Product Lifecycle Management in Odoo 18

In simple words, Product Lifecycle Management (PLM) in Odoo is all about managing the complete journey of a product, right from its design stage to manufacturing, revisions and finally phasing out. It helps companies bring new products to market faster, manage changes smoothly and make sure everyone such as design, engineering, production and quality teams is working with the same updated information.

For example, when engineers design a product and later make changes (like updating a material or dimension), Odoo PLM ensures that the change is properly documented, approved and communicated to all relevant teams. This avoids confusion, reduces errors and ensures the product lifecycle is well tracked

Business Rules / Key Features

- Every new product or process change must go through an Engineering Change Order (ECO) before implementation

- Track changes and create multiple versions of Bills of Materials (BOM)

- Attach CAD files, drawings, PDFs directly to products and BOMs

- Apply multiple changes without conflict between ECOs

- Real-time chatter, notifications and approval requests

- Automatically updates in Manufacturing, Inventory, Quality, etc

- Once an ECO is approved, the system automatically updates the product version and linked BOM.

- Each BOM must be clearly linked to its version number for full traceability

- Changes to BOM or product documents should always be recorded with reasons and notes

- Old versions of products/BoMs must remain read-only for historical reference

- ECOs can be assigned to specific responsible teams (Engineering, Quality, Production, etc.)

- The system should send notifications or approvals to relevant stakeholders when an ECO is submitted

- No production order should use an outdated or unapproved BOM version

- Each product can have multiple ECOs, but only the latest approved version will be considered active

- All ECO stages, approvals and comments must be visible in the chatter/logs for transparency

Workflow

PLM Masters Management

- Products

- Work Centers

- Eco Types

- Eco Stages

- Eco Tags

PLM Process Management

- Engineering Change Orders

- Bill of Materials

PLM reporting Management

- ECOs

PLM Masters Management

Product

Overview

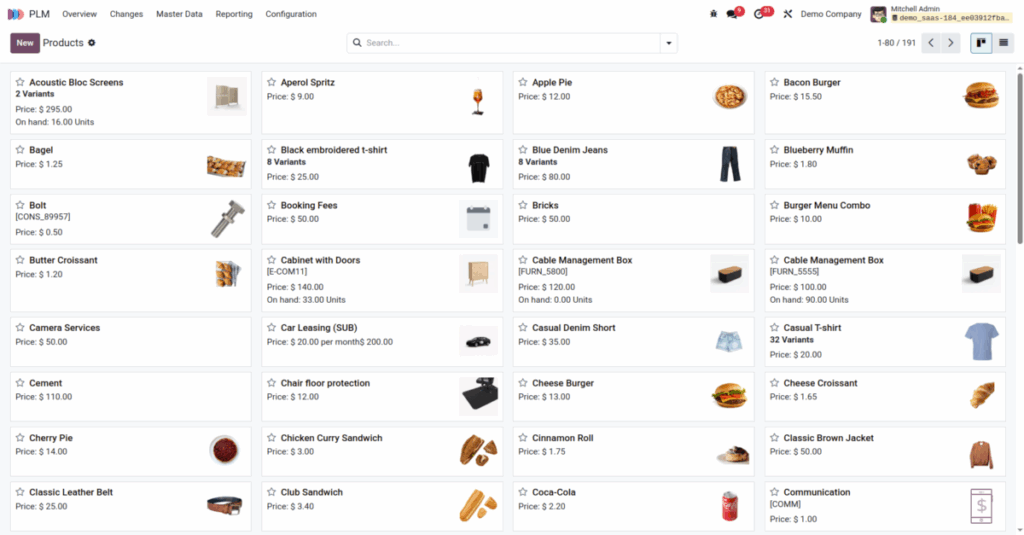

In Odoo, Product Lifecycle Management (PLM) is closely connected with products because it manages all stages of a product’s life from initial design, through production, to retirement. Each product can have multiple versions or revisions and PLM ensures that every change is properly documented, approved and communicated to the right teams. With ECOs (Engineering Change Orders), businesses can update product designs, bills of materials (BoM), or production processes in a structured way. This prevents confusion on the shop floor and ensures that only the latest product version is produced and sold. In simple words, product-related PLM keeps the product data always accurate, updated and aligned between engineering, manufacturing and quality control

