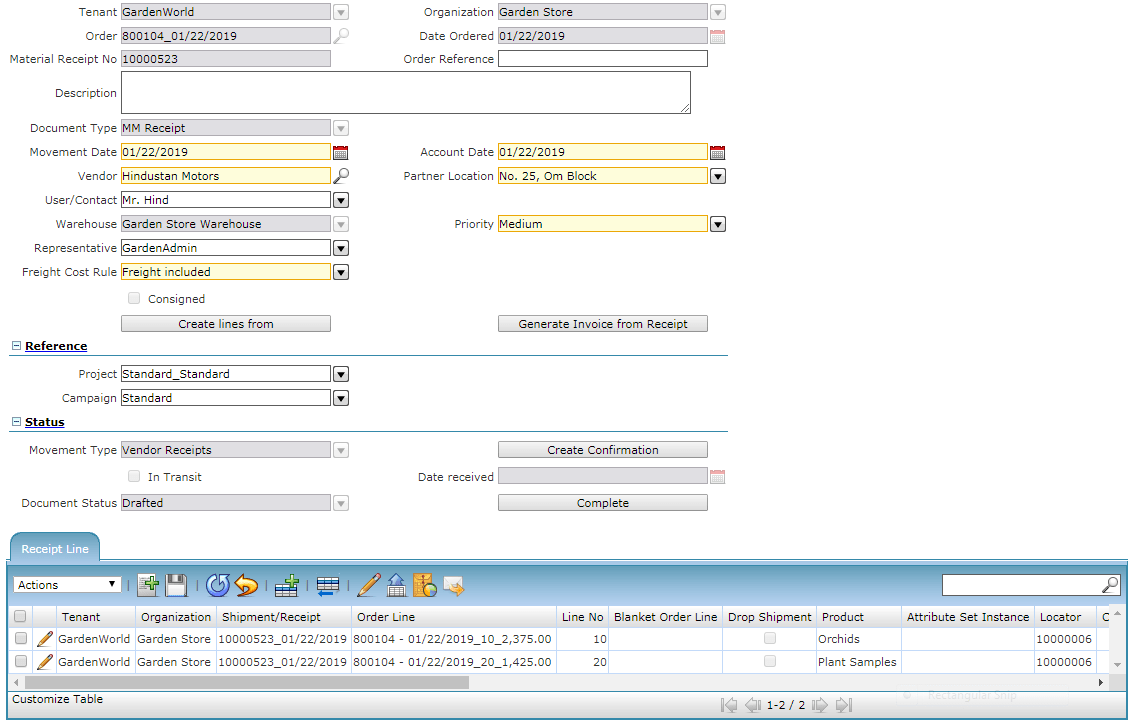

Mapping the Purchase order to the New Material Receipt. If required can edit the Quantity while mapping the Purchase Order and Authorized User can change the quantity.

