Quality Management in Odoo 18

In Odoo, the Quality Management module helps you maintain product quality at every step from receiving goods to manufacturing and shipping. It works like a digital inspection system. By using set up with checkpoints, create test procedures and assign quality teams. When something doesn’t meet the quality standards, the system raises alerts and suggests corrective steps.Users can analyse trends with intuitive dashboards and reports and manage quality issues effectively. Everything links seamlessly with your Inventory, Manufacturing, Purchase and Sales workflows, which makes quality control smooth.

Key Features

- Define the control points at product, category, operation or process level

- Set quality type such as manual, pass/fail, measurement, checklist, etc.

- Schedule checks automatically during Receipts, Manufacturing or Delivery

- Define the frequency such as Periodically, randomly Ondeman and all

- Assign responsible users for control check points

- Perform manual or automated inspections during workflow

- Enter measured values directly into the system

- Upload images or documents as proof of inspection

- Link checks directly with stock moves, lots, or serial numbers.

- Raise alerts when defects are found during checks

- Categorize alerts by type

- Assign alerts to responsible users/teams for quick resolution

- Track priority levels such as low, medium, high, critical

- Communicate directly on the alert records through chatter & notes

- Escalation possible if not resolved in time

- Define corrective actions for immediate issue resolution

- Define preventive actions to avoid recurrence of the issue

- Track action status until closure

- Maintain history for audits and compliance

- Maintain the attachments while doing quality checks or alerts

- Inventory: Quality checks on incoming, internal stock and outgoing deliveries

- Manufacturing: In-process and final quality checks during production completion

- Maintenance: Link machine breakdowns with quality issues

- Full history of every quality check stored against the process/operations

- Track by lot/serial number for product recalls

- Generate inspection certificates when required

- Dashboard with open alerts, failed checks and trend analysis

- Reporting on vendors, products or processes with high defect rates

- Mobile/tablet friendly for shop floor usage easily

- Barcode scanning for quick product identification

- Smart buttons for quick navigation such as checks, alerts

- Multi-company and multi-warehouse support

- Quality Control Points – Set up automatic quality checks at different stages like production or delivery.

- Quality Checks – Perform manual or automated checks on products or processes.

- Quality Alerts – Create alerts for any issues or non-conformities found during checks.

- Quality Teams – Assign tasks and alerts to specific teams responsible for quality.

- Module Integration – Works smoothly with manufacturing, inventory, and purchasing modules.

- Flexible Check Types – Use different check formats like pass/fail, measurements, or notes.

- Reports & Dashboards – View reports and KPIs to track quality performance.

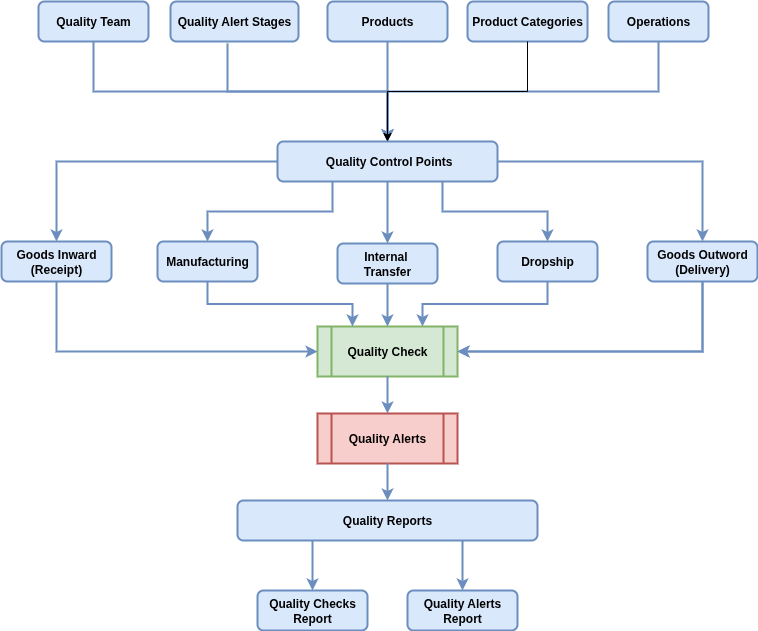

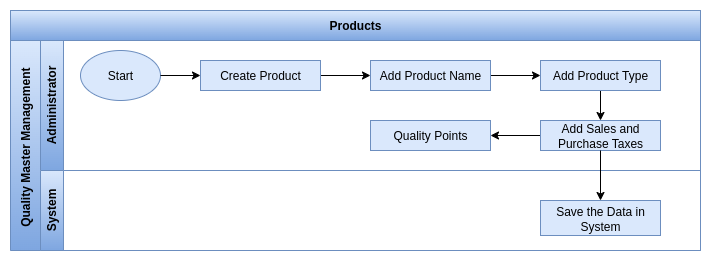

Quality WorkFlow

Quality Master Management

- Quality Teams

- Quality Worksheet Templates

- Quality Spreadsheet Templates

- Products

- Quality Alert Stages

- Quality Tags

Quality Management

- Quality Control Points

- Quality Checks

- Quality Alerts

- Quality Overview

Quality Reports

- Quality Checks Report

- Quality Alerts Report

Quality Teams

Overview

In Odoo, Quality Team is like a dedicated group that looks after quality-related activities inside a company. Just like we have sales teams or support teams, the quality team manages all inspections, checks and alerts related to the quality of products and processes. Each team can be responsible for a specific department, product line or location. Having quality teams makes it easy to divide responsibility, assign tasks to the right people and track performance. This helps companies maintain standards and quickly solve any quality issues

Process Flow

Business Rules / Key Features

- Each quality team can be given a unique name for easily identification

- Teams can be assigned to specific products, production lines or warehouses/Locations

- A responsible person can be assigned to monitor and guide the team

- Multiple members can be added to one team for collaborative work

- Teams can handle both quality checks and quality alerts, when issues arised

- Access rights can be defined to control who can view or manage the team’s work

- Teams are linked with reporting dashboards to track performance, pending checks and alerts

- Each team can have its own email alias for direct communication and alerts

- Able to maintain the team company wise or accress all companies common team

- Able to share the details about own team members using send message, attachments also