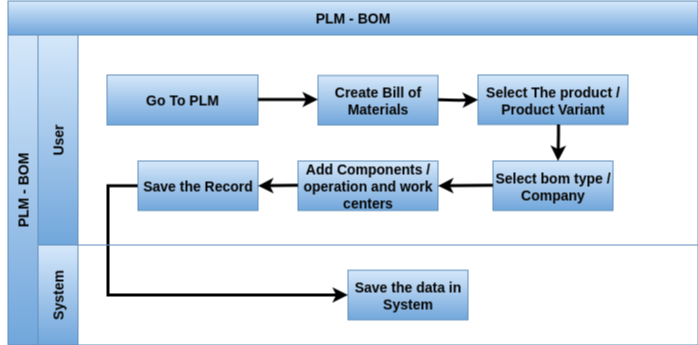

Process Flow

Business Rule

- Products can be linked with Engineering Change Orders (ECOs) to manage updates in design, BoM

- Each product can have multiple versions or revisions, ensuring controlled product evolution

- PLM ensures that changes in BoM automatically sync with production and inventory

- Product documents (like CAD drawings, manuals, certifications) can be attached and version-controlled

- Any product change requires review and approval before release to production

- Helps track the history of product changes, giving full traceability of who changed what and why

- Product-related PLM reduces risk of producing outdated versions of a product

Screenshot

Products

Work Center

Overview

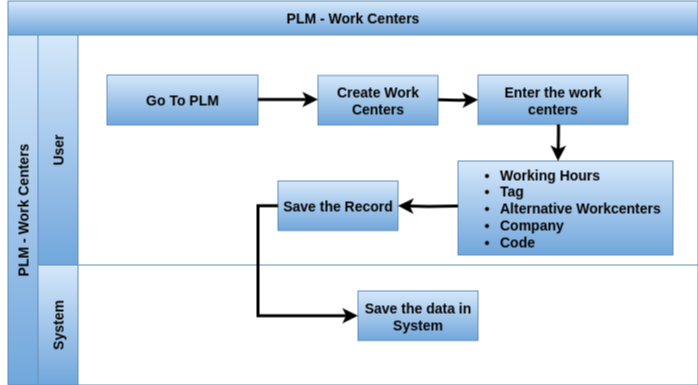

In Odoo, a Work Center represents the physical place or resource where production activities happen, such as a machine, assembly line or labour team. When linked with Product Lifecycle Management (PLM), work centers become an important bridge between engineering changes and shop floor execution. Any time a product design is updated through an Engineering Change Order (ECO), the related operations in the work center also get updated. This ensures that operators always work with the latest version of instructions, documents and quality checks, avoiding mistakes and rework. In simple words, PLM takes care of design accuracy and the work center ensures that the updated design is actually followed during production

Process Flow

Business Rules / Key Features

- Work centers directly connect with Engineering Change Orders (ECOs) to reflect approved design or process changes

- Operators can view the latest version of documents, drawings or worksheets in the work center screen

- ECO approvals can introduce new routing steps or remove old ones in the work center

- Work centers store attachments like CAD files, manuals or setup instructions linked from PLM

- Quality control points defined in PLM automatically apply at the work center during execution

- Each work center maintains version control, ensuring only the correct product revision is manufactured

- Feedback or issues raised on the shop floor can be sent back into PLM for continuous improvement

- Changes in ECOs that impact time or cost are automatically reflected in work center reporting

- Provides traceability, so you know which version of a product was produced in which work center

- Promotes smooth collaboration between Engineering, Production and Quality teams.