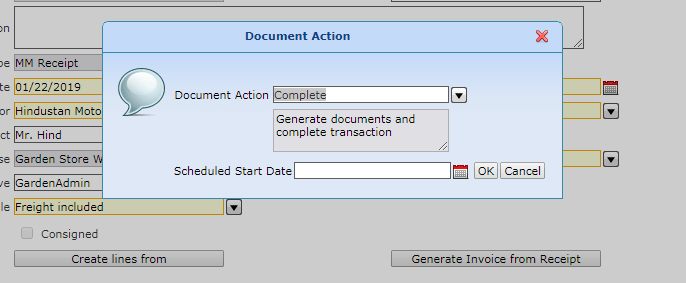

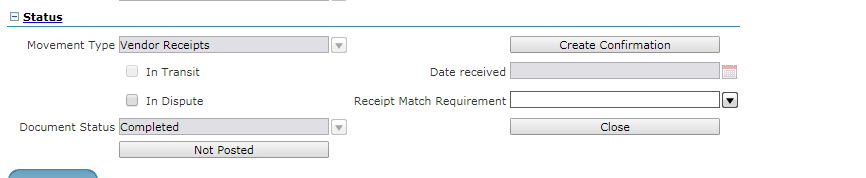

Complete the Material Receipts

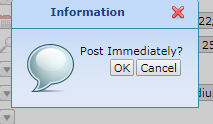

Material Receipt Posting

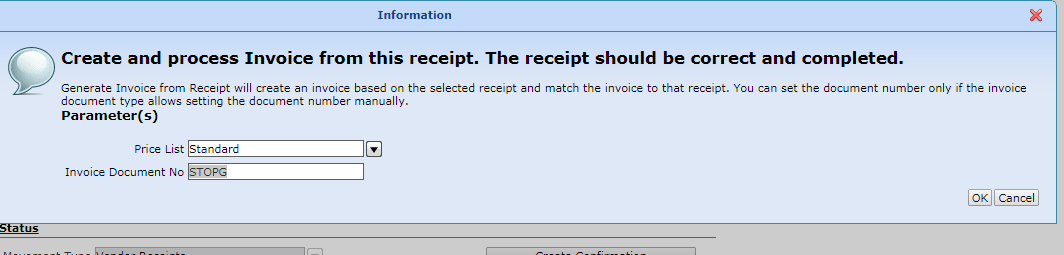

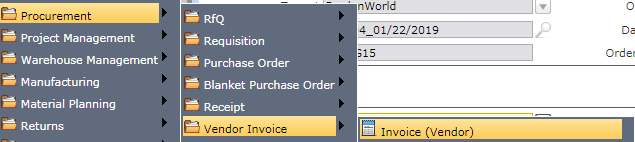

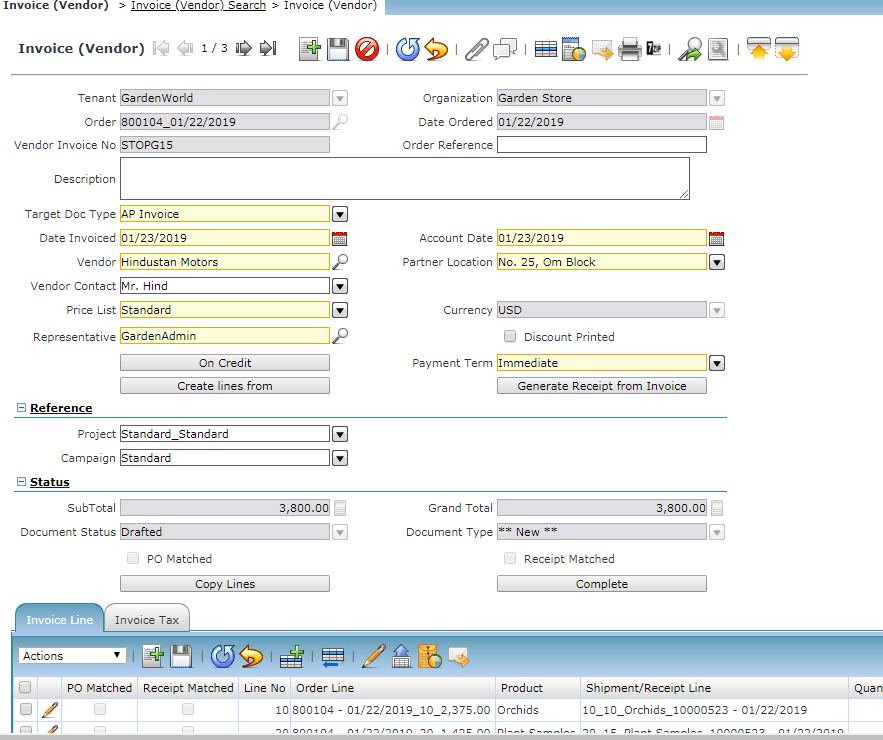

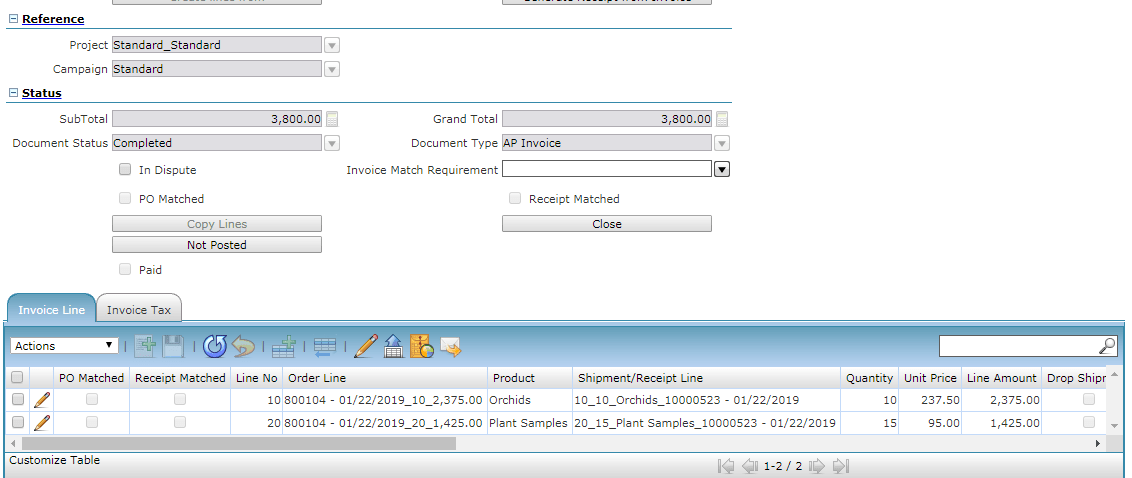

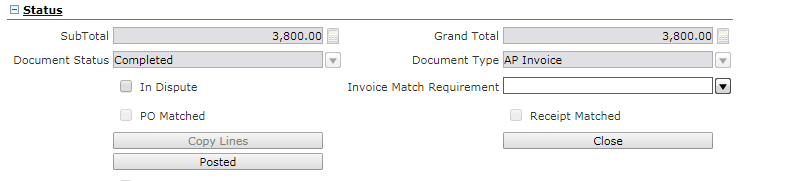

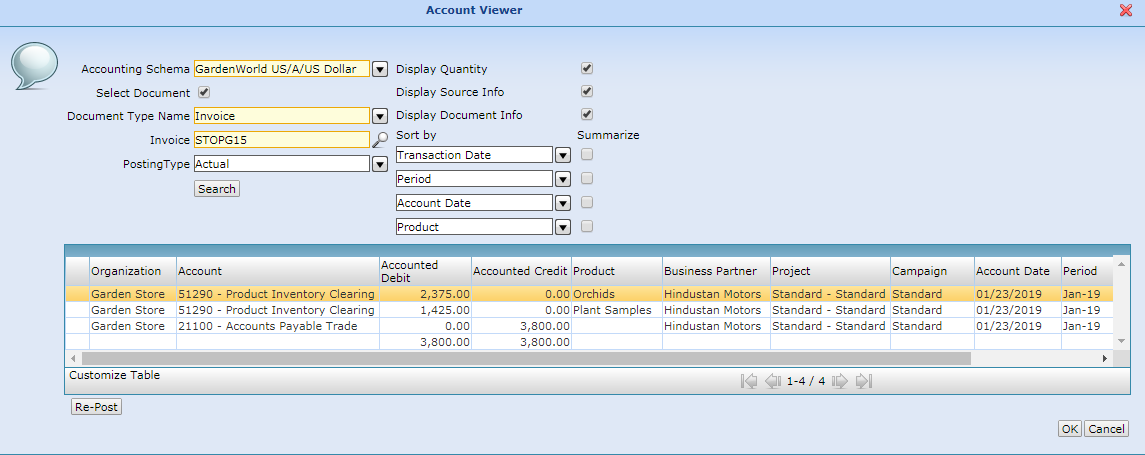

Next Step is to Create an Invoice Vendor Creation

New Invoice Generated. Validate the Created Invoice.

