How to Configure MBQ for a Product in Odoo

MBQ or Minimum Base Quantity, refers to the minimum stock level that must be maintained for a product. It helps with stock planning and auto-replenishment decisions. When the stock falls below the MBQ, alerts or reordering processes can be triggered.

Navigate MBQ tab in Product Master

Go to the Dashboard and click on the Inventory module. From the Products menu, select Product Master and choose a particular product. Then, select the MBQ tab and follow these steps:

- Select the Company.

- Choose the Sales Classification: Fast, Average, or Slow, depending on how quickly the product sells.

- Set the Scheduled Days, which allows you to specify particular days (for example, Monday) when draft purchase orders will be deleted.

Run Scheduler for Calculate MBQ

Open Settings from the Dashboard and select the Technical menu. Click on Scheduled Actions and choose MBQ Process to manage MBQ calculations. You can click Run Manually to execute the scheduler immediately, or set the Next Execution Date to run the scheduler automatically at a later time.

View Min-Max Stock Calculation

After running the scheduler, go to the product screen and click More at the top of the screen, then select MIN/MAX. The system calculates the minimum and maximum values based on the last 56 MBQ sold days, or from the first GRN date if the product age is less than 56 days. These values will be automatically populated after the MBQ process runs.

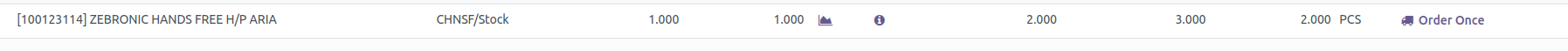

Details of Min-Max Stock Calculation

- Product Name: Name of the product

- Location: Stock location

- On-hand: Current stock available

- Forecast: Expected demand

- Trigger: Manual or automatic reorder

- Min Quantity: Minimum stock level before reordering

- Max Quantity: Maximum stock level to maintain

- To Order Qty: Number of units to order

- UOM: Unit of measurement

Click Order Once to generate the Purchase Order.

Formula Used in MBQ Calculation

• Average Sold Quantity per Day = Total Sold Quantity ÷ MBQ Days

• Minimum Stock = Average Sold Quantity × Stock Holding Days

• Maximum Stock = Average Sold Quantity × Reorder Level Days

• Forecasted Stock = On Hand + Incoming − Outgoing

• To Order Quantity = Maximum Stock − Forecasted Stock