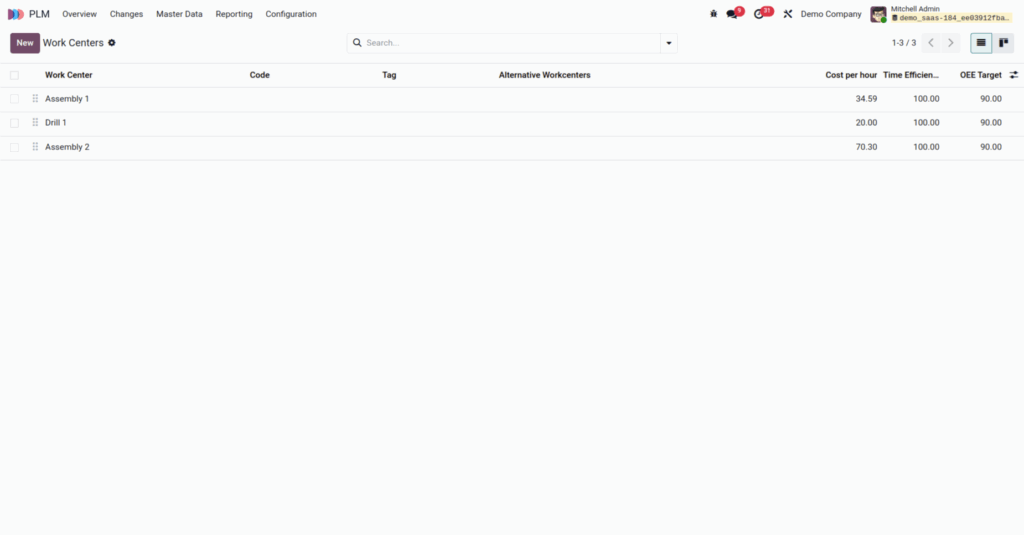

Screenshot

Work Centers

Eco Type

Overview

In Odoo PLM, an ECO Type (Engineering Change Order Type) is like a category or template that defines how a particular type of change request should be managed. For example, some changes may only affect documents, while others may impact the Bill of Materials (BoM) or product routing. ECO Types allow businesses to organize change orders in a structured way, with each type having its own workflow, responsible team and approval rules. This helps companies handle different kinds of product changes systematically, without mixing up engineering changes, document updates or manufacturing adjustments.The ECO Types are used to define and categorize different types of engineering change processes that can occur during the product lifecycle.

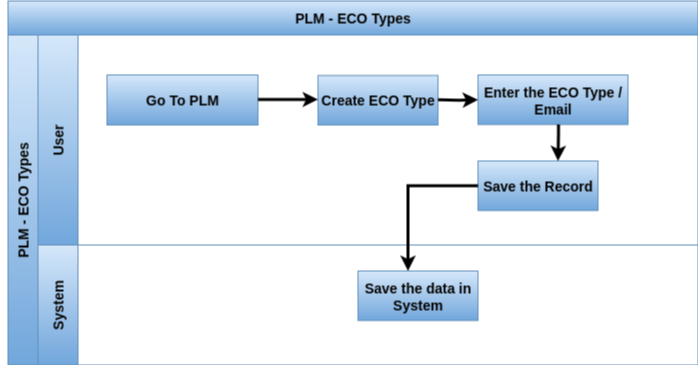

Process Flow

Business Rule

- Products can be linked with ECOs to manage updates in design, BoM

- PLM ensures that changes in BoM automatically sync with production and inventory

- Product documents (like CAD drawings, manuals, certifications) can be attached and version-controlled

- Any product change requires review and approval before release to production

- PLM integrates with work centers so the correct product version is used during manufacturing

- Helps track the history of product changes, giving full traceability of who changed what and why

- Product-related PLM reduces risk of producing outdated versions of a product

- Provides structured workflows for change request, review, approval and implementation

