Repairs in Odoo 18

Repair Management in Odoo helps companies manage repair orders for products, machines or equipment. It is useful for manufacturers, service centres and after-sales teams. From receiving the damaged product to repairing, adding spare parts, labour charges, quality checks and delivering back to customer, the whole cycle is handled in one place.

It also links with Inventory, Sales and Accounting so spare parts consumption and billing are smooth. With capabilities for repair order tracking, technician assignment, warranty management and detailed reporting, the Repair module helps businesses optimize repair processes, reduce downtime and maintain high-quality service standards

Key Features

- Creation and management of repair orders linked to products and customers

- Tracking repair stages including diagnosis, approval, execution and completion

- Assignment of repair tasks to technicians or teams with workload balancing

- Integration with inventory for automatic reservation and consumption of spare parts

- Labor time tracking and cost calculation for accurate billing

- Warranty management and validation during repair process

- Warranty check is compulsory before invoicing

- Support for repair quotations, approvals and invoicing

- Customer communication via notifications and status updates

- Quality control checks and post-repair feedback capture

- Comprehensive reporting on repair operations, costs and performance

- Spare parts automatically deducted from inventory, no manual stock adjustment

- Repair cannot be marked as “Completed” unless all operations are done

- Only authorised user can approve scrap or cancellation

- Invoice is generated only after manager’s confirmation (optional)

- Every action (create, repair, QC, invoice) is logged for audit

- Define repair location (workshop/warehouse)

- Add spare parts and components to repair order

- Track parts consumed directly from inventory

- Automatic journal entries for accounting.

- Capture repair notes, photos or test results in the log

- Ensure repaired product is functional before handover

- Spare parts consumption report

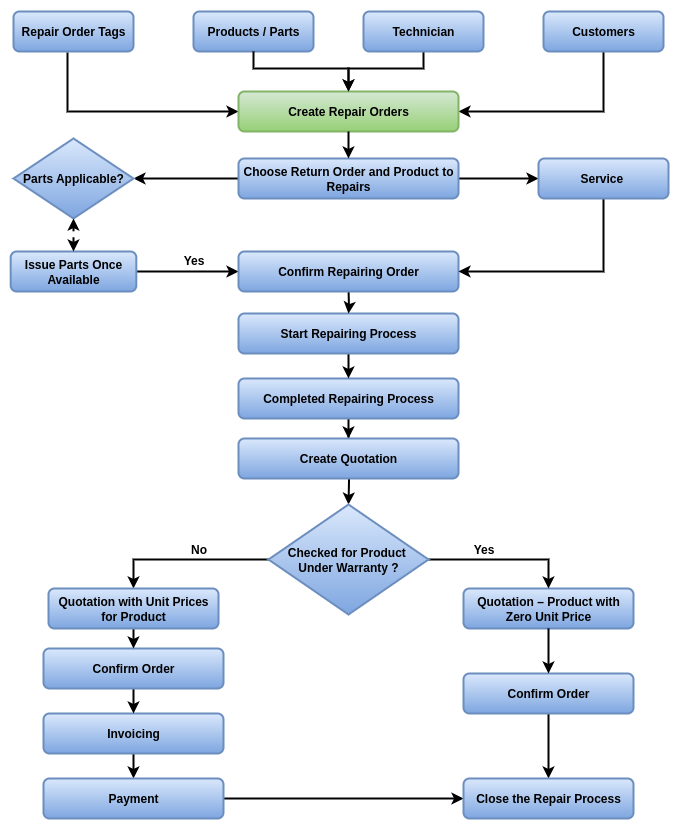

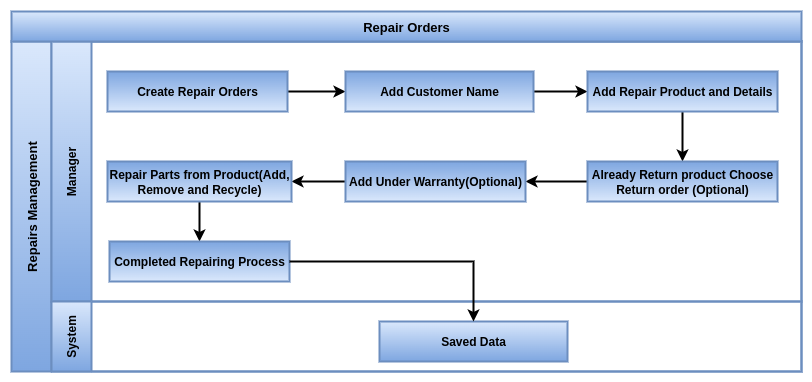

Work Flow

Repairs Master Management

- Repair Order Tags

- Products & Product Variants

- Customers

Repairs Management

- Repair Orders

Repairs Reporting Management

- Repairs Report

Repairs Master Management

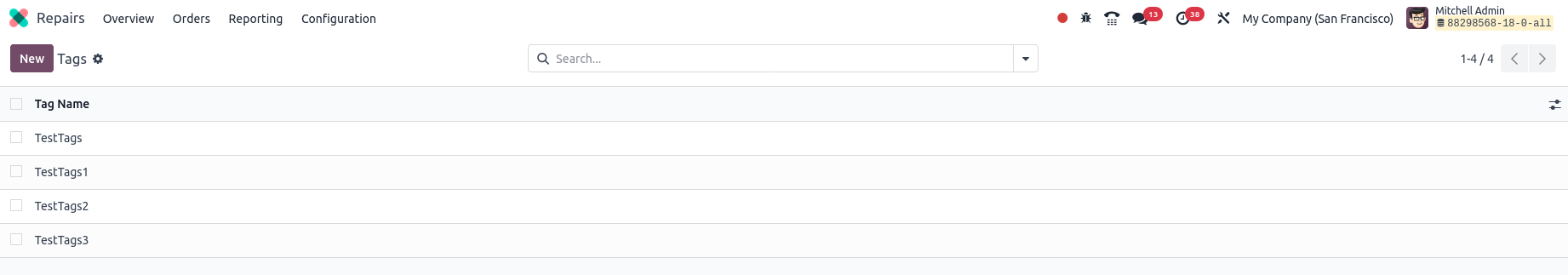

Repair Order Tags

Overview

Repair Order Tags in Odoo are used to categorise and label repair jobs for better organisation and quick identification. They act as visual markers that help technicians and managers classify repairs, prioritise urgent cases and easily search or filter records. Tags do not affect the repair process directly but make the workflow more transparent and efficient by highlighting special conditions such as warranty, urgency or repeat issues.

