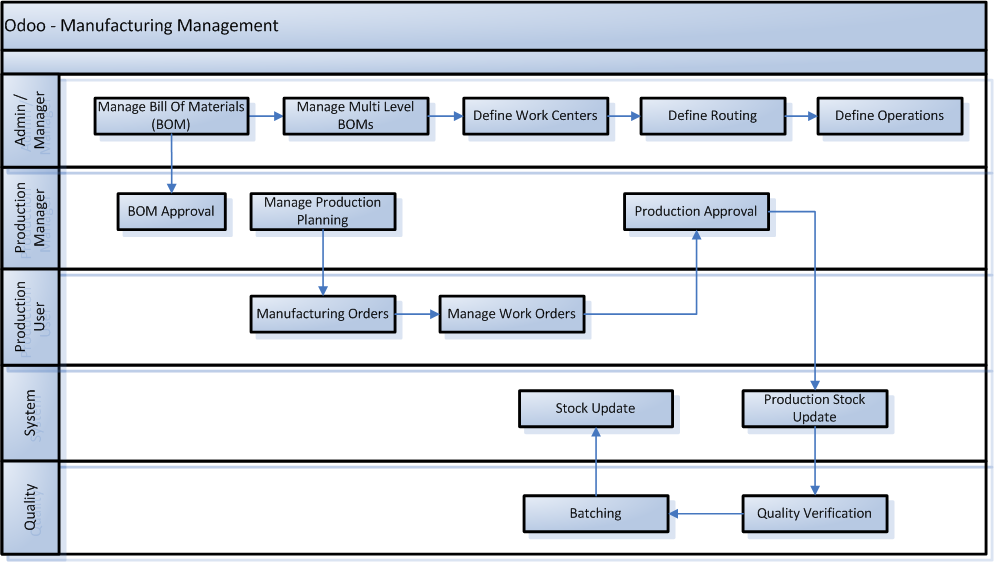

Odoo Manufacturing Management

There are two basic ways to manage manufacturing in Odoo

-

To manage manufacturing without Routing and work order

-

To manage manufacturing with Routing and work orders

Manage manufacturing without routing

You will most likely use manufacturing orders without routing if all the work to produce your product is performed in one place, by one person, in one step, and/or you do not need the level of granular control afforded by work orders and routing.

Managing your operations in this way is the default behavior in Odoo. There are two basic phases from planning to production:

- Create manufacturing orders

- Record Production

Manage manufacturing with routing and work orders

To use work orders and routing, you will need to enable option Manage production by work orders From Configuration ‣ Settings. You will then be able to add routing to bills of materials and configure some additional related fields. You will also be able to create work centers, the locations at which work orders are performed.

When manufacturing with routing and work orders, each work order is scheduled individually. You will also have access to time and capacity planning, and reports on costing and efficiency on a work center level.

Manufacturing using routing can be broken down into several steps. When configuring your BoM, you will need to add a routing defining the component work orders. After planning the manufacturing order, you will have the added step of scheduling work orders.

The workflow is thus divided into three basic phases, as follows:

- Create manufacturing orders

- Schedule the associated work orders.

- Perform the scheduled work and record production.

Odoo Manufacturing process involves the following features readily available for the business.