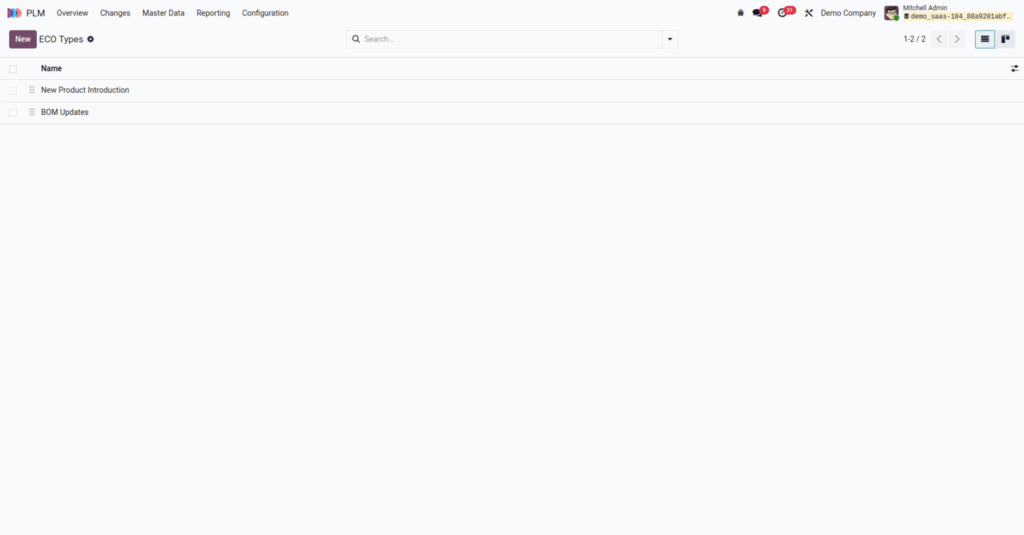

Screenshot

Eco Types

Eco Stage

Overview

In Odoo PLM, ECO Stages represent the different steps an Engineering Change Order (ECO) goes through from creation until completion. Think of it like a journey or approval path for example, “New Request -> In Review -> Approved -> Done”. These stages make it easy for companies to control how product design or manufacturing changes are tracked, reviewed and applied. Each ECO stage can be customised with rules, approvals, responsible persons and activities, so that the change process becomes disciplined and transparent,the ECO stages represent the different phases that an ECO goes through during its lifecycle.

Process Flow

Business Rules / Key Features

- Define multiple stages like New, In Progress, Review, Approved, Done, Cancelled based on company workflow

- Each stage can have its own responsible team or person

- You can set folded stages to keep the kanban board clean (closed stages are collapsed)

- Configure automated activities (like reminders or follow-ups) for each stage

- Control who can move an ECO to the next stage by using user access rights

- Add approval requirements (e.g., manager or engineering lead must approve before moving forward)

- Visualise progress with Kanban and activity view for all ECOs

- Cancelled ECOs can be separated in their own stage for record keeping

- Fully integrated with Work Centers, Products and Bill of Materials so that approved ECOs automatically impact production data

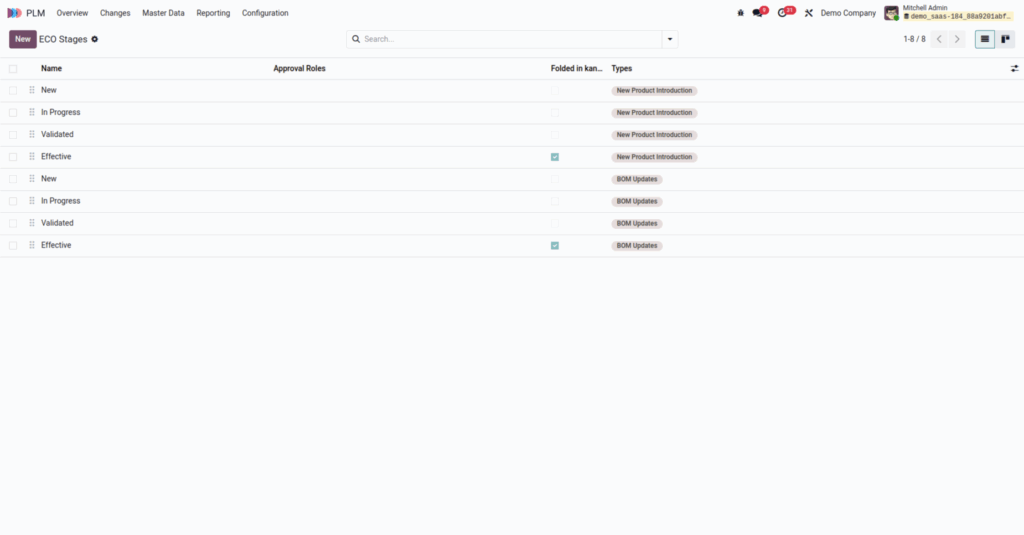

Screenshot

Eco Stages

Eco Tag

Overview

In Odoo PLM, ECO Tags are labels that you can attach to Engineering Change Orders (ECOs) for easy classification and tracking. They work just like coloured stickers or labels that help you quickly identify the type of change, its priority or any special note. For example, you may tag an ECO as Urgent, Cost Saving, Design Update or Customer Request. Tags make searching, filtering and reporting much easier, especially when handling a large number of ECOs