Screenshots

Quality Teams Form View

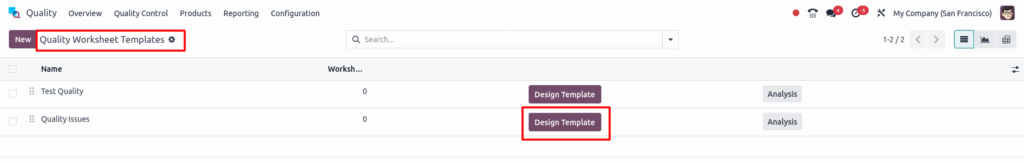

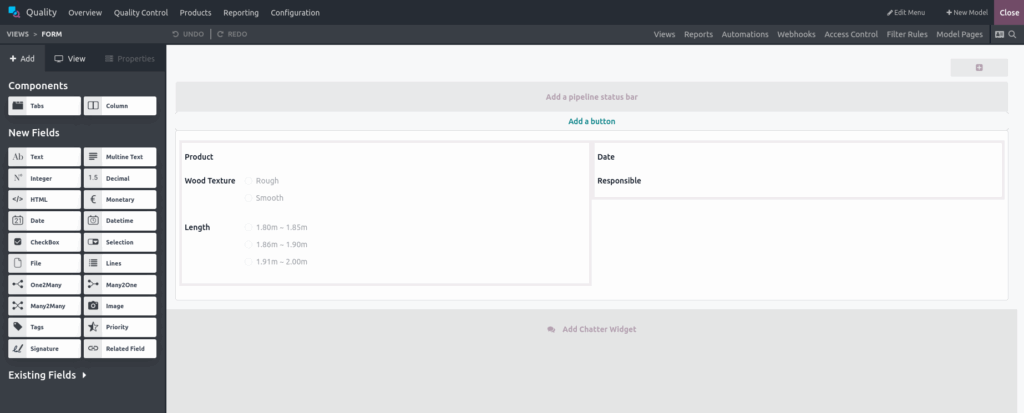

Quality Worksheet Templates

Overview

In Odoo, Quality Worksheet Template is like a ready-made form or checklist used during quality checks. Instead of writing the inspection process every time, companies can prepare templates once and reuse them. For example, a worksheet can guide an inspector to measure product dimensions, check weight or verify packaging. These templates ensure that all team members follow the same steps and nothing important is missed. They also make audits and compliance easier, because the inspection record is always stored in the system

Process Flow

Business Rules/Key Features

- Allows creating reusable forms for quality inspections

- Different question types supported like text, multiple choice, yes/no and measurements

- Can be linked with specific quality control points

- Option to make some fields mandatory so inspectors cannot skip them

- Supports adding images or instructions to guide inspectors

- Templates can be reused across multiple products or processes

- Helps in maintaining standard operating procedures

- Digital records are saved for each inspection, avoiding paperwork

- Can be reviewed later during audits, reports or customer claims

- Easy to update or modify templates when standards change

- To start, Enable worksheets by activating the Quality Worksheets toggle in settings

- Store and export data from completed worksheets for analysis in Excel or via dashboards

Screenshots

Quality Worksheet Templates Tree View

Quality Worksheet Templates Design View

Quality Worksheet Templates Form View

Quality Worksheet Templates Graph View

Quality Spreadsheet Templates

Overview

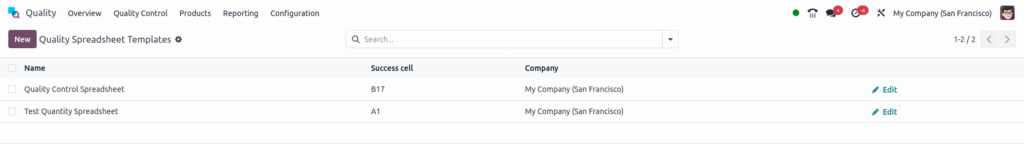

In Odoo, Quality Spreadsheet Templates are ready-made formats that help teams collect, record and analyse quality data in a structured way. Instead of making a new sheet every time, these templates provide a standard format for common quality activities like inspections, test results, or defect tracking. They make data entry simple, ensure consistency, and save time during audits or reporting. Since they are reusable, companies can apply the same template across different products, work centers or quality teams without duplication

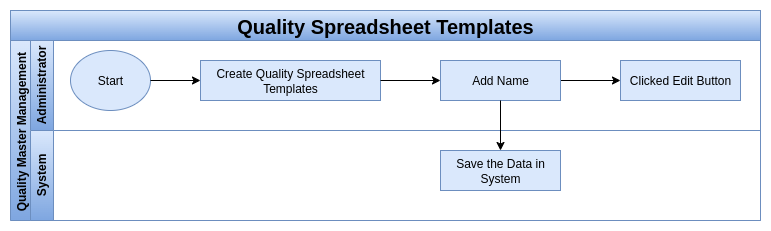

Process Flow

Business Rules / Key Features

- Predefined spreadsheet layouts for common quality control needs

- Easy to customise as per product, process or company standards

- Ensures consistent recording of inspection results and test parameters

- Can be linked with quality checks, work orders or specific processes

- Supports formulas and calculations to analyse data automatically

- Helps maintain clean and standardised records for audits and certifications

- Reusable templates avoid repetitive work and save time

- Improves transparency as all data is stored within Odoo and not in separate files

- Enable the spreadsheet type by choosing “Spreadsheet” as the check type in a Quality Control Point (QCP)

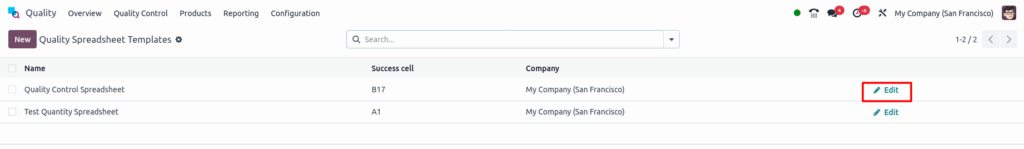

- Create templates via Quality → Configuration → Quality Spreadsheet Templates → New

- Link templates to QCPs, so each check generated uses that spreadsheet format

- Fill interactive spreadsheets during quality checks, with formula-based evaluation

- The defined success cell value dictates check outcome (pass or fail)

- Completed spreadsheet data is stored, enabling export and analysis via dashboards