Procurement --> Vendor Invoice --> Invoice Vendor

Matching PO and Matching Invoice will be automatically created. You need to Post the Matched PO and Matched Invoice

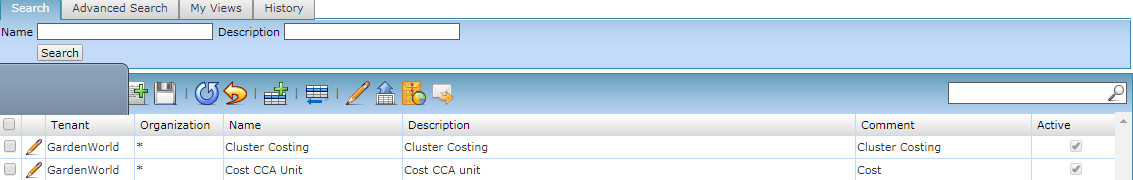

Product Costing

![]()

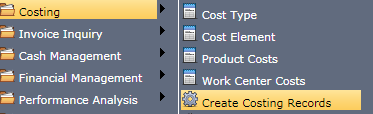

Main Menu --> Costing --> Cost Type

Define the Required Cost type for the tenant Garden World.

Product costing for the BOM Components are automatically created With current price and On-Hand Qty as Follows

| Product | Current Price | On-Hand Qty |

| Orchid | 250.00 | 100 |

| Plant Sample | 100.00 | 100 |

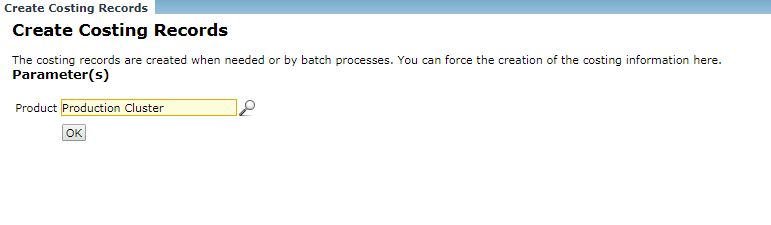

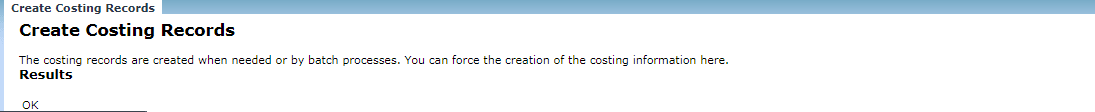

Next Step is Create Product Cost for the Final Product Cluster and Resource by ‘Create Costing Records’