Process Flow

Business Rules / Key Features

- Create unlimited tags to classify ECOs in business required way

- Tags can represent priority, reason, department and category of change

- Multiple tags can be applied to a single ECO

- Tags are colour coded for quick visual recognition on kanban boards and lists

- Easy to use in search, filters and group by to narrow down ECO records

- Tags can be managed by administrators anytime

- Provide better reporting and analytics by grouping ECOs with common tags

- Help teams to quickly understand the nature of a change without reading full details

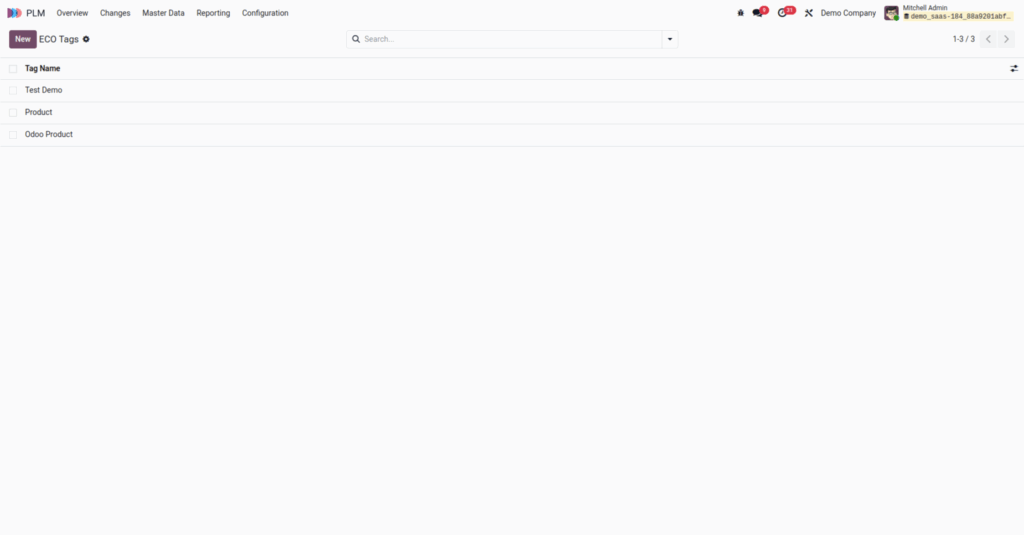

Screenshot

Eco Tags

PLM Process Management

Bill of Materials

Overview

In Odoo, the Bill of Materials is a fundamental part of the Product Lifecycle Management module, especially in manufacturing and engineering workflows. PLM in Odoo enhances BoM management by introducing version control, engineering change orders and collaboration tools

The Bill of Materials (BoM) is not just a list of components used to make a product, but a living document that keeps evolving as designs and engineering changes happen. Whenever a design update, material substitution or process improvement is approved through an Engineering Change Order (ECO), the BoM gets updated automatically. This ensures that production teams are always working with the latest approved version of the product structure.

From a PLM perspective, the BoM acts as the link between the design office (engineering) and the shop floor (manufacturing). It keeps all stakeholders aligned on which parts, sub-assemblies, or raw materials should be used at any given stage