Process Flow

Key Features

- Create and manage unlimited custom tags as per the business need

- Apply single or multiple tags to a repair order

- Quickly filter and search repair orders using tags

- Classify repairs based on urgency, warranty or customer type

- Generate analytical reports based on tags

- Integrate tags across repair teams for consistent tracking

Business Rules

- Tags are optional and not mandatory for repair order creation

- A repair order can hold more than one tag

- Tags are only for classification and do not impact workflow stages

- Only authorised users can create or edit tags

- Tags must follow standard naming conventions for consistency

Screenshot

Repair Order Tags Create Screen

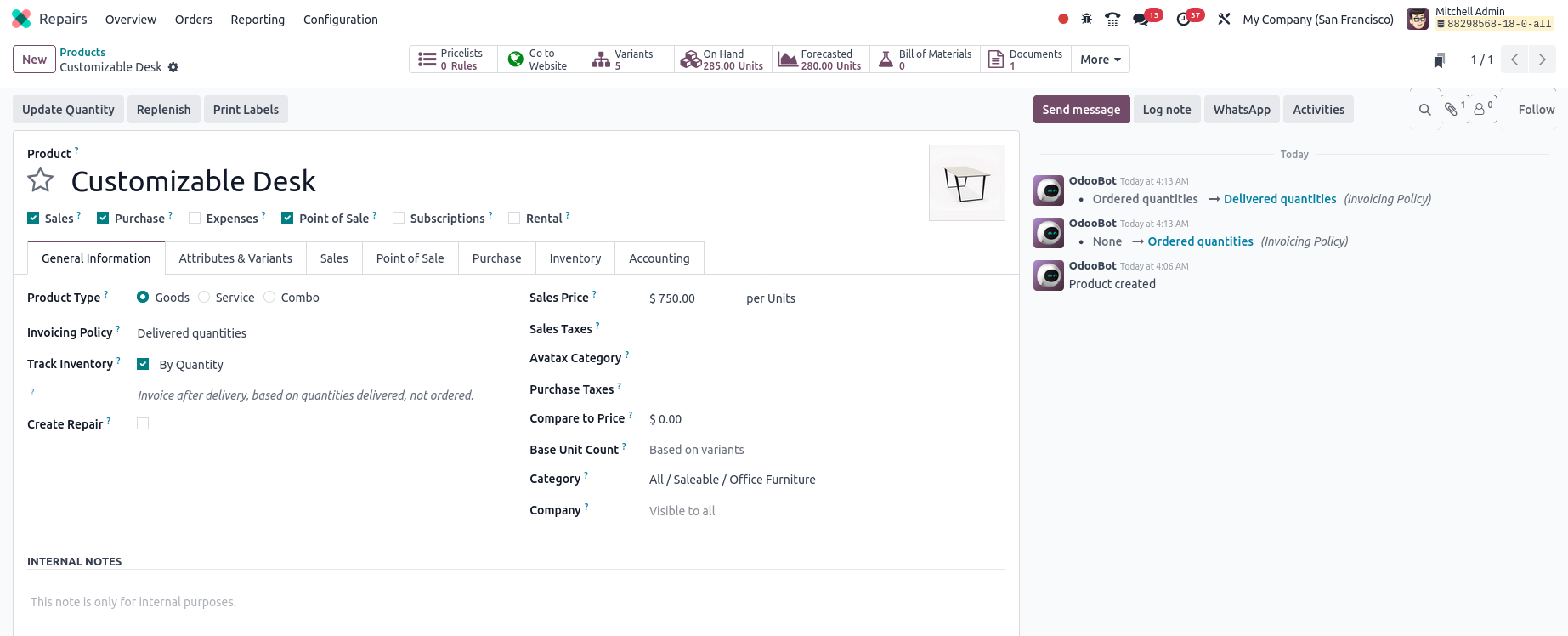

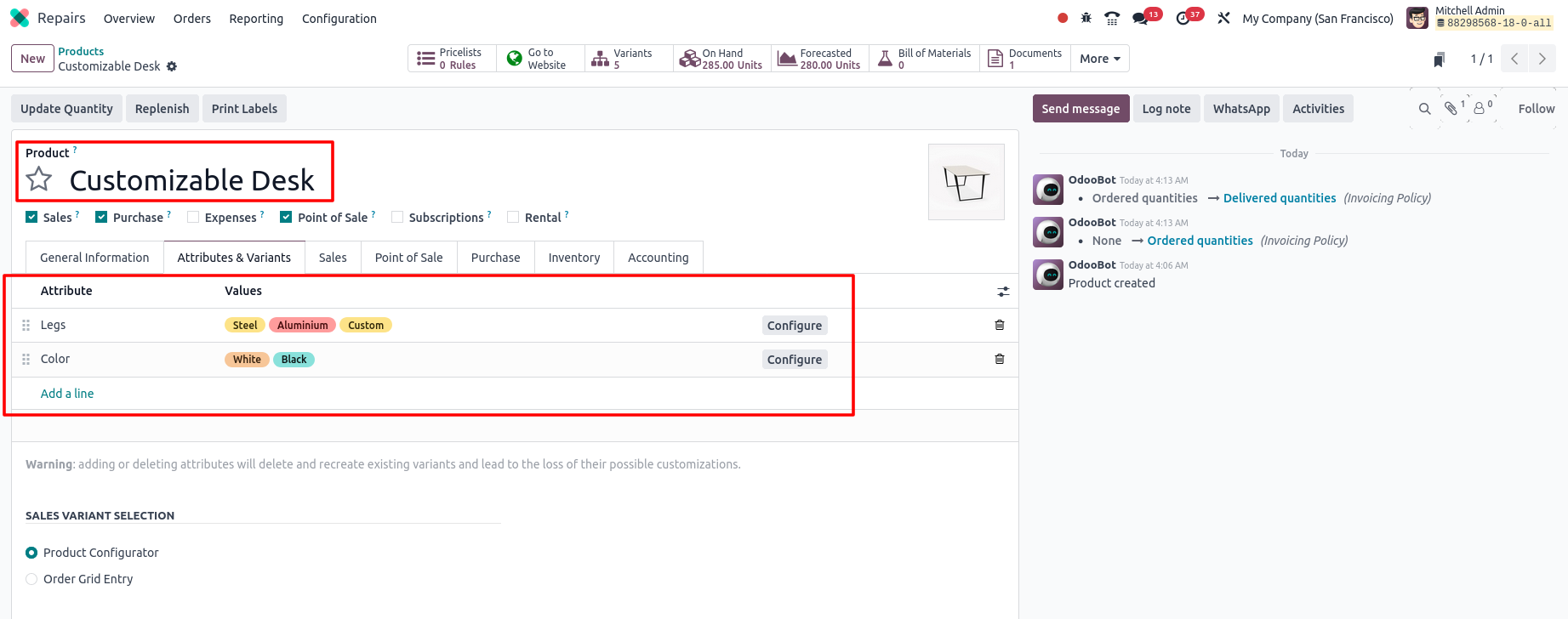

Products & Product Variants

Overview

In the Repair Order process, products mainly represent the items being repaired and the spare parts or services used during the repair. The product master ensures that every repair job is properly linked to a product, whether it is a customer’s machine, an internal asset or a spare part consumed. It also allows costing, warranty checks, stock tracking and invoicing to be accurate and traceable within the repair cycle

Process Flow

Business Rules

- Identify the main product that is sent for repair

- Record serial numbers and warranty details of repaired items