Main Menu --> Create Costing Records

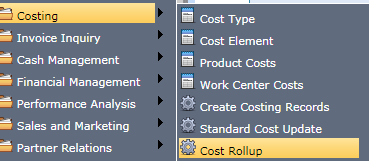

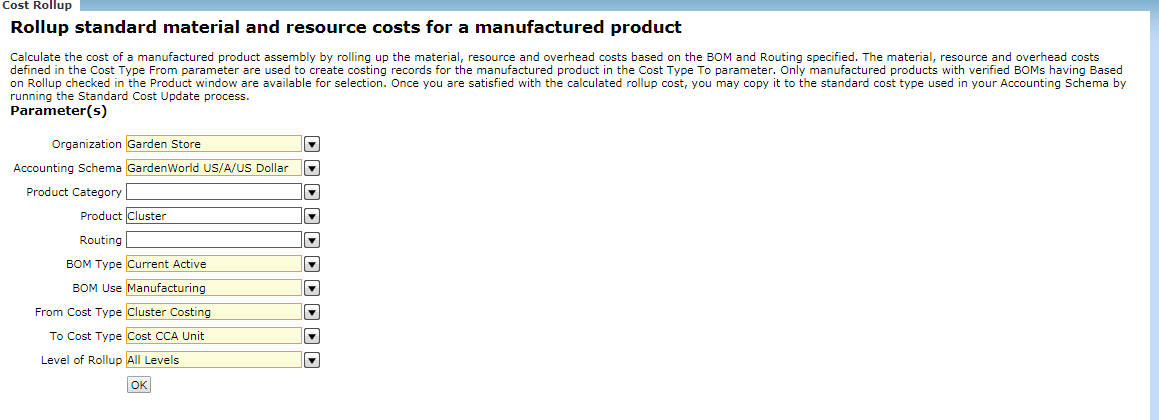

Cost Roll UP is the next Step

Main Menu --> Costing --> Cost RollUP

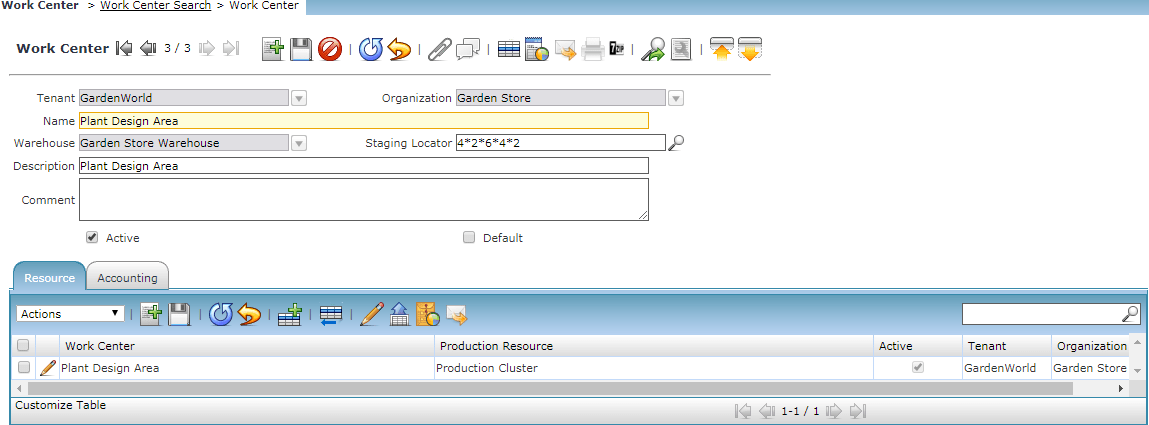

Work Center

Main --> Manufacturing --> Manufacturing Setup --> Work Center

Create a New Work center

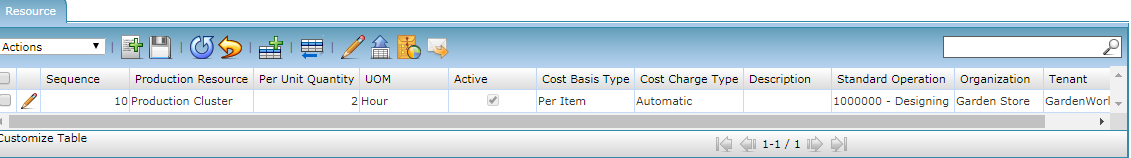

In the Resource Tab Choose the Production Resource as Production Cluster.

The Next Step will be the

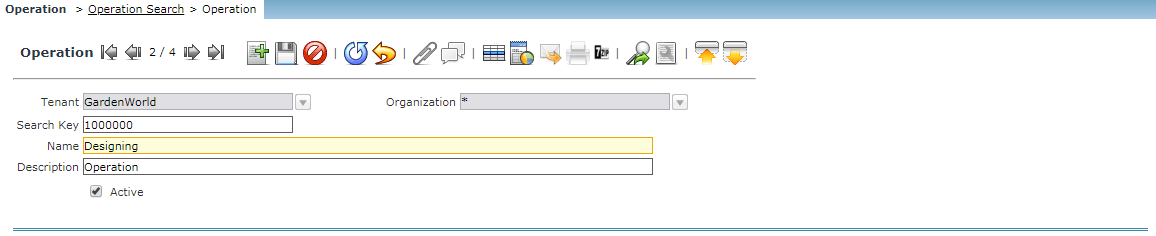

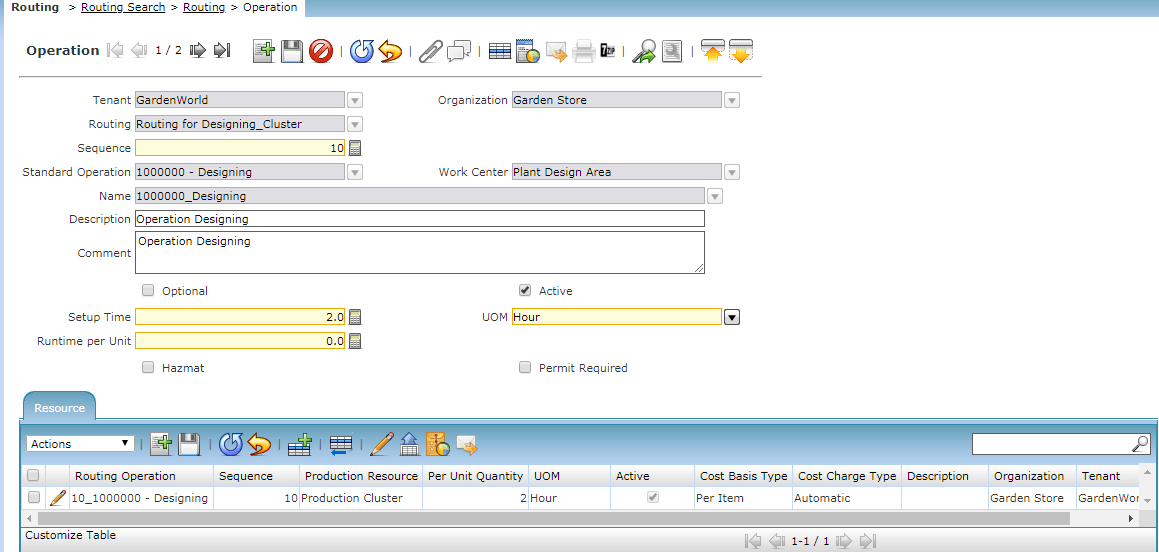

Operation

Main --> Manufacturing --> Manufacturing Setup --> Operation

- Create a Number of Operations.

- This operation is used in routing, standard operation templates and work order operations.