Process Flow

Business Rules / Key features

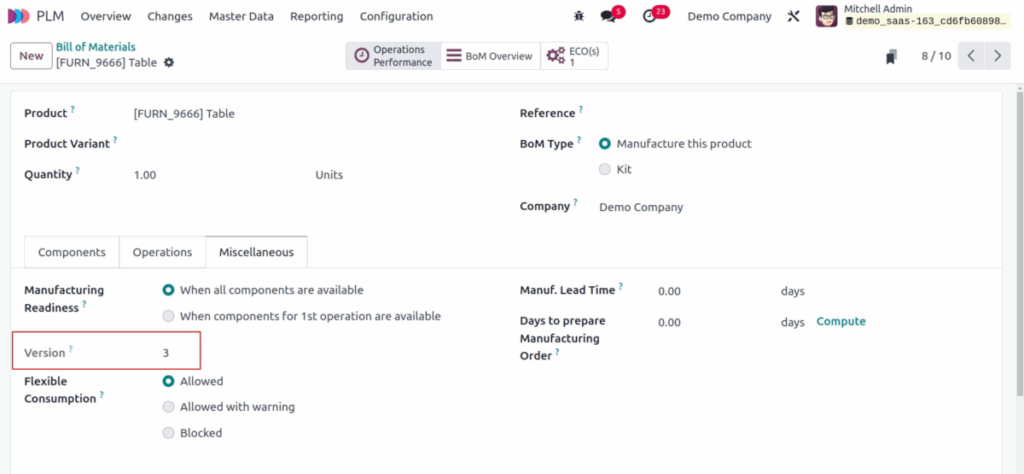

- Version Control, Every ECO can create a new version of the BOM, keeping history

- Approval Flow, Changes in BOM like new parts or updated quantities can only apply after ECO approval

- Multi-Level BOM, Supports sub-assemblies and complex product structures

- Alternative Components, Engineers can define substitute materials or parts in BoM

- Traceability, Audit trail of who changed what and when for compliance

- Collaboration, Design, production and quality teams all access the same updated BoM

- Product Document Linking, CAD files, drawings or instructions can be attached to BoM lines for clarity

- Cost and Impact Analysis

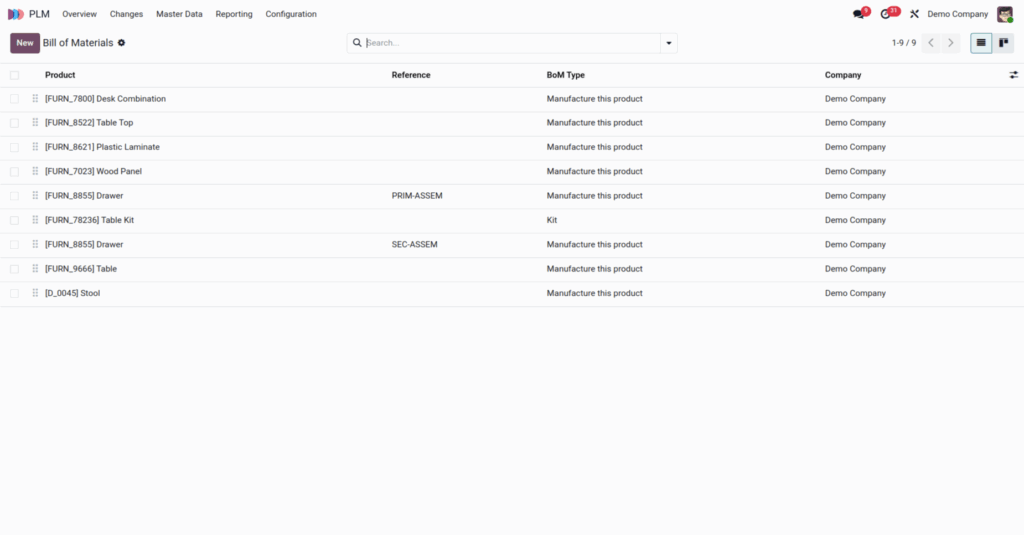

Screenshot

Bill of Material

Engineering Change Orders

Overview

An Engineering Change Order is a formal request or instruction to modify a product’s design, bill of materials, or manufacturing process. It is a key part of product lifecycle management and quality control in manufacturing companies.