- Manage spare parts used during repairs with automatic stock updates

- Define service products like labour charges or diagnostic fees

- Link products with suppliers for spare part procurement

- Use product categories for reporting and cost analysis

- Control pricing for parts and services applied in repair orders

- Track warranty and contract rules directly through product setup

- Attach technical documents, manuals or images for repair reference

- Ensure proper accounting entries for parts and labour in repair billing

Screenshot

Products Form View Screen

Products – Attributes & Variants Screen

Products Variants – Form View Screen

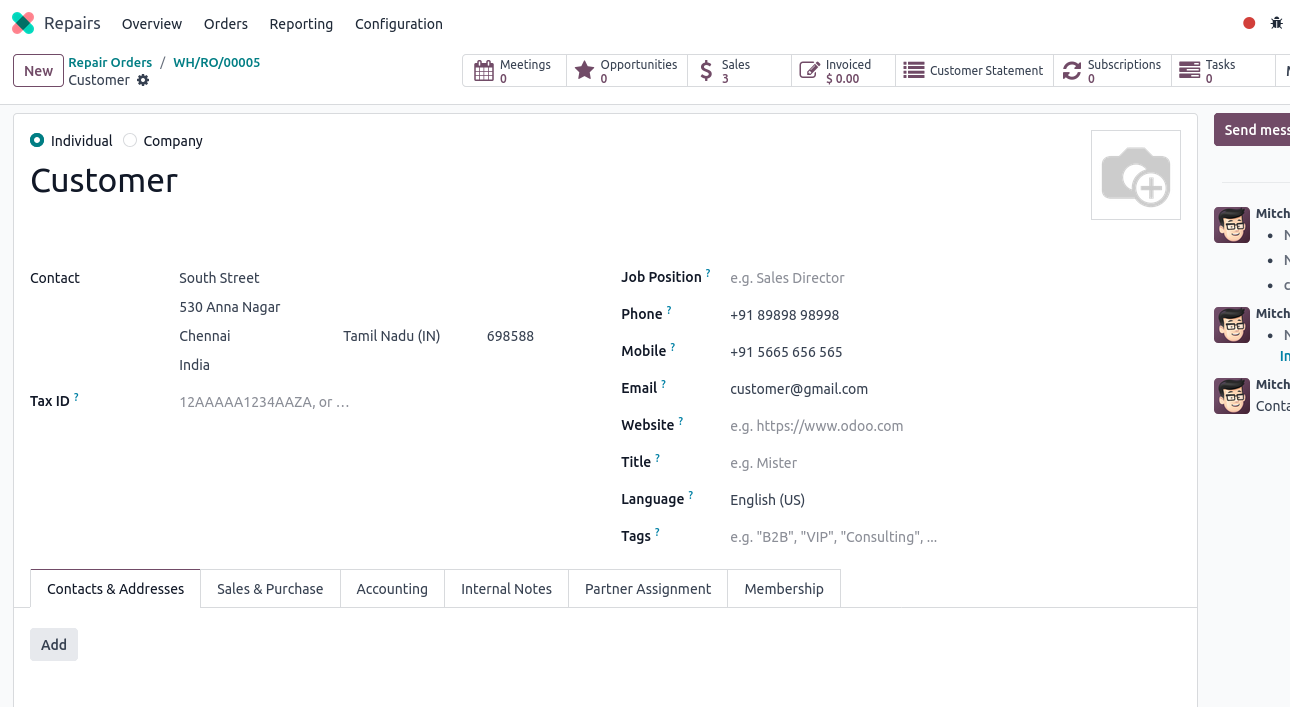

Customers

Overview

In the Repair Order process, the customer represents the person or company that owns the product being repaired. The customer record ensures that all repair jobs are properly linked to the right client, making communication, billing, warranty validation and after-sales service seamless. By maintaining complete customer details in Odoo, businesses can track service history, manage payments and improve the customer relationships

Process Flow

Business Rules

- Store full customer profile with name, contact details and address

- Define whether the customer is an individual or a company

- Link repair orders directly to the customer for tracking service history

- Maintain multiple contacts under the same customer (e.g., billing, shipping)