1. Create a new operation name as ‘Designing’

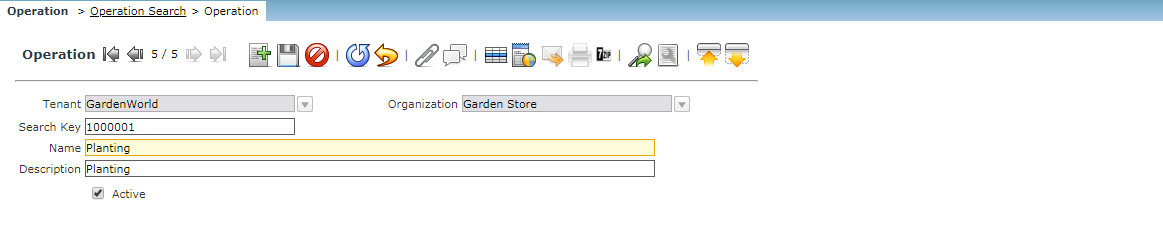

Create Another operation name as ‘Planting

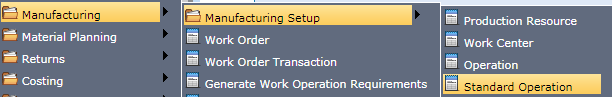

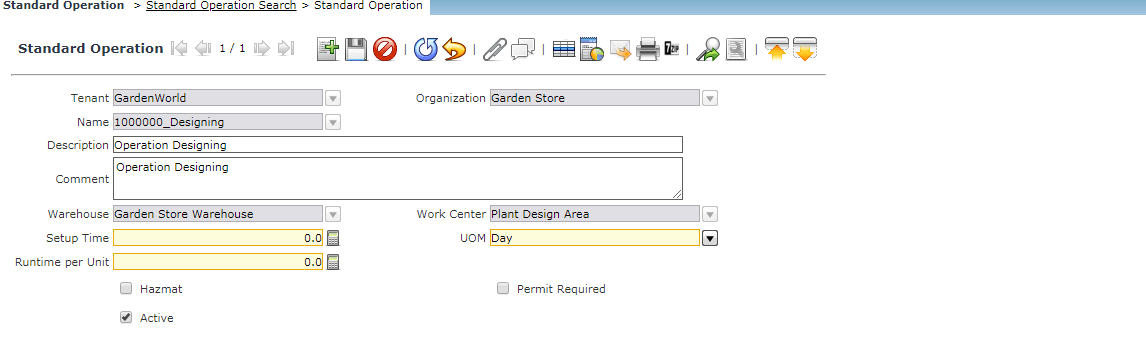

Standard Operation

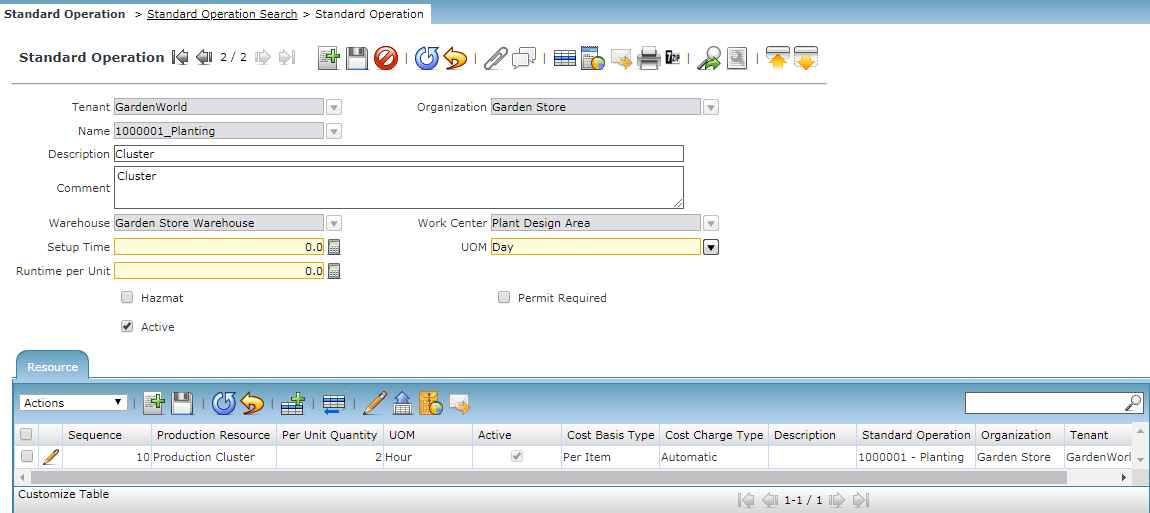

Main --> Manufacturing --> Manufacturing Setup --> Standard Operation.

- Create Standard Operation for each Operation.

- Each operation must occur in a work center (Designing Area)

Standard Operation 1 :

- Create Standard Operation for Operation ‘Designing’.

- In the Resource, the tab chooses the resource as ‘Designer’. Give Quantity as ‘1’

Standard Operation 2 :

- Create Standard Operation for Operation ‘Planting’.

- In the Resource, the tab chooses the resource as ‘Designer’. Give Quantity as ‘1’

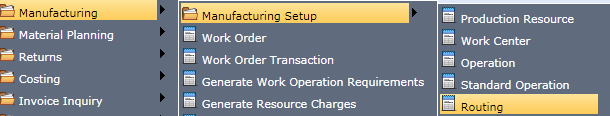

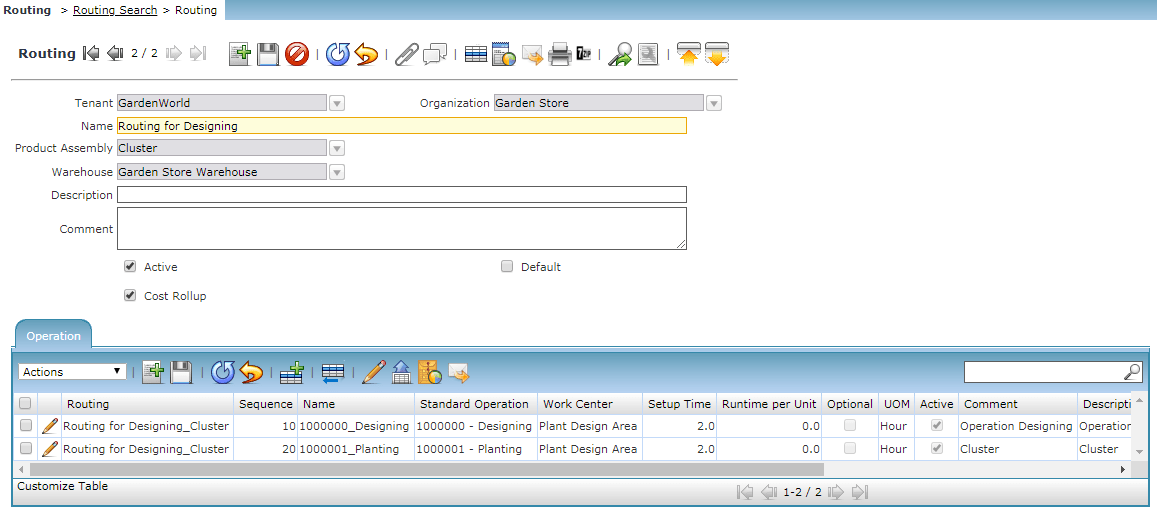

Routing

Main Menu --> Manufacturing Setup --> Routing

- It will Define the manufacturing operations and resources required to create a product in a warehouse.