Screenshots

Quality Spreadsheet Templates Tree View

Quality Spreadsheet Templates Tree View Click Edit Button

Quality Spreadsheet Templates Design View

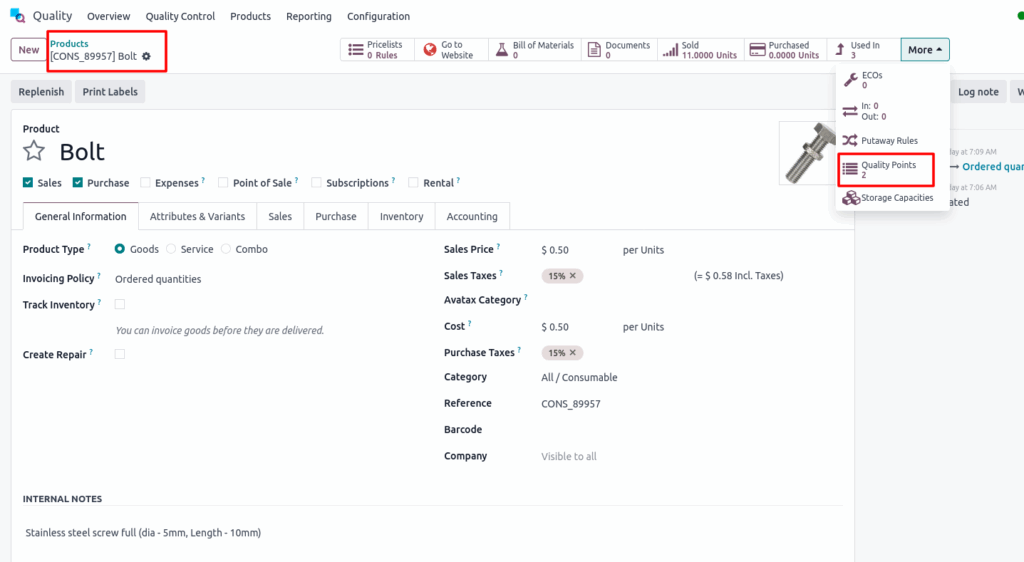

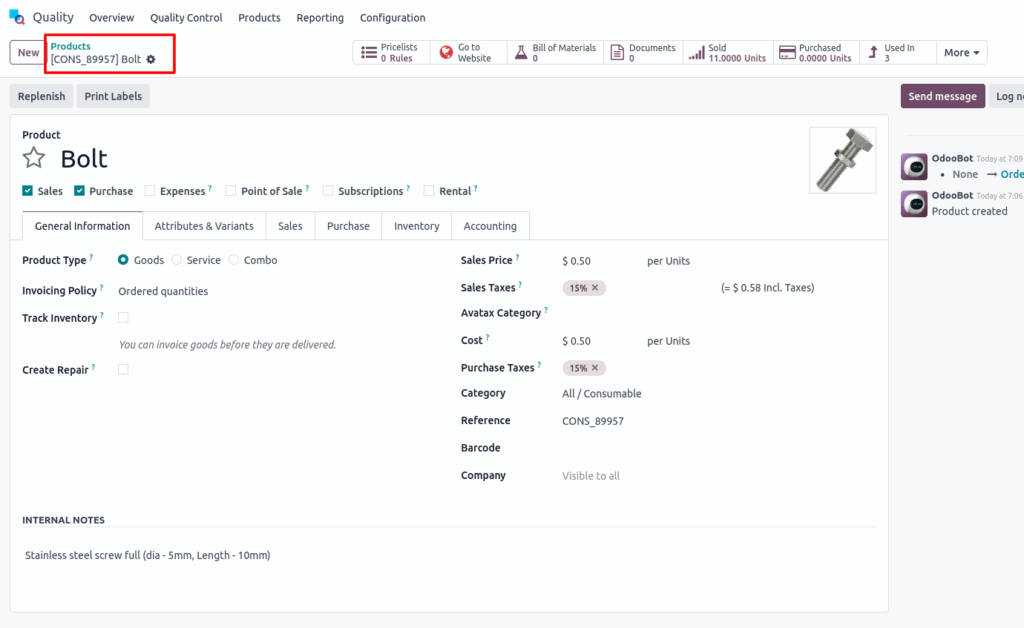

Products

Overview

Products in Odoo Quality Management are the items or goods for which quality controls and inspections are defined and tracked

Process Flow

Business Rules

- Link Quality Control Points to specific products or product categories.

- Define inspection triggers on product events (e.g., receipt, production, delivery).

- Use product attributes (batch, serial number) to track quality checks precisely.

- Enforce quality alerts on products failing inspection, requiring corrective actions.

- Assign responsible quality teams for product inspections and follow-ups.

- Record inspection results for each product batch/serial for traceability and audits.

- Adjust inspection frequency or rules based on product risk or supplier quality history.

Screenshots

Products Form View

Products Form View – Quality Points Menu

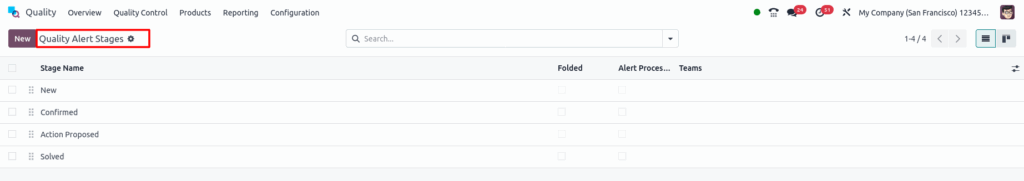

Quality Alert Stages

Overview

In Odoo, Quality Alert Stages represent the different steps through which a quality alert passes until it is resolved. They work like a pipeline, helping teams clearly see the status of each issue whether it is newly reported, under review, being fixed or closed. By using stages, companies can standardise how alerts are handled and make sure no issue is left unattended. It also helps managers track delays, assign responsibilities and improve overall process efficiency.Quality Alerts help track issues with products or processes. Each alert moves through stages to show its progress.

Typical stages

- New – A problem is reported.

- Confirmed – The issue is reviewed and accepted as valid.

- Action Proposed – A solution or corrective action is planned.

- Solved – The problem is fixed, and the alert is closed.

Process Flow

Business Rules / Key Features

- Define multiple stages such as New, In Progress, Under Review, Resolved, Closed

- Fully customizable stages to match company-specific workflows

- Stage specific rules can be applied, such as requiring approvals or assigning responsible persons.

- Automatic notifications or activities can be set when an alert enters a particular stage.

- Provides better visibility to management for monitoring unresolved or overdue alerts

- Ensures a structured and consistent resolution process for quality issues

- Create alert when a quality issue is found.

- Move to “Confirmed” after checking the issue is valid.

- Assign alert to the responsible team or person.

- Do root cause analysis before proposing a solution.

- Add corrective or preventive action in “Action Proposed” stage.

- Mark as “Solved” only after action is completed and verified.