- Use customer data for warranty verification and eligibility

- Generate invoices for repairs against customer accounts

- View complete history of products repaired for the customer

- Enable customer portal access to check repair status online

- Integrate customer record with sales, repairs and accounting modules

Screenshot

Customers Form View Screen

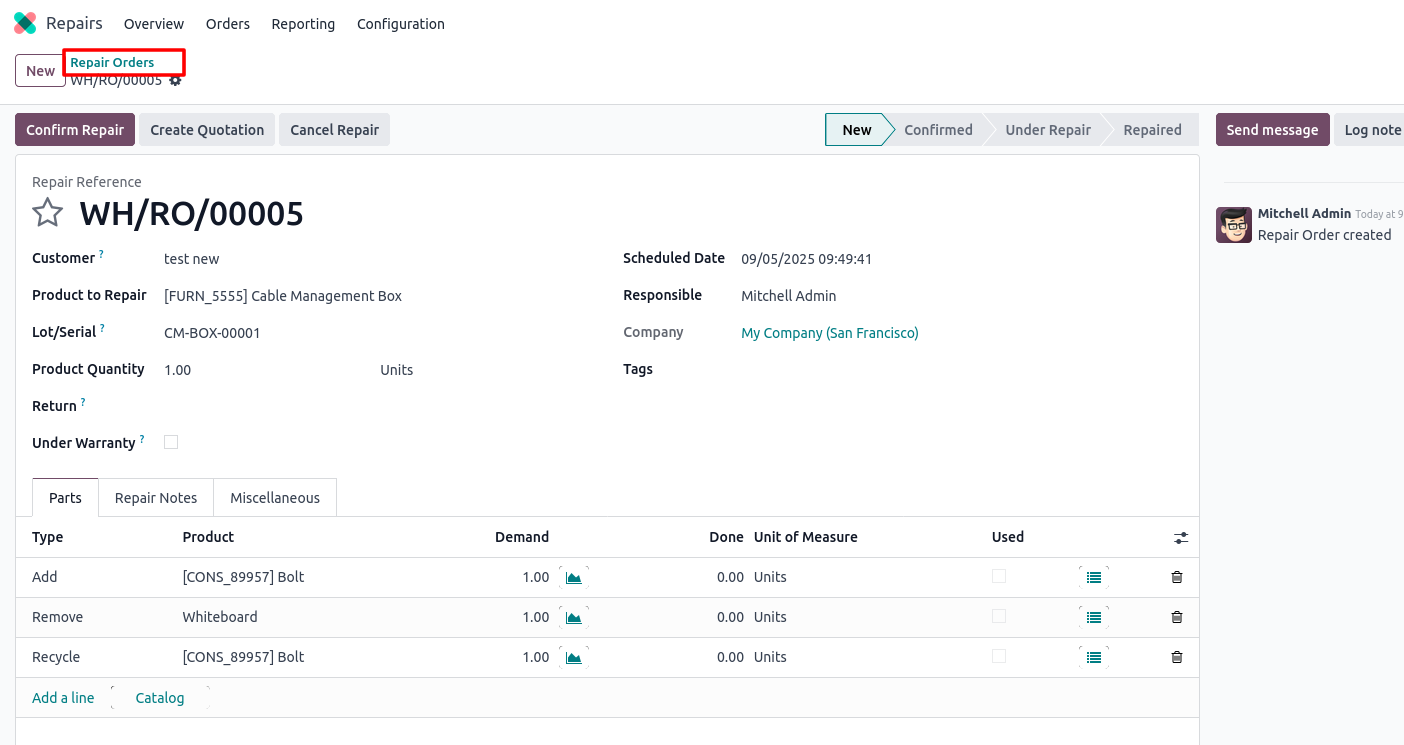

Repairs Management

Repair Orders

Overview

Repair Orders in Odoo are the central documents used to manage the entire repair process for a product. They capture all key details such as the product being repaired, customer information, repair reason, spare parts, labour, costs and final outcome. Each order follows a structured workflow from creation to completion, ensuring that repairs are tracked, authorised and invoiced correctly. By using repair orders, businesses maintain full visibility of repair operations, control spare part usage, validate warranties and provide accurate billing to customers