- Create Routing name ‘Routing-Designer’.

- Choose the final Product ‘Cluster’ as the Product assembly.

- Choose Warehouse as ‘Raw material Warehouse’. All the Standard Operations must be in the same Warehouse.

- In Operation Tab map the two operations ‘Designing’ and ‘Planting’.

- Choose the work center as ‘Designing Area’.

- The Operations Dropdown will list only the operation which is in ‘Raw material Warehouse’.

- When you choose the operation and save the record, the routing will automatically be filled based on the selected Operation.

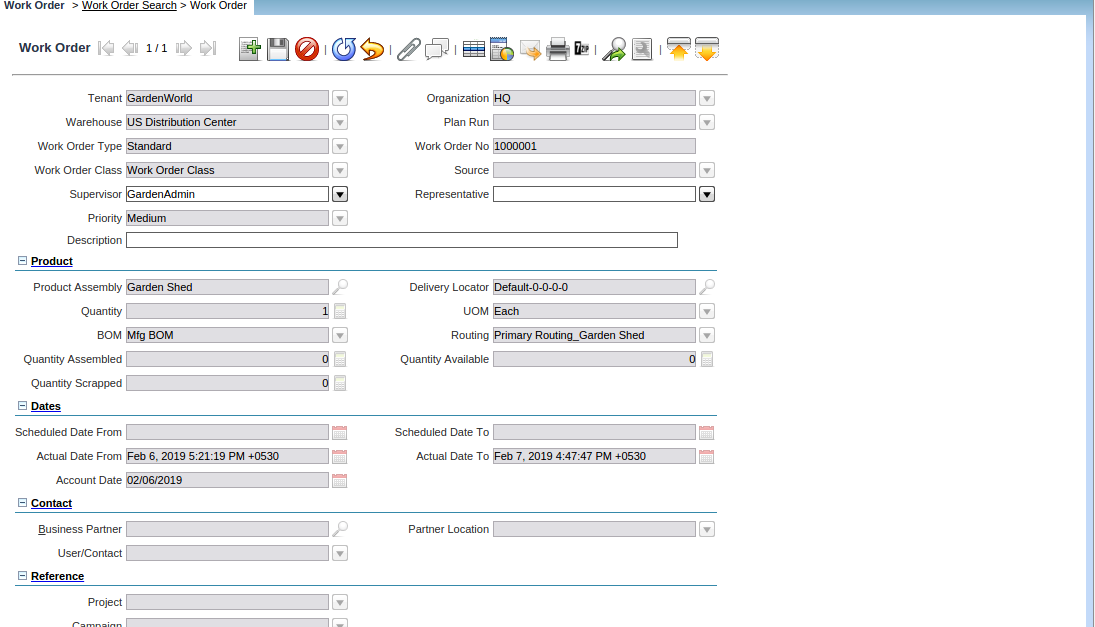

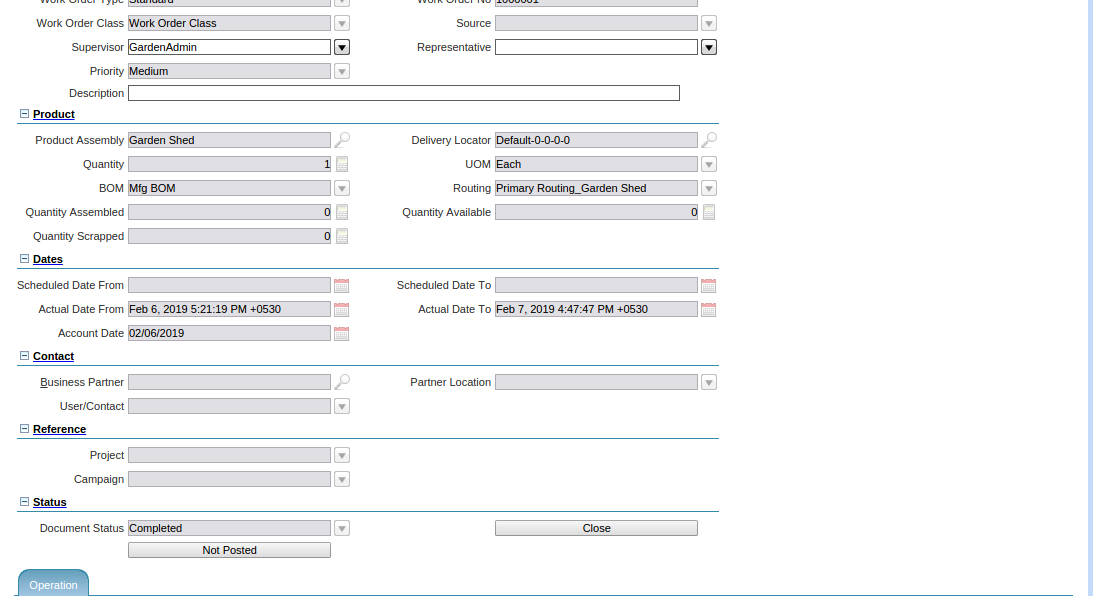

Work Order

- Create a new Work order for the Final Product Cluster’

- Choose Product Assembly as the Final Product

- Choose BOM as ‘BOM_Silver’. Choosing this, BOM Products ‘Plant Samples’ and ‘Orchid’ will automatically assigned with corresponding Qty for the work order

- Choose the Routing as ‘Routing_Designer’. The resource will automatically be assigned with corresponding Qty for the work order

Main Menu --> Manufacturing --> Work Order

Work Order Types

You can create Standard, Repair, or Refurbish work orders. For Repair or Refurbish work orders, you can create a work order that accepts its product assembly as a component. This allows you to issue the same item to the work order (in addition to other components if necessary) as the item that comes out.