- Send notifications when alerts are created or moved.

- Close alert with a reason (Solved or Rejected).

Screenshots

Quality Tags

Overview

Quality Tags in Quality Management are labels or keywords that help categorize and organize quality checks, quality alerts, and quality control points. These tags make it easier to filter, search, and report on quality issues or inspections by grouping similar types of quality data.

Process Flow

Business Rules

- Each quality tag has a unique name.

- Tags classify quality issues (e.g., Critical, Minor).

- Tags can be added to quality checks or alerts.

- Multiple tags can be used on one quality record.

- Tags help prioritize and filter quality problems.

- Tags can be edited or deactivated, but not deleted if used.

- Only authorized users can create or change tags.

- Tags are used in reports to track quality trends.

Screenshots

Quality Tags – Tree View

Quality Tags – Click View Button Show Form View

Quality Control Points

Overview

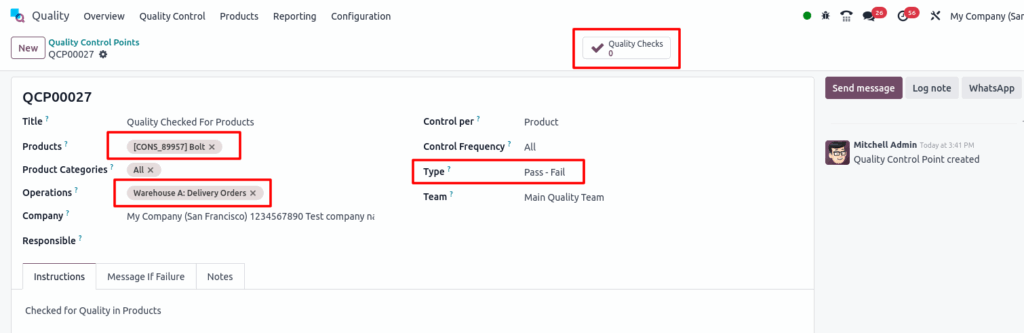

In Odoo Quality Management, Quality Control Points are the predefined checks or inspections that need to be performed at different steps in the production or incoming/outgoing process. They act like checkpoints where the system reminds users to perform a test, measure or inspection before moving forward. For example, a control point can be set to check raw materials when they arrive, verify dimensions during manufacturing or inspect packaging before delivery. By setting these control points, businesses ensure consistent quality without missing any critical check

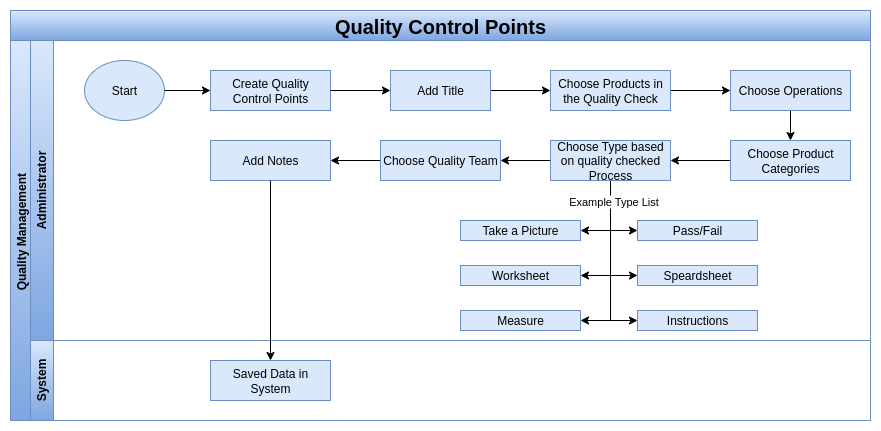

Process Flow

Business Rules / Key Features

- Create QCPs and assign them to products, operations, or suppliers.

- Define the type of check for each QCP (pass/fail, measurement, worksheet, spreadsheet).

- Set inspection frequency and sampling rules (e.g., every batch, random).

- Link QCPs to responsible quality teams for accountability.

- Automatically trigger inspections at defined process stages (receipt, production, delivery).

- Record inspection results and trigger alerts on failures.

- Support on-demand and recurring quality checks through QCPs.

- Use QCP data for reporting, analysis, and continuous improvement.

- Assign control points to specific products, product categories or operations

- Flexible trigger options like “per operation”, or “per unit”

- Automatic pop-up of control points when the related operation is performed

- Can be linked to Quality Worksheet Templates for detailed step-by-step inspection