Process Flow

Key Features

- Create repair orders with customer, product and reason for repair

- Define repair type, priority and responsible technician

- Add spare parts and automatically deduct them from inventory

- Include labour and service charges as part of the repair

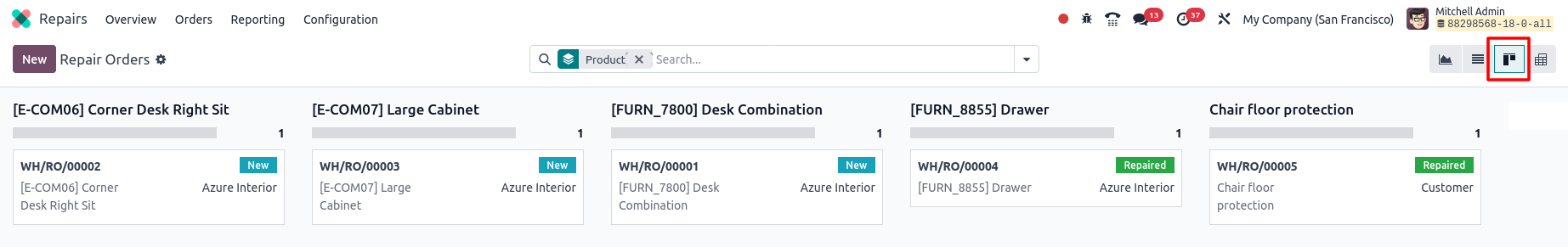

- Track repair stages such as New, Confirmed, Under Repair and Repaired

- Attach supporting documents, images or test reports

- Verify warranty status and apply warranty rules

- Generate invoices for repairs including parts and labour

- Cancel or scrap repair orders if repair is not feasible

- Monitor repair history and performance for each product

Business Rules

- Repair order must always include a customer and product

- Warranty check is mandatory before generating invoice

- Spare parts linked to repair are automatically updated in stock

- Repair cannot be marked completed unless all operations are finished

- Only authorised users can cancel or scrap a repair order

- High-value repairs may require approval before execution

- Invoices are generated only after repair order confirmation

- All changes in repair order are logged for audit purposes

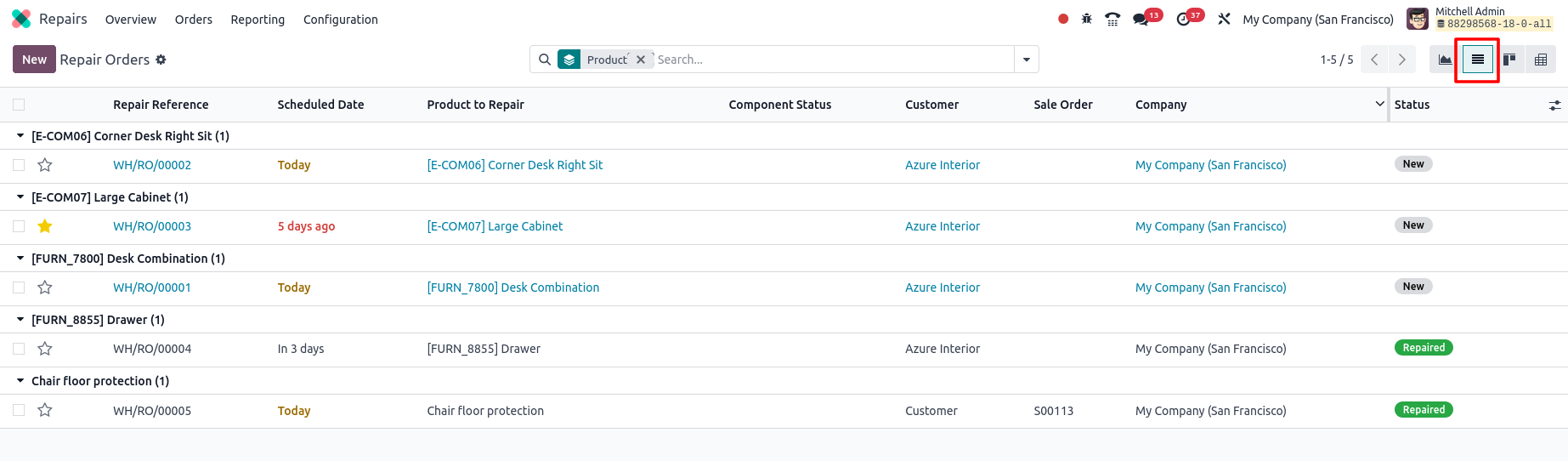

Screenshot

Repair Orders Create

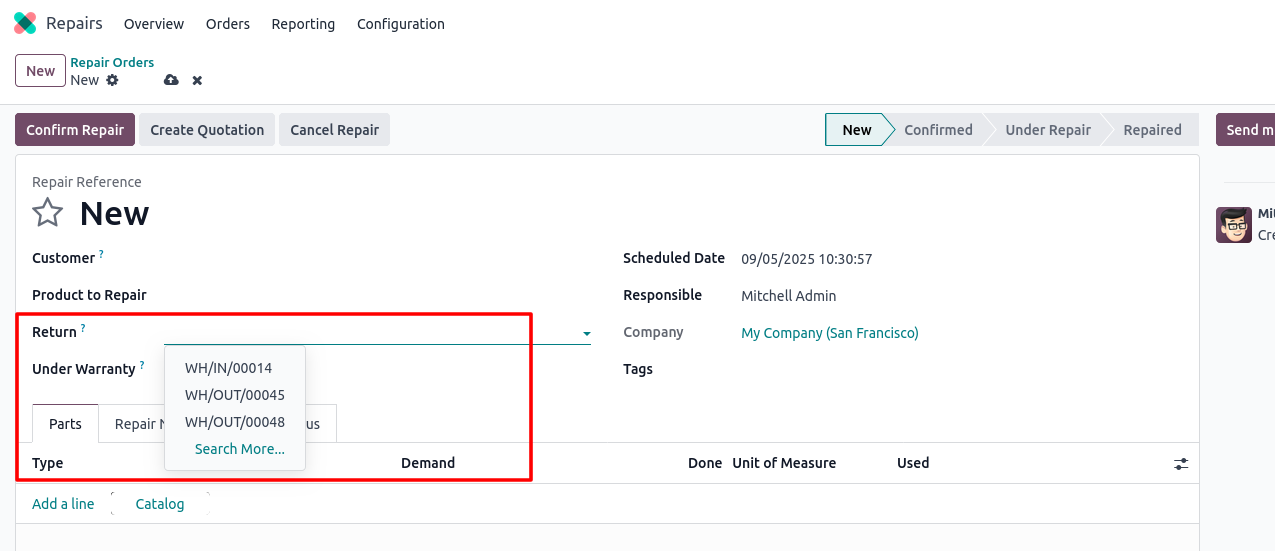

Repair Orders Choose Return order (Optional)

