Optimize Your Production with iDempiere ERP Manufacturing Management

Whether managing raw materials, work orders, shop floor operations, or costing, iDempiere ERP Manufacturing Management Module module provides real-time insights and automation to drive efficiency. With its scalable and flexible architecture, iDempiere ERP supports discrete, process, and custom manufacturing, making it an ideal solution for businesses looking to improve productivity while maintaining cost control. Overcome manual inefficiencies and experience seamless manufacturing execution with iDempiere ERP.

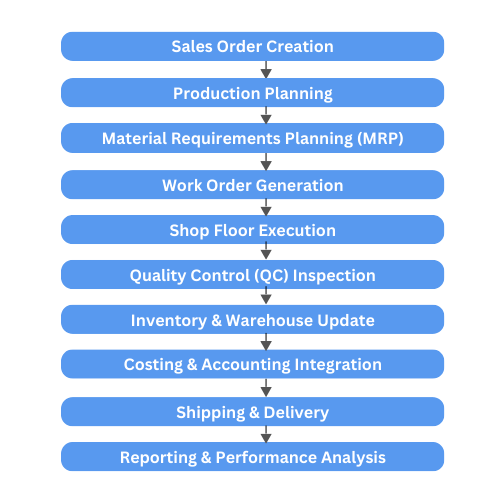

iDempiere ERP Manufacturing Management Workflow

- Sales Order Creation – A customer order triggers the production process.

- Production Planning – The system generates a Master Production Schedule (MPS) based on demand and resource availability.

- Material Requirements Planning (MRP) – The system checks inventory and creates purchase orders for missing materials.

- Work Order Generation – A work order is created, specifying BOM, routing, and resource allocation.

- Shop Floor Execution – Operators execute tasks, track progress, and log labor/machine usage in real-time.

- Quality Control (QC) Inspection – Finished goods undergo inspection at various production stages.

- Inventory & Warehouse Update – Approved finished goods are moved to stock, and material consumption is updated.

- Costing & Accounting Integration – Production costs are recorded, and financial reports are updated.

- Shipping & Delivery – The final product is shipped to the customer based on the sales order.

- Reporting & Performance Analysis – KPI reports are generated to track efficiency, wastage, and overall performance.

Key Features of iDempiere ERP Manufacturing Management Module

Production Planning & Scheduling

- Master Production Scheduling (MPS): Plan production based on demand forecasts, stock levels, and capacity.

- Capacity Planning: Balance workloads across machines and work centers to prevent bottlenecks.

- Real-time Scheduling: Optimize production timelines with drag-and-drop scheduling tools.

- Multi-Plant Support: Manage multiple manufacturing locations efficiently.

Bill of Materials (BOM) & Routing

- Multi-Level BOMs: Define hierarchical product structures for accurate assembly.

- Dynamic BOMs: Configure BOMs based on customer-specific requirements.

- Routing & Workflows: Map manufacturing processes step-by-step for efficient execution.

- Version Control: Maintain revision history and track BOM modifications.

Work Order & Job Tracking

- Automated Work Orders: Generate work orders based on production schedules and material availability.

- Shop Floor Control: Monitor progress with real-time job tracking and status updates.

- Workforce Allocation: Assign tasks efficiently based on worker skills and availability.

- Time & Labor Tracking: Record machine and labor hours for accurate cost tracking.

Material Requirements Planning (MRP)

- Automated Procurement: Trigger purchase orders based on material shortages.

- Real-time Inventory Tracking: Prevent stockouts and overstock situations.

- Just-in-Time (JIT) Inventory: Optimize inventory levels to reduce carrying costs.

- Supplier Integration: Connect with suppliers for better raw material planning.

Quality Control & Compliance

- Inspection Points: Set up mandatory quality checks at each production stage.

- Defect Tracking: Identify, record, and analyze defects to improve processes.

- Traceability & Lot Tracking: Maintain full visibility of raw materials and finished goods.

- Regulatory Compliance: Ensure adherence to industry standards like ISO, FDA, or GMP.

Shop Floor Management & Automation

- IoT & Sensor Integration: Connect machines for real-time production monitoring.

- Production Dashboards: Get live updates on production efficiency and downtime.

- Preventive Maintenance: Schedule maintenance to prevent unexpected equipment failures.

- Barcode & RFID Support: Enable quick scanning for inventory and production tracking.

Costing & Financial Integration

- Standard & Actual Costing: Track real-time cost variances for better financial control.

- Work Order Costing: Calculate labor, material, and overhead costs accurately.

- Seamless ERP Integration: Sync manufacturing costs with accounting and financial reports.

- Profitability Analysis: Identify cost-saving opportunities through analytics.

Reporting & Analytics

- Production Performance Reports: Gain insights into efficiency, output, and wastage.

- KPI Dashboards: Track yield rates, lead times, machine utilization, and labor efficiency.

- Custom Reports & BI Integration: Create tailored reports for in-depth analysis.

- Predictive Analytics: Use AI-driven forecasts to optimize production planning.

Manufacturing Execution System (MES) Features

- Shop Floor Data Collection: Capture real-time production data.

- Operator Dashboards: Provide task lists and work instructions digitally.

- Real-Time Production Adjustments: Make changes instantly based on demand shifts.

Inventory & Warehouse Management

- Raw Material Tracking: Monitor consumption and reorder levels.

- Finished Goods Inventory: Manage stock ready for distribution or shipping.

- FIFO/LIFO Management: Ensure accurate material movement.

Benefits of Using iDempiere Manufacturing Module

- End-to-End Integration – Connects production with inventory, sales, and finance.

- Reduced Production Costs – Optimized material usage and minimized waste.

- Increased Efficiency – Automated workflows for faster production cycles.

- Better Quality Control – Inbuilt compliance and inspection tracking.

- Real-Time Decision Making – Instant access to critical production data.

- Scalability – Customizable to meet growing manufacturing needs.

Why Choose iDempiere for Manufacturing Management?

- Open-Source Flexibility: Customize to fit your unique manufacturing processes.

- Seamless ERP Integration: Works alongside supply chain, accounting, and CRM.

- User-Friendly Interface: Easy to use, even for non-technical staff.

- Mobile & Cloud Ready: Access manufacturing data anytime, anywhere.

Take Your Manufacturing to the Next Level with iDempiere ERP!

Optimize your production planning, shop floor management, and quality control with the iDempiere ERP Manufacturing Management Module. Reduce costs, improve efficiency, and gain real-time insights into your operations—all in one powerful system!