- Supports mandatory checks, work cannot continue until the inspection is done

- Results are recorded in the system for traceability and reporting

- Helps in maintaining compliance with quality standards and audit requirements

- Easy integration with Quality Alerts in case of failed checks

Screenshots

Quality Control Points Form View

Quality Control Points – Type List Screen

Quality Checks

Overview

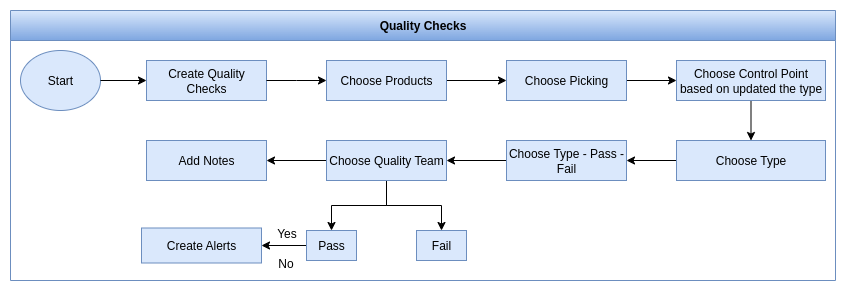

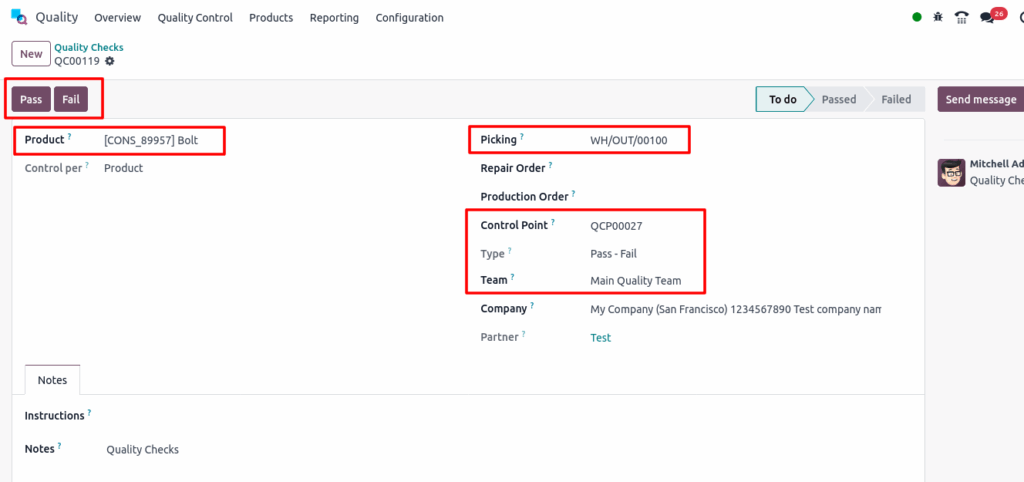

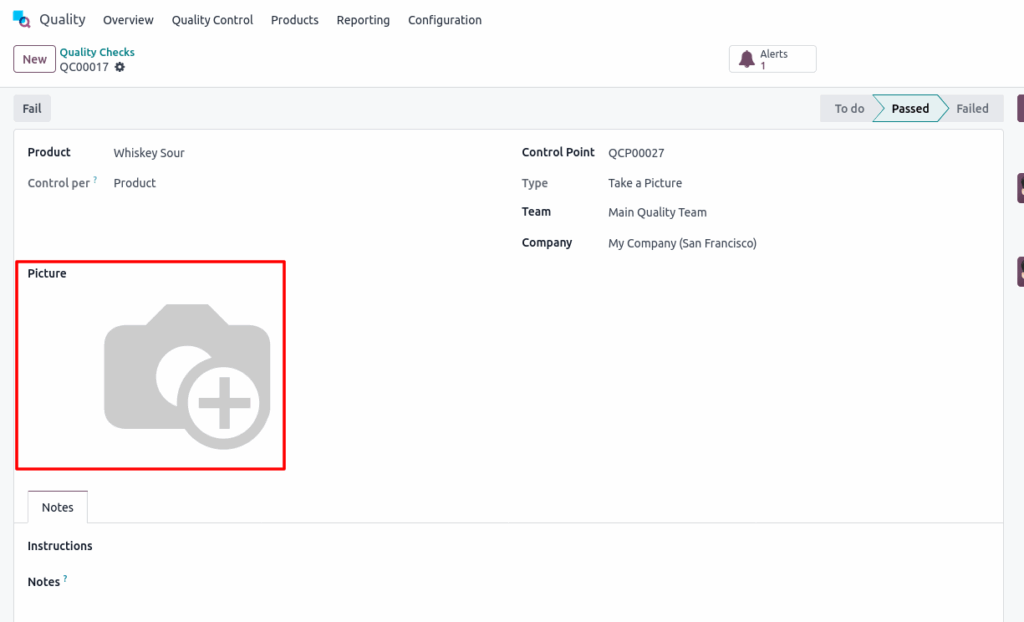

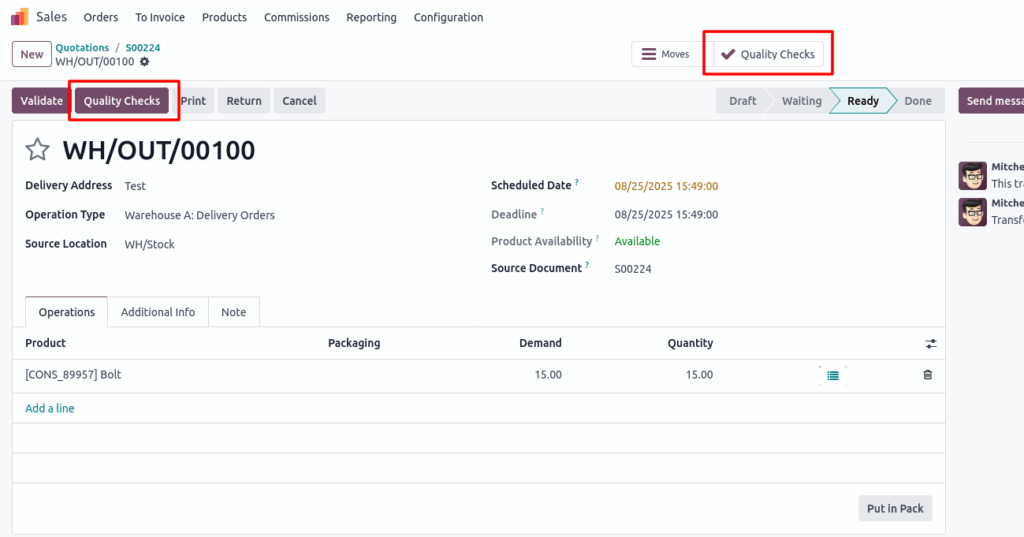

In Odoo Quality Management, Quality Checks are the actual inspections or tests performed by users based on the defined Quality Control Points. While control points act as rules or guidelines for when and what to check, the quality checks are the real-time actions taken during operations. For example, if a control point says “check product dimensions during production” then the operator will record the measurement as a quality check. These checks ensure that every step in the process is properly verified and documented, making the system reliable for audits and continuous improvement

Process Flow

Business Rules / Key Features

- Automatically triggered by Quality Control Points at the right stage

- Quality Checks are executed based on Quality Control Point definitions

- Checks can be automatic (triggered by processes) or manual (on demand)

- Each check records inspection results and status (pass/fail, measurement values)

- Checks must be completed to proceed with product movement or process steps

- Failed checks trigger alerts and corrective workflows

- Results are linked to product batches/serials for full traceability

- Checks can include worksheets or spreadsheet templates for detailed inspections