- Manage Bill Of Materials

- Manage Work centers

- Manage Routing and Operations

- Manage Production planning

- Manufacturing orders

- Manage Work orders

- Production of By Products & Finished products

Manufacturing Process flow

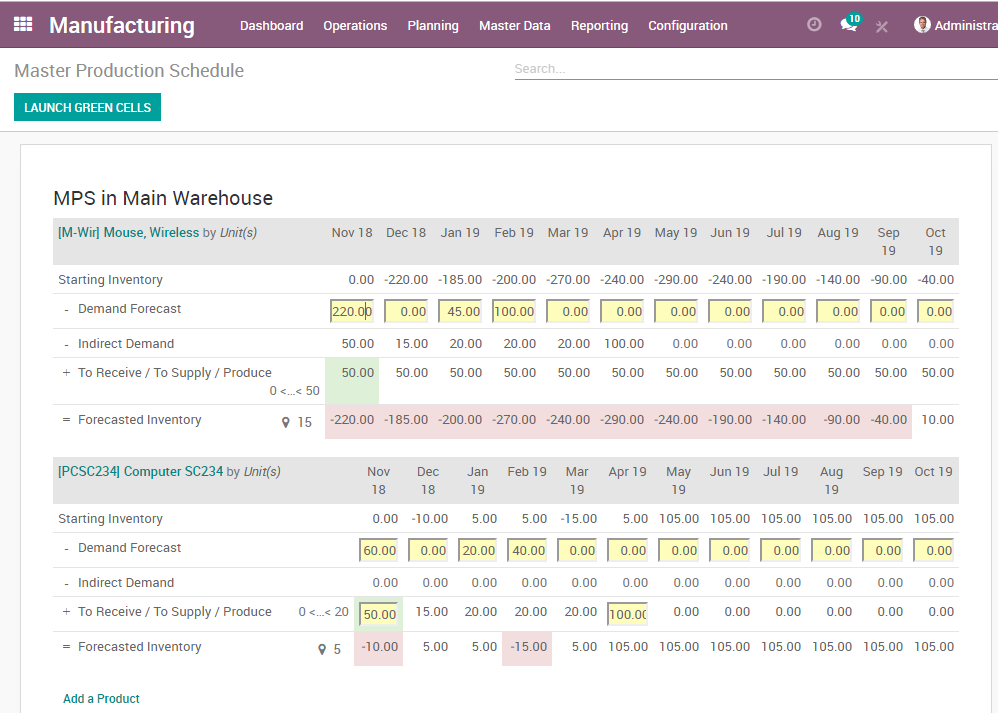

Master Production Schedule (MPS)