Work Order Components

Define the list of components and quantity required to manufacture the product assembly. This list can be defaulted from the BOM using the Copy BOM Components or BOM Explode functions. Make updates as needed before running any work order transactions. You can track component quantities issued and consumed in a work order.

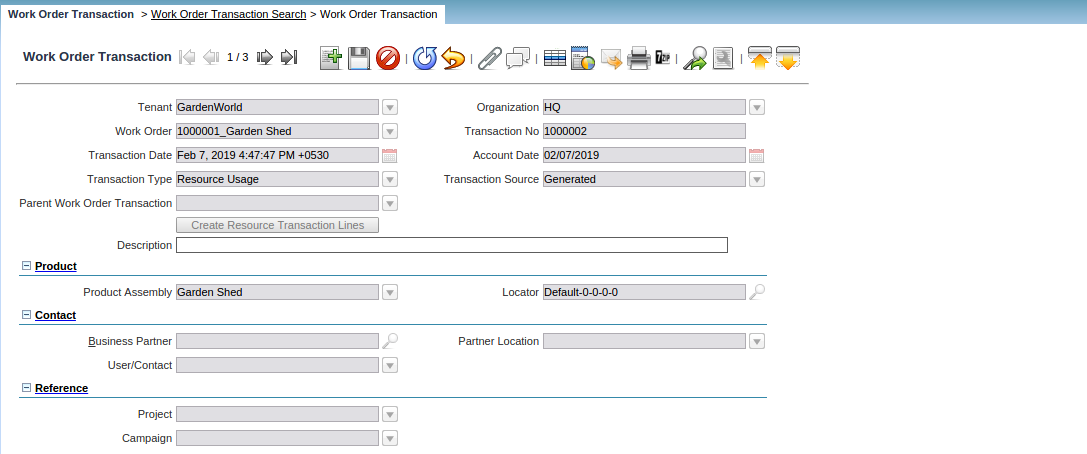

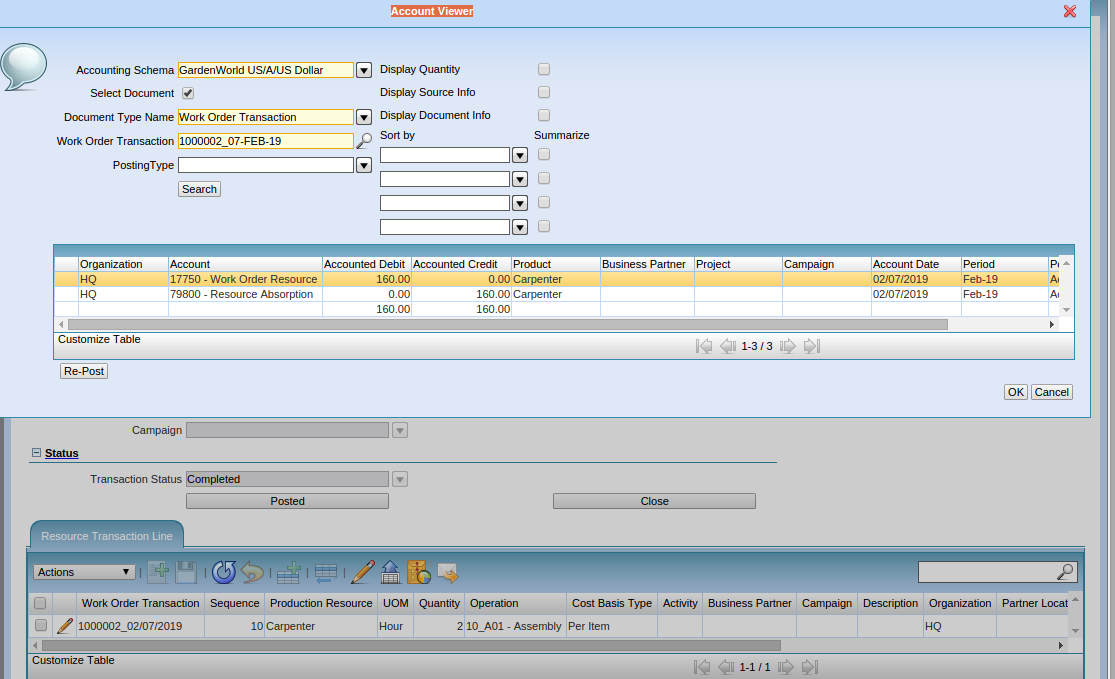

Work Order Transactions

Use work order transactions to issue and return components and product assemblies and to create product assemblies. The different types of work order transactions are Component Issue to Work Order, Component Return from Work Order, Work Order Movement, Assembly Issue to Inventory and Assembly Return from Inventory. All transactions except Work Order Movement update Inventory and product costs. Accounting these transactions uses the Product Asset and Work Order Material accounts to track product moves into and out of Inventory and Work Orders.

Component Issue to Work Order Transactions

Before assembling products, you need to issue the required components from Inventory to a work order. You can only issue components listed in work order components to a work order. In the case of Repair and Refurbish work orders, you can also issue the product assembly to the work order. To automatically issue all work order components, run the Generate Push Component Lines function.

Work Order Movement Transactions

Use work order movements to manufacture a product assembly based on the component requirements in a work order. After issuing the required components to a work order, use a work order movement transaction to create the product assembly. Optionally choose to complete the product assembly and automatically move it into Inventory.

Assembly Issue to Inventory Transactions

Assembly issues are used to transfer the assembly from the work order to inventory. As these are generated automatically by the move transaction, the user rarely needs to do this manually. Users could possibly have a need for this if they have previously returned assemblies to the work order. The completion locator specified on the work order will be used by default but can be overridden by the user while entering the move transaction.