- Quality teams are assigned to review and manage checks and alerts

- Helps businesses maintain consistent quality standards and reduce errors

Screenshots

Mapped Picking Order Number and Control Point

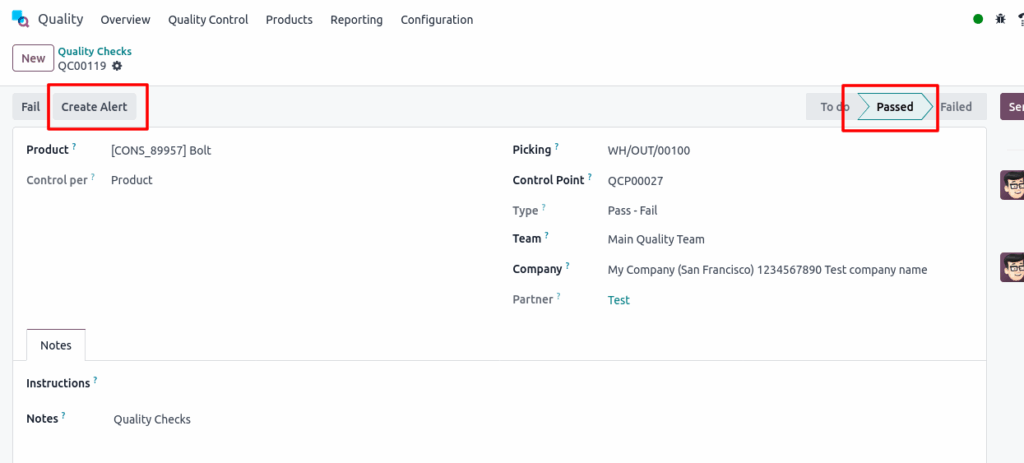

Create Alert Button

Type Selected in Take a Picture

Sale(Confirmed) – Delivery Order (Quality Checked)

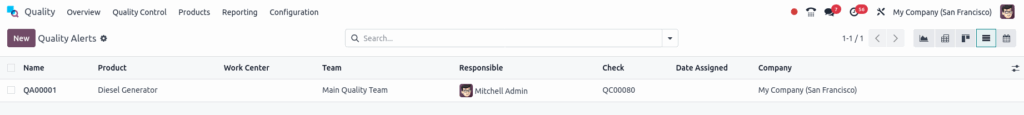

Quality Alerts

Overview

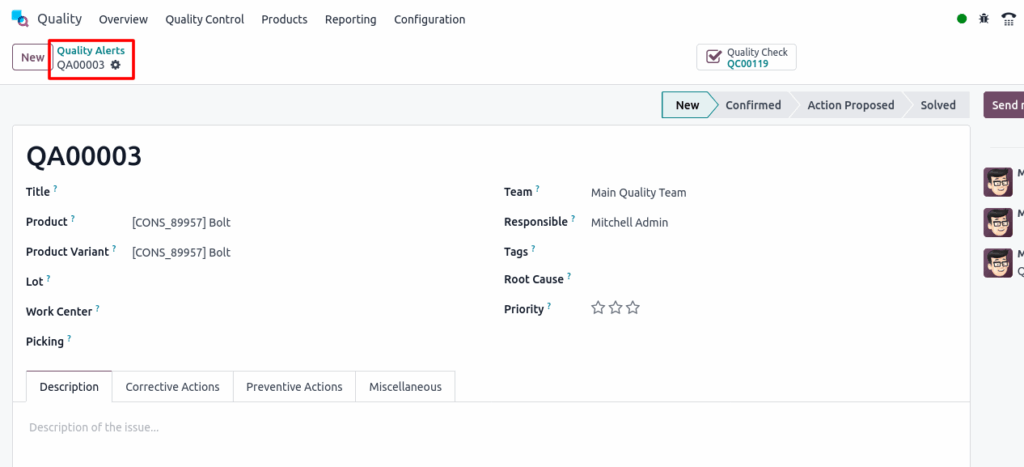

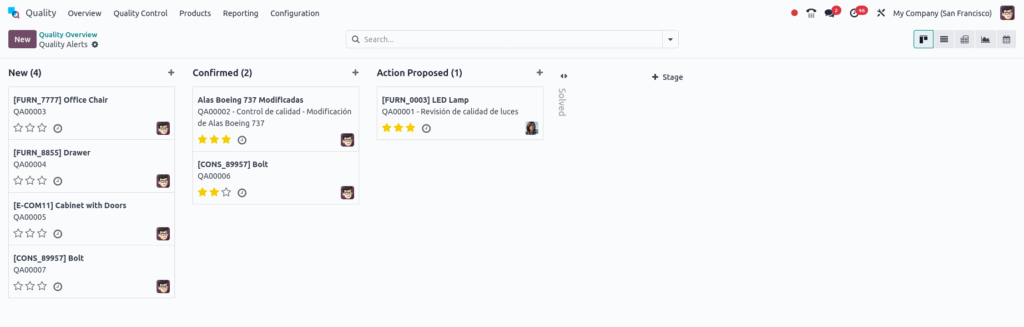

In Odoo Quality Management, Quality Alerts are notifications or issues raised when a product, process or operation does not meet the expected quality standards. They act like tickets or cases that capture the problem, assign it to the right person or team and track the resolution. Quality Alerts can come from failed Quality Checks, manual reporting by employees or customer feedback. They ensure that problems are not ignored and corrective actions are properly taken. For example, if a batch fails inspection due to wrong dimensions, a quality alert is created to investigate the cause, assign responsibility and decide whether to rework, scrap, or adjust processes

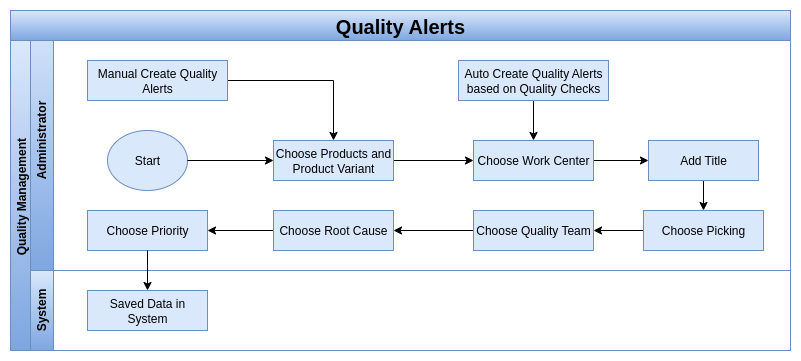

Process Flow

Business Rules

- Generate alerts automatically from failed quality checks or create manually.