Process Flow

Business Rule

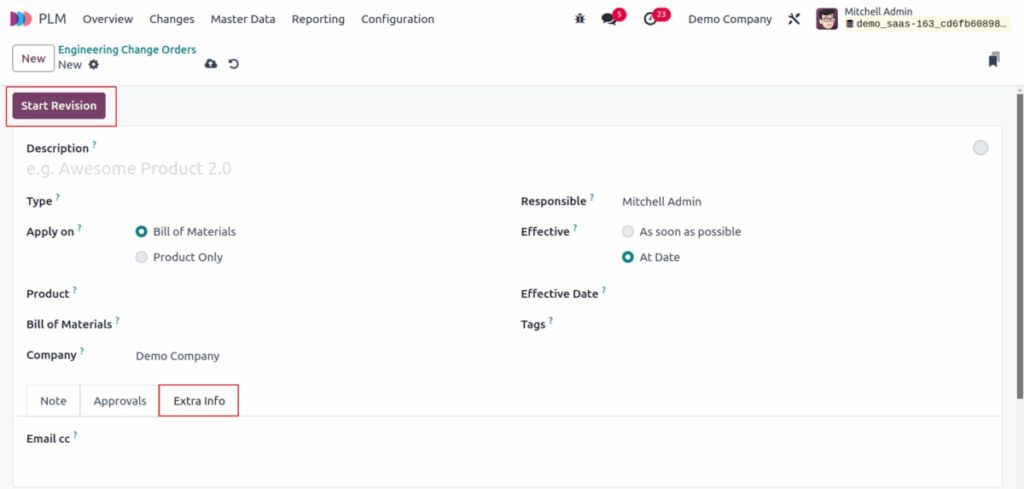

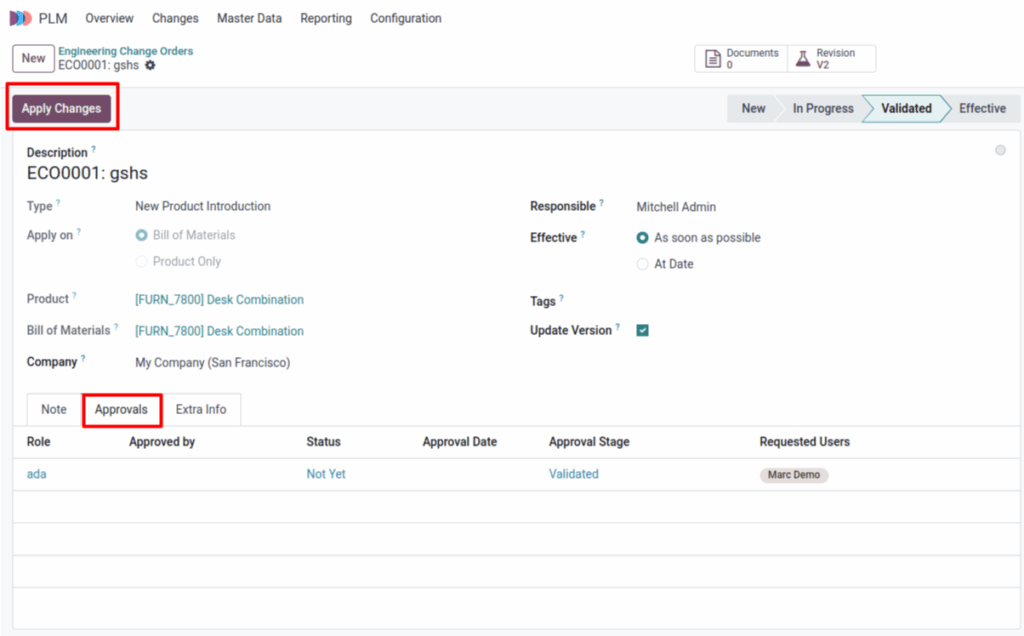

- When setting up the stages of an ECO, you can add details about the employee whose approval is needed to move the ECO to the next step.This includes information like Role, Approved By, Status, Approval Date, Approval Stage, and Requested Users.

- Create an Engineering Change Order to enter a description, select the ECO type, and automatically map the product against its existing Bill of Materials.

- After that, click the “Start Revision” button, this will enable the next stage and make it clickable.

- You can then move the ECO through the stages by clicking on each stage.

- The files linked to the ECO will show up when you click the Documents smart button.

Once the ECO is in the Validated stage, you will see an Apply Changes button. You can use this to update the product with the suggested changes. - After you apply the changes, the product will be updated based on the Effective Date.

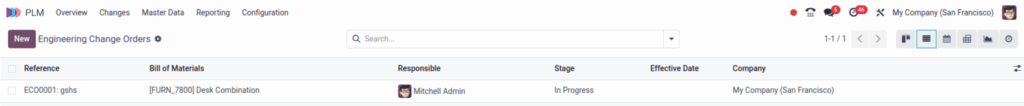

- You can also create engineering change orders for an existing BoM by clicking the smart button on the form, as shown below.