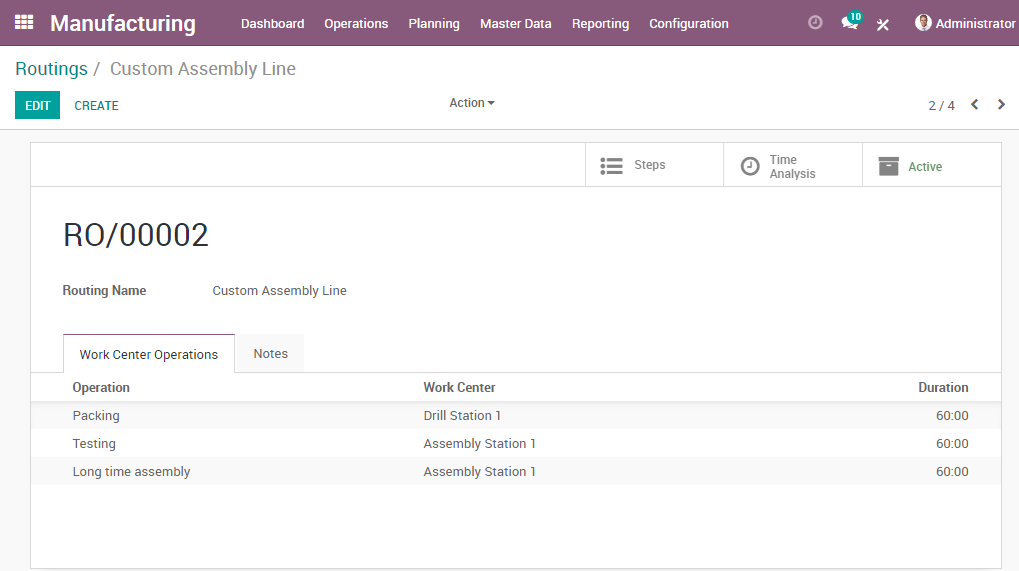

Routing

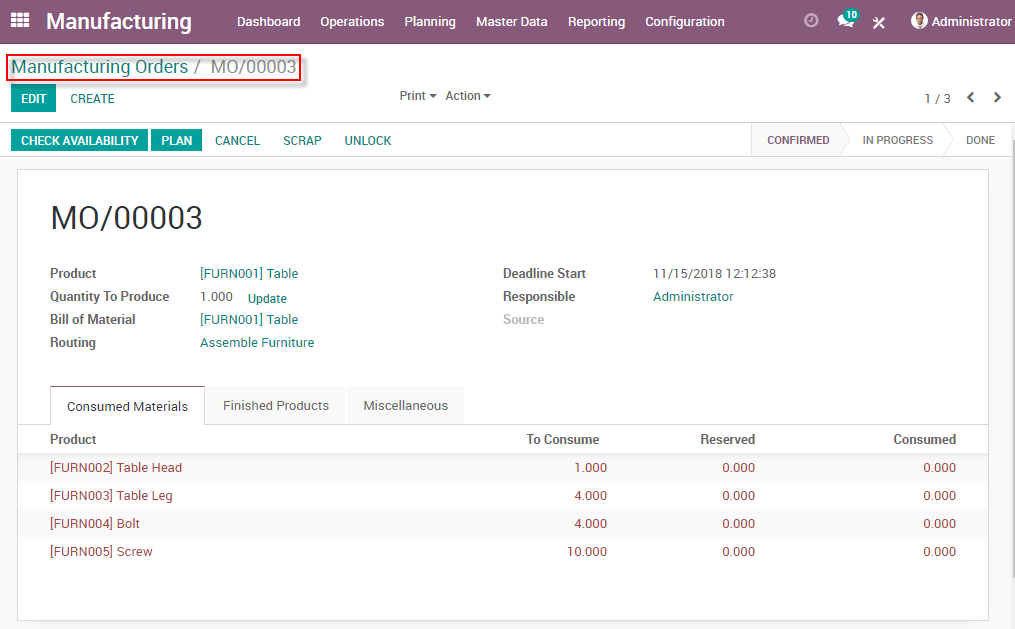

Manufacturing Order

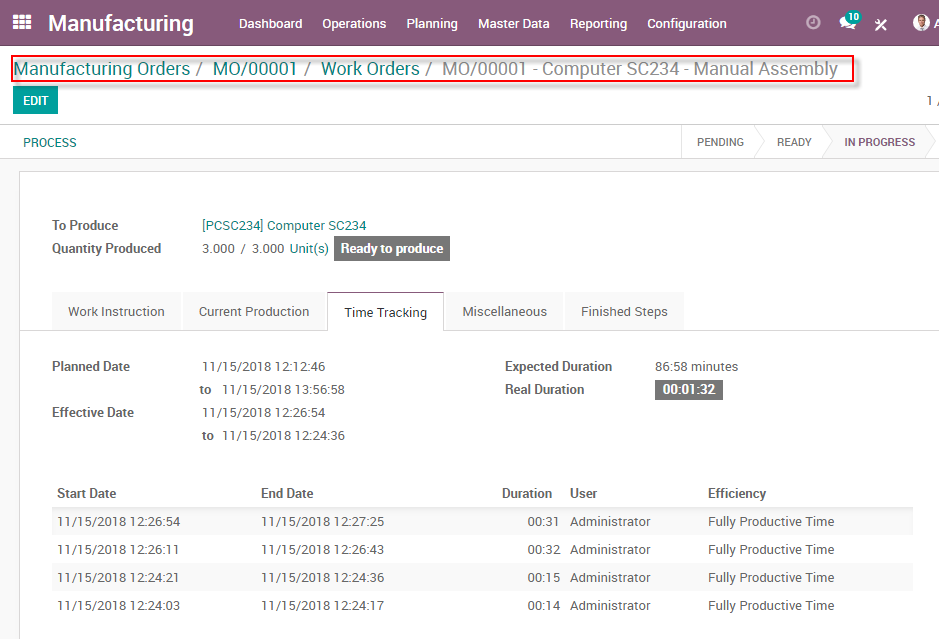

Work Orders