- Assign alerts to specific quality teams or responsible users

- Record detailed information about the issue and affected products/batches

- Track corrective actions and follow-up activities within each alert

- Close alerts only after confirming the issue is resolved

- Use alerts data for reporting and root cause analysis

- Link alerts to quality checks and control points for traceability

- Escalate alerts if unresolved within defined timeframes

- Helps improve compliance, reduce recurrence of issues and continuous improvement efforts

Screenshots

Quality Alert Form View

Quality Overview

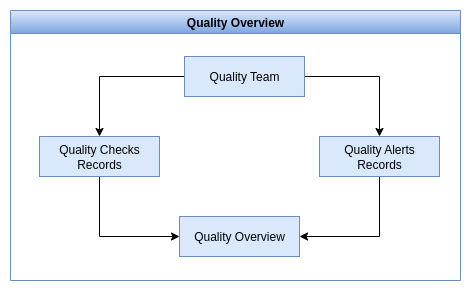

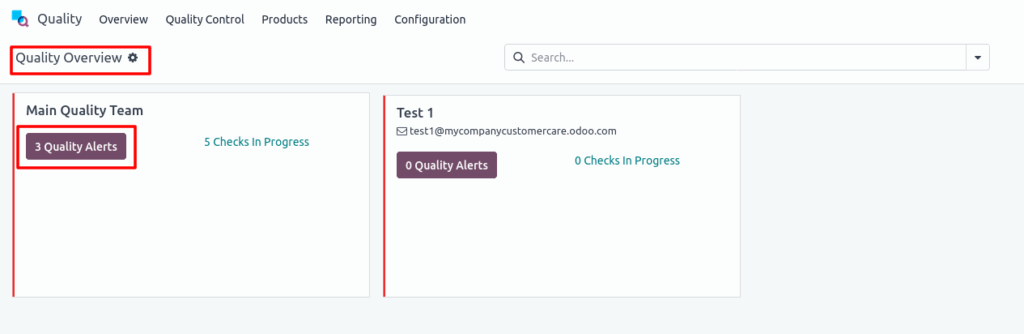

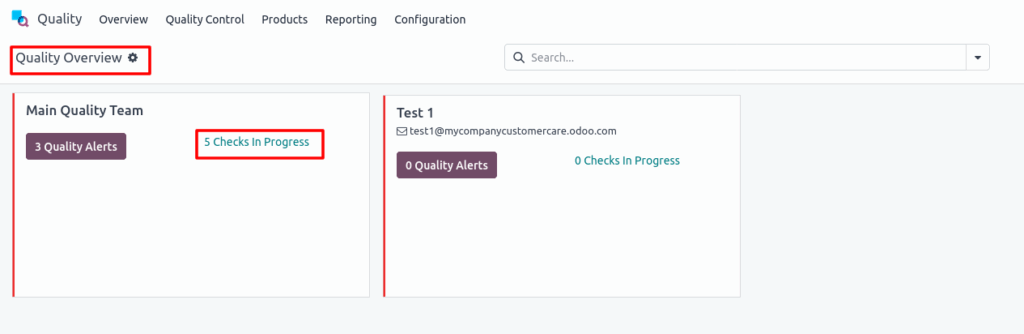

Overview

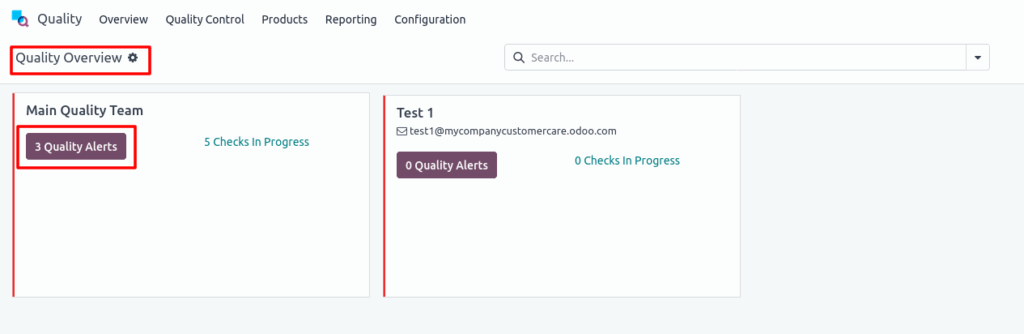

The Quality Overview Screen is a centralized dashboard that provides a real-time snapshot of all quality activities across teams, products, and control points.

Process Flow

Business Rules

- Display all pending and completed quality checks grouped by teams or products.

- Show open and closed quality alerts with status updates.

- Provide summary metrics on inspection results (pass/fail rates, defect counts).

- Allow filtering by quality team, product, or control point for focused views.

- Update data in real-time to reflect current quality status.

- Enable quick access to detailed records and corrective actions.

- Support role-based access so users see relevant quality data only.

- Use overview data to trigger escalations or improvement initiatives.