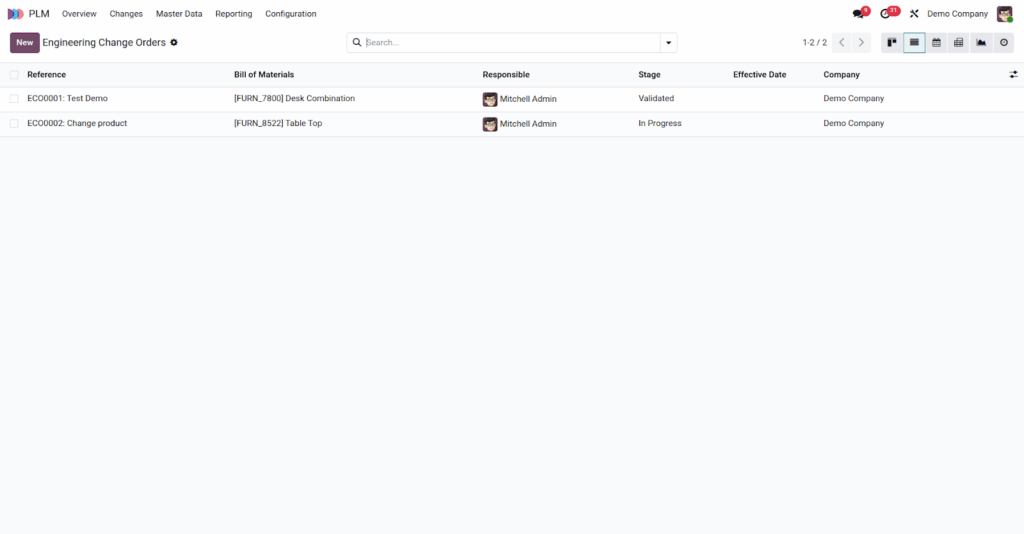

Screenshot

Engineering Change Order – Form View

Screenshot

ECOs – Start Revision

Screenshot

ECOs – Apply Changes

Screenshot

ECOs – Bill Of Materials

Screenshot

ECOs – List View

PLM Report Management

ECOs

Overview

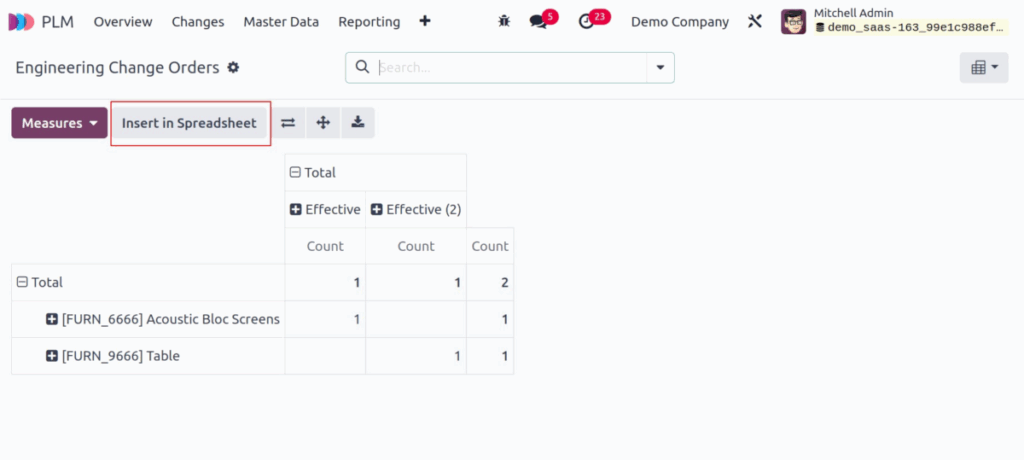

The Reporting feature in the Odoo PLM module helps you check engineering change orders. This tool gives you real-time reports about product changes your company is thinking about. A picture of the report.

Business Rule

- Visualize project data using line, bar, and pie charts, making it easier to track progress and identify trends.

- Analyze data by grouping by product, state, stage, and company. Measures like BoM revision and count can be used to gain insights into the change process.

- Export reports to spreadsheets for further analysis or presentation.

Screenshot

Ecos