Component Return from Work Oder Transactions

Use component returns to return components issued to a work order but not consumed in creating product assemblies back into Inventory.

Assembly Return from Inventory Transactions

Use assembly returns to return product assemblies from Inventory back to a work order.

Work Order Complete

We can complete a work order so long as there are no open Work Order Transactions. Any material value associated with unused components or unissued product assemblies in the work order will be flushed to the Work Order Close Expense account.

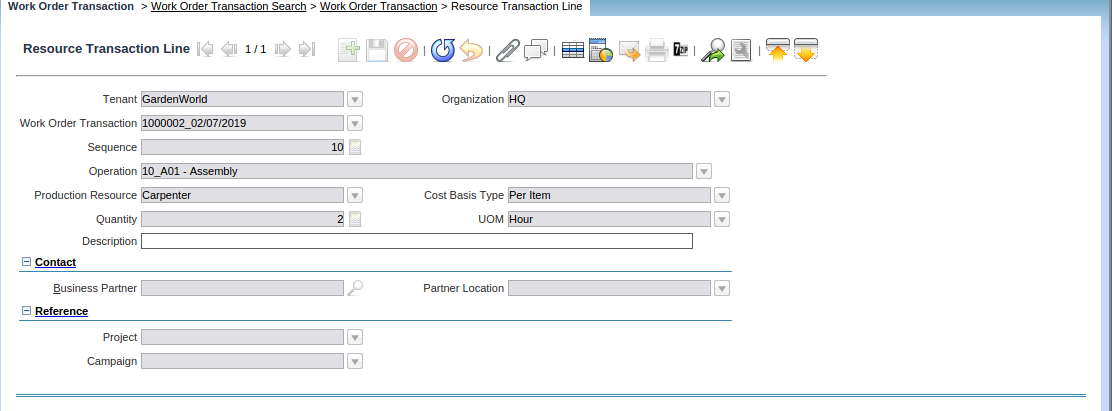

Main Menu --> Manufacturing --> Work Order Transaction

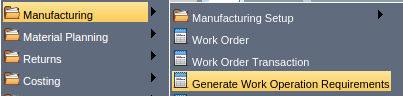

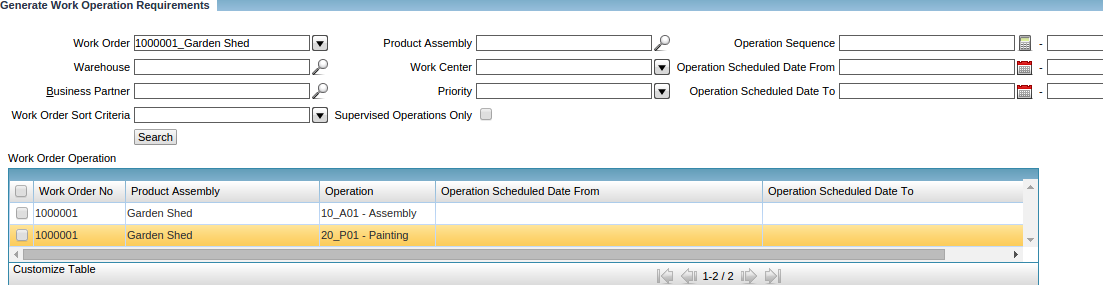

Main Menu --> Generate Work Operation Requirement

Main Menu --> Manufacturing Resource Charges

List of the functionalities involved in Manufacturing in the above screens.

| Bill of Materials | List of components (products) required to assemble a product. Also referred to as BOM. It serves as the core of any manufacturing process because it lays out all the information required to assemble. Eg Plant Wheel Barrow –> [Wheels, Legs, Handles, Bucket Tray] –> [Axle, Spacer, Axle Brackets, Leg Braces, Bolts, Wheel Guard, Spacers]. |

| Component | The line item of the Bill of Materials or Work Order. Components are used to create the Product Assembly. The terms Component and Material are used interchangeably. |

| Work Order | The document tracks the components required to assemble a product and the assembly process. A Work Order is a document that is given to the manufacturing shop floor by the Production Planner as a signal to produce a certain quantity of a certain Item. The Work Order also helps to generate the material requirements (Stock Entry) for the Item to be produced from its Bill of Materials.

|

| Assembly | Identifies the product that is going to be assembled using a Work Order. |

| Routing | Describes all the operations necessary to assemble a product. Each operation takes place in a work center and uses resources assigned to that work center. |

| Component Issue | Work Order Transaction that moves a component from Inventory to the Work Order. The component is intended for consumption in the assembly process. |

| Component Return | Work Order Transaction that moves a component from the Work Order to Inventory. These are typically components that were unused in the assembly process or failed quality assurance. |

| Resource Usage | Work Order Transaction that commits charges for operation resources to a Work Order. Resources include both labor and equipment. |

| Assembly Completion | Work Order Transaction that moves the finished product assembly from the Work Order to Inventory. |

| Assembly Return | Work Order Transaction that moves the finished product assembly from Inventory to the Work Order. This is typically used in case the finished product assembly requires some rework. |

| Work Order Move | Work Order Transaction consumes components and creates the finished product assembly. It tracks the movement of the in-progress product assembly across routing operations. |

| Cost Basis Type | Specifies how the cost for materials and resources is to be allocated to determine the cost of manufacturing a product assembly. The cost may be tracked by Per Item or Per Batch. |

| Cost Charge Type | Specifies how resources will be charged for a work order. Resources with a cost charge type of Manual must be explicitly charged by entering and completing a Resource Usage transaction. Resources with an Automatic cost charge type will be charged automatically by Compiere when an operation is completed. |

| Work Order Class | One time setup to control document type and accounting setup for Work Orders and Work Order Transactions. |

| Work Center | Identifies a location inside a warehouse where manufacturing operations are carried out. |