Repair Orders Choose Return order with Product

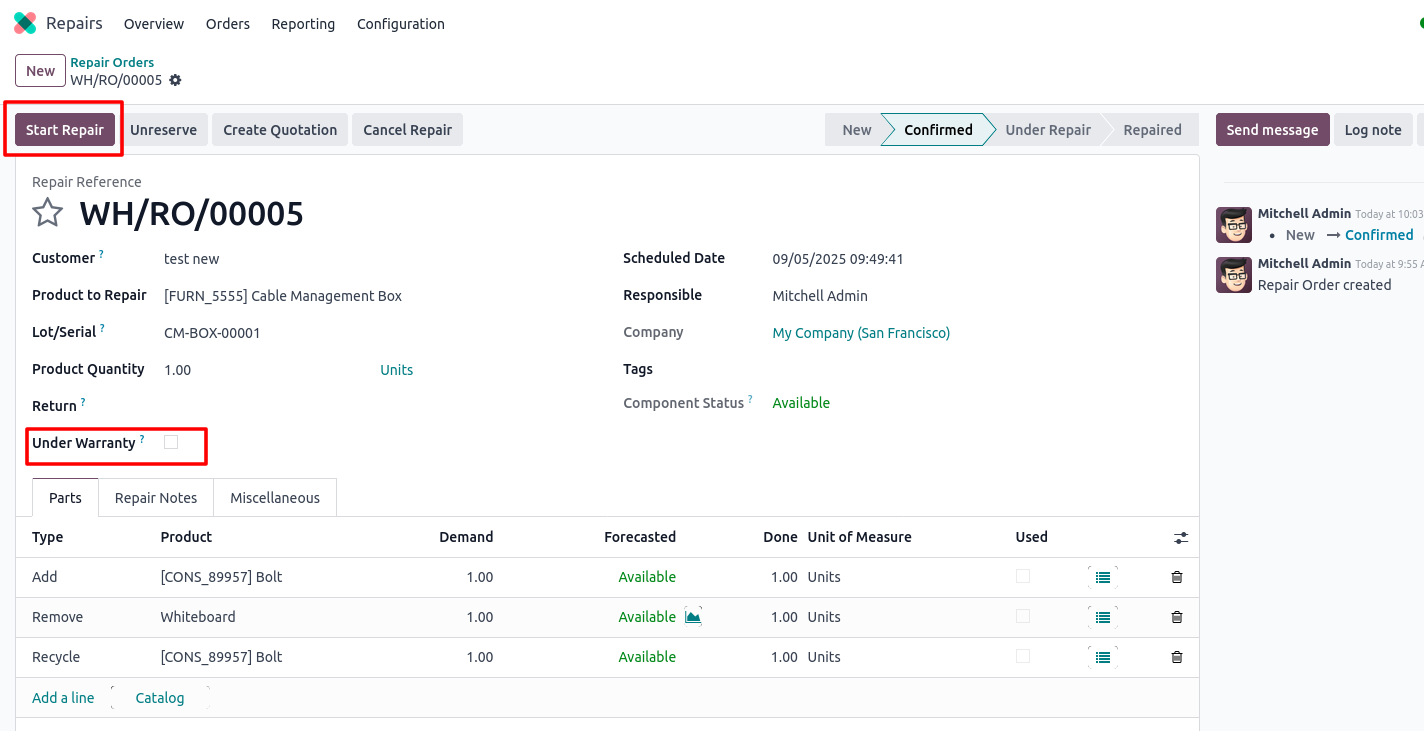

Repair Orders Start Repair and Under Warranty

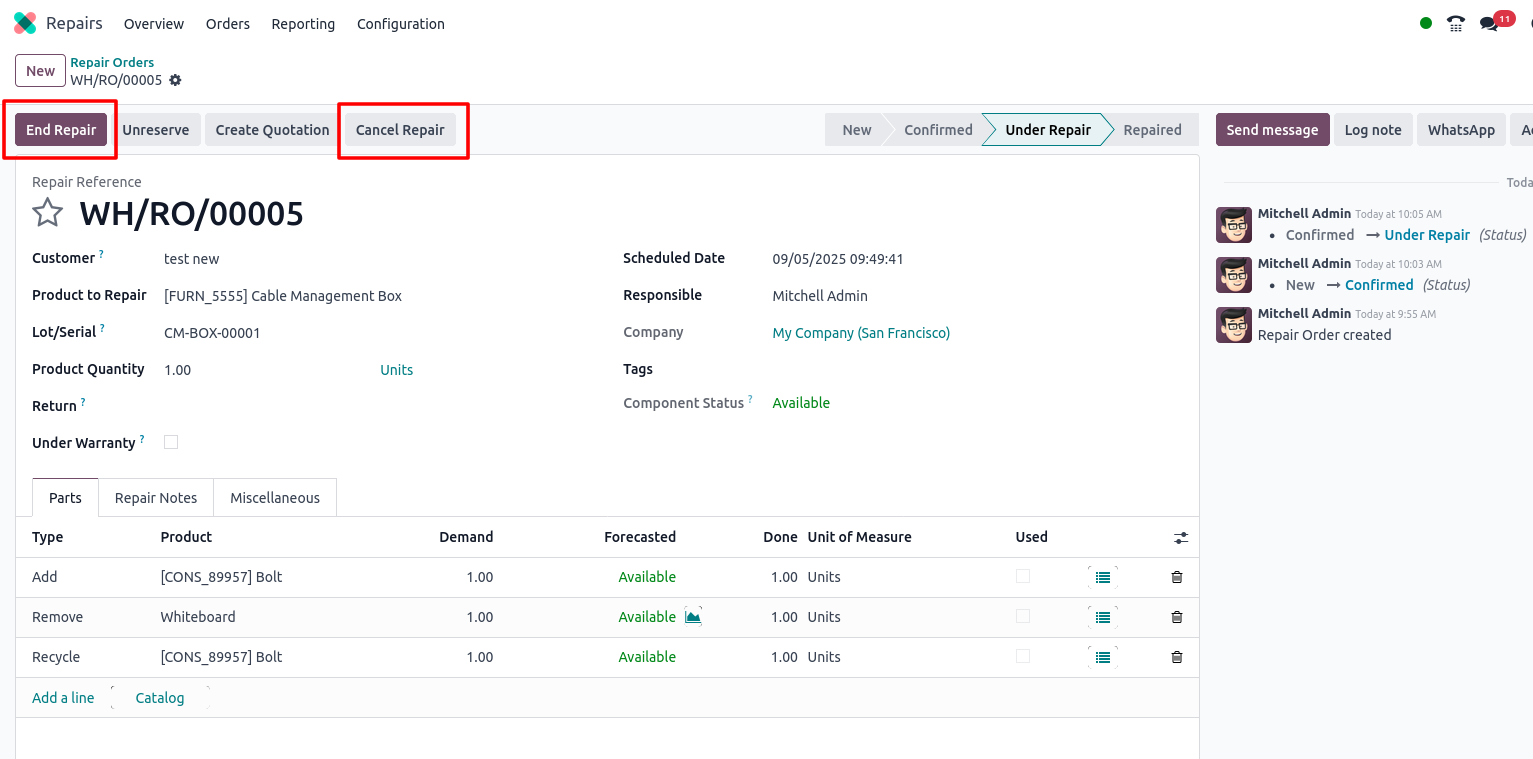

Repair Orders End Repair and Cancel Repair

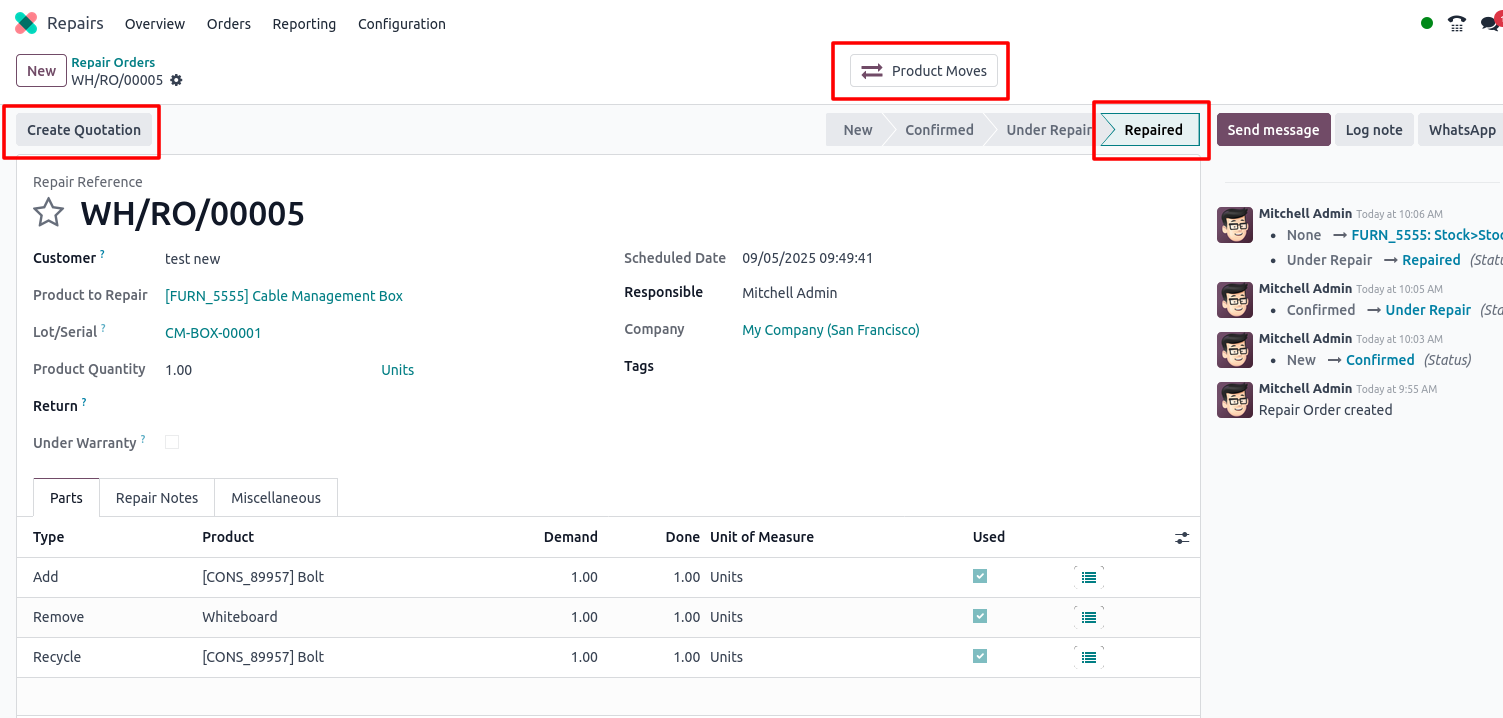

Repair Orders Completed Repair

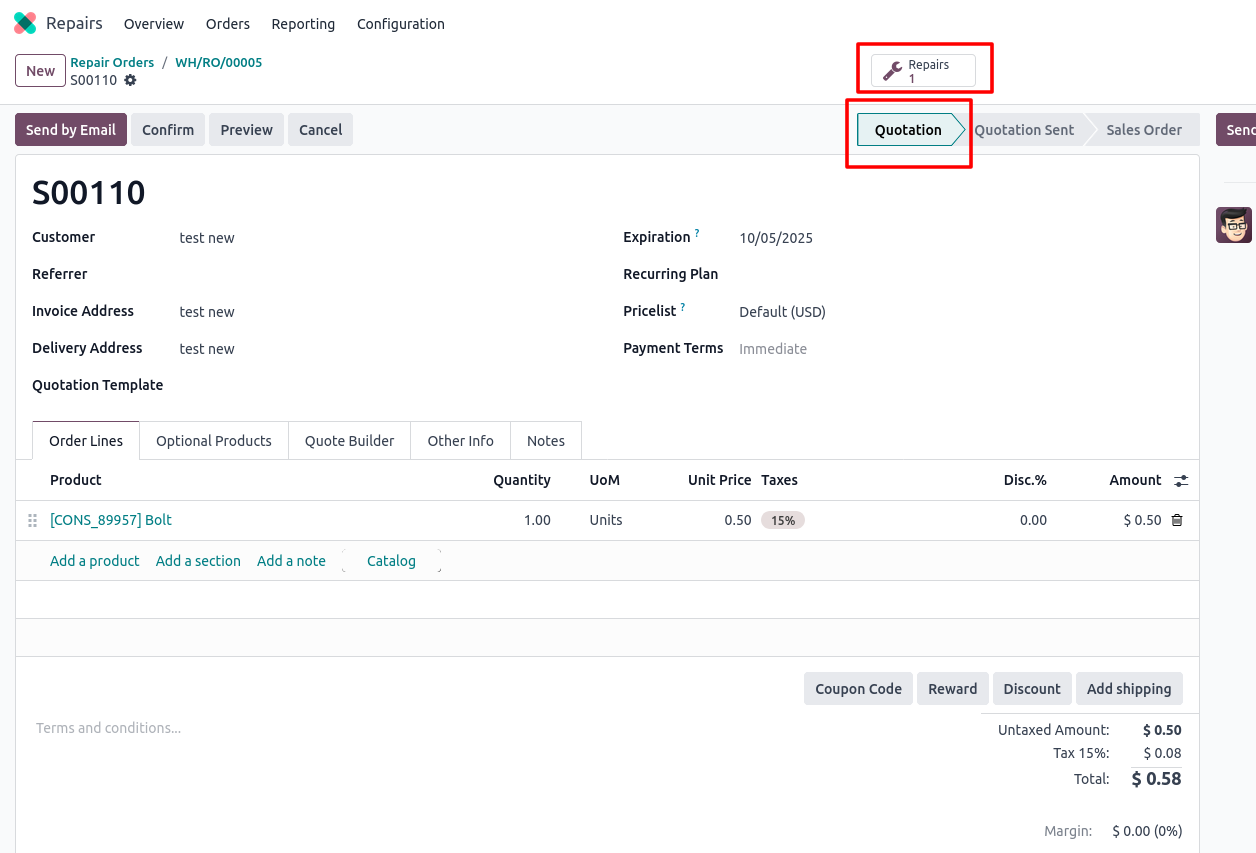

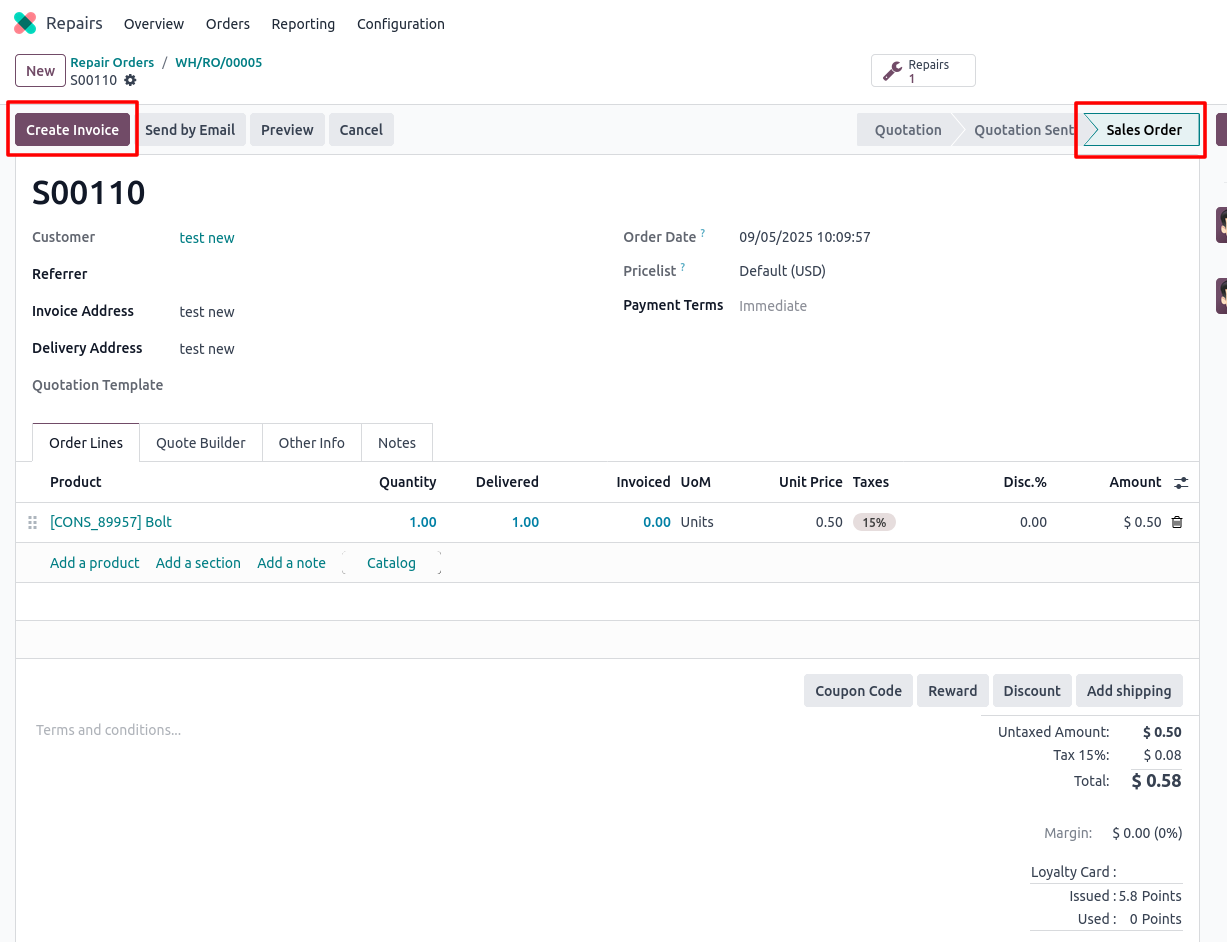

Repair Orders based on create Sale Quotations

Repair Orders based on Sale Quotations Confirm

Repairs Reporting Management

Repairs Report

Overview

Repairs Report in Odoo provides detailed insights into all repair activities, helping managers track performance, efficiency, costs and customer service quality. It consolidates data from repair orders, spare part usage, labour costs and warranty handling into meaningful reports. With this, businesses can monitor technician productivity, identify common repair issues, control spare part expenses and evaluate overall profitability of repair operations

Key Features Repairs Reports

- View repair orders filtered by status, product, customer or technician

- Analyse repair trends such as volume by period, product type or issue type

- Track spare parts consumption and associated costs

- Compare warranty repairs versus paid repairs

- Measure technician productivity based on completed jobs and time spent

- Generate profitability analysis per repair order or customer

- Export reports into Excel or PDF for sharing

- Use pivot tables and graphs for visual insights

- Apply custom filters and groupings for deeper analysis

- Monitor pending, completed or cancelled repairs in real time

Business Rules

- Only authorised users can access financial and cost-related reports

- Data shown in reports is always based on confirmed repair orders

- Cancelled repairs are tracked but excluded from revenue reporting

- Warranty and non-warranty repairs must be clearly separated in reporting

- Technician performance metrics are calculated based on completed repairs only

- Reports should follow company-defined time frames (weekly, monthly, yearly)

- All exported reports must respect user access rights

Screenshot

Repairs Report Graph View Screen

Repairs Report Graph List Screen

Repairs Report Kanban View Screen