Screenshots

Quality Overview Screen

Quality Overview – Click Check In Progress Button Screen

Quality Overview – Quality Checks View

Quality Overview – Click Quality Alerts Button Screen

Quality Overview – Quality Alert View

Quality Reporting Management

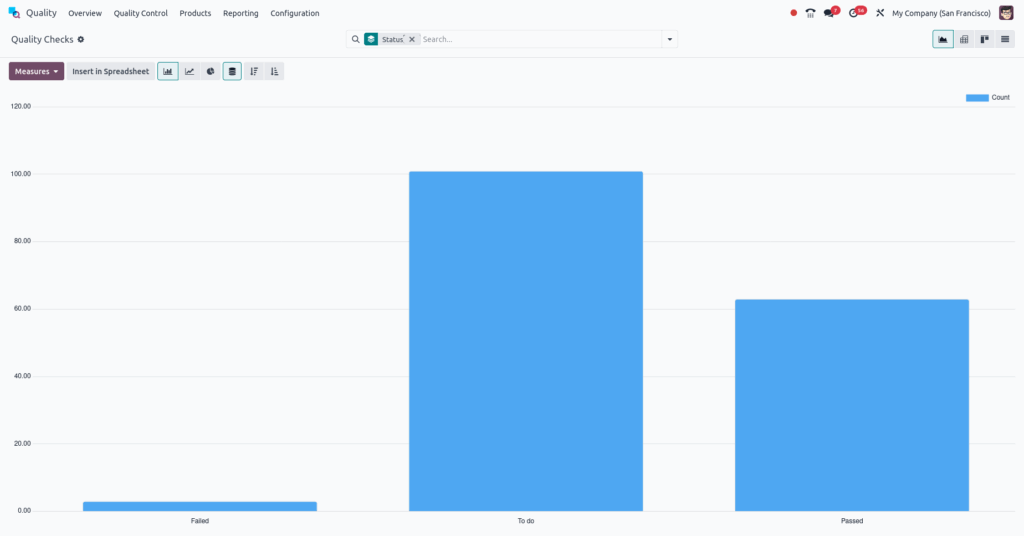

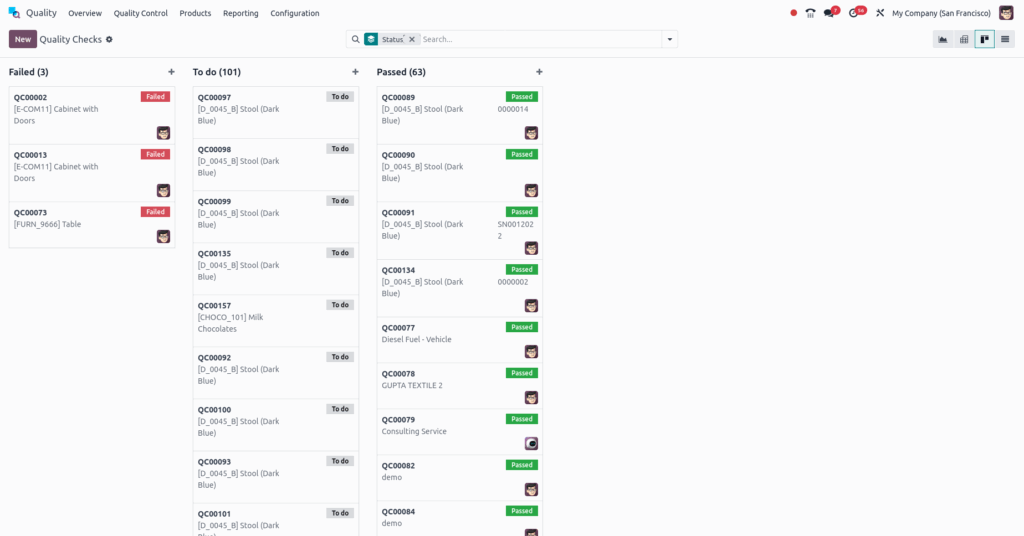

Quality Checks Report Overview

The Quality Check Report in Odoo 18 provides a detailed overview of all quality inspections performed across products, batches, and manufacturing processes. It enables quality teams to monitor inspection results, verify compliance with quality standards, and track non-conformities in real time.

Business Rules

- Quality checks must be created for products at specific stages (e.g., production, receipt, before shipping).

- Each quality check is linked to a product, lot/batch, and operation/work order.

- Quality checks include defined inspection points and measurable parameters.

- Checks must record pass/fail results or measured values.

- Failed checks should trigger alerts or corrective actions automatically.

- Quality checks move through statuses: Scheduled → In Progress → Completed.

- Only authorized users can perform or validate quality checks.

- Quality checks must be documented with timestamps and inspector details.

- Reports can be filtered by product, date, status, or inspection type.

- Regular monitoring of checks helps identify recurring defects and improve processes.

Screenshots

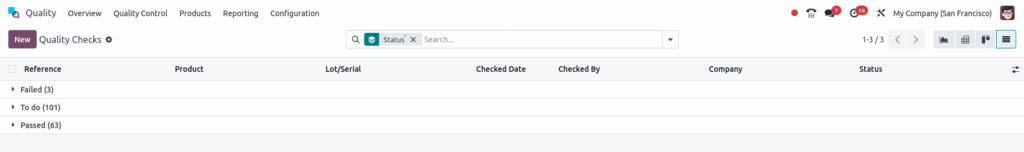

Quality Checks Report(Graph View)

Quality Checks Report(Kanban View)

Quality Checks Report(List View)

Quality Alerts Report

Overview

The Quality Alert Report in Odoo 18 offers a centralized summary of all quality alerts raised within the organization. It tracks non-conformities, defects, and issues detected during production, purchasing, or customer feedback, helping teams to monitor and resolve quality problems effectively.

Business Rules

- Quality alerts are created whenever a problem or defect is found.

- Each alert must have a type and priority (low, medium, high).

- Alerts must be linked to the related product, batch, or order.

- Alerts go through stages: Draft → Open → Investigating → Resolved → Closed.

- Investigations and root causes must be recorded before closing alerts.

- Notifications are sent to the right people when alerts are created or updated.

- Only authorized users can create or change alerts.

- The report can be filtered by product, priority, status, and date.

- Alerts connect with other modules like manufacturing and inventory.

- Regular reviews help find trends and improve quality.

Screenshots

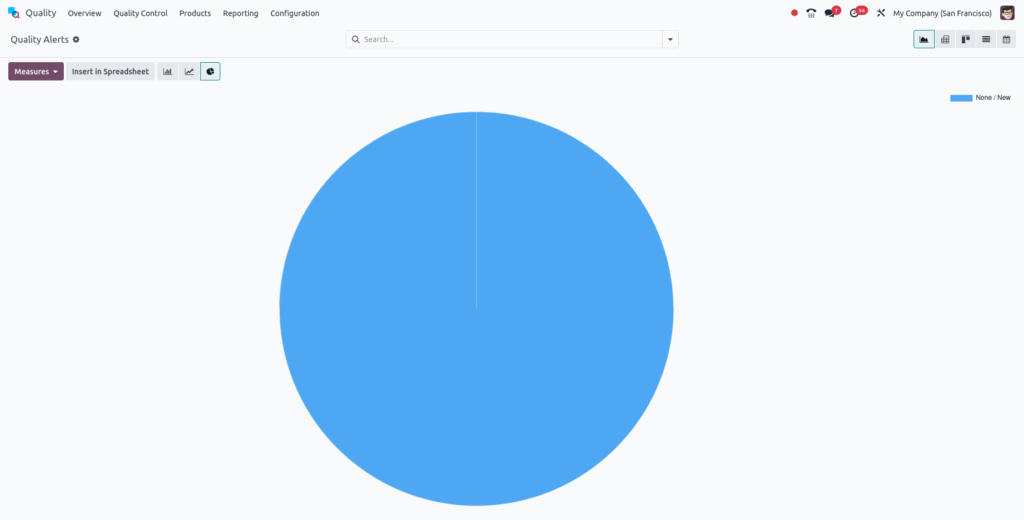

Quality Alerts Report(Graph View)

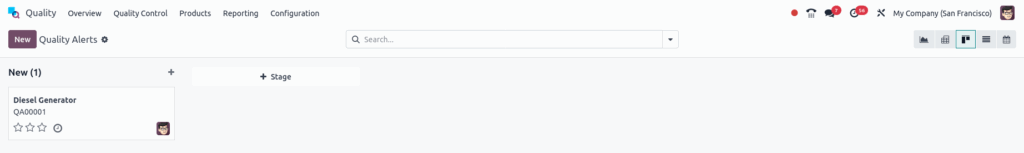

Quality Alerts Report(Kanban View)

Quality Alerts Report(List View)